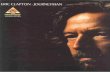

W ELDING Reference Text JOURNEYMAN PROGRAMME

Welcome message from author

This document is posted to help you gain knowledge. Please leave a comment to let me know what you think about it! Share it to your friends and learn new things together.

Transcript

WELDING Reference Text

JOURNEYMANPROGRAMME

ForewordMIC has produced this book for us in its Industrial Maintenance Journeyman Programme and it is specifically designed to introduce the basics of maintenance.

This book is intended for use as a reference text to be supplemented by notes and explanations and does not stand alone.

Compilation of this book was completed with standard published material, Tel-A-Train and resource personnel at MIC. No claim is made to the ownership of any material contained herein.

THIS BOOK IS NOT FOR SALE

REFERENCE TEXT USED

2

TABLE OF CONTENTS

1 WELDING SAFETY 3

2 FUNDAMENTALS OF ELECTRICITY 7

3 ARC WELDING EQUIPMENT 11

4 BASIC SCIENCE OF METALS 20

5 BASIC WELDING METALLURGY 27

6 ARC WELDING ELECTRODES 32

7 GAS WELDING EQUIPMENT 38

8 THE WELDING PROCESS 46

9 DISTORTION AND RESIDUAL STRESS 61

10 WELDING SYMBOLS 68

11 INSPECTION AND QUALITY CONTROL 75

12 TEMPERATURE CONVERSION TABLE 92

3

Welding Safety

4

5

6

1.2 CXYACETYLENE SAFETY RULES

1. Blow out the cylinder valves before attaching the regulators to the cylinders.

2. Release the adjusting screw on the regulator before opening up the cylinder valve.

3. Stand to one side of the regulator before opening the cylinder valve.

4. Open the cylinder valve slowly.

5. Do not use or compress acetylene in a free state at pressures higher than 15 psi.

6. Purge the oxygen plus acetylene gas passages individually before lighting the torch.,

7. Light the acetylene before opening the oxygen valve on the torch.

8. Neveruseoilonregulatorsktorchesfittingsorotherequipment#1contactwithoxygen.

9. Do not use oxygen as a substitute for air.

10. Keep the work area clean of anything that will burn.

11. Always wear eye protection.

12. Never use a regulator designed for one type gas on a different type. gas.

13. Never try to use gas fran a cylinder without a regulator..

14. Cylinders should be secured on the cart or rack before the protective cap is removed.

15. Replace the protective cap before moving tanks.

16. Always close the valves on empty cylinders to prevent dust and moisture from entering the tank.

17. Compressed gas cylinders should never be subjected to temperatures above 1250F.

7

Fundamentalsof Electricity

8

WELDING (CURRENT AND VOLTAGE)

In the behavior of a welding electrical current there are three distin¬guishable types of voltages.

OPEN CIRCUIT VOLTAGEThis is the voltage before beginning the arc (60 to 70 V approximately).PRIMARY VOLTAGEThis is the voltage at the moment that the arc is struck (minimum)WORKING VOLTAGEThis is the voltage during welding (30 V approximately).Inweldingwithalternatingcurrent,onlytheintensityofcurrent(amperage)requiredcanberegulated. For welding with direct current, there are devices which enable regulating the voltage also.In direct current welding it is possible to change the direction of circula¬tion of the current (po-larity) this change of polarity is indicated in the booklet on electrodes. To calculate the normal working current of an electrode, 35 A for each millimeter of thickness of the nucleus is taken.ExampleFor an electrode of 4 mm in diameter the normal intensity would be: I = 4 mm x 35 A/mm I = 140 AThe usual values are presented in the following table:

Observation:These values may be increased or decreased from 5% to 15% depending on the electrode and the machine to be used.

9

Electric machinery which transforms the alternating current, lowering the voltage of the supply toanadequatevoltageandintensityforwelding.Suchalternatingcurrentoflowvoltage(65to75 volts open circuit) and of constant amperage, supplies the heat source needed for welding.

THE TRANSFORMER IS MADE UP OF

A core, which is composed of steel sheets with silicon and with two wire windings (coils); the high voltage coil is called primary,andthelowvoltageprimaryiscalledsecondary(fig.1).The current which comes from the supply lines, passes through the primary coil. Transformers are made adaptable for different voltages, with the aim of facilitating their connection with supply nets. The action of the transformer is ex-plainedinthisway.Theelectriccurrentwhichmovesthroughtheprimarycoil,generatesafieldofmagneticlinesofforceinthecore.Thisfieldactsonthesecondarycoil,andproducesinitalow voltage current of high intensity which is used for welding.

CHARACTERISTICS:The regulation of the intensity is commonly done in two ways:1.Regulationbyadisplacementcoil(fig.2).Consists in separating the primary and the secondary from each other

OBSERVATION:This system is recommended because of its gradual regulation.

10

WELDING MACHINE (TRANSFORMER)

2Regulationbyplugs(fig.3)It works by increasing or decreasing the number of turns.

The transformers are also known as static machines, because they do not have moving parts. Those made for high intensity carry a fan which is used to cool the system.

ADVANTAGES:The use of the transformer has become generalized because of:• Lowcost.• Longerdurationandlessmaintenanceexpenses.-Greateroutput-andlessopencircuit consumption.• Lessinfluenceofthemagneticblow.

DISADVANTAGES:Among its disadvantages that can be mentioned are:• Limitationoftheuseofsomeelectrodes.

CARE:It must be kept free from dust.

PRECAUTION: ALL CLEANING JOBS MUST BE DONE WITH THE MACHINE DISCON- NECTED. WHEN INSTALLING IT YOU OUGHT TO CHOOSE A DRY PLACE FIXING ON TO IT AN EARTH CONNECTION.

11

Arc WeldingEquipment

12

3.1 SAFETY WEAR FOR ARC WELDING

This is composed of elements made of leather and they are used by the welder to protect himself fromtheheatandradiationproducedbetheelectricarc.Thisequipmentiscomposedofgloves,apron, jackets, sleeves and leggings.

GLOVES:Made of leather or asbestos, and their shape varies as can beseeninfigures1and2.Theasbestosglovesareusedonly for jobs of a high temperature. Avoid handling very hot work pieces with the gloves, because they lose their shapeandflexibility.

APRON: Itisofacommonshape(fig.3)ORwithlegprotectors(fig.4).Itsobjectiveistoprotectthefront part of the body and legs up to the knees.

JACKET:Itsshapecanbeseeninfig.5.Itisusedtospeciallyprotectthearmsandpartofthechest.Itisusedfrequentlywhenwelding is done in a vertical, horizontal or overhead position.

13

PROTECTIVE EQUIPMENT (LEATHER CLOTHING)

SLEEVES:Thisgarmentismeantonlytoprotectthearmsofthewelder(fig.6).itismostlyusedforweld-ingwhichisdoneatawork-benchandinaflatpositionThereareothertypesofsleevesintheshapeofavestwhichalsocoverspartofthechest(fig.7)

LEGGINGS:Theseareusedtoprotectpartofthelegsandthewelder’sfeet(fig.8).Theleggingscanbere-placedbyhigh,plainboots(fig.9)withasteeltip.

CHARACTERISTICS:Theyarecuredleather,flexible,lightweight,treatedwithleadsalttoavoidradiationformtheelectric arc.

CARE:It is important to keep these elements in good working condition, free from tears and with their fastenings in good condition. They must be kept clean and dry to ensure good insulation. PROTECTIVE EQUIPMENT (MASK)

Theprotectivemaskismadeoffiberglassorcompressedfiberandithasanopeninginwhichneutralizing as well as protective glasses are placed. It is used to protect the eyes and to avoid burns on the face.

14

TYPESTherearedifferenttypesofweldingmasks(figs.1,2and 3). There are also combined masks with a safety helmettodoconstructionwork(fig.4)andwithadapt-ers for protection of the eyes when there is (……….) to becleaned(fig.5).Thehandshield(fig.6)isusedwhenassembling or tack welding is done. Its use is not con-venient in jobs at a height where the welder needs to hold parts or tools.

CONDITIONS OF USEThemasksmustbeusedwiththeglassesinthequantityandse-quencerequired(fig.7).

The tinted glass must be selected according to the amperage used. It must maintain good visibil-itybychangingtheprotectiveglasswhenthishastoomanysplatters.Avoidlightfilteringintothe mask. It must not be exposed to heat or knocks.They must be lightweight and must have a headband for adjusting to heat or knocks.They must have a mechanism which allows them to be used comfortably. The changing of glasses must be done by means of a mechanism that is east to handle.

15

BASIC MACHINE TYPES

Direct Current (D.C.) EquipmentTheequipmentusedisclassifiedintotwogroupsi.e.generatorsandrectifiers.

Generator A genereator may be driven by an electric motor cancelled to the main supply or by a petrol or diesel motor.

RectifierAweldingrectifierusuallyincorporatesatransformer.The welding lead from this power source carries power to the electrode holder

Electrode HolderThis is used to hold the electrode during the welding process. The handle is insulated to pro-tect the welder from electric shock.

