Integrating bioenergy and food production—A case study of combined ethanol and dairy production in Pontal, Brazil A. Egeskog a, ⁎, G. Berndes a , F. Freitas b , S. Gustafsson a,1 , G. Sparovek b a Physical Resource Theory, Department of Energy and Environment, Chalmers University of Technology, SE-412 96 Göteborg, Sweden b USP- Esalq- University of São Paulo Av. Pádua Dias 11, Piracicaba-SP 13.418-900, Brazil abstract article info Article history: Received 24 September 2010 Revised 10 January 2011 Accepted 10 January 2011 Keywords: Dairy production Sugarcane Ethanol Land-use change Greenhouse gas mitigation Brazil Increased Brazilian sugarcane ethanol production is expected in response to increasing domestic and international ethanol demand. The Pontal do Paranapanema region, located in the western parts of the São Paulo state, is one of the regions where sugarcane is expected to expand on a large scale. This expansion will most likely affect small-scale dairy farmers in the region and may lead to displaced milk production. Interviews have been made with small-scale dairy farmers in areas where sugarcane has already been established. These interviews show that many farmers who substitute milk production for sugarcane production experience economic stagnation after the change. However, both systems can coexist, using sugarcane residues as high-quality cattle feed. This feed can easily be made at the ethanol mills using sugarcane residues and some additional protein and mineral supplements. Analyses indicate that the dairy farmers can increase their income ten-fold by adopting this integrated system. The increased total output and higher land-use efficiency in dairy production may counteract possible indirect land-use change. Greenhouse gas emissions per unit of milk produced as well as liter ethanol produced depend on several factors, including effects of diverting bagasse from other uses to feed production. © 2011 International Energy Initiative. Published by Elsevier Inc. All rights reserved. Introduction Brazil is the world's largest producer and exporter of sugarcane- based ethanol (Dossa, 2009) and is expected to increase its production as domestic and international demand increases. Increased ethanol production will likely be accomplished based on establishment of new mills and plantations, but also requiring increased output from existing ethanol mills and fields. The greenhouse gas (GHG) emissions reduction from replacing gasoline with ethanol depends on the size of GHG emissions from sugarcane cultivation and conversion to ethanol as well as the (direct and possibly indirect) land-use change (LUC) emissions that may arise when new sugarcane plantations are established (see, e.g., Fargione et al., 2008; Gibbs et al., 2008; Lapola et al., 2010). Approximately 60% of Brazil's sugarcane production is located in the state of São Paulo (Instituto Brasileiro de Geografia e Estatística, IBGE, 2009). In this state, sugarcane occupies an area almost twice as large as the aggregated area for the next five crops (Instituto Brasileiro de Geografia e Estatística, IBGE, 2009) and during the period from 2002 to 2008 it increased by more than 70%, from 2.7 to 4.6 Mha (São Paulo Institute of Agricultural Economy (Instituto de Economia Agrícola, IEA, 2010a). It has been projected that the sugarcane area will increase further to reach almost 7 Mha in 2016 (Instituto de Economia Agrícola, IEA, 2010b). Further sugarcane expansion is possible in a few regions in the state of São Paulo. Freitas and Sparovek (2008) point to Pontal do Paranapanema (Pontal) in the western part of the state as one region where sugarcane expansion is likely to take place. Beef and milk cattle production presently dominates land use in Pontal, occupying about 55% of the 1.4 million ha region (Freitas and Sparovek, 2008). About half of the total area in Pontal (almost all pasture land) is judged to be suitable (from an agronomical perspective) for growing sugarcane. There are about 5000 small-scale family farmers (settlers) in Pontal living in settlements created by a national Agrarian Reform process (see, e.g., Freitas and Sparovek, 2008). The settlers received their land to produce for self-consumption and sell small amounts of surplus on local markets. Most settlers in Pontal use their land for milk production and their main income comes from selling milk and livestock (Egeskog and Gustafsson, 2007). The prevailing low- productive and extensive milk production system in the settlements in Pontal (i.e., low-productive cows and limited pasture management) has constrained income growth for the settlers. Approximately 12% of the total land suitable for sugarcane in Pontal is located within the settlements (Freitas and Sparovek, 2008). This article presents results from a study of an integrated ethanol/ dairy system involving the settlers as sugarcane and dairy producers Energy for Sustainable Development 15 (2011) 8–16 ⁎ Corresponding author. Tel.: +46 31 772 31 59; fax: +46 31 772 31 50. E-mail addresses: [email protected] (A. Egeskog), [email protected] (G. Berndes), fl[email protected] (F. Freitas), [email protected] (S. Gustafsson), [email protected] (G. Sparovek). 1 Present address: Naturvårdsverket, Stockholm, Sweden. 0973-0826/$ – see front matter © 2011 International Energy Initiative. Published by Elsevier Inc. All rights reserved. doi:10.1016/j.esd.2011.01.005 Contents lists available at ScienceDirect Energy for Sustainable Development

Welcome message from author

This document is posted to help you gain knowledge. Please leave a comment to let me know what you think about it! Share it to your friends and learn new things together.

Transcript

Energy for Sustainable Development 15 (2011) 8–16

Contents lists available at ScienceDirect

Energy for Sustainable Development

Integrating bioenergy and food production—A case study of combined ethanol anddairy production in Pontal, Brazil

A. Egeskog a,⁎, G. Berndes a, F. Freitas b, S. Gustafsson a,1, G. Sparovek b

a Physical Resource Theory, Department of Energy and Environment, Chalmers University of Technology, SE-412 96 Göteborg, Swedenb USP- Esalq- University of São Paulo Av. Pádua Dias 11, Piracicaba-SP 13.418-900, Brazil

⁎ Corresponding author. Tel.: +46 31 772 31 59; fax:E-mail addresses: [email protected] (A. E

[email protected] (G. Berndes), [email protected]@naturvardsverket.se (S. Gustafsson), g

1 Present address: Naturvårdsverket, Stockholm, Swe

0973-0826/$ – see front matter © 2011 International Edoi:10.1016/j.esd.2011.01.005

a b s t r a c t

a r t i c l e i n f oArticle history:Received 24 September 2010Revised 10 January 2011Accepted 10 January 2011

Keywords:Dairy productionSugarcaneEthanolLand-use changeGreenhouse gas mitigationBrazil

Increased Brazilian sugarcane ethanol production is expected in response to increasing domestic andinternational ethanol demand. The Pontal do Paranapanema region, located in the western parts of the SãoPaulo state, is one of the regions where sugarcane is expected to expand on a large scale. This expansion willmost likely affect small-scale dairy farmers in the region and may lead to displaced milk production.Interviews have been made with small-scale dairy farmers in areas where sugarcane has already beenestablished. These interviews show that many farmers who substitute milk production for sugarcaneproduction experience economic stagnation after the change. However, both systems can coexist, usingsugarcane residues as high-quality cattle feed. This feed can easily be made at the ethanol mills usingsugarcane residues and some additional protein and mineral supplements. Analyses indicate that the dairyfarmers can increase their income ten-fold by adopting this integrated system. The increased total output andhigher land-use efficiency in dairy production may counteract possible indirect land-use change. Greenhousegas emissions per unit of milk produced as well as liter ethanol produced depend on several factors, includingeffects of diverting bagasse from other uses to feed production.

