-

7/21/2019 Labsheet Translation Mechanical System

1/33

UNIVERSITI TUN HUSSEIN ONN MALAYSIA

Faculty of Mechanical and Manufacturing Engineering__________________________________________________________________

DEPARTMENT OF ENGINEERING MECHANICS

CONTROL LABORATORY

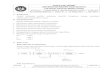

LAPORAN MAKMAL/LABORATORY REPORT

Kod M/Pelajaran/

Subject Code

ENGINEERING

LABORATORY VIBDA 37101

Kod & Tajuk Ujikaji/

Code & Tit le of Experiment

Kod Kursus/

Course Code

Seksyen/ Section

Kumpulan/GroupNo. K.P / I.C No.

Nama Pelajar/Name of

Student

No. Matrik

Lecturer/ Instructor / Tutor s

Name

1.

2.

Nama Ahli Kumpulan/

Group Members

No.

MatrikPenilaian / Assesment

1. Teori / Theory 10 %

2.Keputusan /

Results15 %

3.Pemerhatian

/Observation20 %

4.Pengiraan /

Calculation10 %

5.Perbincangan /

Discussions25 %

Tarikh Ujikaji /

Date of Experiment

Kesimpulan /

Conclusion15 %

Tarikh Hantar /

Date of Submission

Rujukan /

References5 %

JUMLAH / TOTAL 100%

COP DITERIMA/APPROVED

STAMP

ULASAN PEMERIKSA/COMMENTS

-

7/21/2019 Labsheet Translation Mechanical System

2/33

UNIVERSITI TUN HUSSEIN ONN MALAYSIA

Faculty of Mechanical and Manufacturing Engineering__________________________________________________________________

BDA37101-Edition III/2011 2

COURSE INFORMATION

COURSE TITLE: ENGINEERING LABORATORY VI (BDA 37101)

TOPIC 4: RECTILINEAR CONTROL SYSTEM

(TRANSLATION MECHANICAL SYSTEM)

1. INTRODUCTION

In control engineering, the transfer functionof a linear system is a mathematicalrepresentation of the system which defined as the ratio of the Laplace transform of

the output variable to the Laplace transform of the input variable, with all initialconditions assumed to be zero. The transfer function represents the relationship

describing the dynamics of the system under consideration.

Nevertheless, it is often not possible or practical to obtain a systems transfer

function analytically. This may due to the component parts that are not easily

identifiable or the system itself is closed. Given that the transfer function is a

representation of the system from input to output, the systems step response can

lead to a representation even though the inner construction of the system is notknown. With a step input, several parameters value can be measured, from which

the transfer function of the system can be calculated. This technique which usesthe experimental approach to get the transfer function of a system is known as

system identification.

2. OBJECTIVES

The objectives of this experiment are:

i. Identify the plant parameters, andii. Determine the transfer function of two degree of freedom (DOF)

rectilinear plant.

3. LEARNING OUTCOMES

At the end of this experiment, students should be able to:

i. Configure the two degree of freedom rectilinear plant for systemidentification purposes,

ii. Calculate the plant parameters, andiii. Find the transfer function of two degree of freedom (DOF) rectilinear

plant.

-

7/21/2019 Labsheet Translation Mechanical System

3/33

UNIVERSITI TUN HUSSEIN ONN MALAYSIA

Faculty of Mechanical and Manufacturing Engineering__________________________________________________________________

BDA37101-Edition III/2011 3

4. THEORY (TWO DEGREE OF FREEDOM PLANTS)

Figure 1: Two DOF Plant Model

Figure 1(a) shows the most general form of the two degree of freedom plant

where friction is idealized as being viscous. The transfer function for the 2DOF

plant model can be obtained analytically by using the Newton second law and the

free body diagram. A dynamic equation of m1will be obtained by summing all

forces acting on it as shown in Figure 1(b):

(4.1)

Similarly from Figure 1(c)for m2:

(4.2)

By Laplace transform of Eqs (4.1,4.2) and assuming zero value of initialconditions, the transfer functions of the 2DOF plant model are:

(4.3)

m1x1 +c1x1 + (k1 +k2)x1-k2x2=F(t)

m2x2+c2x2+(k2 +k3)x2-k2x1=0

x1(s)

F(s) =

m2s 2 +c2s+k2 +k3D(s)

-

7/21/2019 Labsheet Translation Mechanical System

4/33

UNIVERSITI TUN HUSSEIN ONN MALAYSIA

Faculty of Mechanical and Manufacturing Engineering__________________________________________________________________

BDA37101-Edition III/2011 4

(4.4)

Where,

(4.5)

The transfer functions may also be expressed in the general form as:

(4.6)

(4.7)

Where the i's and i's are the natural frequencies and damping ratios

respectively, and the gains K1& K2, are nominally equal to 1/m1and k1/m1m2

(but often may be measured more directly).

