MRV Regulaon Dalian Anda Marine Propellers Viking Life-Saving Seminar for Crew Members What’s new? In this issue… Newsleer February 2017 Visit us www.technava.gr TECHNAVA S.A. 6 Loudovikou Sq. 18 531 Piraeus Greece 210 411 39 16 [email protected] MRV - Monitoring, Reporng and Verificaon Regulaon Monitoring, Reporng and Verificaon of Carbon Dioxide Emissions (CO2) from marime transport in Europe. Brief Descripon According to latest European Commission reports (3 rd IMO GHG study), marime transport emits around 1000 million tons of CO 2 annually and is responsible for about 2.5% of global greenhouse gas emissions. The European Commission adopted in July 1 st 2015 the MRV Regulaon, which will come into force in January 2018, creang thus an EU-wide legal framework for the monitoring, reporng and verificaon of CO 2 emissions from marime transport and of other relevant informaon (such as energy efficiency parameters). Relevant regulaon refers to vessels larger than 5,000 GT calling EU ports (to, from and between EU ports) and actually requires Shipowners/operators to publish thereaſter above results on a regular basis. The MRV regulaon is designed to progressively integrate marime emissions into EU’s policy for reducing domesc greenhouse gas emissions (EU regulaon 2015/757). Timeline in detail 31 August 2017 – Submission of ship-specific monitoring plans of shipping companies to verifiers for approval 1 January 2018 – Start of CO 2 monitoring (Data collecon) on per-voyage basis 30 April 2019 – Preparing, Verifying and then Subming to EC and Flag State the verified annual CO 2 emission report. 30 June 2019 – Issuance of Document of Compliance and CO 2 Emission data made publicly available by the EC Going forward, Shipowners will have to monitor the following parameters on a per-voyage basis: Port of departure and port of arrival, including the date and hour of departure and arrival Amount and emission factor for each type of fuel consumed in total CO 2 emied -> CO 2 Emissions = Fuel Consumpon * Emission Factor Distance travelled Time spent at sea Cargo carried Transport work METHODS FOR DETERMINING CO2 EMISSIONS Actual fuel consumpon for each voyage shall be used and be calculated using one of the following methods: 1. Bunker Fuel Delivery Note (BDN) and periodic fuel tank measurements 2. Bunker fuel tank monitoring on board 3. Flow meters for applicable combuson processes 4. Direct CO 2 emissions measurements

Welcome message from author

This document is posted to help you gain knowledge. Please leave a comment to let me know what you think about it! Share it to your friends and learn new things together.

Transcript

MRV Regulation

Dalian Anda Marine Propellers

Viking Life-Saving Seminar for Crew Members

What’s new?

In this issue…

Newsletter February 2017

Visit us www.technava.gr TECHNAVA S.A. 6 Loudovikou Sq. 18 531 Piraeus Greece 210 411 39 16 [email protected]

MRV - Monitoring, Reporting and Verification Regulation

Monitoring, Reporting and Verification of Carbon Dioxide Emissions (CO2) from maritime transport in Europe.

Brief Description

According to latest European Commission reports (3rd IMO GHG study), maritime transport emits around 1000 million tons of CO2 annually and is responsible for about 2.5% of global greenhouse gas emissions.

The European Commission adopted in July 1st 2015 the MRV Regulation, which will come into force in

January 2018, creating thus an EU-wide legal framework for the monitoring, reporting and verification

of CO2 emissions from maritime transport and of other relevant information (such as energy efficiency

parameters). Relevant regulation refers to vessels larger than 5,000 GT calling EU ports (to, from and

between EU ports) and actually requires Shipowners/operators to publish thereafter above results on a

regular basis. The MRV regulation is designed to progressively integrate maritime emissions into EU’s

policy for reducing domestic greenhouse gas emissions (EU regulation 2015/757).