16

Power Sources

Theseareclassifiedintotwogroups,AlternatingCurrent(A.C.)orDirectCurrent(D.C.)ac-cording to the output current supplied by either a mains supply or mobiles generator.

Alternating Current (A.C.)Where input is from tea minas the power source must:• Reducethemainsinputvoltagetogiveanoutputopen-circuitvoltagebetween40and 100 volts.• Increasethemainsinputcurrenttogivetheoutputcurrentsrequiredforwelding.

17

DESCRIPTION OF THE ARC (WELDING CIRCUIT)

Manual welding with an electric arc is a system that uses a heat source (electric arc) and a gase-ous medium generated by the combustion of the coating of the electrode by means of which it is possibletofusethefillermetalandtheworkpiece.Thisprocessisdonebymeansoftheelectricalcircuit(fig.1)

The source of energy for welding is supplied by a direct current machine (D.C.) or one of al-ternating current (A.C.), which creates an electrical circuit, through the conducting cables from the electrode to the work piece. This circuit is closed when the electrode makes contact with the work piece. The arc produced is the part where the circuit encounters the greatest resistance and is the point where the heat source is generated.The high temperature generated in the arc enables the fusion of the base metal and the contrib-uting rod.This temperature also enables the igniting of the component elements of the coating which, on gasifying, accomplish various functions, such as: deoxidizing, eliminating impurities, facilitat-ingtheflowofcurrentandespeciallyprotectingthemoltenmetalfromatmosphericinfluences.This system is characterized by its versatility and economy. This process may be applied in join-ing different metals, in small jobs or in those of great size.

THE FUNCTIONING OF THIS PROCESS SHOULD BE ADJUSTED TO THE TECHNICAL INDICATIONS REQUIRED BY THE METAL TO BE WELDED AND THE ELECTRODES TO BE USED.

18

Theseareaccessoriesthatmakeuppartoftheweldingequipment.Theyareusedtoensureagood conduction of current through the work piece and the electrode. They are easy to handle, theyarebalancedandprovideasafeandfastfunctioning(fig.1).

ELECTRODE HOLDER

StructureTheelectrodeholderconsistsofahollowfibershankwhichenablesrapidcooling:theslotsal-lowforeasyhandlingasthehandfitsperfectlyonthehandle.Thetriggerinsulatedwithfiberisto open the jaws and to change (by pressing the trigger downwards) the electrode held between them.Thetwojawsaremadeofsteelandhavecopperbitsontheirendswhichensureafluentflowofthe current, at the same time being protected at the back with an insulating Material to prevent contactwiththepart.Thereareothertypesofelectrodeholdersshowninfigures2and3.CharacteristicsElectrode holders should be light weight and balanced to prevent tiring and ensure a rapid ma-nipulation. It should be thermally and elec¬trically insulated.

Conditions of useThecontactpointintheelectrodeholdershouldbesafeandallowtheflowofcurrentwithoutany electrical resistance. The jaws should be cleaned in such a way that the electrode may ad-just perfectly to the slots of the bits. The electrode holder should not be subjected to amperages (………………………)

19

GROUND CONNECTION

StructureItconsistsoftwoarms(fig.4)connectedtoeachotheratthecenterbymeansofametalbolt.Itis furnished with a spring situated around the bolt to keep the jaws tightly closed. These jaws arefittedwithcoppercontactorsattheirendsthatensureanefficientcontactbetweenthepartandthegroundconnection.Thecableterminalissecuredfirmlytothegroundconnectionwithascrew. The ends of the arms are covered with an insulating plastic tube.

CharacteristicsThegroundconnectionclampsarelightweightforquickconnectiontothework.Theyaremade of steel and copper.

20

Basic Scienceof Metals

21

22

METALLURGY THE USES OF PLAIN CARBON STEEL

23

4.3 EFFECTS OF ALLOYING ELEMENTS

These are ferrous elements made by the fusion of steel with other elements such as:• Nickel(Ni)• Chromium(Cr)• Manganese(Mn)• Tungsten(W)• Molybdenum(Mo)• Vanadium(Va)• Silicon(Si)• Cobalt(Co)• Aluminum(A1)

Steelalloysareusedtomanufacturepartsandtoolswhichdependingontheiruse,requireintheir composition the presence of one or several of the above mentioned elements. The resulting alloy receives the name of the element or elements, as the case may be, that compose it. Each one of these elements gives the following properties to the steel.

NICKEL (Ni)Thisisoneofthefirstmetalstobeusedsuccessfullyinrenderingcertainqualitiestosteel.Nickel increases its resistance and toughness, raises its limit of elasticity, makes it a good con-ductor and increases its resistance to corrosion. Nickel steel contains 2 to 5% Ni and 0.1 to 0.5% carbon. The percentages 12 to 21% Ni and 0.1% carbon produce stainless steels which are very hard and resistant.

CHROMIUM (Cr)It also renders to the steel high resistance, hardness, high elasticity limit and good resistance to corrosion.Chromium steel contains 0.5 to 2% chromium and 0.1 to 1.5% C. The special chromium - steel (stainless type) contains 11 to 17% Chromium.

MANGANESE (Mn)Steels with 1.5 to 5% manganese are brittle. Manganese, nevertheless, when added in correct quantities,increasestheresistanceofsteeltowearandshock,maintainingitsductility.Manga-nese steel usually contains 11 to 14% Mn and 0.8 to 1.5% carbon.

TUNGSTEN (W)It is generally added to steels with other elements. Tungsten increases hardness, the breaking point, limit of elasticity and resistance to heat.Steels with 3 to 18% W and 0.2 to 1.5% C are very resistant.

24

MOLYBDENUM (Mo)Its effect on steel is similar to that of tungsten. It is used generally, added to chromium, to pro-duce chrome-molybdenum steel of great stress, especially under repeated stress.

VANADIUM (Va)It improves, in steels, the resistance to tension, without loss in ductility, and elevates the limits of elasticity and fatigue. Chrome-vanadium steels generally contain, 0.5 to 1.5% Cr. 0.15 to 3% Va and 0.13 to 1.1% C.

SILICON (Si)Increases the elasticity and resistance of steels. Silicon steels contain 1 to 2% Si and 0.1 to 0.4% C. Silicon has the property of insulating or suppressing magnetism.

COBALT (Co)Itfavorablyinfluencesthemagneticpropertiesofsteels.Besides,cobaltassociatedwithtung-sten increase the resistance of steels to heat.

ALUMINIUM (Al)Itdeoxidizessteel.Inthethermo-chemicaltreatmentprocesscallednitriding,itisconfinedwithnitrogentoaidinformingaveryhardsuperficiallayer.

NOTES ON ENGINEERING MATERIALS

4.4 GENERAL: The Physical Properties of Materials

1. DUCTILITY: Is the property which enables a material to be drawn out to a consid-erable length without fracturing materials selected to make wire must be extremely ductile.

2. ELASTICITY: Is the ability of a material which has been deformed in sane way to return to its original shape and size after the deforming force has been removed.

3. HARDNESS: Is the property of resistance to surface wear of identation.

4. MALLEABILITY: Is the property which allows a material to be deformed by hammer-ing, rolling or pressing, without fracturing. Heating improves malleability.

5. PLASTICITY:Istheabilityofamaterialtoflowintonewshapesunderpressure,andtoretain its new form.

6. TENACITY: Is the property of resistance under tensile force. This property is ex-pressed as (lbf/in2 ) or (Tons.f/in2) (NM-2) or (N/m2) Tensile strength and is of great, impor-

25

tance to designers.

7. TOUGHNESS: Is the property of resistance to fracture under sudden shock loads. It is usually found in a material which carbines high tenacity with good ductility. Heating usually lessens toughness.

8. BRITTLENESS: Is the opposite of toughness: Brittle materials fracture cleanly under shock loads but may with¬stand constant pressures. The property is also referred to as short-ness. A material brittle at room temperatures is said to be cold short and when hot, as hot short.

Fig. 15.6 - stages of deformation exhibited by a Ductile Round Bar Tensile Specimen.

The original specimen is shown at A. Successive stages of elongated are shown in B,C and D. B represents uniform strain; C and D illustrate necking

26

4.4.1 STRESS/STRAIN CURVES

The curve is plotted from information gathered during tensile (or compression) testing. The en-tire curve is shown at A, while an expanded view of the departure from as straight line relation-ship is drawn at B.

Somemetalshaveaclearlydefinedyieldpoint.Thisindicatedthatatsomecriticalstressvalue,a considerable extension occurs with no additional increase in stress.

27

Basic WeldingMetallurgy

28

29

5.3 HEAT TREATMENT

Welding inspectors normally are interested only in the left hand portion of the diagram up to about 0.35% C. It must be recognized that the addition of alloying elements will cause a low carbon steel to harden on rapid cooling in a manner similar to high carbon steels.

At this point, some of the terms relating to the iron-carbon alloy system will be reviewed.

Phases

Ferrite(α-Fe):Thebody-centeredcubic(bcc)formofpureiron,stablebelow912C(1674F).Carbon content ranges from 0 to 0.022%.