© 2011 International Energy Initiative. Published by Elsevier Inc. All rights reserved.

Introduction

Brazil is the world's largest producer and exporter of sugarcane-based ethanol (Dossa, 2009) and is expected to increase its productionas domestic and international demand increases. Increased ethanolproductionwill likely be accomplished based on establishment of newmills and plantations, but also requiring increased output fromexisting ethanolmills and fields. The greenhouse gas (GHG) emissionsreduction from replacing gasoline with ethanol depends on the size ofGHG emissions from sugarcane cultivation and conversion to ethanolas well as the (direct and possibly indirect) land-use change (LUC)emissions that may arise when new sugarcane plantations areestablished (see, e.g., Fargione et al., 2008; Gibbs et al., 2008; Lapolaet al., 2010).

Approximately 60% of Brazil's sugarcane production is located inthe state of São Paulo (Instituto Brasileiro de Geografia e Estatística,IBGE, 2009). In this state, sugarcane occupies an area almost twice aslarge as the aggregated area for the next five crops (Instituto Brasileirode Geografia e Estatística, IBGE, 2009) and during the period from2002 to 2008 it increased by more than 70%, from 2.7 to 4.6 Mha (São

+46 31 772 31 50.geskog),ail.com (F. Freitas),[email protected] (G. Sparovek).den.

nergy Initiative. Published by Elsev

Paulo Institute of Agricultural Economy (Instituto de EconomiaAgrícola, IEA, 2010a). It has been projected that the sugarcane areawill increase further to reach almost 7 Mha in 2016 (Instituto deEconomia Agrícola, IEA, 2010b).

Further sugarcane expansion is possible in a few regions in thestate of São Paulo. Freitas and Sparovek (2008) point to Pontal doParanapanema (Pontal) in the western part of the state as one regionwhere sugarcane expansion is likely to take place. Beef andmilk cattleproduction presently dominates land use in Pontal, occupying about55% of the 1.4 million ha region (Freitas and Sparovek, 2008). Abouthalf of the total area in Pontal (almost all pasture land) is judged to besuitable (from an agronomical perspective) for growing sugarcane.

There are about 5000 small-scale family farmers (settlers) inPontal living in settlements created by a national Agrarian Reformprocess (see, e.g., Freitas and Sparovek, 2008). The settlers receivedtheir land to produce for self-consumption and sell small amounts ofsurplus on local markets. Most settlers in Pontal use their land formilkproduction and their main income comes from selling milk andlivestock (Egeskog and Gustafsson, 2007). The prevailing low-productive and extensive milk production system in the settlementsin Pontal (i.e., low-productive cows and limited pasturemanagement)has constrained income growth for the settlers. Approximately 12% ofthe total land suitable for sugarcane in Pontal is located within thesettlements (Freitas and Sparovek, 2008).

This article presents results from a study of an integrated ethanol/dairy system involving the settlers as sugarcane and dairy producers

ier Inc. All rights reserved.

9A. Egeskog et al. / Energy for Sustainable Development 15 (2011) 8–16

and the mills as ethanol and feed producers. The system concept wasdeveloped based on a similar project in the Orlândia region, São Paulo(Burgi, 1985). The settlers can increase both milk production and netincome by investing in (i) sugarcane plantations, (ii) more productivedairy cattle, (iii) pasture improvements, and (iv) supplementarycattle feedmainly based on sugarcane residues. The analyses aremadefor the case of sugarcane expansion only on pasture land, since this isthe most common land type in Pontal.

The study focuses on two main questions:

• What economic benefits may a combined ethanol/dairy system havefor small-scale farmers, such as the settlers in Pontal?

• How may GHG emissions be affected if pastures (within and outsidesettlements) are converted to sugarcane plantations, milk productionin the settlements is intensified, and the ethanol produced from thesugarcane replaces gasoline?

In 2007 almost 20% of Brazil's total ethanol production wasexported but this share is assumed to decrease as domestic demandincreases (Dossa, 2009). However, the GHG emissions are estimatedfor the case where the produced ethanol is exported and used toreplace gasoline in the European Union (EU). The rationale is that EUhas so far been among the more progressive regions concerningintegration of biofuel sustainability requirements into legislation. TheEUmay therefore be considered a target market for actors investing inthe integrated ethanol/dairy production system.

Methodology

Two differentmodels were developed to analyze selected effects ofimplementing the integrated ethanol/dairy system in Pontal; onemodel for quantifying the net revenues from milk production in thesettlements (the Change of Cattle (CoC) model, see the Economics ofmilk production in the settlements (CoC model) section) and onemodel for quantifying the associated GHG emissions (the BIOenergynet GreenHouse Gas emissions (BIOGHG) model, see the Net GHGemissions (BIOGHG model) section).

The introduction of the integrated ethanol/dairy system can alsoaffect other actors, such as beef cattle ranchers outside thesettlements and the sugarcane industry, but this is outside thescope of this study which focuses on settlers in Pontal. Readers arereferred to Sparovek et al. (2009a) for a more comprehensive accountof how ethanol can be integrated with milk and beef production inBrazil.

Economics of milk production in the settlements (CoC model)

The CoCmodel is constructed to represent the transition from low-productive to medium-productive dairy cattle; it describes thesettlers' incomes and expenses connected to their dairy cattleproduction system. The annual net income for the settlers isquantified for the time period when they make the transition fromthe current milk production systems with low-productive dairy cattleto the integrated ethanol/dairy systemwithmedium-productive dairycattle. Themodel is developed using information from a questionnairesurvey conducted in Pontal in 2006 (Egeskog and Gustafsson, 2007).

The transition from low- to medium-productive dairy cattleinvolves several changes. The settlers allocate part of the landpresently used for subsistence and pasture to sugarcane. In exchangethe sugarcane industry provides the settlers with cattle feed based onsugarcane residues and produced at the ethanol mill. The settlers alsoincrease the number of animals they keep and reduce the area usedfor pasture (see Fig. 1).

The CoC model only includes income and expenses connected tothe cattle management and sugarcane production and leaves outadditional income and expenses, such as pension, salary from otheractivities, and income and expenses associated with the production of

other goods. Thus, milk, cattle, and sugarcane are the only incomesources considered. This is since income and expenses from cattlemanagement and sugarcane production are assumed to be the onlyparameters that change. For more detailed information regarding theCoC model, see Egeskog (2010a).

The mean annual income for settlers who do not grow and sellsugarcane to the industry is almost R$ 4900 (Egeskog and Gustafsson,2007). A R$ 18,000 loan, made available for the promotion of ruralagricultural development (Pronaf, 2006), is assumed to be usedduring the first 3 years to cover investment costs for new cattle, cattlefeed, artificial inseminations, change in pasture management, milkmachines, and milk refrigerators.

Improvement of cattle stock and milk productionThe low-productive cattle currently used by the settlers in Pontal

will not produce additionalmilkwhengiven supplementary feed;hencea transition to more productive cattle is necessary in order to increasemilk production. This new cattle stockwill need improved pastures andsupplementary feed (Ricardo Burgi, BürgiConsultoriaAgropecuáriaLtda,Piracicaba, Brazil. Personal communication, November 2006).