Timeline in detail

31 August 2017 – Submission of ship-specific monitoring plans of shipping companies to verifiers for approval

1 January 2018 – Start of CO2 monitoring (Data collection) on per-voyage basis 30 April 2019 – Preparing, Verifying and then Submitting to EC and Flag State the verified annual

CO2 emission report. 30 June 2019 – Issuance of Document of Compliance and CO2 Emission data made publicly available

by the EC

Going forward, Shipowners will have to monitor the following parameters on a per-voyage basis:

Port of departure and port of arrival, including the date and hour of departure and arrival

Amount and emission factor for each type of fuel consumed in total

CO2 emitted -> CO2 Emissions = Fuel Consumption * Emission Factor

Distance travelled

Time spent at sea

Cargo carried

Transport work

METHODS FOR DETERMINING CO2 EMISSIONS Actual fuel consumption for each voyage shall be used and be calculated using one of the following methods: 1. Bunker Fuel Delivery Note (BDN) and periodic fuel tank measurements 2. Bunker fuel tank monitoring on board 3. Flow meters for applicable combustion processes 4. Direct CO2 emissions measurements

Visit us www.technava.gr TECHNAVA S.A. 6 Loudovikou Sq. 18 531 Piraeus Greece 210 411 39 16 [email protected]

Coriolis Flow Meters

It is taken for granted, that accuracy in Measurement - at a reasonable investment cost – along with

accuracy in the vessel’s Performance Monitoring will be in favor of the Owners and of their highest

interest

Therefore, with regards to the 3rd measuring method, the Fuel Mass Flow Measurement, with the use of

Coriolis Mass Flowmeters, seems to be a particularly preferred method by the market, since it provides

accurate measuring of fuel consumption independent of temperature and pressure, based on mass flow

rate.

Coriolis Mass Flow Meters operate with two parallel tubes with coils that cause them to oscillate at

their resonance frequency. Should the measured liquid medium enter the measuring tube, Coriolis

forces will be generated.

Coriolis forces appear in oscillating systems when a mass moves towards or away

from a rotational axis. They act on the inlet and outlet side in the opposite

direction and minimally deform the measuring tubes. The deflection of the

measurement tubes is captured by sensors on the inflow and outflow side.

These two sensors measure a phase shift that is proportional to the mass flow.

The resonance frequency of the tubes varies depending on the density of the medium to be measured.

Benefits of Coriolis Mass Flow-meters are well known in general.

TECHNAVA represents Messrs. TRICOR KEM Küppers Elektromechanik GmbH, who go one step further

providing also the following advantages:

All in one mass flow and density meter

Direct mass flow measurement

Outstanding density measurement performance for fuel quality control

Customized meters for your requirement --- possible replacement of all kind of existing volume

based flow meters without piping modification!

No upstream and downstream piping reconfiguration required

Maintenance free

Calibration according DIN EN ISO/IEC 17025:2005 for various oils

Up to four (4) years warranty

Authorized to re-calibrate any type/maker of Coriolis Mass Flow-meter

In addition to the companies’ reporting annually aggregated

figures for the parameters, the data collected shall also be used

in order to calculate and report the vessels’ average energy

efficiency.

Newsletter February 2017

Newsletter February 2017

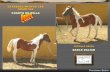

A new collaboration with Dalian Anda Marine Propeller

Dalian Anda Marine Propeller Co., Ltd (DMP) is a market leader, specializing in

marine propellers manufacturing. DMP covers an area of 40,000 square meters

and occupies more than 120 employees.

Their experience in the propeller manufacturing sector, along with their high levels of technical

expertise and performance standards has established their dominance in the market. DMP designs,

produces and develops all kinds of fixed pitch marine propellers, parts of controllable pitch propellers

and copper alloy castings.

It is noteworthy that DMP can produce propellers with diameter up to 10 meters and 70 tons in finished

weight. The factory is equipped with 35 tons medium frequency induction furnace, with one-time

melting capacity of 100 tons, lifting capacity of 120 tons and an advanced propeller static balance

device. DMP has provided propellers and other products to more than 3000 vessels worldwide,

throughout South Korea, Japan, Philippines, Singapore, Australia, India, Finland, Denmark, Britain,

Germany, France and Spain.