Austenite(ϒ-Fe):Asolidsolutionofoneormoreelementsinface-centeredcubic(fcc)iron.Unless otherwise designated, the solute is generally assumed to be carbon, ranging in content from 0 to 2.11%.

Ferrite(δ-Fe):Asolidsolutionofoneormoreelementsinbody-centeredcubic(bcc)iron.Un-less otherwise designated, the solute is generally assumed to be carbon, ranging in content from 0 to about 0.10%.

Cementite: A compound of iron and carbon, known chemically as iron carbide and having the approximate chemical formula Fe, C. It is characterized by an orthorhombic crystal structure.

Graphite: Carbon in the Free State occurring in several geometric forms.

Alloy Carbide: A chemical compound of carbon and alloying elements that form both simple and complex chemical compounds with carbon, usually Fe, Mn, Cr, V, W, Mo, Cb and Ti.

The microstructures that can be produced within the system as a function of cooling rate and chemical composition are listed below:

30

Microstructures

Ferrite:SeedefinitionsunderPhases.Austenite:SeedefinitionunderPhases.Cementite:SeedefinitionunderPhases.

Pearlitic:coarseandfine.Amixtureofferritearidcementiteconsistingofalternateplateletswith the thickness of the ferrite being about seven times the thickness of the cementite

Spheroidite: An aggregate of iron or alloy carbides of essentially spherical shape dispersed throughout a matrix of ferrite.

Bainite: A decomposition product of austenite consisting of an aggregate of ferrite and carbide. Ingeneral,itformsattemperatureslowerthanthosewhereveryfinepearliteformsandhigherthan those where martensite begins to form on cooling. Its appearance is feathery if formed in the upper part of the temperature range; acicular, resembling tempered martensite, if formed in the lower part.

Tempered Martensite:Amixtureofferriteandcementiteinwhichthecarbidesareveryfinelydispersed in a submicroscopic spheroidal form

Martensite: A metastable phase of steel, formed by a transformation of austenite below the Ms (or At”) temperature. It is an interstitial supersaturated solid solution of carbon in iron having a body-centered tetragonal lattice. Its microstructure is characterized by an acicular, or needlelike, pattern.

Graphite:SeedefinitionunderPhases.Freecarbonwhoseshapeeitherasaflake,noduleorspheroid describes the type of cast iron, which is gray, malleable or ductile; respectively.

Alloy Carbide:SeedefinitionunderPhases.

Cooling rates are often described as follows:

Spheroidizing: Very slow, forming spheroidized carbides and ferrite.

Annealing: Furnace cool, forming lamellar, pearlite and ferrite.

Normalizing:Aircooling,formingfinelamellarpearliteandferrite.

31

5.3.5 TTT CURVES

Fig.135 idealizedTTTcurvefor0.6%carbonsteeldepictingtimeintervalrequiredforbe-ginning, 50 and 100% transformation of austenite at a constant temperature.

A = AusteniteF = FerriteP = PearliteB = Bainite

32

Arc WeldingElectrodes

33

6.1 FLUX COATED ELECTRCOE

Metallicrod,speciallypreparedtobeusedasfillermaterialinthearcweldingprocesses.It is made of ferrous or non-ferrous material.

TYPES:There are two types: the coated electrode and the bare wire electrode.

Coated ElectrodeIt has a metallic core, a coat based with chemical substances and an uncoated end which is to be fixedintotheelectrodeholder(fig.1).

The coreisthemetallicpartoftheelectrodewhichisusedasthefillermetal.Itschemicalcom-ponents vary, and their selection is done according to the material to be welded.The coating is a material composed of different chemical substances. Its functions area) It directs the arc, leading to a balanced and uniform fusion.b) It gives off gases which act as a protective shield keeping out oxygen and nitrogen.c) It forms a slag which covers the bead avoiding sudden cooling and contact with oxygen andnitrogen(fig.2).

d) It contains certain elements which allow a good fusion with different types of metals.e) Stabilizes the arc.

34

CARE:1. It must be free from humidity and its core must be concentric (fig.3).2. It must be kept in a dry place.

Naked electrode (without coating)It is a drawn, laminated wire. Its use is limited by the high absorption of oxygen and nitrogen from the air, and by the instability of its arc.

Technical Vocabulary - Naked- Bare 6.2 CLASSIFICATION OF STEEL ELECTRODES

Electrodesareclassifiedbyacombinedsystem-ofnumbersandlettersfortheiridentification,this permits one to select the type of electrode recommended for a particular job. The following factors must be considered:

a) Type of current available.b) Position of the work piece to be welded.c) Nature of the metal and resistance it must have.

Thisclassificationusesasystemcomposedofacapitalletterplacedfirst,calledaprefix,fol-lowedbyfourdigits(fig.1).

35

Theprefix“E”meanselectricarcweldingelectrode.Thefirsttwodigitsfromatotaloffourindicatetheresistancetotensilestressinthousandsofpoundspersquareinch.Infigure1number60means60.000poundspersquareinch,whichisequivalentto42.2Kgpersquaremillimeter.The third digit, from a total of four indicates the welding position. The number one means: welding in any position.The Last two digits jointly indicate the type of current to be used and the kind of coating. Num-ber thirteen means coating with rutile, direct or alternate current, negative polarity.

Todeterminethemeaningofthethirddigit,thefollowingequivalenceisused: For third digit1 - All positions.2-Jointsonaninnerangleinahorizontalpositionorflatposition.3 - Flat position only.

For the third and fourth digits jointly10 - D C (+) cellulose coating.11 - D C (+) cellulose coating.12 - D C or A C (-) rutile coating.13 - A C or D C (+) coating with rutile and iron powder(30% approximately)16 - D C (+) low hydrogen condition.18 D C or A C (+) coating with low hydrogen content and iron powder.20 - D C or A C (+) coating with low hydrogen content and iron powder (25% approximately).24 - A C or 0 C (+) with rutile and iron powder (approximately 50% of this last element).

OBSERVATIONS:D C direct current.A C alternate current.+ positive pole.- negative pole.

ExampleE.9012-isanelectrodewhichhasaresistancetoatensilestrengthof90000poundspersquareinch,whichisequivalentto63.2Kgpersquaremillimeter;itcanbeusedwithdirectcurrent,negative pole or alternate current; its coating is rutile, and it is used in any position.Because of the nature of the coating material, there are three basic types made industrially. These are: basic which has a coating of calcium or calcite. Rutilic which has a high content of rutile oxide (titanium) and the cellulose type, whose coating contains more than 12% of com-bustible organic matter.

36

ELECTRODE WITH BASIC COATING

thickness of coatingGenerally is of a thick coating, on few occasions it has a medium size coating.

drop formationNormally the drops are of medium size.

Current and polarityThese electrodes are used with D.C. current placing the electrode at the positive end. In some cases it can be used with alternating current.

welding positionWelding in all positions.

depth of penetrationThe depth of the penetration with this electrode is medium.

handlingThe arc must be kept short.

type of slagDense with a brown appearance.

applicationThey are used for thick work pieces as in rigid constructions, for steels of low alloys and for steels of high carbon content,

ELECTRODE WITH RUTILIC COATING

thickness of coatingIs generally of medium or thick coating, very seldom of thin coating.

drop formationThick when the coating is small, medium size when the coating is medium size and small when the coating is thick.

current and polarityThe majority of these types of electrodes can be used with both currents. Generally the elec-trode is on the negative pole; only in some cases to the positive pole.

37

welding positionYou can weld in any position.

depth of penetrationAccording to thickness of coating.

handlingEasy, giving a soft and smooth arc.

type of slagDense, uniform distribution.

applicationThincoatingforsmallthickness,thoseofmediumorthickcoatingforfilling.

CELLULOSE COATED ELECTRODE

thickness of coatingIn this case the coating is medium.

drop formationMedium and large.

current and polarityThese electrodes can be used with both currents. Generally used with D.C. current and reverse polarity that is to say the electrode into the positive pole and the work piece into the negative pole

welding positionAny position.

depth of penetrationWith these types of electrodes a good penetration is obtained.

handlingIt is of easy handling with a short arc.

type of slagLittle slag formation; it makes a thin coat and it crystallizes rapidly.

applicationThesetypesofelectrodesareespeciallysuitablefordifficultjobsandforjobsofhighstress.

38

Gas WeldingEquipment

(Oxy-Acetylene)

39

7.1 PREPARATION OF OXY-ACETYLENE EQUIPMENT

Thisisabasicoperationwhichtheweldershouldcorrectlymasterashewillrepeatitfrequentlywhen doing different jobs of oxy-acetylene welding. It consists of mastering the knowledge dealingwiththefunctioningoftheoxy-acetyleneequipmentsoastorenderitinworkingcondi-tion.

METHOD OF EXECUTION:1st Step - Mount the regulators, thus:

SAFETY MEASURE:THE CYLINDERS SHOULD BE IN A VERTICAL POSITION AND BE SECURED, SO AS TO PREVENT TOPPLING.

a) Remove the cover of the cylinders.b) Slightly open and close the valve to expel the impurities.