4.1 ADDITIONAL THEORY

x2(s)

F(s) =

k2D(s)

D(s)=m1m2 s4+ m1c2 +m2c1 s3+ m1(k2 +k3)+m2(k1 +k2)+c1c2 s2+ c1(k2 +k3)+c2(k1 +k23) s +k1k2+k1k3+k2k3

x1(s)

F(s) =

K1 s 2+2zzs +z2

s 2+2p1p1s +p12 s 2+2p2p2s +p2

2

x2(s)

F(s) =

K2

s 2+2p1p1s +p12 s 2+2p2p2s +p2

2

-

7/21/2019 Labsheet Translation Mechanical System

5/33

UNIVERSITI TUN HUSSEIN ONN MALAYSIA

Faculty of Mechanical and Manufacturing Engineering__________________________________________________________________

BDA37101-Edition III/2011 5

-

7/21/2019 Labsheet Translation Mechanical System

6/33

UNIVERSITI TUN HUSSEIN ONN MALAYSIA

Faculty of Mechanical and Manufacturing Engineering__________________________________________________________________

BDA37101-Edition III/2011 6

5. APPARATUS

Figure 2 shows the equipment used for this experiment. The equipment consists

of:

a. Electromechanical plantb. System interface softwarec. Real-time controller & I/O

Figure 2: The Experimental Equipment

Figure 3 shows the possible plant configurations during the experiment to

determine the parameter values.

Figure 3 : Plant Configurations

Figure 4shows the guidelines for setting stop position.

-

7/21/2019 Labsheet Translation Mechanical System

7/33

UNIVERSITI TUN HUSSEIN ONN MALAYSIA

Faculty of Mechanical and Manufacturing Engineering__________________________________________________________________

BDA37101-Edition III/2011 7

Figure 4: Guidelines for Setting Stop Positions

6. PROCEDURES

6.1 IDENTIFYING THE PLANT PARAMETER S1

This section gives a procedure for identifying the plant parameters applicable to

Eq's (4.1 through 4.7). The approach will be to indirectly measure the mass,

spring, and damping parameters by making measurements of the plant while setup in a pair of classical spring-mass configurations.

1. Clamp the second mass to put the mechanism in the configuration shownin Figure 5a using a shim (e.g. 1/4 inch nut) between the stop tab and stop

bumper so as not to engage the limit switch. Verify that the medium

stiffness spring (nominally 400 N/m) is connecting the first and second

mass carriages.

2. Secure four 500g masses on the first and second mass carriages.

3. With the controller powered up, enter the Control Algorithmbox via theSet-up menu and set Ts = 0.00442. Enter the Command menu, go to

Trajectoryand select Step, Set-up. Select Open Loop Stepand input astep size of 0 (zero), a duration of 3000 msand 1 repetition. Exit to the

background screen by consecutively selecting OK. This puts the controllerin a mode for acquiring 6 sec of data on command but without driving the

actuator. This procedure may be repeated and the duration adjusted tovary the data acquisition period.

-

7/21/2019 Labsheet Translation Mechanical System

8/33

UNIVERSITI TUN HUSSEIN ONN MALAYSIA

Faculty of Mechanical and Manufacturing Engineering__________________________________________________________________

BDA37101-Edition III/2011 8

4. Go to Set up Data Acquisitionin the Data menu and select Encoder #1and Encoder #2 as data to acquire and specify data sampling every 2

(two) servo cycles (i.e. every 2 Ts's). Select OK to exit. Select Zero

Positionfrom the Utilitymenu to zero the encoder positions.