In 2006, settlers received about 70% of the averagemilk price paid inSão Paulo, see Table 1. It is assumed that improved milk management(centralized cooling systems, refrigerators) and increased total milkproduction in the settlements will lead to higher milk quality, stablesupply, and thus a better trade position towards the milk buyers. Thiswillmake it possible for the settlers to charge the sameprice as is paid onaverage in São Paulo.

By changing from hand-milking to machine-milking, settlers areassumed to double their milking capacity (see Table 1). The number ofmilk-producing animals will be doubled in 4 years; after 10 additionalyears all milk-producing animals are medium-productive animals.However, there is no restriction set on the proportion of heifers tocows. Since the heifers only lactate during one-fourth of the year,compared to four-fifths for the cows, the annual milk production willvary over the years. A pasture area of 10 ha—50% of each settler'sproperty—can sustain a herd of 32 milk-producing animals. However,the time available for milking is assumed to be a limiting factor andthe settlers will only be able to double their herd size from 12 to 24milk-producing cattle due to this.

Full ration feedEach settler needs about 170 tons of feed per year when they have

doubled the herd size. The feed is needed during the winter when thepasture cannot provide enough grass. This full ration (FR) feed is a mixof residues from ethanol production, including raw (4%) as well assteam-treated bagasse (51%), liquid yeast (29%), and molasses (1%).The FR feed also includes sorghum (8%), soybeanmeal (4%), urea (1%),limestone (0.5%), and minerals (1%). Producing this feed requiresabout 270 tons raw bagasse (3 kg raw bagasse is needed for eachkilogram steam-treated bagasse), as well as 14 tons sorghum and8 tons soybean meal. The demand for bagasse (corresponding toabout 11 ha of sugarcane plantations) and other residues from theethanol production cannot be covered by the sugarcane produced onthe settlers' land alone. Additional bagasse from sugarcane grownoutside the settlements (see Fig. 1) is required for the feed production,and also for covering the internal energy demand of the ethanol mill.On average, each settler can provide 70% of the bagasse needed forfeed when the transition to the integrated ethanol/dairy system iscompleted. Cultivation of the sorghum and soybean needed for the FRfeed production requires almost 4 ha of cropland each and is assumedto take place outside the settlements. The feed will be produced at theethanol mills.

As for the combined ethanol/dairy system in Orlândia, the FR feedis assumed to be sold to the settlers at a price corresponding to theproduction cost as an incentive for making the settlers' land availablefor sugarcane production. This production cost corresponds to about

20 % for subsistence

80 % for pasture

Pasture suitable for sugarcane

soy and sorghum

Sugarcane on 80 % of pasture suitable for sugarcane

soy and sorghum

Sugarcane on 80 % of pasture suitable for sugarcane

soy and sorghum

Within settlements Outside settlements

Sugarcane from 6 ha

feed

Bagassereplacingelectricity

To the market

Bagassereplacingelectricity

To the market

20 % for subsistence

80 % for pasture

20 % for subsistence

50 % for pasture

30 % for sugarcane

Ethanol plant

a

b

c

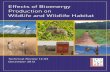

Fig. 1. Panel (a) shows the present system when each settler uses 80% for pasture, panel (b) shows a system where the expansion of sugarcane only takes place outside thesettlements and all excess bagasse (when internal heat and electricity demands are covered) is used to produce electricity. This electricity can then substitute electricity from othersources, e.g., oil-based electricity. All soy and sorghum produces is sold to the market. Panel (c) shows a system where the settlers are included in the sugarcane production. Part ofthe bagasse used for electricity and part of the soy and sorghum production which in (b) was sold to the market will in this case be used to produce feed for the settlers' cows.

10 A. Egeskog et al. / Energy for Sustainable Development 15 (2011) 8–16

50–70% of the market price for cattle feed that in 2006 was 0.18 R$/kg(Ricardo Burgi, BürgiConsultoriaAgropecuáriaLtda, Piracicaba, Brazil.Personal communication, February 2010). The capital cost associatedwith the feed production is low compared to other capital costs in thesugarcane ethanol industry. And, since settlers pay a pricecorresponding to the feed production cost, the FR feed productionwill be cost neutral from the perspective of the ethanol producer.

Net GHG emissions (BIOGHG model)

The BIOGHGmodel is constructed to quantify emissions connectedto a scenario for sugarcane expansion in Pontal where the settlers shiftto the combined ethanol/dairy system. The BIOGHG model considersGHG emissions and avoided GHG emissions associated with threedifferent activities; (1) the use of fossil-based inputs in sugarcane andethanol production; (2) the conversion of pastures to sugarcaneplantations leading to changes in soil carbon; and (3) the replacementof gasoline with ethanol in the transportation sector and provision ofelectricity generated from bagasse. The annual as well as cumulativenet GHG emissions are calculated for the studied period. For a moredetailed description of BIOGHG, see Egeskog (2010b).

In contrast to the settlers, large land owners in Pontal are assumedto shift from beef cattle production to conventional sugarcaneproduction. Decisions about future land use by the large land ownerscan influence the size of GHG emissions associated with the shift tosugarcane—e.g., they may intensify their remaining cattle productionand/or convert forests and other natural ecosystems to new pasturesto compensate for lost beef production—but these considerations areoutside the scope of this analysis, which focuses on the settlers'production. LUC emissions arising due to the new demand for soybean

and sorghum as ingredients in FR feed production are not consideredwithin the BIOGHG model. Such LUC effects are instead explicitlytreated in illustrative sensitivity quantifications in the Indirect land-use change section.

The sugarcane expansion scenarioThe scenario for the sugarcane expansion is defined so that 80% of

the area outside settlements that is suitable for growing sugarcane isused for sugarcane production by the end of the scenario period, i.e., in2030. The remaining 20% of the suitable land is reserved in equalshares for (i) roads and industrial areas developed as part of thesugarcane expansion and (ii) protection of nature, soils, and waterresources. According to Brazilian environmental legislation, 20% ofprivate farmland in São Paulo should be protected as legal reserves(Sparovek et al. 2010). Our assumption of only 10% of suitable land setaside for protection implies that unsuitable land is also reserved forthis purpose. Outside the settlements, 487,200 ha is allocated tosugarcane (based on Freitas and Sparovek, 2008). Given that eachsettler is assumed to allocate 6 ha for sugarcane (30% of 20 ha),30,000 ha of pasture will be converted to sugarcane plantations insidethe settlements. The expansion will proceed at a constant rate duringthe whole expansion period, both within and outside the settlements.

Sugarcane and ethanol production

Production of sugarcane. Emissions connected to production ofsugarcane depend on direct emissions from the production as wellas yields. Emissions directly associated with sugarcane productioncome from production and use of agricultural inputs such as diesel,fertilizers, and herbicides, the production, use and maintenance of

Table 1Assumptions regarding present and future situation for the small-scale dairy cattle farmers in Pontal. Milk prices are assumed to increase at the inflation rate; values for 2030 are in2006 R$.