SAFETY MEASURES: 1) BEFORE OPENING THE ACETYLENE CYLINDER, MAKE SURE THAT THERE IS NO EXPOSED FLAME NEARBY. 2) WHEN HANDLING THE CYLINDERS YOUR HANDS SHOULD BE CLEAN OF GREASE AND OIL, AS THESE MAY CAUSE EXPLOSIVE COMBUSTIONS.

c) Connect the regulators to their respective cylinders.

OBSERVATIONS: 1) Theconnectornutshouldbetightenedwiththespannerfortheequipment. 2) The dials should remain in such a way that the operator should be able to take the pressure readings with ease. d)Turnthepressureregulatingscrewwhichregulatestheflowofgastothegaugewhichindi-cates the working pressure.

SAFETY MEASURE:WHEN TURNING THE PRESSURE-REGULATING SCREW DO SO IN AN ANTI-CLOCKWISE DIREC-TION(fig.1).

40

2nd Step – Position the hoses, thus – a)Connectthehosestotheregulators(fig.2)

b) Connect the hoses to the welding torch shank

OBSERVATIONS 1. The hose that supplies acetylene is red in color and its connectors have left-handed threads. 2. The hose that supplies oxygen is blue or green in color and its connectors have right-handed threads.

41

3rd Step – Install the nozzle, thus:

a) Adjust the nozzle manuallyb) Placethenozzleinworkingcondition(fig.4)

4th Step – Regulate the pressures, thus:

a) Open the cylinder valvesb) Turn the knobs that regulate the oxygen and acetylene 5th Step - Eliminate the pressures, thus: a) Close the cylinder valves.b) Loosen the pressure levers of the regulators.

SAFETY MEASURE:OXYGEN IN CONTACT WITH OIL OR GREASE PRODUCES A RAPID COMBUSTION THAT CAN ALSO AFFECT THE METALS OF THE VALVES AND THREADS.

c) Open the valves in the torch to clear away the gases from the hoses; then close them.

NOTE:Duringthewelding,atanyinstantback-firinginthetorchmayoccur.THIS IS DANGEROUS; IT CAN PRODUCE AN EXPLOSION.

In this case, immediately, proceed in the following manner:a) Close the oxygen valve.b) Close the acetylene valve.c) Cool the torch by placing it in a container with water.d) Removethetorchandlettheoxygenflowtoclearawaythewaterwhichenteredit.

TECHNICAL VOCABULARY: NOZZLE - tip

METHOD OF EXECUTION – PROCEDURE

42

6th Step - Ignite the torch, thus: a) Open the acetylene valve in the torch for a 1/4 turn. b)Operatethelighter(fig.5).

SAFETY MEASURE:WHEN THE TORCH IS IGNITED, AIM THE NOZZLE OVER A FREE SECTION AND MANIPULATE THE LIGHTER, WITHOUT PUTTING OUT THE FLAME, SO AS TO PRE-VENT ACCIDENTS.

c)Slowlyopentheoxygenvalveofthetorchuntilobtainingawellregulatedflame,“neutral”.

OBSERVATION:It is important that the welder be able to distinguish between the neutral, oxidizing and carbur-izingflames(figs.6,7,and8).

43

7th Step - Turn off the torch, thus:

a) Shut off the acetylene valve in the torch.b) Shut off the oxygen valve in the torch.

SAFETY MEASURE:EACH TIME YOU TURN OFF THE TORCH, FIRST SHUT OFF THE ACETYLENE VALVE. 7.2 SAFETY WEAR FOR GAS WELDINGSafety goggles are devices used to protect the eyes of the operator when carrying out cleaning, grinding,turning,machining,weldingoranotheroperationwhichrequiresprotectionofyoureyes.Therearevarioustypesofgoggles(figs.1,2and3).

The body is generally made of plastic or metal, making it possible to exchange the glass or transparent plastic when the latter deteriorates. Safety goggles must be easy to put on, resistant andadaptabletotheconfigurationoftheface.Therearealsoprotectiveelementsintheshapeofamask(fig.4),whichbesidesprotectingtheeyes, also protect the face; this mask must be well adjusted to the head to avoid it dropping.

CONDITIONS OF USE:Clean the goggles before using them to obtain better vision.Change the elastic when necessary.

CARE:Keep the goggles in the case when not in use, thus protecting them in case of dropping or knocking.Avoid putting the goggles in direct contact with hot work pieces.

44

OBSERVATION:l) For the oxyacetylene welding, goggles with a greenish color are used, graduated in numbers ofwhichthemostfrequentlyusedisNo.6.2) For annealing, a bluish color is used. 7.3 CLEANING ACCESSORIES These are suitable tools for cleaning work pieces before and after welding are done.They are studied jointly even though they have different characteristics.

WIRE BRUSH:Thisismadeofsteelwiresandawoodenhandlebywhichitisheld(fig.1).

CHIPPING HAMMER:Itismadewithahandlewhichcanbeofwoodasshowninfigure2ormadeofsteelasinfig-ures 3, 4 and 5.

45

Its body is long; one of its ends has a point and the other has the shape of a chisel. The Chipping hammer has its end hardened and pointed.

There are other types of chipping hammers com-binedwiththewirebrushasshowninfigure6.

46

The WeldingProcesses

47

8.1 SMAWLearning To Weld

The serviceability of a product or structure utilizing this type of information is and must be the sole responsibility of the builder/user. Many variables beyond the control of The Lincoln Elec-tric Company affect the results obtained in applying this type of information. These variables include, but are not limited to, welding procedure, plate chemistry and temperature, weldment design,fabricationmethodsandservicerequirements. No one can learn to weld simply by reading about it. Skill comes only with practice. The fol-lowing pages will help the inexperienced welder to understand welding and develop his skill. Formoredetailedinformationorderacopyof“NewLessonsinArcWelding”listedonthebackcover.

The Arc-Welding CircuitThe operator’s knowledge of arc welding must go beyond the arc itself. He must know how tocontrolthearc,andthisrequiresaknowledgeoftheweldingcircuitandtheequipmentthatprovides the electric current used in the arc. Figure 1 is a diagram of the welding circuit. The circuit begins where the electrode cable is attached to the welding machine and ends where the workcableisattachedtotheweldingmachine.Currentflowsthroughtheelectrodecabletotheelectrode holder, through the holder to the electrode and across the arc. On the work side of the arc,thecurrentflowsthroughbasemetaltotheworkcableandbacktotheweldingmachine.Thecircuitmustbecompleteforthecurrenttoflow.Toweld,theworkclampmustbetightlyconnected to clean base metal. Remove paint, rust, etc. as necessary to get a good connection. Connect the work clamp as close as possible to the area you wish to weld. Avoid allowing the welding circuit to pass through hinges, bearings, electronic components or similar devices that can be damaged.This arc-welding circuit has a voltage output of up to 79 volts which can shock and kill. This “opencircuit”voltage(79VAC)ispresentwhennotwelding.Thechanceofreceivinganelec-tric shock is greatest when no welding is being done. Do not weld if you or your work area is wet or if you cannot insulate yourself from work using insulation such as a rubber mat or dry wood.

The electric arc is made between the work and the tip end of a small metal wire, the electrode, which is clamped in a holder and the holder is held by the operator. A gap is made in the welding circuit (see Figure 1) by holding the tip of the electrode 1/16-1/8” (1.6-3.2mm) away from the work or base metal being welded. The electric arc is established in this

48

gap and is held and moved along the joint to be welded, melting the metal as it is moved.Arcweldingisamanualskillrequiringasteadyhand,goodphysicalcondition,andgoodeye-sight.Theoperatorcontrolstheweldingarcand,therefore,thequalityoftheweldmade.

What Happens in the Arc?Figure 2 illustrates the action that takes place in the electric arc. It closely resembles what is actually seen during welding.

The“arcstream”isseeninthemiddleofthepicture.Thisistheelectricarccreatedbytheelec-triccurrentflowingthroughthespacebetweentheendoftheelectrodeandthework.Thetem-perature of this arc is about 6000°F. (3315°C) which is more than enough to melt metal. The arc is very bright, as well as hot, and cannot be looked at with the naked eye without risking painful injury.Theverydarklens,specificallydesignedforarcwelding,mustbeusedwiththehandorface shield whenever viewing the arc.The arc melts the base metal and actually digs into it, much as the water’ through a nozzle on a garden hose digs into the earth. The molten metal forms a molten pool or crater and tends to flowawayfromthearc.Asitmovesawayfromthearc,itcoolsandsolidifies.Aslagformsontop of the weld to protect it during cooling.

The function of the covered electrode is much more than simply to carry current to the arc. The electrode is composed of a core of metal wire around which has been extruded and baked a chemical covering. The core wire melts in the arc and tiny droplets of molten metal shoot across thearcintothemoltenpool.Theelectrodeprovidesadditionalfillermetalforthejointtofillthe groove or gap between the two pieces of the base metal. The covering also melts or burns in the arc. It has several functions. It makes the arc steadier, provides a shield of smoke-like gas around the arc to keep oxygen and nitrogen in the air away from the molten metal, and provides afluxforthemoltenpool.Thefluxpicksupimpuritiesandformstheprotectiveslag.Theprin-cipal differences between the various types of electrodes arc in their coatings. By varying the coating, it is possible to greatly alter the operating characteristics of electrodes. By understand-ing the differences in the various coatings, you will gain a better understanding of selecting the best electrode for the job you have at hand. In selecting an electrode you should consider:

1. The type of deposit you want, e.g. mild steel, stainless, low alloy, hardfacing.

49

2. The thickness of the plate you want to weld.3. The position it must be welded in (downhand, out-of-position).4. The surface condition of the metal to be welded.5. Your ability to handle and obtain the desired electrode.