Figure 5: Configurations for Plant Identification

5. Select Executefrom the Command menu. Prepare to manually displacethe first mass carriage approximately 2.5 cm. Exercise caution in

displacing the carriage so as not to engage the travel limit switch. With

the first mass displaced approximately 2.5 cm in either direction, select

Runfrom the Executebox and release the mass approximately 1 secondlater. The mass will oscillate and attenuate while encoder data is collected

to record this response. Select OKafter data is uploaded.

6. Select Set-up Plot from the Plotting menu and choose Encoder #1Position then select Plot Data from the Plottingmenu. You will see thefirst mass time response.

7. Choose several consecutive cycles (say ~5) in the amplitude rangebetween 5500 and 1000 counts (This is representative of oscillation

amplitudes during later closed loop control maneuvers. Much smaller

amplitude responses become dominated by nonlinear friction effects and

do not reflect the salient system dynamics). Divide the number of cycles

by the time taken to complete them. Be sure to take beginning and end

times from the same phase of the respective cycles.1 Convert the resulting

1You may zoom the plot via Axis Scalingfor more precise measurement in various areas. For aneven greater precision, the data may be examined in tabular numerical form

-

7/21/2019 Labsheet Translation Mechanical System

9/33

UNIVERSITI TUN HUSSEIN ONN MALAYSIA

Faculty of Mechanical and Manufacturing Engineering__________________________________________________________________

BDA37101-Edition III/2011 9

frequency in Hz to radians/sec. This damped frequency, d, approximates

the natural frequency, n, according to:

(6.1)

where the "m11" subscript denotes mass #1, trial #1. (Close the graph

window by clicking on the left button in the upper right hand corner of thegraph. This will collapse the graph to icon form where it may later be

brought back up by double-clicking on it.)

8. Remove the four masses from the first mass carriage and repeat Steps 5

through 7 to obtain nm12for the unloaded carriage. If necessary, repeatStep 3 to reduce the execution (data sampling only in this case) duration.

9. Measure the initial cycle amplitude Xoand the last cycle amplitude Xnfor

the n cycles measured in Step 8. Using relationships associated with the

logarithmic decrement:

(6.2)

find the damping ratio m12 and show that for this small value the

approximations of Eq's (6.1, 6.2) are valid.

10.Repeat Steps 5 through 9 for the second mass carriage. Here in Step 6 youwill need to remove Encoder #1 position and add Encoder #2 position to

the plot set-up. Hence obtain nm2 , nm22 and m22. How does this

damping ratio compare with that for the first mass? Be sure to save this

plotted data as it will be used in the next experiment.

11.Connect the mass carriage extension bracket and dashpot to the secondmass as shown in Figure 5c. Open the damping (air flow) adjustment knob

2.0 turns from the fully closed position. Repeat Steps 5, 6, and 9 with four

500 g masses on the second carriage and using only amplitudes 500

counts in your damping ratio calculation. Hence obtain dwhere the "d"

subscript denotes "dashpot".

nm11=dm11

1-m112

dm11 (for s mall m1)

m12

1-m122

= 12n

lnXoXn

m12 12n

lnXoXn

(fo r s mall m12)

-

7/21/2019 Labsheet Translation Mechanical System

10/33

UNIVERSITI TUN HUSSEIN ONN MALAYSIA

Faculty of Mechanical and Manufacturing Engineering__________________________________________________________________

BDA37101-Edition III/2011 10

12.Each brass weight has a mass of 500 10 g. (You may weigh the pieces ifa more precise value is desired.) Calling the mass of the four weights

combined mw, use the following relationships to solve for the unloaded

carriage mass mc2, and spring constant k.2

k/(mw+mc2) = (nm21)2 (6.3)

k/mc2= (nm22)2 (6.4)

Find the damping coefficient cm2by equating the first order terms in the

equation form:

(6.5)

Repeat the above for the first mass carriage, spring and damping mc1, cm1

and krespectively.3 4 Calculate the damping coefficient of the dashpot,cd.

13.Remove the carriage extension bracket and dashpot from the second masscarriage, replace the medium stiffness spring with a high stiffness spring

(800 N/m nominally), and repeat Steps 5 and 6 to obtain the resulting

natural frequency m23. Repeat this frequency measurement using the

least stiffspring (nominally 200 N/m)to obtain m24.Calling the value

of stiffness obtained in Step 12 above kmed stiffness; calculate khigh

stiffnessand klow stiffnessfrom the frequency measurements of this step.