Pontal 2006 Pontal 2030

Milk price R$/litera 0.38 0.55Income from sugarcane (R$/ha)b – 300Milk producing animals 12 24Emissions from milk production (kg CO2 eq./liter milk)c 3 1.3Animals/hab 1.4 3.3Milk production 3.6 l/animal/dayb 12 l/animal/day

Cows 50% in lactation Cows 80% in lactationHeifers 25 % in lactation Heifers 25 % in lactation

Milk producing animals Cows: 10 Cows: 18–21d

Two-year-old heifers: 2 Two-year-old heifers: 3–6d

Share of property used for different land uses (each settlers owns 20 ha)b Pasture 80% Pasture 50%Sugarcane 0% Sugarcane 30%Subsistence 20% Subsistence 20%

Time spent by one person on hand milkinge 3 h 6 hTime spent by one person on milking with machinef – 3 h

a Based on communication with Ricardo Burgi, BürgiConsultoriaAgropecuáriaLtda, Piracicaba, Brazil. Personal communication, November 2006.b Same as prices paid in 2006 (Egeskog and Gustafsson, 2007).c Values based on calculations using the ALBIO model (see, e.g., Kasimir-Klemedtsson andWirsenius, 2004). Values include CH4 emissions from the animals' enteric fermentation

and CH4 and N2O emissions from manure management.d The numbers vary, but in total they never exceed 24.e Assumes it takes 1 h to hand-milk 8 cows/heifers (the productivity of the animals does not affect the time), and that milking is done twice a day by one person (Alberto Barretto,

Department of soil science, ESALQ/USP, Piracicaba, Brazil. Personal communication, November 2009).f Assumes it takes 1 h to machine-milk 16 cows/heifers and that milking is done twice a day by one person (Alberto Barretto, Department of soil science, ESALQ/USP, Piracicaba,

Brazil. Personal communication, November 2009).

11A. Egeskog et al. / Energy for Sustainable Development 15 (2011) 8–16

machines and buildings, as well as emissions from transport (seeTable 2). The average sugarcane yield in São Paulo in 2008was 85 tonsfresh cane/ha (Instituto de Economia Agrícola, IEA, 2010a),corresponding to 70 tons fresh cane/ha/year if assuming a 6-yearcycle with five harvests. The annual sugarcane yield has increased onaverage 0.84% per year over the last 10 years (Instituto de EconomiaAgrícola, IEA, 2010a). Following Macedo et al. (2008), the yields areset to continue increasing at half this rate, giving an annual yield ofabout 94 tons fresh cane/ha in 2030.

Nitrogen (N) application rate, crop type, fertilizer type, soil organiccarbon content, soil pH and texture are factors that significantly

Table 2Emissions from processes connected to sugarcane and ethanol production (based onMacedocarbon change in pastures that are turned into sugarcane fields in Pontal.

Emissions from activities connected to sugarcane ethanolproduction

kgCO2 eq./tonsugarcane

AcC/h

Agricultural operation at the sugarcane field b 4.8–5 Me

Production of agricultural inputs 8.4 Ma

Production and maintenance of agricultural equipment 2.8 MaAll transportf 20–22 Me

Production of industrial inputs 0.6 MaConstruction and maintenance of equipment and buildings 4Release of N2O from fertilizer decompositiong 12.1–9.8Release of CH4, N2O and COh when sugarcane is burned beforeharvestl

26

a The pastures in Pontal are assumed to have a soil carbon stock of 40 ton C/ha (Carlos CeNovember 2006).

b Linearly increased yields of sugarcane from about 70 to 90 ton sugarcane/ha lead to decharvest are about half of the emissions from mechanical harvest and the area of manually h

c Based on communication with Carlos Cerri, Department of soil science, ESALQ/USP, Pirad Based on Lal et al. (2006).e Based on communication with Carlos Cerri, Department of soil science, ESALQ/USP, Piraf 2.8 kg CO2 eq./ton sugarcane excluding transport to Europe.g Linearly increased yields of sugarcane from about 70 to 90 ton sugarcane/ha lead to dec

included direct and indirect emissions.h The global warming potential for CO is uncertain; it may vary from 1 to 3 (IPCC, 2001)l Calculations based on IPCC (2006b).

influence N2O emissions from agricultural production; a summary ofavailable measurements and modeling show large variations in N2Oemissions even when many important factors are equal (Stehfest andBouwman, 2006). The Tier 1 methodology presented in IPCC (2006a)was used for calculating direct and indirect N2O emissions. The Nfertilization is assumed to correspond to 60 kg N/ha/year (Macedoet al. 2004); residues left on the field are assumed to provide plant-available N corresponding to 100 kg N/ha/year based on (Basantaaet al., 2003); and N in mineral soils is assumed to become availableduring mineralization at a rate corresponding to 1 kg N/ha/year(based on a C:N ratio of 5). Improvements in crop management, e.g.,

et al. (2004) unless otherwise indicated) and assumptions regarding soil carbon and soil

tivities affecting soil carbon levels (40 tonaa)

Change in soil carbon

chanical harvest c New soil carbon equilibrium 95% of startvalue

nual harvest d,e New soil carbon equilibrium 70% of startvalue

ximum loss of soil carbon each cycle e 10%chanical harvest after manuale New soil carbon equilibrium 95% of start

valueximum gain of soil carbon each cyclee 5%

rri, Department of soil science, ESALQ/USP, Piracicaba, Brazil. Personal communication,

reased emissions per ton from operations in the field. However, emissions from manualarvested fields decreases.cicaba, Brazil. Personal communication, November 2006.

cicaba, Brazil. Personal communication, November 2006.

reased emissions from operations in the field. Values calculated based on IPCC (2006a),

. Here, we assume it is 3.

12 A. Egeskog et al. / Energy for Sustainable Development 15 (2011) 8–16

optimized use of fertilizer, may substantially reduce N2O emissions(see, e.g., Smeets et al., 2009), but the default in BIOGHG is based onpresent situation.

Harvesting of sugarcane. It is assumed that pre-harvest field-burning—affecting soil C and leading to significant emissions of CH4, N2O, andCO (Table 2)—always takes place in fields that are harvested manuallybut never in fields that are mechanically harvested (see Change in soilcarbon as a result of land use change from pasture to sugarcanesection regarding soil carbon). The current law states that burningshould be phased out by 2021 in large and flat areas suitable formechanical harvest and by 2031 in small and sloping areas notsuitable for mechanical harvest; see São PauloState law # 11,241,September 19, 2002. In 2008, the sugarcane industry union (UNICA,2009) signed a protocol of intentions in which its associates(individually and voluntarily) set out to phase out field-burningbefore harvest by 2014 in areas suitable for mechanical harvest, andby 2017 in areas not suitable for mechanical harvest (Macedo et al.2008). Although compliance with the protocol is voluntary, the stategovernment is considering new legislation (Alves and Del Duca, 2007)and it is assumed as default that the phase-out of field burning willfollow the agreement. Sensitivity analyses are made where the rate ofphase-out of field burning is to show how this influences the totalemissions from sugarcane production.

Production of ethanol. We assume the ethanol mills will only produceethanol, even though a majority of the presently operating ethanolmills in Brazil produce both sugar and ethanol. This assumption willhowever only affect the total amount of ethanol produced because ofthe very clear system boundaries between the sugar and ethanolproduction, Macedo et al. (2008).