Four simple manipulations are of prime importance. Without complete mastery of these four, further welding is more or less futile. With complete mastery of the four, welding will be easy.

1. The Correct Welding Position

Illustrated is the correct welding position for right-handed people. (For left-handed it is oppo-site):a. Hold the electrode holder in your right hand.b. Touch left hand to the underside of right hand.c. Put the left elbow into your left side.Weld with two hands whenever possible. This gives complete con-trol over the movements of the electrode.Whenever possible, weld from left to right (if right-handed). This enables you to see clearly what you are doing.Hold the electrode at a slight angle as shown.

(missing photo of correct right-handed welding position)

2. The Correct Way to Strike an ArcBe sure the work clamp makes good electrical contact to the work.Lower your headshield and scratch the electrode slowly over the metal, and you will see sparks flying.Whilescratching,lifttheelectrode1/8”-(3.2mm)andthearcisestablished.

NOTE: If you stop moving the electrode while scratching, the electrode will stick.

NOTE: Most beginners try to strike the arc by a fast jabbing motion down on the plate. Result: They either stick or their motion is so fast that they break the arc immediately.

3. The Correct Arc LengthThe arc length is the distance from the tip of the electrode core wire to the base metal.Once the arc has been established, maintaining the correct arc length becomes extremely impor-tant. The arc should be short, approximately 1/16 to 1/8” (1.6 to 3.2mm) long. As the electrode burns off the electrode must be fed to the work to maintain correct arc length.The easiest way to tell whether the arc has the correct length is by listening to its sound. A nice, shortarchasadistinctive,“crackling”sound,verymuchlikeeggsfryinginapan.Theincor-rect, long arc has a hollow, blowing or hissing sound.

50

4. The Correct Welding SpeedThe important thing to watch while welding is the puddle of molten metal right behind the arc. Do NOT watch the arc itself. It is the appearance of the puddle and the ridge where the molten puddlesolidifiesthatindicatecorrectweldingspeed.Theridgeshouldbeapproximately3/8”(9.5mm) behind the electrode.

Mostbeginnerstendtoweldtoofast,resultinginathin,uneven,“wormy”lookingbead.Theyare not watching the molten metal.

IMPORTANT: For general welding it is not necessary to weave the arc; neither forwards and backwardsnorsideways.Weldalongatasteadypace.Youwillfinditeasier.

NOTE:Whenweldingonthinplate,youwillfindthatyouwillhavetoincreasetheweldingspeed, whereas when welding on heavy plate, it is necessary to go more slowly in order to get good penetration.

PRACTICE

The best way of getting practice in the four skills that enable you to maintain:1. Correct Welding Position2. Correct Way to Strike An Arc3. Correct Arc Length4. Correct Welding Speedis to spend a little more time on the following exercise.

Use the following:Mild Steel Plate: 3/16” (4.8mm) or heavierElectrode: 1 /8” (3.2mm) Fleetweld® 180Current Setting: 105 Amps AC or 95 Amps DC(+)

Do the following:1. Learn to strike the arc by scratching the electrode over the plate. Be sure the angle of the electrode is right and be sure to use both hands.

2. When you can strike an arc without sticking, practice the correct arc length. Learn to dis-tinguish it by its sound. 3. When you are sure that you can hold a short, crackling arc, start moving. Look at the

51

moltenpuddleconstantly,andlookfortheridgewherethemetalsolidifies.

4. Runbeadsonaflatplate.Runthemparalleltothetopedge(theedgefarthestawayfromyou). This gives you practice in running straight welds, and also, it gives you an easy way to checkyourprogress.The10thweldwilllookconsiderablybetterthanthefirstweld.Bycon-stantly checking on your mistakes and your progress, welding will soon be a matter of routine.

The Advantages of DC

DCweldingpermitsauniform,continuousflowofcurrenttohelpmaintainasmoothweldingarc.DC(+),electrodepositive,causesthecurrenttoflowinonedirectionandDC(-),electrodenegative, in the opposite direction. Usually DC(-) is preferred for very thin material or when minimum penetration is desired. Electrodes designed to operate on DC(+) usually give maxi-mum penetration. This makes them very well suited for such applications as welding pipe and burning through rust, mill scale or other materials which cannot be easily removed.

Stainless, low hydrogen, non-ferrous, hardfacing and other specialty electrodes usually run smoother on DC than AC. However,- LH-73 operates well on either AC or DC. The smoother DC arc also makes it easier to weld with small diameter electrodes, so important for critical out-of-position work.

When welding with AC the current changes from DC(+) to DC(-) 60 times each second (50 times in most overseas areas) which means the welding current goes through zero 120 times each second. AC electrodes are designed to maintain the arc through this rapid cycling. AC welding is characterized by the hissing sound of the arc due to this alternating current. AC is usually preferred for larger electrodes and for applications where arc blow is encountered. Common MetalsMost metals found around the farm, small shop or home are low carbon steel, sometimes re-ferred to as mild steel. Typical items made with this type of steel include most sheet metal, plate,pipeandrolledshapessuchaschannels,angleironsand“I”beams.Thistypeofsteelcan usually be easily welded without special precautions. Some steel, however, contains higher carbon. Typical applications include wear plates, axles, connecting rods, shafts, plowshares and scraper blades. These higher carbon steels can be welded successfully in most cases, however, care must be taken to follow proper procedures, including preheating the metal to be welded and, in some cases, carefully controlling the temperature during and after the welding process. For further information on identifying various types of steels and other metals, and for proper proceduresforweldingthem,weagainsuggestyoupurchaseacopyof“NewLessonsinArcWelding” (see page 19).Regardlessofthetypeofmetalbeingwelded,itisimportantinordertogetaqualityweldthatitbe free of oil, paint, rust or other contaminants.

52

Types of WeldsFive types of welding joints are: Butt Welds, Fillet Welds, Lap Welds, Edge Welds and Corner Welds.Of these, the Butt Weld and Fillet Weld are the two most common welds.

Welding Procedures

Butt WeldsPlace two plates side by side, leaving 1/16” (1.6mm) (for thin metal) to 1/8” (3.2mm) (for heavy metal) space between them in order to get deep penetration.Tack the plates at both ends; otherwise the heat will cause the plates to move apart. (See draw-ing):

Now weld the two plates together. Weld from left to right (if right handed). Point the electrode down in the crack between the two plates, keeping the electrode slightly tilted in the direction of travel.

Watch the molten metal to be sure it distributes itself evenly on both edges and in between the plates.

PenetrationUnless a weld penetrates close to 100%, a butt weld will be weaker than the material welded together.

53

In this example, the total weld is only 1/2 the thickness of the material; thus the weld is only approximately half as strong as the metal.

Inthisexample,thejointhasbeenflamebeveledorgroundpriortoweldingsothat100%pen-etration could be achieved. The weld, if properly made, is as strong or stronger, than the original metal.

Successive passes must be used to build up butt welds on heavier metals.

Fillet WeldsWhenweldingfilletwelds,itisveryimportanttoholdthe electrode at a 45° angle between the two sides, or the metal will not distribute itself evenly.To make it easy to get the 45° angle, it is best to put the electrode in the holder at a 45° angle, as shown:

Multiple Pass WeldsMakemultiplepasshorizontalfilletsasshowninthesketch.Putthefirstbeadinthecornerwithfairlyhighcurrent. Hold the electrode angle needed to deposit thefillerbeadsasshownputtingthefinalbeadagainstthe vertical plate.

Welding In the Vertical PositionWelding in the vertical position can be done either vertical-up or vertical-down. Vertical-up is used whenever a large, strong weld is desired. Vertical-down is used primarily on sheet metal for fast, low penetration welds.

54

Vertical-Up Welding

The problem, when welding vertical-up, is to put the molten metal where it is wanted and make it stay there. If too much molten metal is deposited, gravity will pull it downwards and make it “drip’Thereforeacertaintechniquehastobefollowed:

1. Use 1 /8” (3.2mm) at 90-105 amps or 3/32” (2.4mm) at 60 amps Fleetweld® 180 elec- trode.2. When welding, the electrode should be kept horizontal or pointing slightly upwards. (See drawing)3. The arc is struck and metal deposited at the bottom of the two pieces to be welded togeth- er.4. Before too much molten metal is deposited, the arc is SLOWLY moved 1/2-3/4” (12.5- 19mm)upwards.Thistakestheheatawayfromthemoltenpuddle,whichsolidifies.(If the arc is not taken away soon enough, too much metal will be deposited, and it will“drip’)5. Theupwardmotionofthearciscausedbyaveryslightwristmotion.Mostdefinitely,the arm must not move in and out, as this makes the entire process very complicated and dif- ficulttolearn.6. If the upward motion of the arc is done correctly with a wrist motion, the arc will auto- matically become a long arc that deposits little or no metal. (See drawing)7. During this entire process, the ONLY thing to watch is the molten metal. As soon as it has solidified,thearcisSLOWLYbroughtback,andanotherfewdropsofmetalaredepos- ited. DO NOT FOLLOW THE UP AND DOWN MOVEMENT OF THE ARC WITH THE EYES. KEEP THEM ON THE MOLTEN METAL.8. Whenthearcisbroughtbacktothenowsolidifiedpuddle.ITMUSTBESHORT,other- wisenometalwillbedeposited,thepuddlewillmeltagain,anditwill“drip”9. It is important to realize that the entire process consists of SLOW, DELIBERATE move- ments. There are no fast motions.

