-

8/6/2019 me-pres

1/18

Microencapsulation

Creating a protective journey for

vulnerable moleculesMorag Meikle

2008

-

8/6/2019 me-pres

2/18

Contents

! Introduction

!The Host component

!The Carrier component!The Shell component

!Techniques

!Efficiency!Active research topics

-

8/6/2019 me-pres

3/18

Introduction

Encapsulation is a technique by which a quantity of a

given substance, be it a gas, solid or liquid is

packaged with a secondary material with the aim of

protecting it from its surroundings (Adamiec &Marciniak, 2004)

!The host is the substance to be

encapsulated, the core material

!The carrier is the hosts emulsifier

!The shell is the encapsulating wall

-

8/6/2019 me-pres

4/18

The Host component! Hosts are sensitive substances which exhibit

substantial biological, organoleptic or technologicalproperties! Probiotics, vitamins, marine oils

! Food aromas

! Processing aids

(Bhathena, et al., 2007)

! Are not stable in in food systems! Oxidation of fatty acids and vitamins

! Volatilization of aromas

! Bioactivity of vitamins! Undesirable interaction with the food

(Schrooyen et al., 2001; Yeo et al., 2004)

-

8/6/2019 me-pres

5/18

Common Host component

Acids Activated carbon

Alcohols Aldehydes

Amines Amino acids

Anima l feed ing red ients Ant ib io tic

Antibodies Antioxidants

Antiseptics Aqueous solutions

Bacteria Biocells

Bleaches Catalysts

Chemiluminescent materials Adhesives

Corrosion inhibitors Active metals

Deodorants DyesEnzymes Flame retardants

Flavors Food ingredients

Fuels Fumigants

Fungi Fungicides

Hydrocarbons Indicators

Inks Inorganic salts

Ion-exchange res ins L iquid hydrocarbons

Lubricant additives Monomers

Oils Organometallic compounds

Oxidizers Paints

Peptides Perfumes

Peroxides Pesticides

Pharmaceuticals Phase-change material s

Phenols Photographic agentPigments Proteins

Radioprotectors Reflective products

Resin-curing agents Retinoids

Salts Sealants

Solvents Sterilants

Steroids Sweeteners

Vaccine adjuvants Viruses

Vitamins Water

Widely used in pharmaceutical

and agriculture for controlled

release of active ingredients

Increased interest in the food

industry

!Nutrition

!Flavour

!Preservative!Technological

(Schrooyen et al., 2001)

-

8/6/2019 me-pres

6/18

The Host component:

emulsification! Ampheteric properties of emulsifiers

! Retard diffusivity of volatiles

! Inhibit penetration of unwanted extrinsic factors

(Rusli et al., 2006)! Common example gum arabic, maltodextrins, .

! Stabilizers restrict coalescence in emulsions

! Common examples gelatin, xanthan gum, gum arabic,

modified starches

-

8/6/2019 me-pres

7/18

-

8/6/2019 me-pres

8/18

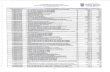

Carriers

Active research topic! Gum arabic (GA) and modified starch show best

retention of lipophilic volatile flavour compounds

(Bruckner et al., 2007; Partanen et al., 2008)

!Hydrophilic compounds

present substantial

challenges in emulsifying

to inhibit loss of volatiles

through cell wall!Spray dried W1/O/W2double emulsion in GA

Table 1. Flavour retention as a function of carrier material and time

-

8/6/2019 me-pres

9/18

Carriers

Active research topic! Heated whey/soy protein isolate with dried glucose

system, forming Maillardreaction by-productstabilizers

! Proteins able to form covalent viscoelastic S-S filmsat O/W interface

! WPI higher ME efficiency and oxidative stability thanSPI

! Formulation and processing conditions of emulsionprior to drying influential on functionality

(Rusli, Sanguansri & Augustin, 2006)

-

8/6/2019 me-pres

10/18

The shell

! Engineered to be in resist extrinsic factorsand facilitate targeted release

!Material varies depending on application

! Proteins! Polysaccharides

! Starches

!Waxes

! Fats

!Resins

!Natural / synthetic polymers

-

8/6/2019 me-pres

11/18

Protein Shell

Active research topic! Zein (corn prolamine) has

equal amounts of hydro andlipo philic A.A residues

! Self assembles intopolymorphologic bilayersnano tubes, sponges andspheres

! Future possibilities in foodflavour and bioactive

release systems(Wang et. al, 2008)

!Skim milk powder andwhey protein isolate used to

encapsulate herb oils

(Baranauskiene et. al, 2006)

-

8/6/2019 me-pres

12/18

Protein-sugar Shell

Active research topic! SPI and ribose cross linked by a combination of

transglutaminase and Maillardreaction products

used for a shell wall waterial

! Antioxidative properties of the Maillardreactionproducts limit oxidation of core material! Advantageous for ME of O2 sensitive marine oils, functional food

molecules, vitamins

! SPI-ribose complex suited for controlled release and

oxidative stability systems(Gan, Cheng & Easa, 2008)

-

8/6/2019 me-pres

13/18

Polysaccharide Shell

Active research topic! cyclodextrin! 7 D-glucose !(1-4), forms a

hollow cone

! Lipophilic core, hydrophilic wall! Successful stabilisation of

antimicrobial and aromatic lipidswithin cone

! Stoichiometry limits

complexation at maximum 10%compared to 20% in spray drying(Partanen et. al, 2002; Zavalaet. al, 2008)

-

8/6/2019 me-pres

14/18

Microencapsulation

Techniques! Broadly grouped into physical or chemical

methods, but are interrelated

! Chemical Mechanism! Complex coacervation Polyionic complexation! Interfacial polymerization Surface polymer reaction

! Phase separation Reactant dependant

! In situ polymerization Non reactant dependant

! Physical!

