Disclosure to Promote the Right To Information Whereas the Parliament of India has set out to provide a practical regime of right to information for citizens to secure access to information under the control of public authorities, in order to promote transparency and accountability in the working of every public authority, and whereas the attached publication of the Bureau of Indian Standards is of particular interest to the public, particularly disadvantaged communities and those engaged in the pursuit of education and knowledge, the attached public safety standard is made available to promote the timely dissemination of this information in an accurate manner to the public. इंटरनेट मानक “!ान $ एक न’ भारत का +नम-ण” Satyanarayan Gangaram Pitroda “Invent a New India Using Knowledge” “प0रा1 को छोड न’ 5 तरफ” Jawaharlal Nehru “Step Out From the Old to the New” “जान1 का अ+धकार, जी1 का अ+धकार” Mazdoor Kisan Shakti Sangathan “The Right to Information, The Right to Live” “!ान एक ऐसा खजाना > जो कभी च0राया नहB जा सकता ह ै” Bhartṛhari—Nītiśatakam “Knowledge is such a treasure which cannot be stolen” IS 3694 (1991): Test chart for woodworking turning lathes [PGD 3: Machine Tools]

Welcome message from author

This document is posted to help you gain knowledge. Please leave a comment to let me know what you think about it! Share it to your friends and learn new things together.

Transcript

Disclosure to Promote the Right To Information

Whereas the Parliament of India has set out to provide a practical regime of right to information for citizens to secure access to information under the control of public authorities, in order to promote transparency and accountability in the working of every public authority, and whereas the attached publication of the Bureau of Indian Standards is of particular interest to the public, particularly disadvantaged communities and those engaged in the pursuit of education and knowledge, the attached public safety standard is made available to promote the timely dissemination of this information in an accurate manner to the public.

इंटरनेट मानक

“!ान $ एक न' भारत का +नम-ण”Satyanarayan Gangaram Pitroda

“Invent a New India Using Knowledge”

“प0रा1 को छोड न' 5 तरफ”Jawaharlal Nehru

“Step Out From the Old to the New”

“जान1 का अ+धकार, जी1 का अ+धकार”Mazdoor Kisan Shakti Sangathan

“The Right to Information, The Right to Live”

“!ान एक ऐसा खजाना > जो कभी च0राया नहB जा सकता है”Bhartṛhari—Nītiśatakam

“Knowledge is such a treasure which cannot be stolen”

“Invent a New India Using Knowledge”

है”ह”ह

IS 3694 (1991): Test chart for woodworking turning lathes[PGD 3: Machine Tools]

IS 3094 : 1991 IS0 7997 : 1985

Indian Standard

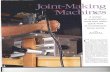

TEST CHART FOR WOODWORKING TURNING LATHES

( Second Revision )

UDC 674.057 : 621.941 : 620.1 ( 084.3 )

0 BIS 1991

BUREAU OF INDIAN STANDARDS MANAK BHAVAN, 9 BAHADUR SHAH ZAFAR MARG

NEW DELHI 110002

December 1991

i Price Group 5

IS 3694 : 1991 IS0 7997 : 1996

Indian Standard

TEST CHART FOR WOODWORKING TURNING LATHES

( Second Revision )

NATIONAL FOREWORD

This ‘Indian Standard ( Second Revision ) which is identical with IS0 7987 : 1985 ‘Woodworking machines - Turning lathes - Nomenclature and acceptance conditions’, issued by the International Organization for Standardization ( IS0 ), was adopted by the Bureau of Indian Standards on the recommendations of the Woodworking MachinesSectional’Committee ( PE 01 ) and approval of the Production Engineering Division Council.

This standard was first issued in 1966 and subsequently revised in 1976.- Consequent upon the publication of IS0 7987 : 1985, this standard has been revised by adopting IS0 7987 : 1985 to bring it in line with IS0 standard. In this revision, clause references of IS0 230/t : 1986 for method of tests has been incorporated which were not there earlier.

The text of ISO’ standard has been approved as suitable for publication as Indian Standard without deviations. Certain conventions are however not identical to those used in Indian Standards. Attention is particularly drawn to the following:

a) Wherever the words ‘International Standard’ appear referring to this standard, they should be read as Jlndian Standard’.

b) Comma ( , ) has been used as a decimal marker while in Indian Standards, the current practice is to use a point ( . ) as the decimal marker.

In this adopted standard, reference appears to lSO/R 230 ‘Test code for machine tools’ ( since revised as IS0 230/l : 1986 ). .The Indian Standard IS 2063 : 1988 ‘Acceptance code for machine tools - Geometric accuracy of machines operating under no load or finishing conditions ( first revision )’ which is identical with IS0 230/l : 1988 is to be substituted in its place.

Only the English language text,of the International Standard has been retained while adopting it as Indian Standard.

IS 3894 : 1991 IS0 7997 : 1999

1 Scope and field of application

This International Standard specifies the nomenclature appropriate to each part of the machine and, with reference to ISO/R 230, the geometrical tests for turning lathes, and gives the corresponding permissible deviations which appl,y to machines for general purpose use and normal accuracy.