Vertical-Down WeldingVertical-down welds are applied at a fast pace These welds are therefore shallow and narrow, andassuchareexcellentforsheetmetal.Donotusethevertical-downtechniqueonheavymetal. The welds will not be strong enough.1. Use 1/8” (3.2mm) or 3/32” (2.4mm) Fleetweld® 180 electrode.2. On thin metal, use 60-75 amps. 14 ga 75 amps - 16 ga 60 amps (1.9mm 75 amps - 1.5mm 60 amps).3. Hold the electrode at a 30-45° angle with the tip of the electrode point ing upwards.4. Hold a VERY SHORT arc, but do not let the electrode touch the metal.

55

5. An up and down whipping motion will help prevent burn-through on very thin plate.6. Watch the molten metal carefully.

The important thing is to continue lowering the entire arm as the weld is made so the angle of the electrode does not change. Move the electrode so fast that the slag does not catch up with the arc. Vertical-down welding gives thin, shallow welds. It should not be used on heavy mate-rialwherelargeweldsarerequired.

Overhead WeldingVarioustechniquesareusedforoverheadwelding.However,intheinterestofsimplicityfortheinexperiencedweldersthefollowingtechniquewillprobablytakecareofmostofhisneedsforoverhead welding:

8.2 OXY-ACETYLENE WELDING This is the operation by which two thin plates are joined with the same material, fusing their edgesbymeansofaflameproducedbythecombustionofoxygenandacetylenemixedinawelding torch. It is a basic operation to initiate the oxy-acetylene welder into uniform move-mentwiththetorch.Itisusedfrequentlyinsheet-metalwork.

METHOD OF EXECUTION:1st Step - Prepare the equipment.

OBSERVATIONS:1) The tip is selected according to the base metal. 2) Before mounting the tip, ensure that its hole is clean. 3) Use the needle that is suited to the hole of the tip.

2nd Step – Prepare the material, thus:a) Clean the platesb) Even-up the platesc) Positiontheplatesfortacking(fig.1)

3rd Step – Tack, thus:

a) Igniteandregulatethetorchflameb) Put on the welding goggles

OBSERVATIONThe pressures and tip are selected according to the tables provided by the manufacturers.

56

SAFETY MEASURESFOR WELDING, USE GOGGLES WITH THE APPROPRIATE GLASS NUMBER

c) Bringtheconetoadistanceof3mmfromthebasematerial(fig.2)d) Preheat the area to be tackede) Fuse the edges with a circular movement.

OBSERVATION:Thetackingshouldbekeptatadistanceequalto25timesthethicknessofthebasematerial.

SAFETY MEASURE:TAKE CARE! THE FLAME BACK-FIRE CAN PRODUCE AN EXPLOSION.

4th Step - Weld, thus:

a) Incline the tip through 45° and direct the cone to the center ofthejoint(fig.3)b) Preheat the base material in the area to be welded.c) Begin the bead, maintaining the cone at a constant heightd) Advancethetipwhileoscillating(fig.4).e) Finish the bead.f) Turn off the torch.

57

Thistypeofjointisdoneinaflatposition,withthefillermaterial.Itallowstheweldertomakejoints in the sheets. It is extensively used in car bodies, ventilation ducts and metal furniture.

METHOD OF EXECUTION:1st Step - Prepare equipment.

OBSERVATION:Look at table for selection of tips with relation to thickness.

2nd Step - Prepare material, thus:-a) Clean sheets eliminating rust and impurities.b) Even up the work-piece.c) Assembleandtackaccordingtofig.1. PRECAUTION: WEAR THE SAFETY EQUIPMENT.

d) Even up by correcting distortions, after tacking.e) Start a small bead in the opposite direction to the advance(fig.2).

OBSERVATION:This small bead is known by the name of a heel. 3rd Step - Weld the joint, thus: a) Inclinetipwithregardtotheworkpiece(fig.3)and preheat the base metal on starting the bead.b) Inclinetherodasseeninfigure4.c) Advance making a semi-circular movement with the tip(fig.4).d) Oscillatethefillerrodasyouadvanceinazig-zag manner.

OBSERVATIONS:1) When oscillating the rod, avoid coming out of the fusing zone.2) Themovementsofthetipandthefillerrodmustbe uniform and coordinated between them.

58

8.3 THERMAL CUTTING

Fissures are small or moderately sized separations along grain boundaries. They are readily formed here because of the large grains. High restraint stresses cause the separation.

Thermal CuttingProcesses allied to welding that interest the weld-ing inspector are oxyfuel gas cutting (OFC) and air carbon-arc cutting or gouging (AAC). A welding inspector may also encounter plasma arc cutting (PAC). These processes are used for edge preparation, repairing welds and back-gouging.

Quality, of cut surfaces varies with the nature of the weldment. The welding inspector should knowwhatdifficultiestheweldermayhavewithirregularitiesinthecutsurface.Unaccepta-ble sizes and locations of irregularities must be marked for repair, just as defective welds are marked.

Gouging grooves for welding and back-gouging the root passes from the reverse side are usu-ally done manually, but they also can be done by machine and automatic methods.The air carbon-arc process may allow carbon to dissolve in the surface of stainless steel grooves or cuts. To minimize carbide precipitation, the inspector should recommend grinding the cut stainless steel surfaces to remove the outer 0.4 mm (1/64 in.).

Oxyfuel Gas Cutting

Oxyfuel gas cutting (OFC) was at one time exclusively oxyacetylene cutting (OFC-A), but in present day practice, the inspector will encounter natural gas (OFC-N), propane (OFC-p) and a proprietary mixture of stabilized methylacetylene and propadiene (Mapp gas). Metal powder cutting (Poc) of stainless steel, aluminum and copper alloys may also be encountered. Oxygen cutting severs ferrous metals by burning the iron in oxygen to form iron oxide. Above a kindling temperature of about 940 C (1700 F) the familiar oxidation of iron (rusting) becomes a combus-tion,whichmaybeconfinedtoanarrowwell-definedzoneofcontrolledwidthcalledthekerf.

Fig. 5-19. Oxygen culling attachment on a welding lorch.(Linde Division, Union Carbide)

59

Thepartstobecutareheatedtothekindlingtemperaturebypreheatflamesdisposedaroundtheoxygencuttingjet.Torchmodificationstosuiteachfuelgasarerequired.An oxygen cutting attachment for a welding torch is shown in Fig. 5-19. The lever opens the oxygen jet.

Oxyfuel gas cutting is often applied as a manual, machine or fully automatic method of plate preparation.Thequalityofcutsurfacevariesoverwidelimits.Theskilloftheoperatoraffectsalloperations,becausethecuttingflamemustbemanuallyadjustedevenforautomaticcutting.Plasma arc cutting is less susceptible to this variable.

Air Carbon-Arc Cutting and Gouging

The air carbon arc (ARC-AIR) process removes metal by melting the metal with a carbon arc, then blowing out the molten metal by compressed air. A high velocity air jet, traveling parallel to the electrode and striking the puddle just behind the arc, blows the molten metal away. The principle of air carbon-arc gouging is shown in Fig. 5-20.

Thebasicequipmentrequiresapowersourcewithsuitablecapacity(upto1300Afor16mm-or5/8 zinc electrodes), compressed air at 0.55 to 0.7 MPa (80 to 100 psi), welding cables and work clamp, an air carbon arc torch and carbon electrodes.

Air carbon arc gouging is performed both manually and automatically.

Plasma Arc CuttingThe greater heat of the plasma arc (15,000 C or 27,000 F) will melt a kerf through any metal, ferrous or nonferrous, removing the molten material with its high velocity jet of hot ionized gas. The process operates on direct current electrode negative (dcen) with a constricted arc, struck between the water-cooled electrode in the torch and the work piece.

Fig. 5-20. Schematic diagram for air carbon-arc gouging.(Hobart Brothers Co.)

Theorifice,whichconstrictsthearc,alsoiswater-cooled.TheschematicviewinFig.5-21shows the power supply and _controls, the pilot arc circuit through a current-limiting resistor, the dcen circuit through the work piece and the water-tooled torch with gas inlet for either ni-

60

trogen or argon, plus 0 to 30% hydrogen. Water may be injected into the torch nozzle to further constrictthearcandsquareupthekerf.

Plasma arc cutting is a machine or automatic process.

