Lecture 3. Underlying Principles of TQM (Shewhart, Deming, and Juran)

Lecture 3 - TQM

Jan 12, 2016

Principles of TQM Part I

Welcome message from author

This document is posted to help you gain knowledge. Please leave a comment to let me know what you think about it! Share it to your friends and learn new things together.

Transcript

Lecture 3. Underlying Principles of TQM (Shewhart,

Deming, and Juran)

The Shewhart Philosophy

Shewhart was the pioneer and visionary of modern quality control.

Shewhart is most widely recognized for his control chart development and statistical contributions through Bell Laboratories.

Indeed, the Shewhart charts (e.g., X-bar and R charts) have become fundamental tools of quality control; but, of wider impact, Shewhart published, in 1931, Economic Control of Quality of Manufactured Product, a landmark book in modern quality control.

His book was used by the Japanese after World War II, with the aid of visiting consultants, to help shape modern quality practice in Japan.

The Shewhart Philosophy

Shewhart, using a literal definition of quality (Latin qualitas, from qualis, meaning "how constituted"), defined two common aspects of quality:

(1) "objective quality," which deals with the quality of a thing as an "objective reality" (of the thing) independent of the existence of man and

(2) "subjective quality," which deals with the quality of a thing relative to what man thinks, feels, or senses as a result of the "objective reality."

The Shewhart Philosophy

Shewhart linked the subjective quality property with value and concluded "it is impossible to think of a thing as having goodness independent of some human want."

This definition has been expanded by Ishikawa to include "true" (customer-language based) and "substitute" (technical-language-based) quality characteristics which form the basis for modem quality planning and quality function deployment.

The Shewhart Philosophy

It is of great historical interest to point out that the Shewhart postulates (lines of reasoning) and general conclusions published in 1931 laid the foundation for modern quality theory and practice throughout the industrial world.

The Shewhart Philosophy

His general conclusions are stated below:It seems reasonable to believe that there is an objective state

of control, making possible the prediction of quality within limits even though the causes of variability are unknown....It has been pointed out that by securing this state of control, we can secure the following advantages:

1. Reduction in the cost of inspection.2. Reduction in the cost of rejection.3. Attainment of maximum benefits from quantity production.4. Attainment of uniform quality even though the inspection

test is destructive.5. Reduction in tolerance limits where quality measurement

is indirect.

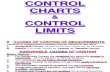

PDCA CYCLE / Deming Wheel

Problem identificationProblem selectionProblem analysis

Cause VerificationTarget Setting

Propose interventionManagement Consent

Problem identificationProblem selectionProblem analysis

Cause VerificationTarget Setting

Propose interventionManagement Consent

TrainingImplement

Counter measures

TrainingImplement

Counter measures

MonitoringComparing Against

TARGET

MonitoringComparing Against

TARGET

StandardizationFuture Plan

StandardizationFuture Plan

The Deming Quality Philosophy

Deming's 14 points Deming’s seven deadly diseases Deming's profound knowledge

system

Deming's 14 points

1. Create constancy of purpose toward improvement of product and service, with the aim to become competitive and to stay in business, and to provide jobs (create vision and commitment).

2. Adopt/learn the new philosophy. We are in a new economic age. Western management must awaken to the challenge must learn their responsibilities, and take on leadership for change.

3. Cease dependence on inspection to achieve quality. Eliminate the need for inspection on a mass basis by building quality into the product in the first place. (worker must take responsibility for their work – understand variation & seek to reduce the common causes)

Deming's 14 points

4. End the practice of awarding business on the basis of price tag. Instead, minimize total cost. Move toward a single supplier for any one item, on a long-term relationship of loyalty and trust.

5. Improve constantly and forever the system of production and service, to improve quality and productivity, and thus constantly decrease costs.

6. Institute training on the job (both management & workers – require proper tools & knowledge).

Deming's 14 points

7. Institute leadership. The job of management is leadership, not supervision – leadership means providing guidance to help employees do their job better with less effort.

8. Drive out fear. Create trust. Create a climate for innovation so that everyone may work effectively for the company.

9. Break down barriers between departments (optimize the efforts of team).

Deming's 14 points

10. Eliminate slogans, exhortations, and targets for the work force asking for zero defects and new levels of productivity (workers become frustrated when they cannot improve or are penalized for defects) – overlook the source the problems – the system.

11. A. Eliminate work standards on the factory floor (Eliminate numerical quotas for production. Instead learn and institute methods for improvement). B. Eliminate management by objective – numbers without a method to achieve them (Instead, learn the capabilities of processes, and how to improve them). – Numbers have no meaning without a method to achieve them.

Deming's 14 points

12. A. Remove barriers that rob the hourly worker of his right to pride of workmanship. B. Remove barriers that rob people in management and in engineering of their right to pride of workmanship (Performance appraisal destroys teamwork by promoting competition).