This International Standard deals only with the verification of accuracy of the machine. It does not apply to the testing of the running of the machine (vibrations, abnormal noises, stick-slip motion of the components etc.), nor to its characteristics (speeds, feeds etc.) which should generally be checked before testing accuracy.

This International Standard does not impose any practical test. ’ For turning lathe machines, practical tests should be ex-

ceptions and have to be stated in a previous agreement be- tween the producer and the user.

2 Reference

ISO/R 230, Test code for machine tools.

3 Preliminary remarks

3.1 In this International Standard all dimensions and permiss- ible deviations are expressed in millimetres. ’

3.2 To apply this International Standard, reference should be made to ISO/R 230, especially for installation of the machine before testing, the warming up of the main spindle and other moving parts, and description of measuring methods. The measuring instruments shall not permit errors over l/3 of the checked tolerances.

3.3 The sequence in which the geometrical tests are given is related to the sub-assemblies of the machine and this in no way defines the practical order of testing. In order to make mount- ing of instruments or gauging easier, tests may be applied in any order.

3.4 When inspecting a machine, it is not always possible or necessary to carry out all the tests gEen in this International Standard.

3.5 It is up to the user to choose, in agreement with the manufacturer, those tests relating to the properties which are of interest to him, but these tests are to be clearly stated when ordering a machine.

3.6 A movement is longitudinal when it takes place in the working direction of the piece.

3.7 When establishing the tolerance for a measuring range different from that given in this International Standard (see 2.311 in ISO/R 2301, it should be taken into consideration that the minimum value of the tolerance is 0,Ol mm. I

3

c

IS 3994 : 1991 IS0 7997 i 1995

._

4 Nomenclature

m

., I 4

3.6. '5.4 --------_I_ !

3.5

3.1

4.2 6.7

/ /'

5.3 I

3.3 6.4 3.2 6.15 6.,6

I I j I I I / I

,/4.3

612

6.12 P

I-

I 1

611, 5.2 6.10 6.9 5.4 8.2

IS 3694 : 1991 IS0 7987 : 1985

leference Turning lathe Tour parall&le

1 ramework 1.1 ase (headstock end) 1.2 ase (tailstock end) 1.3 #ed 1.4 rutside toolrest support 1.5 #tideways

X3sature jocle b&i Socle support 3anc Bati du support exterieur d’outils Slissiere

2 eed of workpiece and/or tools Deplacement des pihces etlou outils

3 Vorkpiece support, clamp and guide

3.1 leadstock spindle 3.2 ‘ailstock 3.3 .ailstock quill/centre/drill chuck 3.4 jutside faceplate 3.5 Iside faceplate 3.6 :huck

Support, maintien et guidage des pieces Broche Contre-poupee Contre-pointe Plateau exterieur Plateau interieur Mandrin trois mors

4 roolholder and tools 4.1 -oolholder 4.2 nside tooirest (hand turning) 4.3 nside toolrest support 4.4 Iutside toolrest 4.5 rurning tools 4.6 iand turning tools

Porte-outils et outils Porte-outils Support a main d’outils Pied du support a main d’outils Support exterieur d’outils Outils de tournage Gouges de tournage

5 Norkheads and tool drives 5.1 ieadstock 5.2 Zarriage 5.3 Compound cross slide 5.4 Traversing rack

Unite de travaii et son entrainement Poupee Tablier du chariot Tourelle Porte-outils Cremaillere

6 Controls 6.1 Btoplstart switch. 6.2 Spindle speed control 6.3 Coupling lever 6.4 Tailstock quill clamp 6.5 Tailstock quill handwheel 6.6 Tailstock clamp 6.7 Inside toolrest support clamp

Commandes Commutateur

6.8 Outside toolrest support clamp

6.9 Carriage traversing handwheel 6.10 Carriage traversing clamp 6.11 Compound cross slide index and clamp 6.12 Lathe bed displacement flongitudinal)

Levier de vitesse Levier d’embrayage Blocage de la contre-pointe Volant de reglage de la contre-pointe Blocage de la contre-poupee Levier de blocage du support a main d’outils Levier de blocage du support exterieur d’outils Volant de commande du chariot Levier de blocage du chariot Reglage de la tourelle porte-outils Levier de coulissement longitudinal du bane

7 7.1

8 8.1 8.2

Safety devices (examples) Dispositifs de sbcuritb (exemplesl

Chuck guard Capot de protection

h+cellaneous Indexing device for grooving Tailstock cross travel,screw with index device for tapering work

Divers Diviseur Dispositif d’orientation de la contre-poupec pour travaux coniques

9

10 10.1

10.2

10.3

Free Libre

Exemples of work Turning -on the outside faceplate, using hand turning tool Turning onlthe inside faceplate, using hark turning tool Turning between cenres with tool /

Exemples de travail Tournage sur plateau exterieur. avec goug

Tournage sur plateau interieur, avec gougr

Tournage entre pointes, outil sur tourelle

English French

6

5 Acceptance conditions and permissible deviations - Geometrical tests

No.

