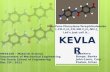

KEVLAR PRESENTED BY : PRANAV NANDA 7 th SEM B.ARCH,SU SECTION B

Kevlar

Jan 27, 2016

Kevlar is the future of reinforcement materials

Welcome message from author

This document is posted to help you gain knowledge. Please leave a comment to let me know what you think about it! Share it to your friends and learn new things together.

Transcript

KEVLAR

PRESENTED BY :PRANAV NANDA

7th SEM B.ARCH,SUSECTION B

WHAT IS KEVLAR ?

RAW KEVLAR

SPUNED KEVLAR

Kevlar is simply a super-strong plastic that is made by polymerization (joining together long chain molecules) and they have widely different properties. Kevlar's amazing properties are partly due to its internal structure (how its molecules are naturally arranged in regular, parallel lines) and partly due to the way it's made into fibers that are knitted tightly together.Kevlar is not like cotton—it's not something anyone can make from the right raw materials. It's a proprietary material made only by the DuPont™ chemical company and it comes in two main varieties called Kevlar 29 and Kevlar 49. Kevlar is example of chemicals called synthetic aromatic polyamides or aramids for short.

PROPERTIES OF KEVLAR1.) It's strong but relatively light. The specific tensile strength (stretching or pulling strength) of both Kevlar 29 and Kevlar 49 is over eight times greater than that of steel wire.

2.) Unlike most plastics it does not melt: it's reasonably good at withstanding temperatures and decomposes only at about 450°C (850°F).

3.) Unlike its sister material, Nomex, Kevlar can be ignited but burning usually stops when the heat source is removed.

4.) Very low temperatures have no effect on Kevlar: DuPont found "no embrittlement or degradation" down to −196°C (−320°F).

5.) Like other plastics, long exposure to ultraviolet light (in sunlight, for example) causes discoloration and some degradation of the fibers in Kevlar.

6.) Kevlar can resist attacks from many different chemicals, though long exposure to strong acids or bases will degrade it over time.

7) In DuPont's tests, Kevlar remained "virtually unchanged" after exposure to hot water for more than 200 days and its super-strong properties are "virtually unaffected" by moisture.

KEVLAR IS A ANTIBALLISTIC

MATERIALKevlar is an excellent antiballistic (bullet- and knife-resistant) material because it takes a great deal of energy to make a knife or a bullet pass through it. The tightly woven fibers of highly oriented (lined-up) polymer molecules are extremely hard to move apart: it takes energy to separate them. A bullet (or a knife pushed hard by an attacker) has its energy "stolen" from it as it tries to fight its way through. If it does manage to penetrate the material, it's considerably slowed down and does far less damage.

Although Kevlar is stronger than steel, it's about 5.5 times less dense (the density of Kevlar is about 1.44 grams per cubic centimeter, compared to steel, which is round about 7.8–8 grams per cubic centimeter). That means a certain volume of Kevlar will weigh 5–6 times less than the same volume of steel.

USES OF KEVLAR

1.) Kevlar can be used by itself or as part of a composite material (one material combined with others) to give added strength. It's probably best known for its use in bulletproof vests and knifeproof body armor, but it has dozens of other applications as well.

2.) It's used as reinforcement in car tires, in car brakes, in the strings of archery bows, and in car, boat, and even aircraft bodies.

3.) It's even used in buildings and structures, although not (because of its relatively low compressive strength) as the primary structural material.

DRAWBACKS OF KEVLAR

Kevlar has very poor compressive strength (resistance to squashing or squeezing). That's why Kevlar isn't used instead of steel as a primary building material in things like buildings, bridges, and other structures where compressive forces are common.

KEVLAR IN ARCHITECTURE

In the architecture world, Kevlar suffered from false starts. The spectacularly unsuccessful roof for Montreal’s Olympic Stadium, designed by architect Roger Taillibert with engineer Luc Lainey around 1976, featured a dramatic leaning tower and Kevlar-fortified retractable fabric spans. The overpromising monument took a decade to complete and only survived another ten years.

Miami’s new building codes for storm resistance and, a decade later, security concerns following the September 11 attacks. Architects and security experts gravitated to more resilient façade claddings and structures, such as Alcoa’s Reynobond, which combined aluminum composite with a thin Kevlar fabric layer as an optional, impact-proof spec.

Kevlar became a standard-bearer for resilient building products, but avant-garde designers saw wilder possibilities.

California architect Peter Testa designed amazing, space-age storefronts and spider-web installations from Kevlar-carbon panels and woven mesh.

Then the French firm Serero unveiled a super-lightweight Kevlar netting to expand the Eiffel Tower’s observation deck, proclaiming it winner of a competition to honor the landmark’s anniversary.In the real world, architects favor Kevlar for two reasons, and both are about performance: It’s lightweight and easy to integrate.

A thin blanket can serve as structural reinforcement or ballistic protection, everywhere from seismic shear walls to bank counters.

Sprinkle the fibers into carbon composites to cut weight and boost strength.

The grades Kevlar 49 and 149 are the lightest and most robust; Kevlar 29 is comparable in potency to glass fiber, but weighs less.

THANK YOU

Related Documents