The company has acquired Plant Type Approval from all major Classification Societies and is also

‘ISO-9001: 2000’ certified, as of June 2004. With great pleasure we announce that Dalian Anda Marine

Propeller Co., Ltd (DMP) has signed an Agency Agreement with TECHNAVA SA during Posidonia

Exhibition 2016, promoting marine propeller manufacturing in Greece and Cyprus.

Visit us www.technava.gr TECHNAVA S.A. 6 Loudovikou Sq. 18 531 Piraeus Greece 210 411 39 16 [email protected]

Reporting & Verification

With regards to the “Reporting & Verification” for the MRV regulation, TECHNAVA is vividly active and

can provide you with relevant Data Acquisition, Online Performance Monitoring & Online Electrical

Energy Monitoring Systems. Accredited verifiers will have three key tasks: To verify ship-specific monitoring plans (completeness, accuracy, relevance and conformity) To verify that the annual ship-specific emission reports comply with the monitoring plans To verify that the figures contained in the annual ship-specific emission reports are accurate TECHNAVA, being always in the forefront of providing complete solutions to its’ customers, can assist you with all 4 measuring methods accordingly: 1st measuring method of BDN, through Coriolis Mass Flowmeters, for measuring directly and with

accuracy the mass of bunkered fuel 2nd method of Tank monitoring, through Tank gauging systems 3rd method Flow Meters, again through Coriolis Mass Flowmeters in the Engine Room 4th method of direct CO2 measurement, through CEMS (Continuous Emissions Monitoring

System) by using direct in-situ exhaust gas analyzers The plan of IMO has many similarities to the plan of EU and may trigger an EU review of the MRV regulation, conceivably leading to changes aimed at aligning the EU MRV with the IMO system. Please contact us for any further information.

Visit us www.technava.gr TECHNAVA S.A. 6 Loudovikou Sq. 18 531 Piraeus Greece 210 411 39 16 [email protected]

Newsletter February 2017

Viking Life - Saving Equipment Seminar for Crew Members Corporate social responsibility is TECHNAVA’s target.

Within that framework, TECHNAVA organized for a second consecutive year, a seminar dedicated to Viking Marine Evacuation Systems and liferafts, at TECHNAVA Service Station, which fulfills the latest safety and quality requirement and standards.

VIKING LIFE-SAVING EQUIPMENT A.S, is a market leader in maritime safety, providing products and services of essential safety equipment for passenger and commercial vessels, offshore installations as well as the defence sector, industrial firefighting and leisure yachts.

VIKING offers a variety of global safety solutions and their product portfolio includes: marine evacuation systems, offshore evacuation and crew transfer systems, liferafts, boats, lifesaving appliances and protective clothing such as immersion suits, work suits, fire suits and lifejackets.

TECHNAVA has held with great success on 29th of November, 2016 the 2nd Viking Seminar for Crew Members at TECHNAVA premises at Schisto Industrial Park. More than 120 customers participate free of charge in Viking Seminar such as crew mem-bers, Technical Managers of passenger and cruise companies,

as well as naval architects and academics.

Attendees had the opportunity to discuss with our technicians and see real-time liferaft inflation and overall procedure of annual inspection. The authorized technicians of TECHNAVA, assisted all participants to understand the use of MES (Marine Evacuation Systems) equipment and to improve their knowledge and performed all relevant presentations for the function of raft/MES and new designs.

Apart from the theoretical course, participants had also the opportunity to use a Mini Chute, which had been installed in our premises for the needs of the Semi-nar. The Chute was inflated, connecting the first and ground floor of TECHNAVA premises and attendees had the opportunity to perform an actual fall, as a real time experience. (see picture below)

After the completion of both the theoretical as well as the practical course, all attendees showed great enthusiasm, encouraging us to repeat this seminar once again. Relevant seminar is already planned for March 2017.

Being a market leader since 1968, TECHNAVA has established a duty of care and responsibility towards our customers.

Furthermore, our goal is to improve the knowledge of the crew and ensure a high level of security of the Greek shipping regarding the safety of life at sea.

Related Documents