Gl

“_

Diagram Object + Permissible deviation Measuring Observations and references instruments in test code &O/R 230

Length of slideways L

a)

O,?O

for L < 1250

Checking of straightness of g,40 the slideways :

for 1250 < I_ G 2500 Precision levels,

a) longitudinally straightedge and Clause 5.212 and 5.222

6.56 feeler gauge

b) transversely for L > 2500

b)

0.20

for a measured length of loo0

Measuring of run-out of spindle nose 0.03 Dial gauge Clause 5.612.2

0.05

Measuring of run-out of spindle internal taper

for A = 200

Measured at a and b

Dial gauge and test mandrel

Clause 5.612.3

I

No. Diagram Object Permissible deviation Measuring Observations and references

instruments in test code ISO/R 230

Checking of alignment of 0,lO Clause 5.442

67 tailstock to headstock Dial gauge

for R = 100 Tailstock locked.

“-

C Checking of parallelism of

* the headstock axis to the a) and 6)

t’ slideways :

08 ‘4 Dial gauge and test

0,20 Clause 5.412.4 mandrel

a) in a horizontal plane for C = 250

6) in a vertical plane

Checking of parallelism of the tailstock axis to the a) and 6) slideways :

G9 0,lO Dial gauge Clause 5.412.4

a) in a horizontal plane for D = 100

bj in a vertical plane

No. Diagram Object Permissible deviation Measuring Observations and references instruments in test code ISO/R 230

6)

E A-

a) ,a)

Checking of parallelism of -l

l-l

c_ 0,lO

the carriage movement to

t the axis between centres : for E = 500 Dial gauge and test

GlO mandrel between Clause 5.422.3

a) in a horizontal plane b) centres

6) in a vertical plane 0,20

for E = 500 c..

Checking of parallelism of

the compound slide move-

ment to the axis between a) and bl

Gll centres : Dial gauge and test

085 Clause 5.422.3 mandrel

a) in a horizontal plane for G = 100

b6) in a vertical plane

-

Checking of squareness of 612

Dial gauge and test cross slide movement to 0,05/100*

disc Clause 5.522.3

the spindle axis

l Distance H

Bureau of Indian Standards

BIS is a statutory institution established under the Bureau of Indian Standard Act, 2986 to promote harmonious development of the activities of standardization, marking and quality certification of goods and attending to connected matters in the country.

Copyright

BIS has the copyright of all its publications. No part of these publications may be reproduced in any from without the prior permission in writing of BIS. This does not preclude the free use, in the course of implementing the standard, of necessary details, such as symbols and sizes, type of grade designations. Enquiries relating to copyright be addressed to the Director (Publications), BIS.

Revision of Indian Standards

Indian Standards are reviewed periodically and revised, when necessary and amendments, if any, are issued from time to time. Users of Indian Standards should ascertain that they are in possession of the latest amendments or edition. Comments on this Indian Standard may be sent in BIS giving the foil owing reference :

Dot : No. PE 01 ( 5335 )

Amendments Issued Since Publication

Amend No. Date of Issue Text Affected

-

BUREAU OF INDIAN STANDARDS

Headquarters :

h4anak Bhavan, 9 Bahadur ShahZafar Marg, New Delhi 110002 Telegrams : Manaksanstha Telephone : 33101 31, 331 13 75 (Common to all Offices)

Regional Offices : Telephone

central :

Eastern :

Manak Bhavan, 9 Bahadur Shah Z&r Marg NEW DELHI 11ooO1

I/14, C.I.T. Scheme VII M, V.LP. Road, Maniktola, CALCUTTA 700054

t

331 01 31 331 13 75

37 86 62

Northern :

Southern :

Western. :

SC0 445-446, Sector 35-C CHANDIGARH 160036

C.I.T. Campus, IV Cross Road, MADRAS 600113

Manakaiaya, E9 MUX, Marol, Andheri ( East ) BOMBAY 400093

53 38 43

41 29 16

6 32 92 95

Branches :_? AHMADABAD. BANGALORE. BHOPAL. BHUBANESHWAR. COIMBATORE. FARIDABAD. GHAZIABAD. GUWAHATI. HYDERABAD. JAIPUR. KANPUR. PATNA. THIRWANANTHAPURAM.

Printed at the Central Electric Prasr, Delhi-7 India

Related Documents

![2013-2014 Bill 3694: Timothy Hellaby II - South Carolina ... · Web view[3694]1 South Carolina General Assembly 120th Session, 2013-2014 H. 3694 STATUS INFORMATION House Resolution](https://static.cupdf.com/doc/110x72/6138bfb30ad5d206764972f3/2013-2014-bill-3694-timothy-hellaby-ii-south-carolina-web-view-36941-south.jpg)