All internal process energy needs are assumed to be covered bybagasse; non-CO2 emissions from combustion of bagasse at theethanol mill are considered relatively small (Macedo et al., 2004) andare therefore not included. Hence, the only emissions connected toethanol production come from production and maintenance ofindustrial inputs and equipment (Table 2).

Assuming the same rate of increase as in Macedo et al. (2008), theethanol yields will increase from 86 l ethanol/ton sugarcane (2009) toalmost 98 l ethanol/ton sugarcane in 2030. This increase onlyconsiders improvements in cane quality (increased sucrose content)and does not take into consideration the possibility of using bagasse asfeedstock for ethanol production.

Transport of ethanol. All of the ethanol is assumed to be transportedfrom Pontal to Santos by truck and shipped to Europe across theAtlantic (the resulting GHG emissions are given in Table 2) where it isblended with gasoline. The additional distribution emissions arisingdue to the lower energy density of ethanol compared to gasoline areestimated to be small and are therefore not included. With an averagetransportation distance of 1000 km within EU, about 2% of totalemissions would have come from this transport.

Change in soil carbon as a result of land-use change from pasture tosugarcane

The conversion of pastures to sugarcane plantations gives rise todifferent GHG emissions depending on how the sugarcane isharvested. The soil carbon content is higher in sugarcane fieldsharvested mechanically than in fields harvested manually (see, e.g.,Razafimbelo et al., 2006; Galdos et al., 2009). Manual harvest lowerssoil carbon content due to tillage and because no biomass is left in thefields (Galdos et al., 2009). With mechanical harvest, some residuesare left in the field; in the first year, soil carbon decreases due totillage, but after that, the soil carbon will remain stable since thecarbon input via residues balances the loss of soil carbon from tillage(Carlos Cerri, Department of soil science, ESALQ/USP, Piracicaba,

Brazil. Personal communication, November 2006). Based on Grahamet al. (2002) and Robertson and Thorburn (2007), it is assumed thatthe soil carbon content gradually increases after a shift from manualto mechanical harvest and that this increase continues until the soilcarbon content is equal to that in a field that has always beenharvested mechanically. Table 2 presents the values and assumptionsmade regarding soil carbon content in Pontal and how it is influencedby land conversion and use.

Based on Freitas and Sparovek (2008), 20% of the expansion inPontal is defined to take place in areas that are not suitable formechanical harvest. The two different harvesting practices havesimilar annual cost, but the mechanical harvesting involves highercapital costs due to the required investment in a harvester. Weassume that mechanical harvest is always the practice whensugarcane expands in areas where manual harvest will be prohibitedby 2014—andwhere the land is suitable for mechanical harvest—sinceit is very unlikely that manual harvesting systems will becomeestablished in such areas. Areas wheremanual harvest is allowed until2017 are mainly owned by smaller farmers that usually have lesscapital available for investing in harvesters. In these areas, manualharvest with burning is assumed to be phased out gradually so thathalf of the area is burned in 2011 and none in 2017.

Avoided emissionsThere are avoided emissions both fromethanol replacing gasoline and

from bagasse based electricity replacing oil-based electricity on themargin. EachMJof ethanol replaces onMJof gasoline,with correspondingreduction in GHG emissions from gasoline use. The ethanol mills in SãoPaulo require on average about 94%, and at best about 80%, of the bagasseto cover internal demand for heat and electricity (Macedo et al., 2004). Itis assumed that newmills will use 85% of generated bagasse for meetinginternal process heat and electricity requirements and that the remaining15% is used for FR feed production and production of electricity that isexported to the grid with corresponding reduction in GHG emissions. In2007, hydroelectric power stood for 85%of Brazil's total generated power.About 8%was fossil fuel based,mainly natural gas and petroleum, and theremaining electricity was generated through nuclear power and fromother renewables (Energy Information and Administration, EIA, 2009). Itis assumed that the bagasse based electricity will replace oil-basedelectricity.

Sensitivity calculations are made where important parameters arevaried.

Presentation and discussion of the results

Increased sugarcane ethanol production in Pontal to meet importdemand from Europe can lead to reduced GHG emissions. TheBrazilian settlers in Pontal can at the same time improve their incomeby integrating sugarcane and dairy production.

Income from milk and sugarcane production

When the settlers change from 12 low-productive to 24 medium-productive dairy cattle, they increase milk production by more thanan order of magnitude, from about 7000 to about 80,000 l annually.However, the price for FR feed and income from milk are two crucialfactors for income development from the present level of about R$4900. If the settlers pay 2/3 (0.12 R$/kg) of the market price for the FRfeed, and income frommilk sales increases to the average liter-price inSão Paulo (R$ 0.55), the net annual income will be fivefold higher14 years after the transition started (Fig. 2). If instead the settlers paythe market price for the FR feed when the transition is complete, theirnet annual income would roughly triple. If the milk price paid to thesettlers remains at the present level (70% of the São Paulo price) theaverage annual net income would more than double by year 14,assuming two-thirds of the market price for FR feed. However, if the

-40

-30

-20

-10

0

10

20

30

40

2009 2011 2013 2015 2017 2019 2021 2023 2025 2027 2029-90

-70

-50

-30

-10

10

30

50

70

90

net income full ration feed new dairy cattle

production costamortization milk production

ann

ual

milk

pro

du

ctio

n (

1000

litr

es)

ann

ual

inco

me

and

exp

ense

s (1

000

$R)

Fig. 2. Milk production and net income and expenses for average integrated ethanol/dairy system for a settler who starts cattle stock transition in 2010. The variation in milkproduction is due to variation in dairy cattle stock.

13A. Egeskog et al. / Energy for Sustainable Development 15 (2011) 8–16

settlers pay the market price for FR feed and the milk price remains atthe present level, the average net annual income by year 14 would beless than one-fourth of today's income. If the settlers maximize theherd size (32 instead of 24 animals) they would improve their netannual income but would need to spend 1 h more per day milking.

During years 4 to 14 the settlers will have full costs for FR feed butlower incomes from milk. Mixed herds containing cows with a breedof low- and medium-productive animals need as much FR feed peranimal as herds containing only medium-productive animals. Sincethese herds produce less milk, settlers need to see reduced feed pricesand increased milk prices—or some type of economic support—inorder to maintain their annual net income during these 10 years oftransition. Experience from the Orlândia case, referred to earlier,indicates that the transition to the integrated ethanol/dairy systemmight not be considered an attractive option if the net annual incomeis substantially reduced during the transition period.

The settlers need to allocate 20% of their land to subsistence foodproduction but the remaining 80% (16 ha) could be used for whateverthey want. If the 80%were used only for sugarcane, the income from itwould have to be more than 875 R$/ha to match the annual netincome of the fully integrated ethanol/dairy system (assuming 24milk-producing animals, market price for FR feed and 0.55 R$/l milk).This is almost 600 R$/ha more than settlers in Pontal are paidcurrently (2010).