Calling the value of stiffness obtained in Step 12 above kmed stiffness;calculate khigh stiffness and klow stiffness from the frequency

measurements of this step.

Now all dynamic parameters have been identified! Values for m1and m2for any

configuration of masses may be found by adding the calculated mass contributionof the weights to that of the unloaded carriages5.

6.2 ESTABLISHING THE HARDWARE GAIN

The following procedure is necessary to establish the hardware gain for

control modeling purposes.

2Note that the calculated masses mc1and mc2will include the reflected inertias of all connected

elements e.g. motor pinion and armature.3Step 12 may be done later, away from the laboratory, if necessary.

4The resulting value for kshould be very close to that measured when considering the second mass

case. You may use the average of the two for your identified kvalue.5In Model 210 configurations where the third mass is used, the inertia and damping parameters of

the third carriage may generally be assumed to be the same as for the second carriage. For moreprecise results, steps 5 through 9 and 12 may be repeated for the third mass.

s2+2ns +n2=s2+ c/m s +k/m

-

7/21/2019 Labsheet Translation Mechanical System

11/33

UNIVERSITI TUN HUSSEIN ONN MALAYSIA

Faculty of Mechanical and Manufacturing Engineering__________________________________________________________________

BDA37101-Edition III/2011 11

1. Remove the spring connecting the first and second masses and secure four500 g masses on the first mass carriage. (You should label this particular

spring so that the identified parameter k2will be consistent when used in

later experiments). Use the limit clamps to secure the second mass clearfrom the first. Verify that the masses are secure and that the carriage slides

freely. Hook up the drive power to the mechanism. Position the first mass

approximately 3 cm to the left (negative x1position) of its center of travel.

2. In the Trajectory window deselect Unidirectional moves (i.e. enablingbi-directional inputs) select Step, Set-up. Choose Open Loop Step, andinput 2.00 Volts, 75 ms, 2 reps. Execute this open loop step via the

Execute menu. (This move may trip a software speed limit or motiontravel limit which disables the controller indicated by "Limit Exceeded" inthe Controller Status box in the "desk top". Again, to reset, simply

reselect Execute from the Execute menu.) Go to Set-up in the PlotData menu and select Encoder #1velocity for plotting.

3. Plot this data and observe four velocity profile segments with nominalshapes of: linear increase (constant acceleration), constant (zero

acceleration6), linear decrease (deceleration), and constant. Obtain the

acceleration, ex1

, (counts/s2) by carefully measuring the velocity

difference and dividing by the time difference (75 ms) through the

positive-sloped linear segment. 7,8 Repeat this for the negative-sloped

segment. Calculate the average magnitude of the positive and negative

accelerations for use in obtaining khwbelow.

4. Save any files or plots of interest. Exit the executive program and powerdown the system.

6.3 TRANSFER FUNCTION CALCULATION

The so-called hardware gain, khw,9of the system is comprised of the

product:

khw= kckaktkmpkekepks (6.6)

6Some small deceleration will exist due to friction.7For more precise measurement you may "zoom in" on this region of the plot usingAxis Scalingin

the Plotting menu.8It is possible to read the accelerations directly by plotting Encoder #1 acceleration. This data,

obtained by double numerical differentiation, is typically somewhat noisy however. The studentmay want to verify this by observing the acceleration plot

9It contains software gain also. This software gain, ksis used to give higher controller-internalnumerical resolution and improves encoder pulse period measurement for very low rate estimates.

-

7/21/2019 Labsheet Translation Mechanical System

12/33

UNIVERSITI TUN HUSSEIN ONN MALAYSIA

Faculty of Mechanical and Manufacturing Engineering__________________________________________________________________

BDA37101-Edition III/2011 12

Where:

kc, the DAC gain, = 10V / 32,768 DAC counts

ka, the Servo Amp gain, = approx 2 (amp/V)kt, the Servo Motor Torque constant = approx 0.1 (N-m/amp)

kmp, the Motor Pinion pitch radius inverse = 26.25 m-1

ke, the Encoder gain, = 16,000 pulses / 2 radians

kep, the Encoder Pinion pitch radius inverse = 89 m-1

ks, the Controller Software gain, = 32 (controller counts / encoder or ref

input counts)10

In Step 15, we obtained the acceleration ex1

(counts/s2) of a known inertia,

m1=mw+mc1with a known voltage applied at the DAC. This relates to theapplied force during the acceleration according to:

Applied Force = )/(1111 epeeavg kkxmxm

(6.7)

Thus we have a direct measurement of the five-term product

kaktkmpkekep. i.e.:

2.00V kaktkmp= Applied Force in Step 15 (6.8)

Use (6.6 through 6.8) to solve for khwusing the specified values for keand ks.Forcontrol purposes it is generally desirable to put the transfer function indenominator-monic form (leading term in D(s) has unity coefficient).