13. Institute a vigorous program of continuing education and self-improvement.

14. Take action to accomplish the transformation. Put everybody in the company to work to accomplish the transformation. The transformation is everyone's job. – A major cultural change

The seven deadly diseases that obstruct the quest for quality:

1. Lack of constancy of purpose to plan product and service that will have a market and keep the company in business, and provide jobs.

2. Emphasis on short term profits – invest in research & development.

3. Evaluation of performance, merit rating, or annual review (annual appraisal) – destroy teamwork.

4. Mobility of management; job hopping (personal career advancement is placed ahead of welfare of the organization).

5. Management by use only of visible figures, with little or no consideration of figures that are unknown or unknowable.

6. Excessive medical costs – bad for long-term competitiveness.

7. Excessive costs of liability/warranty, fueled by lawyers who work on the basis of contingency fees. – proliferation of lawsuits and multimillion dollars judgments.

The seven deadly diseases that obstruct the quest for quality: (con’t.)

The System of Profound Knowledge

The system of profound knowledge is made up of four areas:

(1) appreciation for a system, (2) knowledge about variation, (3) theory of knowledge, and (4) psychology.

System of Profound Knowledge: APPRECIATION OF A SYSTEM

A system is a set of functions or activities within an organization that work together for the aim of the organization.

A production system is composed of many smaller, interacting subsystems.

These subsystems are linked together as internal customers and suppliers.

The components of any system must work together if the system is to be effective.

System of Profound Knowledge: APPRECIATION OF A SYSTEM

Management's job is to optimize the system. Sub-optimization results in losses to

everybody in the system. All the people who work within a system can

contribute to improvement, which will enhance their joy in work.

System of Profound Knowledge: KNOWLEDGE ABOUT VARIATION

The second part of Profound Knowledge is a basic understanding of statistical theory and variation.

We see variation everywhere & variation exists in production processes.

Actually, a production process contains many sources of variation

System of Profound Knowledge: Causes of Variation Product manufacturing was measured and

where variations occurred in manufacture the cause was traced back to either (1) special causes or (2) common causes. (1) Special causes are easily identifiable and

solvable at a local level - for example a change in operator, shift of procedure.

(2) A common cause is due to the design or process of the system and is the responsibility of management to solve.

System of Profound Knowledge: Proportion of Variation Common causes of variation generally

account for about 80 to 90 percent of the observed variation in a production process.

The remaining 10 to 20 percent are the result of special causes of variation, often called assignable causes.

System of Profound Knowledge: THEORY OF KNOWLEDGE

The third part of profound knowledge is the theory of knowledge, the branch of philosophy concerned with the nature and scope of knowledge, its presupposition and basis, and the general reliability of claims to knowledge

System of Profound Knowledge: THEORY OF KNOWLEDGE

Deming emphasized that knowledge is not possible without theory, and experience alone does not establish a theory.

Any rational plan, however simple, requires prediction concerning conditions, behavior, and comparison of performance.

System of Profound Knowledge: THEORY OF KNOWLEDGE

A statement devoid of prediction or explanation of past events conveys no knowledge.

Experience only describes-it cannot be tested or validated-and alone is no help in management.

Theory , on the other hand, shows a cause and effect relationship that can be used for prediction.

System of Profound Knowledge: PSYCHOLOGY

Psychology helps us understand people, interactions between people and

circumstances, interactions between leaders and employees,

and any system of management.

System of Profound Knowledge: PSYCHOLOGY Much of Deming's philosophy is based on

understanding human behavior and treating people fairly.

People differ from one another. A leader must be aware of these differences and

work toward optimizing everybody's abilities and preferences.

Most managers operate under the assumption that all people are alike.

However, a true leader understands that people learn in different ways and at different speeds, and manages the system accordingly.

Concluding remark on the system of profound knowledge A leader of transformation, and managers

involved, need to learn the psychology of individuals, the psychology of a group, the psychology of society, and the psychology of change.

Some understanding of variation Including appreciation of a stable system, and

some understanding of special causes and common causes of variation, are essential for management of a system, including management of people.

The Juran Philosophy

Juran defined quality as (I) product performance that results in customer satisfaction; (2) freedom from product deficiencies, which avoids customer dissatisfaction-- simply summarized as "fitness for use."

The Juran Philosophy

This definition can be broken down into four categories:

(1) quality of design, (2) quality of conformance, (3) availability and (4) field service.

The Juran Philosophy

Quality of design concentrates on market research, the product concept, and design specifications.

Quality of conformance includes technology, manpower, and management.

Availability focuses on reliability, maintainability, and logistical support.

Field service quality comprises promptness, competence, and integrity.

The Juran Philosophy

The pursuit of quality is viewed on two levels: (l) The mission of the firm as a whole is to

achieve high product quality; and (2) The mission of each department in the

firm is to achieve high production quality.

The Juran Philosophy

Juran's prescriptions focus on three major quality processes, called the Quality Trilogy:

(1) quality planning --the process of preparing to meet quality goals;

(2) quality control-- the process of meeting quality goals during operations; and

(3) quality improvement --the process of breaking through to unprecedented levels of performance.

The Juran Quality Trilogy® Diagram

Related Documents