Ethanol production and use

In 2030, when the sugarcane expansion is complete, the totalannual ethanol production in Pontal will be about 3,190,000 m³ethanol (67 PJ). This is equivalent to 2.4% of the EU demand forrenewable transportation fuel in 2030, assuming a share of 14.25 %(about 2800 PJ) renewable fuels in the transportation sector(European Commission, EC (2008).

Net GHG emissionsGHG emissions/liter ethanol associated with sugarcane production,

local transport and conversion to ethanol decrease over time, partly dueto increasing cane yields/ha and ethanol yields/ton cane (Fig. 3a/b). Thetransition from manual harvest (with field burning) to mechanicalharvest also contributes to decreased emissions. The mechanical

harvesting requires more diesel use in the field, but this is more thancompensated for by avoided emissions from field burning.

Use of Brazilian ethanol in the European transportation sectorleads to avoided GHG emissions (possible effects of iLUC notconsidered). In Fig. 4, emissions and avoided emissions as well astotal accumulated avoided emissions are shown. In addition toemissions from ethanol production (Fig. 3a/b), emissions fromethanol transport to the EU, and soil carbon oxidation associatedwith pasture conversion to sugarcane plantations are included.Avoided emissions arise from replacement of gasoline by ethanoland of oil-based electricity by bagasse-based electricity. Emissionsfrom soil carbon oxidation decrease as manual harvest is phased outover time. If manual harvest is totally phased out by 2017 (as in Fig. 4),cumulative avoided GHG emissions by 2030 would correspond toabout 45Tg CO2 eq. (Fig. 4). This equals an average of 40 g CO2/km forall ethanol produced in Pontal during the given time period, assumingthat the ethanol is used in a car running on 0.05 l gasoline/km. The carwould emit 140 g CO2/km if running on gasoline, assuming direct andindirect emissions from gasoline are 2.8 kg CO2/l gasoline. If manualharvest is instead phased out completely by 2031, about 43 Tg CO2 eq.would be avoided by 2030 (46 g CO2/km).

Avoided emissions from displacement of oil-based electricity withbagasse-based electricity decrease slightly over time as the demand forFR feed increases within the settlements. Assumptions about bagasserequirements for process heat and electricity production influence theresults. Ethanol mills are assumed to require 85% of the bagasse forinternal energy demands. If all new ethanol mills instead require 80% ofthe bagasse, avoided emissions by 2030 would be almost 10% higher. If95% of the bagasse is required to meet internal energy demand—theaverage in São Paulo state today (Macedo et al., 2004)—the surplusbagasse would not suffice to meet the requirements for FR feedproduction from year 3 and onwards. Thus, bagasse would need to betransported from other plants in order to meet the total demand.

N2O emissions associated with fertilizer use shown in Fig. 3a/b arecalculated using the IPCC emission factor of 1%. Crutzen et al. (2008)proposed a higher emission factor and stated that N2O emissions frombiofuels have been underestimated by a factor of two to three inearlier studies. However, the differences between IPCC tier 1 andCrutzen et al. (2008) arise due to use of different accountingapproaches. Using the emission factor proposed by Crutzen et al.

0.0

0.1

0.2

0.3

0.4

0.5

0.6

0.7a

b

2009 2011 2013 2015 2017 2019 2021 2023 2025 2027 2029

2009 2011 2013 2015 2017 2019 2021 2023 2025 2027 2029

3.0

3.2

3.4

3.6

3.8

4.0

4.2

4.4

4.6

4.8

5.0

N2O emissions from N-fertilizers production of agricultural inputs

industrial areas and buildings transport

agricultural equipment production of industrial inputs

agricultural operations at the sugarcane field burning before harvest

total emissions/ha (right axis)

kgC

O2

eq./

litre

eth

ano

l

Mg

CO

2eq

./h

aM

gC

O2

eq./

ha

0.0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

3.0

3.2

3.4

3.6

3.8

4.0

4.2

4.4

4.6

4.8

5.0

kgC

O2

eq./

litre

eth

ano

l

Fig. 3. a/b Emissions (kg CO2eq./liter ethanol, left axis; kg CO2eq./ha, right axis) from annual production of ethanol. Panel A shows emissions when burning is totally phased out in2017. Panel B shows emissions when burning is totally phased out in 2031. The differences between the two cases are emissions from burning and emissions from agriculturaloperations at the field.

14 A. Egeskog et al. / Energy for Sustainable Development 15 (2011) 8–16

(2008) when calculating the N2O emissions from N fertilization of aspecific bioenergy plantation makes this bioenergy productionresponsible for all N2O emissions taking place subsequently whenpart of the applied N is re-circulated into other agriculture systemswhere it substitutes for other N input. Since N2O emissions from theanimal production system are treated separately in this study, use ofthe higher emission factor proposed by Crutzen et al. (2008) wouldlikely overestimate N2O emissions associated with the sugarcaneproduction. Nevertheless, N2O emissions can have an importantimpact on the overall GHG balance of biofuels (Smeets et al., 2009).

Soil carbon changesAs can be seen in Fig. 4, CO2 emissions arising from soil carbon

oxidation can be substantial during the initial phase of the transitionperiod when sugarcane is planted on pastures and part of the harvest

is manual. The influence on the longer term cumulative avoidedemissions depends on how long it takes until a new equilibrium levelfor soil carbon is reached—and on the difference between thisequilibrium level and that in the pastures before conversion. If theequilibrium soil carbon content in fields subject to manual harvestwill remain the same as the pre-conversion soil carbon content,instead of 30% lower as is the base case, cumulative avoided emissionsup to 2030 would be more than 7% higher. This assuming burning isphased out in 2017. Setting the equilibrium soil carbon content to alower level does not affect the results, since the assumed rate of soilcarbon loss is such that the soil carbon content is not reduced by 30 %of pre-conversion level by 2030 anyway.

Similarly, if pre-conversion soil carbon content in pastures inPontal is set to 50 ton C/ha instead of the base case of 40 ton C/ha, totalavoided emissions would decrease by less than 2% due to the larger

-2.5

-2.0

-1.5

-1.0

-0.5

0.0

0.5

1.0

1.5

2.0

2.5

2009 2011 2013 2015 2017 2019 2021 2023 2025 2027 2029-50

-40

-30

-20

-10

0

10

20

30

40

50

replace gasoline by ethanol replace electricity by bagasse

production of sugarcane and ethanol transport of ethanol to EU

change in soil carbon cumulative avoided emissions (right axis)

kgC

O2

eq./l

itre

eth

ano

l

Tg

CO

2eq

.

Fig. 4. Emissions per liter ethanol and cumulative avoided emissions in conjunction with an expansion of sugarcane for ethanol in the Pontal region. Manual harvest is assumed to bephased out completely in 2017. Emissions increase in the first 2 years. Possible deforestation through iLUC is not included.

15A. Egeskog et al. / Energy for Sustainable Development 15 (2011) 8–16

soil carbon emissions. If it is instead set to 30 ton C/ha, total avoidedemissions in 2030 would increase by less than 2%.

The cumulative avoided emissions up to 2030 are sensitive to thepace of sugarcane expansion relative to the pace of phasing outmanual harvesting. Faster sugarcane expansion in the early yearswould lead to larger soil carbon losses, since more sugarcane landwould then be subject to manual harvesting. Conversely, soil carbonlosses would be lower if sugarcane expansion is slower in thebeginning of the expansion period.