Spray drying Atomized emulsion! Fluid bed coating Solid core encapsulated

! centrifugal extrusion Nozzle droplet formation

! Rotational suspension separation Spinning disc method

-

8/6/2019 me-pres

15/18

Microencapsulation efficiency

! Instrumental (HPLC, GC-MS) provides complete dataanalysis! High costs (equipment, time, technicians)

! Complex data often not required

! Solid phase microextraction (SPME) uses fibrescoated with a layer of an organic polymer, whichabsorbs volatiles. They are then desorbed into GC-MS injector for analysis

! Electronic olfaction (e-noses) is an emergingtechnique that evaluates quality and freshness in ashort time! Potential for automatic, on-line evaluation for product

acceptability

(Baranauskiene, et al.,2005)

-

8/6/2019 me-pres

16/18

Active research! RMIT! Folate ME in noodles, Tartaric acid ME in

carnauba wax as processing aid (Widyan & Small,2006)

!CSIRO currently researching!New food grade materials for ME

!Targeting release of bioactives (marine oils,pro/pre biotics) in the gut

! Investigating interaction of components within

the microcapsule!Minimization of loss of bioactive components

! Self assembly of nano-emulsions in food systems(Kurth & Augustin, 2008)

-

8/6/2019 me-pres

17/18

ReferencesAdamiec, J., Marciniak, E. Microencapsulation of oil/matrix/water system during spray drying process. 2004. International Drying Symposium, Sao Paulo, vol. C,

pp. 2043-2050

Baranauskiene, P, Venskutonis, P. R., Dewettinck, K., Verhe, R.Properties of oregano, citronella and marjoram flavours encapsulated into milk basedprotein matrices. 2005. Food research international 39 (2006) 413-425. Retrieved 20th August from www.sciencedirect.com

Baranauskiene, P., Venskutonis, P. R., Galdikas, A., Senuliene, D., Setkus, A. Testing of microencapsulated flavours by electronic nose and SPME-GC.2004.

Food Chemistry 92 (2005) 45-54. Retrieved 20th August, 2008 from www.sciencedirect.com

Bhathena, J., Urbanska, A. M., Martoni, C., Prakash, S. Microencapsulated bacterial cells can be used to produce the enzyme feruloyl esterase: preperation and in

vitro analysis. 2008. Applied microbial Biotechnol 75:1023-1029

Bruckner, M., Bade, M., Kunz, B.Investigations into the stabilization of a volatile aroma compound using a combined emulsification and spray drying process.

2007. Journal of European Food Research Technology 226:137-146

Gan, C. Y., Cheng, L. H., Easa, A. M.Evaluation of microbial transglutaminase and ribose cross linked soy protein isolate based microcapsules containing fish

oils. Innovation Food Science and Emerging Technologies.Retrieved 20th August from www.elsevier.com/locate/ifet

Kheir, M. K. S. E., Yagoub, A. E. G. A., Baker A. A. A.Emulsion stabilizing effect of gum Arabic from acacia senegal (L) wild. The role of quality and grade of

gum oil type, temperature, stirring time and concentration.2008 Pakistan Journal of Nutrition (3):395-339, 2008Kurth, L., Augustin, M. A. Microencapsulation- A delivery vehicle for functional food. CSIRO biotechnology, retrieved 20th August from www.csiro.au/bio

Lui, X. D., Furuta, T., Yoshii, H., Linko, P.Retention of emulsified flavour in a single droplet during drying. 2000. Journal of Food Science and Technology

Research, 6 (4) 335-339

Partanen, R., Ahro, M., Hakala, M., Kallio, H., Forssell, P. Microencapsulation of caraway extract in -cyclodextrin and modified starches. 2002. Journal of

European Food Research Technology 214:242-247

Rusli, J. K., Sanguansri, L., Augustin, M. A. Stabilization of oils by microencapsulation with heated protein-glucose syrup mixtures.2006.AOCS 83, 965-972; paper

number J11336

Schrooyen, P. M. M., Van Der Meer, R., De Kruif, C. G. Microencapsulation: its application in nutrition. 2001. NIZO Food Research, proceedings of the

Nutrition Society, The Netherlands 60, 475-479

Wang, Q., Yin, L., Padua, G. W.Effect of hydrophilic and l ipophilic compounds on Zein Microstructures. 2008. Journal of Food Biophysics 3: 174-181

Widyan, O. A., Small, D. M. Microencapsulation of bakery ingredients and the impact on bread characteristics: effect of tartaric acid encapsulated withcarnuba wax. 2006School of Applied Sciences, RMIT university, Melbourne

Yeo, Y., Chen, A. U., Basaran, O. A., Park, K. Solvent exchange method: A novel microencapsulation technique using dual microdispensers. 2004. Journal of

pharmaceutical research. Volume 21, no 8, August, 2004

Zavala, J. F. A., Valdez, H. S., Leon, A. G., Parrilla, E. A., Belloso, M. O., Aguilar, G. A. G. Microencapsulation of cinnamon leaf and garlic oils in -

cyclodextrin. 2008. Journal Incl Phenom Macrocycl Chem 2008 60:359-368

-

8/6/2019 me-pres

18/18

Hope you enjoyed the journey

Thank you for your attention