Mechanical Cutting

Joints are also prepared for welding either in part or entirely by mechanical means, such as mill-ing, grinding, shaping, sawing, shearing and chipping.

Fig. 5-21. Schematic diagram for plasma-arc cutting. (Aluminum Company of America)

Theinspectorisfrequentlyconcernedaboutresiduesofsulfurizedcuttingoilsusedtolubricatethe cutting tools, not only because sulfur may cause cracking in welds, but also because all oils are a source of hydrogen. The unfused root in passes chipped or ground back from the other side to expose sound metal may be hidden by metal smeared over the unfused root of the joint by a blunt tool or a loaded wheel. On critical jobs, the inspector should have the supposedly exposed bead etched to remove such smeared metal and verify that the weld metal is revealed.

61

Distortion andResidual Stress

62

RESIDUAL STRESSES: The strength of a welded joint depends a great deal on the way expansion and contraction of the metal is controlled during the welding operation. Whenever heat is applied to a piece of metal, expansion forces are created which tend to dis-tort’ the dimension of the piece. Upon cooling, the metal undergoes a change again as it attempts to resume its original shape. When free move-ment is restricted there is likely to occur warping or distortion if the metal is malleable or ductile, and fracture if the metal is brittle, as with cast iron.Ifexpansionisrestrictedinitsmovementthebuildingupforcewillfindanotherdirectionfor uneven expansion in the heated area and some of the original displaced metal will contract unevenly on cooling and the work piece will become permanently distorted.

CONTROLLING RESIDUAL STRESSES: Few simple procedures will help control undue forces caused by expansion and contraction; Properedgepreparationandfitup;Reducedbevelanglewithsufficientroaninthejointtopermitproper manipulation of the electrode. Weld joint nearesttotheneutralaxisfirst,followedbyweld-ing the unit farthest from the neutral axis. On long seams especially thin section allow 3mm per 300mm length for weld expansion during set up procedures. Preset pieces of the joint slightly out of alignment to counteract direction of distor-tion.

FORMS OF DISTORTION: Angulardistortioninafilletweldiscausedbyun-restrained plates being drawn together as the plates and weld cool. Distortion will increase as further unbalancedrunsaredeposited.Aflat,thinplatewill bend upwards as the plate and weld cool. Two butt welded plates which are free to move will be drawn together as welding takes place. Distortion may occur if the welds are made on one side of the joint. Double sided butt joints will distort less. In a T-joint the weld along the seam will bend boththeuprightandflatpiece.Distortioniscounteractedbyweldingtoaspecifiedpatterngiveninweldprocedures.Thisisknown as balanced welding.(= 15.1 x 10-6/0c)

63

LIMITING DISTORTION BY WELD SEQUENCE: Track welds are also used to hold plates in position and control undue expansion on long seams. A long longitu-dinal (end ways) seam is welded before a short transverse (side-ways)seam.Jigsandfixturesareusedtopresetandholdplatesandpreventexcessivemovement,heavyfix-ture plates not only control distortion but they also serve as chill blocks to avoid excessive heat building up in the work.

Intermittent or skip weld is employed to minimize heat input by making a short weld at the be-ginning (1) center of seam (2) end of joint (3) and repeating the cycle for completing the seam.Inback-steporstep-backtechniqueinsteadoflayingacontinuousbeadfromlefttoright,deposit off short sections of the beads from right to left to complete the pass.

PREHEATING: On many work pieces, particularly alloy steel and cast iron, expansion and contraction forces can be better controlled if the entire structure or large parts of the weld area can be preheated before the welding is started. Ensure uniform temperature during welding operation and care for slow cooling.

POST HEATING (STRESS RELIEVING): Stresses set up during welding may be relieved by heat-ing the work piece for a stated temperature and period of time and cooling in controlled rate.

64

9.4 PREVENTION, CONTROL AND CORRECTION OF DISTORTION

TRAINING NOTES

Fixtures

Fixturesmaytemporarilyorspeciallymadeforquickandcorrectpositioningofmaterialstobewelded.

Tack Weld

A short weld used to help assembly by holding work pieces in position during welding.

Backing Bar

A piece of metal tacked behind a butt or corner joint to aid the welding operation but not intended to be-comepartofthefinishedjoint.

Backing Strip

A piece of metal tacked at the root of the joint which becomes part of the joint when welding is complete.

65

BridgePieces of metal of the same shape which are tack welded in sev-eral places round pipes to hold them in position. A bridge may be used to hold the clamp of an earth return lead close to the weld area.

A short continuous weld in the root gap may also be called a bridge.

Strongback

Similartoabridgeandusedtoholdworkpiecesinpositionforbuttweldingintheflat,horizon-tal, vertical and overhead positions.

Temporary Fixtures

a)Temporaryfixturesmaybetackweldedtoworkpiecestoholdmaterialswhicharetobewelded.Caremustbetakentoensurethatthefixturedoesnotmoveduringwelding.Dimensionsshouldalways be checked for accuracy after tacking and before starting to weld.

Tack Welded Cleats as an aid to alignment

66

b) Work pieces may be lap jointed in position for welding, using clamps and angle bars.

c) Cleats temporarily attached to work pieces to hold a T joint in position for welding.

d) A strongback, bolt and clamp may be attached to work pieces to hold them in position whilst a butt joint is weld-ed.

e) A bolt, clamp and hard wood blocks may be used to hold an angle section in position during welding.

67

Positioners

The universal balance type of positioner allows for position-ing of the work piece in any direction.

Manipulators

The most widely used types of manipulators are motor driven anddesignedtorotateandmoveworkattherequiredweldingspeed

Manipulation and Positioning of Work pieces

Ensurethatcomponentsplacedinoronafixture,positioneror welding manipulator are properly balanced and secured.

68

WeldingSymbols

AndBlueprintReading

69

70

71

Welding TerminologyThe following are the meaning of some of the terms used in welding

Angle of BevelThe angle of an edge or end which is cut or cham-fered.

Arc LengthThe distance between the end of an electrode and the surface of the weld pool.

Fusion FaceThe surfaces or edges of the parent metal to be fused by welding.

Fusion ZoneThe place where the deposited metal fuses with the work pieces.

72

GapThe distance between the parts to be joined

Included AngleThe total angle between fusion faces of the parts in position ready for welding.

Parent Metal (or work piece)The materials and or the parts to be welded

PenetrationThe depth the molten metal from the electrode pen-etrates the parent metal

Reinforcement (Excess weld metal)Weld metal lying outside the plane joining the toes.

RootThe position in a prepared butt joint where the parts are to be joined is nearest togetherOrThe corner of the angle formed by the two fusion facesofafilletjoint

73

Root FaceThesquarefacesattherootofpreparedworkpieces

Toe of WeldThe top and bottom position where the weld face joins the parent metal

Leg LengthThe distance from the root to the toe of the weld

Throat ThicknessThe shortest distance from the root of the weld to the weld faceinafilletweld

Tack Weld A short weld used to help assembly by holding work pieces in position during welding

Run or PassThe molten metal deposited during the passage of the electrode.

Root RunThefirstrundepositedintherootofajointwherethereistobe more than one run

74

Filler Runs or PassesThe build up run(s) between root and capping run(s)

Capping or Final RunsThe weld runs which make up the top layer of the joint

Sealing RunA weld deposited on the roof side of a butt or corner joint after completion of the main weld.

Sealing WeldAweldusedtomakeafluidtightjoint

JOINT & WELD SYMBOLS – MANUAL METAL ARC WELDING

TRAINING NOTESTypes of Joint

Butt Welded JointA joint where a weld is made between the ends or edges of metals.

Fillet Welded JointA weld approximately triangular in shape and external to the surfaces to be joined.

Square Butt JointAjointwithpermanentbackingstripheldinplacebyfilletwelds.

Double Lap JointAjointmadebytwofilletwelds

75

Inspection AndQuality Control

76

BASIC WELDING WELDING INSPECTION LECTURER: C. DAVIS TECHNOLOGY & QUALITY CONTROL M.I.C. TRAINING DEPARTMENT

11. 1. COMMON WELD DEFECTS - HANDOUT2. CODES GOVERNING WELDING INSPECTION Every * country has some code for Welding Inspection or adapts to some acceptable interna-tional code e.g. DIN, BS, AWS, ASTM, Lloyds of London. The American codes are com-monly used in our region and are also widely accepted internationally.Some organisations which have formulated codes and rules for welding are as follows:-(a) AWS American Welding Society(b) ASME American Society for Mechanical Engineers.(c) ANSI American National Standards Institute(d) API American Petroleum Institute(e) MIL United States Department of Defence(f) ABS American Bureau of Shipping(g) AWWS American Water Works Association(h) ASNT American Society for Non-Destructive Testing.(i) ASTM American Society for Testing Materials(j) SAE Society of Automotive Engineers.AllthesesocietiesrequirethatrecordsarekeptandbemadeavailablefortheInspector.Alldrawings must be kept together with inspection records.* Japan, Germany, France, British, Italy, NorwegianItshouldbenotedthatmostofthesecodeswerefirstdevelopedbyprivateorganisationsandafter some time were adopted by various government agencies, and eventually some because of laws governing weldments.