10These are the counts that are actually operated on in the control algorithm. i.e. The system input(trajectory) counts and encoder counts are multiplied by 32 prior to control law execution.

-

7/21/2019 Labsheet Translation Mechanical System

13/33

UNIVERSITI TUN HUSSEIN ONN MALAYSIA

Faculty of Mechanical and Manufacturing Engineering__________________________________________________________________

BDA37101-Edition III/2011 13

7. OBSERVATION

-

7/21/2019 Labsheet Translation Mechanical System

14/33

UNIVERSITI TUN HUSSEIN ONN MALAYSIA

Faculty of Mechanical and Manufacturing Engineering__________________________________________________________________

BDA37101-Edition III/2011 14

-

7/21/2019 Labsheet Translation Mechanical System

15/33

UNIVERSITI TUN HUSSEIN ONN MALAYSIA

Faculty of Mechanical and Manufacturing Engineering__________________________________________________________________

BDA37101-Edition III/2011 15

8. RESULT/CALCULATIONS

8.1

Calculation of plant parameters (f, d, mand n) for medium stiffnessspring

a. Plant parameters (f, dm11, m11and nm11) of loaded masses in the firstmass carriage (Encoder #1)

-

7/21/2019 Labsheet Translation Mechanical System

16/33

UNIVERSITI TUN HUSSEIN ONN MALAYSIA

Faculty of Mechanical and Manufacturing Engineering__________________________________________________________________

BDA37101-Edition III/2011 16

b. Plant parameters (f, dm12, m12 and nm1) of unloaded masses in the

first mass carriage (Encoder #1)

-

7/21/2019 Labsheet Translation Mechanical System

17/33

UNIVERSITI TUN HUSSEIN ONN MALAYSIA

Faculty of Mechanical and Manufacturing Engineering__________________________________________________________________

BDA37101-Edition III/2011 17

c. Plant parameters (f, dm21, m21 and nm21) of loaded masses in the

second mass (Encoder #2)

-

7/21/2019 Labsheet Translation Mechanical System

18/33

UNIVERSITI TUN HUSSEIN ONN MALAYSIA

Faculty of Mechanical and Manufacturing Engineering__________________________________________________________________

BDA37101-Edition III/2011 18

d. Plant parameters (f, dm22, m22and nm22) of unloaded masses in the

second carriage (Encoder #2)

-

7/21/2019 Labsheet Translation Mechanical System

19/33

UNIVERSITI TUN HUSSEIN ONN MALAYSIA

Faculty of Mechanical and Manufacturing Engineering__________________________________________________________________

BDA37101-Edition III/2011 19

8.2 Calculation of plant parameter ( d) for medium stiffness spring

a. Find the plant parameter ( d)

-

7/21/2019 Labsheet Translation Mechanical System

20/33

UNIVERSITI TUN HUSSEIN ONN MALAYSIA

Faculty of Mechanical and Manufacturing Engineering__________________________________________________________________

BDA37101-Edition III/2011 20

8.3 Calculation of plant parameters ( unloaded mass carriage, m, spring

constant,k, and damping coefficient,c) for medium stiffness spring

a. Plant parameters (mc1, kmedstiffnessand cm1) of first mass carriage

-

7/21/2019 Labsheet Translation Mechanical System

21/33

UNIVERSITI TUN HUSSEIN ONN MALAYSIA

Faculty of Mechanical and Manufacturing Engineering__________________________________________________________________

BDA37101-Edition III/2011 21

b. Plant parameters (mc2, kmedstiffnessand cm2) of second mass carriage

-

7/21/2019 Labsheet Translation Mechanical System

22/33

UNIVERSITI TUN HUSSEIN ONN MALAYSIA

Faculty of Mechanical and Manufacturing Engineering__________________________________________________________________

BDA37101-Edition III/2011 22

c. Calculate the damping coefficient of the dashpot, cd.