Diversion of bagasse from other uses to feed productionMilk production using low- and medium-productive dairy cows

leads to GHG emissions corresponding to 3 and 1.3 kg CO2 eq./litermilk, respectively (Table 1). Values includeCH4 emissions from theanimals' enteric fermentation and CH4 and N2O emissions frommanure management. The aassumptions regarding GHG emissionsfrom dairy cattle are based on calculations in Kasimir-Klemedtssonand Wirsenius (2004)) and these calculations are consistent withIPCCs guidelines for National Greenhouse Gas Inventories (IPCC,2006c). Both low- and medium productive dairy cattle graze,however, the medium-productive dairy cows also require additionalfeed, which means that additional bagasse is required for the FR feedproduction. The medium-productive dairy cows require almost 3.4 kgraw bagasse/liter milk produced, based on average feed requirementand average milk production for the herd after the transition.Assuming that this bagasse could have been used to replace oil-based electricity on the margin, the GHG savings lost by divertingmore bagasse to FR feed production correspond to about 2 kg CO2 eq./l milk. Hence, in this case the net effect of the transition from low- tomedium-productive dairy cattle would be slightly higher GHGemissions per liter milk for the medium-productive dairy cattle (3.3compared to 3 kg CO2 eq./liter milk). The production of the otheringredients in the cattle feed also gives rise to GHG emissions, whichhave not been quantified. A critical point will be whether theincreased demand for these ingredients results in conversion of forestland to cropland. This is further discussed in the Land use section.

Allocation of avoided emissions from ethanol to milk productionAssuming that production of additional ingredients of the feed is

produced on the settlers premises, each hectare (above the area used

for subsistence) will hold 1 medium-productive dairy cow; soy andsorghum production for that cow; and sugarcane enough to producealmost 3400 l of ethanol. If the avoided emissions from using thisethanol in the transport sector are allocated to the settlers milkproduction, emissions from the medium-productive dairy cow wouldbe 1.6 kg CO2 eq./l milk. Emissions from soy and sorghum productionhave not been quantified, and if included it would increase theemissions. However, reduced demand for land, a consequence fromassuming a constant milk demand, has also not been included.Increased expansion of sugarcane on the freed area would lead toreduced emissions from milk production if avoided emissions fromthis ethanol production were allocated to the milk. This is furtherdiscussed in the Land use section.

Land use

The low- andmedium-productive dairy cattle produce about 660 and3500 l milk/animal/year, respectively (Table 1). Each low-productiveanimal needs 1 ha of pasturewhile themedium-productive animal needsless than one-third of this area. However, the latter also needs the FR feedrequiring additional cropland for soy and sorghum production. Thiscorresponds to almost 0.4 ha/medium-productive dairy cow. Arearequirement forbagasseproduction isnotallocated to themilkproductionbut to the ethanol production that generates bagasse as a by-product.While the transition to the integrated ethanol/dairy system does notobviously lead to reduced GHG emissions/liter milk produced (see theDiversion of bagasse from other uses to feed production section andAllocation of avoided emissions from ethanol tomilk production section),possible GHG emissions reduction frommaking the transition can followfrom the improved land-use efficiency. The medium-productive dairycattle need much smaller area/liter produced milk and this can beimportant with respect to reducing the risk that ethanol expansion onpastures leads to GHG emissions connected to iLUC, as discussed in thenext section.

Indirect land-use change

Sugarcane cannot be stored for long time and cannot betransported over long distances. The sugarcane plantations aretherefore concentrated close to the ethanol mills. Yield gains may

16 A. Egeskog et al. / Energy for Sustainable Development 15 (2011) 8–16

support production capacity increases in existing ethanol mills, but ingeneral increased ethanol production is achieved by building newethanol mills and establishing new sugarcane plantations close tothese ethanol mills.

When sugarcane plantations displace other crop production or—asin this study—pasture production, the lost production is compensatedsomehow. It can be either by (1) intensified production on existingcropland/pastures elsewhere and/or (2) extended production based onconverting new areas into agricultural land and/or (3) consumptiongoesdowndue to an increase in thepriceof relatedproducts.Whennewcroplands/pastures are established, this may lead to significant GHGemissions if forests or other ecosystems storing large volumes of carbonin soils and vegetation are converted (see, e.g., Gibbs et al., 2008).Intensified production may also lead to increased emissions related tothe inputs required for the intensification. For instance, increased use ofsoybean as animal feed can lead to GHG emissions as soybean areasexpand (see, e.g., Nepstad et al., 2008).

Identifying and quantifying iLUC caused by sugarcane expansion indifferent areas of Brazil are presently not possible to achieve with highconfidence due to lack of empirical data and solid model representationsof Brazilian land use (Sparovek et al. 2009b). Hence, iLUC is not treated inthis study of sugarcane expansion in Pontal. However, if significant iLUCoccurs this would strongly impact the GHG emissions reduction fromBrazilian ethanol (see, e.g., Lapola et al., 2010; Sparovek et al. 2009b). Letus assume that an area equal to 10% of the area that the beef cattleranchers in Pontal give up for sugarcane would lead to conversion ofAmazonian rainforest to pasture. Then it would take almost 10 yearsbefore the expanding ethanol production resulted in net GHG emissionsreduction. This is based on the assumption that the GHG emissions due tothe deforestation correspond to about 730 ton CO2/ha following Gibbset al. (2008). Thus, development of sugarcane expansion strategies thatreduce the risk of iLUC emissions should be a priority. The integratedethanol/dairy systemmay be part of such a strategy because it can reducedisplacement risk (since farmers invest in their existing landuse) and alsopromotes higher land-use efficiency in dairy production.

Conclusions

Adoption of the integrated ethanol/dairy production systems couldincrease net income for settlers in Pontal and reduce land conversionpressure by increasing land-use efficiency in milk production. Thereduced land conversion pressure may be important for realizing theGHGsavings potential of the system since iLUC emissions can drasticallyreduce net GHG savings. Incentives may be needed to make settlersconsider the transition as an attractive option. Investigations of thefeasibility of implementing integrated ethanol/dairy system involvingalso large land owners are warranted.

Acknowledgments

Financial support from The Swedish Energy Agency is gratefullyacknowledged. We would like to thank Christian Azar, StefanWirsenius, Ricardo Burgi, Alberto Barretto, Carlos Cerri, FredrikHedenus and Johan Torén for stimulating discussions and/or forreviewing earlier versions of the manuscript.

References

Alves R., Del Duca P., 2007. The National Year of Clean Development ForBrazil, 2007,Latin American Legal Developments Newsletter. American Bar Association Sectionof International Law

Basantaa M, Dourado-Netoa D, Reichardtb K, Bacchib O, Oliveirab J, Trivelinc P, Timmb L,Tominagab T, Correchelb V, Cássarob F, Piresb L, de Macedob J. Management effects onnitrogen recovery in a sugarcane crop grown in Brazil. Geoderma. 2003;116:235–48.