WELDING INSPECTION METHODS 1. Macro-Inspection:Visual,lowmagnificationx52. Micro-Inspection: HighMagnificationx101-1063. Non-Destructive-Inspection: Usingaidstoassistintheidentificationofflaws.Job must not be physically damaged during testing process.4. Destructive Testing - To verify physical and chemical properties of the weld or for failure analysis.

1.1 MACRO INSPECTION Thismethodofinspectionrequiresthattheinspectorbeanexperiencedwelderwhoisveryfamiliar with welding processes and various defects associated with the processes, preferably a coded inspector or one who has completed a welding inspection course of studies from a recog-nized institution, e.g. , AWS, ASM, API, etc.Defectsinthiscategoryofinspectionrequiredirectobservationwiththeeyesorverylowpow-eredmagnificationafteretching.Etchingrequirestheuseofsmallquantitiesofacidsinsolution

77

with alcohol, water or other solvents. Penetration, porosity, fusion zones and other phenomena may be observed.

1.2 MICRO-INSPECTION This is a destructive method of testing since a sample has to be cut out from the welded mem-ber to be tested. Samples are prepared and place under a high power microscope to observe grain structures, Fin, and other micro defects that cannot be seen by macro-inspection. Chemi-calanalysisalsofallsunderthecategoryandrequiresthatsmallpiecesofmaterialsberemovedfrom the job and mounted, polished and view under the optical microscope or Scanning Elec-tion Microscope (S.C.M.)

1.3 NON-DESTRUCTIVE TESTING Thereisarangeoftestsdoneontheactualjobtodetectsurfaceorsub-surfaceflaws,thecom-ponent remains completely functional after the tests.The following are NDT test commonly done on weldments:(a) LiquidPenetrantInspection. (LP)(b) Magnetic Particle Inspection (MP)(c) Ultrasonic Inspection (UT)(d) Radiographic Inspection (RI)(e) Eddy-current Inspection (EI)(f) Acoustic Emission Inspection (AE)(g) Proof Tests (PT)(h) Leak Tests (LT) 1.4 DESTRUCTIVE TESTING There are test done to verify the physical properties and also the chemical properties of weld andbasemetals.Thismethodoftestingrequiresthatthecomponentbedestroyedinordertoobtain a sample for testing. The tests are done to verify: (a) Tensile strength of weld and base metal(b) Impactstrength“”“”“”“”“”“””(c) Compressionstrength“”“”“”“”“”“””(d) Shearstrength“”“”“”“”“”“””(e) Bending strength of welded jointf) Metallographic Inspection

2.1.0 INSPECTION PERIODS

2.1.1 BEFORE WELDING(a) Material to be used for fabrication - scabs, seams, scales, laminations plate dimension, ten-sile testing.(b) After assemblies - root opening, edge preparation and other features of joint geometry.(c) Checks on backing strips, run on and run off plates etc.

78

(d) Cleanliness of material and joint before welding begins.

2.1.2 INSPECTION DURING WELDINGAmong details to be checked are: (a) Welding Process(b) Filler metal(a) Flux or shielding gas(d) Pre-heat and interpass temperature/Post heating and time(e) Cleaning (interPass)(f) Chipping, grinding or gonging(g) Joint preparation for other side(h) Distortion control

2.1.3 INSPECTION AFTER WELDING(a) Conformity to drawings(b) Appearance of weldment(c) Presence of structural discontinuties(d) Any defects that may be visible.

79

WELDING: QUALITIES, CHARACTERISTICS AND RECCMMENDATICNS

Amongotherthings,agoodweldmustoffersafetyandquality.Toattaintheseobjectives,itisnecessary that the welding beads be made with a maximum of skill, good regulation of the cur-rent and proper selection of electrodes.

CHARACTERISTICS OF A GOOD WELDA good weld must have the following characteristics:a) Good penetration.b) No undercuttingc) Complete fusion.d) No porosity.e) Good appearance.f) No cracks.

Good penetrationThisisobtainedwhenthefillermetalfusestherootandisextendedunderthesurfaceofthewelded parts.

No undercuttingA weld without undercut is obtained when near to its root (toe) there is not produced on the base metal any digging ‘which damages the work piece.

Complete fusionAgoodfusionisobtainedwhenthebasemetalandthefillermetalformahomogeneousmass.

No porosityA good weld is free of porosity, when in its inner structure there are no gas pockets nor slag inclusion.

Good appearanceA weld has good appearance, when there is seen in the whole extension of the joint an even welding bead, without cracks or overlapping.

No cracksAweldisconsideredwithoutcrackswhenthefinishedbeadhasnofissuresthroughoutitslength.

Following are some recommendations for producing a good weld.

80

81

82

APPENDIX

83

SAE Steel Numbering System

84

PIPE AND PIPE FITTINGSWrought Steel Pipe — ANSI B36.10-1979 covers dimensions of welded and seamless wrought steel pipe, for high or low temperatures or pressures.The word pipe as distinguished from tube is used to apply to tubular products of dimensions commonly used for pipelines and piping systems. Pipe dimensions of sizes 12 inches and small-er have outside diameters numerically larger than the corresponding nominal sizes whereas outside diameters of tubes are identical to nominal sizes.Size:Thesizeofallpipesisidentifiedbythenominalpipesize.Themanufactureofpipeinthenominal sizes of V8 inch to 12 inches, inclusive, is based on a standardized outside diameter (OD). This OD was originally selected so that pipe with a standard OD and having a wall thick-nesswhichwastypicaloftheperiodwouldhaveaninsidediameter(ID)approximatelyequalto the nominal size. Although there is now no such relation between the existing standard thick-nesses,ODsandnominalsizes,thesenominalsizesandstandardODscontinueinuseas“stand-ard.”The manufacture of pipe in nominal sizes of 14-inch OD and larger, proceeds on the basis of an OD corresponding to the nominal sizeWeight: The nominal weights of steel pipe are calculated values and are tabulated in Table 1. They are based on the following formula:Wpe = 10.68(D –t)tWhere Wpe = nominal plain end weight to the nearest 0.01 lb/ft. D = outside diameter to the nearest 0.001 in.t=specifiedwallthicknessroundedtothenearesto.00tin.Wall thickness: The nominal wall thicknesses are given in Tablet which also indicates the wall thicknesses in API Standards 5L and 5LX. Thicknesses listed in API Standard 5LS are not indi-cated but may be found in that Standard or in ANSI B36.10-1979.Thewallthicknessdesignations“Standard,”“Extra-Strong,”and“DoubleExtra-Strong”havebeencommerciallyuseddesignationsformanyyears.TheScheduleNumbersweresubsequent-lyaddedasaconvenientdesignationforuseinorderingpipe.“Standard”andSchedule40areidenticalfornominalpipesizesupto10inches,inclusive.Alllargersizesof“Standard”have1/2-inchwallthickness.“Extra-Strong”andSchedule8oareidenticalfornominalpipesizesupto8inch,inclusive.Alllargersizesof“Extra-Strong”have1/2-inchwallthickness.Wall Thickness Selection: When the selection of wall thickness depends primarily on capacity to resist internal pressure under given conditions, the designer shall compute the exact value of wallthicknesssuitableforconditionsforwhichthepipeisrequiredasprescribedinthe“ASMEBoilerandPressureVesselCode,”“ANSIB31CodeforPressurePiping,”orothersimilarcodes, whichever governs the construction. A thickness can then be selected from Tablet to suit thevaluecomputedtofulfiltheconditionsforwhichthepipeisdesired.Metric Weights and Mass: Standard SI metric dimensions in millimetres for outside diameters and wall thicknesses may be found by multiplying the inch dimensions by 25.4. Outside diam-eters converted from those shown in Table I should be rounded to the nearest o.t mm and wail thicknesses to the nearest 0.01 mm.The following formula may be used to calculate the SI metric plain end mass in kg/m using the

85

converted metric diameters and thicknesses:Wpe = 0.02466(D t)twhere Wpe = nominal plain end mass rounded to the nearest 0.01 kg/m.D = outside diameter to the nearest o.t mm for sizes shown in Table I. t=specifiedwallthicknessroundedtothenearest0.01mm.

86

87

88

89

90

91

92

TemperatureConversion

Table

93

Related Documents

![Home [] Meeting Minutes - Final.pdf · 9/19/2018 · (b) Mechanical - journeyman sheet metal (JSM), journeyman sprinkler (JS), journeyman refrigeration (JR), journeyman fire protection](https://static.cupdf.com/doc/110x72/600a4cca068c5571b47e37cc/home-meeting-minutes-finalpdf-9192018-b-mechanical-journeyman.jpg)

![· C] Journeyman Ironworker Journeyman Structural Ironworker Journeyman Rodman Journeyman Finisher Welder Ship Yard Rigger [2 Journeyman Rigger, Machinery Mover, Erector C] Other](https://static.cupdf.com/doc/110x72/5fe1355759a7315f5c240bf8/c-journeyman-ironworker-journeyman-structural-ironworker-journeyman-rodman-journeyman.jpg)