-

7/21/2019 Labsheet Translation Mechanical System

23/33

UNIVERSITI TUN HUSSEIN ONN MALAYSIA

Faculty of Mechanical and Manufacturing Engineering__________________________________________________________________

BDA37101-Edition III/2011 23

8.4 Calculation of hardware gain

a. Find the acceleration,

ex1 (counts/s

2

)

-

7/21/2019 Labsheet Translation Mechanical System

24/33

UNIVERSITI TUN HUSSEIN ONN MALAYSIA

Faculty of Mechanical and Manufacturing Engineering__________________________________________________________________

BDA37101-Edition III/2011 24

b. Find the hardware gain, khwusing the specified values for kcand ks.

-

7/21/2019 Labsheet Translation Mechanical System

25/33

UNIVERSITI TUN HUSSEIN ONN MALAYSIA

Faculty of Mechanical and Manufacturing Engineering__________________________________________________________________

BDA37101-Edition III/2011 25

8.5 Calculate the plant parameters (nm23, nm24, khigh stiffness, and klow

stiffness)

-

7/21/2019 Labsheet Translation Mechanical System

26/33

UNIVERSITI TUN HUSSEIN ONN MALAYSIA

Faculty of Mechanical and Manufacturing Engineering__________________________________________________________________

BDA37101-Edition III/2011 26

9. DISCUSSIONS

a. Discuss all printed plots. Please make some results comparisons

-

7/21/2019 Labsheet Translation Mechanical System

27/33

UNIVERSITI TUN HUSSEIN ONN MALAYSIA

Faculty of Mechanical and Manufacturing Engineering__________________________________________________________________

BDA37101-Edition III/2011 27

-

7/21/2019 Labsheet Translation Mechanical System

28/33

UNIVERSITI TUN HUSSEIN ONN MALAYSIA

Faculty of Mechanical and Manufacturing Engineering__________________________________________________________________

BDA37101-Edition III/2011 28

b. Report the measured properties and derived parameter values:mw, mc1,

mc2, mc3, cm1,cm2, cm3 , cd, klow stiffness, kmed stiffness,

khigh stiffness, and khw.

-

7/21/2019 Labsheet Translation Mechanical System

29/33

UNIVERSITI TUN HUSSEIN ONN MALAYSIA

Faculty of Mechanical and Manufacturing Engineering__________________________________________________________________

BDA37101-Edition III/2011 29

-

7/21/2019 Labsheet Translation Mechanical System

30/33

UNIVERSITI TUN HUSSEIN ONN MALAYSIA

Faculty of Mechanical and Manufacturing Engineering__________________________________________________________________

BDA37101-Edition III/2011 30

c. Construct a denominator-monic plant model suitable for control designfor the case of four 500g weights on each of the first and second mass

carriers with the 400 N/m (nominal) spring connecting the two and

dashpot connected to the second mass see Figure 6.1-1d. Use theabove results and equations (5.1-4 through 5.1-6) to generate these

transfer functions where the hardware gain multiplies the numerator foreach transfer function. Construct the plant model for the same case

except where there is no dashpot.

-

7/21/2019 Labsheet Translation Mechanical System

31/33

UNIVERSITI TUN HUSSEIN ONN MALAYSIA

Faculty of Mechanical and Manufacturing Engineering__________________________________________________________________

BDA37101-Edition III/2011 31

d. What are the units of khw?

10. CONCLUSION

Deduce conclusions from the experiment. Please comment on your experimental

work in terms of achievement, problems faced throughout the experiment andsuggest recommendation for improvements.

-

7/21/2019 Labsheet Translation Mechanical System

32/33

UNIVERSITI TUN HUSSEIN ONN MALAYSIA

Faculty of Mechanical and Manufacturing Engineering__________________________________________________________________

BDA37101-Edition III/2011 32

-

7/21/2019 Labsheet Translation Mechanical System

33/33

UNIVERSITI TUN HUSSEIN ONN MALAYSIA

Faculty of Mechanical and Manufacturing Engineering__________________________________________________________________

11. REFERENCES