Burgi, R., 1985. Produção do bagaço de cana-de-açúcar (Saccharum sp.L.) auto-hidrolisado eavaliação de seu valor nutritivo para ruminantes (Hydrolyzed bagasse from sugarcaneand its nutritional value for ruminants), Master Thesis, ESALQ/USP, Piracicaba, Brazil.

Crutzen P, Mosier A, Smith K, Winiwarter W. N2O release from agro-biofuel productionnegates global warming reduction by replacing fossil fuels. Atmospheric Chemistryand Physics. 2008;8:389–95.

Dossa, D., 2009. Projeções do agronegócio, Brasil 2008/09 a 2018/19- Brazilianagribusiness projections, 2008/09 to 2018/19 (In portuguese), Ministério daagricultura, pecuária e abastecimento, Brasília.

Egeskog, A., Gustafsson, S., 2007.Socioeconomic and environmental effects from sugarcaneexpansion into the Pontal do Paranapanema region (state of São Paulo, Brazil), a model-based analysis, Master Thesis, Chalmers, Gothenburg, Sweden.

Egeskog, A., 2010a. Model description of the CoC model, Chalmers, Gothenburg,Sweden. Forthcoming

Egeskog A. Model description of the BIOGHG model, Chalmers, Gothenburg.Forthcoming: Sweden; 2010a.

Energy Information and Administration (EIA), 2009. http://www.eia.doe.gov/cabs/Brazil/Electricity.html, 2011–01–03.

European Commission (EC. European energy and transport trends to 2030—update2007. Luxembourg: Directorate-General for Energy and Transport; 2008.

Fargione J, Hill J, Tilman D, Polasky S, Hawthorne P. Land clearing and the biofuel carbondebt. Science. 2008;319:1235–8.

Freitas, F., Sparovek, G., 2008. Sugarcane expansion near agrarian reform settlements: a casestudyof Pontal, Brazil. Conferenceproceeding at ISPRS, Beijing. Available at: http://www.isprs.org/congresses/beijing2008/proceedings/8_pdf/1_WG-VIII-1/17.pdf

Galdos M, Cerri CC, Cerri CE. Soil carbon stocks under burned and unburned sugarcanein Brazil. Geoderma. 2009;153:347–52.

Graham M, Haynes R, Meyer J. Soil organic matter content and quality: effects of fertilizerapplications, burning and trash retention on a long-term sugarcane experiment inSouth Africa. Soil Biology & Biochemistry. 2002;34:93-102.

Gibbs HK, Johnston M, Foley J, Holloway T, Monfreda C, Ramankutty N, Zaks D. Carbonpayback times for crop-based biofuel expansion in the tropics: the effects of changingyield and technology. Environmental Research Letters 2008;3:034001.

Instituto Brasileiro de Geografia e Estatística (IBGE), National Institute for Geographyand Statistics, 2009. http://www.ibge.gov.br/home/, 2009–11–08.

Instituto de Economia Agrícola (IEA), 2010a http://www.iea.sp.gov.br/out/banco/menu.php 2010–09–02.

Instituto de Economia Agrícola (IEA), 2010b. http://www.iea.sp.gov.br/out/verTexto.php?codTexto=7448, 2010–09–02.

IPCC, 2001. IPCC Climate change 2001: The scientific basis, Chapter 6, Table 6.9 and 6.7.IPCC, 2006a. Guidelines for national Greenhouse gas inventories, Volume 4, Agriculture,

Forestry and Other land Use, Chapter 11, Equation 11.1.IPCC, 2006b. Guidelines for national Greenhouse gas inventories, Volume 4, Agriculture,

Forestry and Other land Use, Chapter 2, Equation 2.27.IPCC, 2006c.Guidelines for national Greenhouse gas inventories, Volume 4, Agriculture,

Forestry and Other land Use, Chapter 10.Kasimir-Klemedtsson Å, Wirsenius S. Scenarios of greenhouse gas emissions from milk

production in EU15: analysis of greenhouse gas mitigation options based onmodeling of carbon and nitrogen flows in the dairy cattle system. In: Weiske A,editor. Greenhouse gas emissions from agriculture: mitigation options andstrategies. Leipzig: Institute for Energy and Environment; 2004.

Lal R, Cerri C, Bernoux M, Etchevers J, Cerri E. Carbon sequestration in soils of LatinAmerica. New York: The Haworth Press Inc; 2006.

Lapola DM, Schaldach R, Alcamo J, Bondeau A, Koch J, Koelking C, Priess JA. Indirectland-use changes can overcome carbon savings from biofuels in Brazil. Proc. Natl.Acad. Sci. USA. 2010;107:3388–93.

Macedo, I., Leal, M., Silva, J., 2004. Assessment of greenhouse gas emissions in theproduction and use of fuel ethanol in Brazil. São Paulo State EnvironmentSecretariat. Available at: www.unica.com.br/i_pages/files/pdf_ingles.pdf.

Macedo I, Seabra E, Silva J. Green house gases emissions in the production and use ofethanol from sugarcane in Brazil: the 2005/2006 averages and a prediction for2020. Biomass and Bioenergy. 2008;32:582–95.

Nepstad D, Stickler C, do Soares-Filho B, Merry F. Interactions among Amazon land use,forests and climate: prospects for a near-term forest tipping point. Philosophicaltransactions of the Royal Society. 2008;363:1737–46.

Pronaf, 2006. Available at: http://www.agronegociose.com.br/agronegocios/coringa.agr?opcao=paginaCoringa&numeroRegistro=14, 2006–10–17.

Razafimbelo T, Barthès B, Larré-Larrouy M, de Luca E, Laurent J, Cerri C, Feller C. Effect ofsugarcane residue management (mulching versus burning) on organic matter in ClayOxisol fromsouthern Brazil. Agriculture, Ecosystems andEnvironment. 2006;115:285–9.

Robertson F, Thorburn P. Management of sugarcane harvest residues: consequences for soilcarbon and nitrogen. Australian Journal of Soil Research. 2007;45:13–23.

Smeets E, Bouwman L, Stehfest E, van Vuuren D, Posthuma A. Contribution of N2O to thegreenhouse gas balance of first-generation biofuels. Global Change Biology.2009;15:1-23.

Sparovek, G, Berndes, G., Barretto A, Martins, S.P., Maule, R.F., Burgi, R., Smorigo, J.N.(2009a). Polos de producao de energia, alimento e cidadania: conceito eaplicacaoempoliticaspublicas (Bioenergy and food production for local develop-ment in Brazil: Inputs for policy-making)

Sparovek G, Barretto A, Berndes G, Martins S, Maule R. Environmental, land-use andeconomic implications of Brazilian sugarcane expansion 1996–2006. Mitigationand adaptation strategies for global change 2009a;14:285–98.

Sparovek G., Berndes G., Klug I., Barretto A., 2010. Brazilian agriculture andenvironmental legislation: status and future challenges. Submitted to Environ-mental Science and Technology, 2010.

Stehfest E, Bouwman L. N2O andNO emission from agricultural fields and soils under naturalvegetation: summarizing available measurement data and modeling of global annualemissions. Nutrient Cycling in Agroecosystems. 2006;74:207–28.

UNICA, 2009. Available at: http://www.english.unica.com, 2009–11–20.

Related Documents