Inspection Needs Supporting Increased Well Integrity Dr.Robello Samuel Halliburton Fellow [email protected] NASA In-Space Inspection Technology Workshop (ISIW 2014) Johnson Space Center, Houston

Welcome message from author

This document is posted to help you gain knowledge. Please leave a comment to let me know what you think about it! Share it to your friends and learn new things together.

Transcript

Inspection Needs Supporting Increased Well Integrity

Dr.Robello Samuel

Halliburton Fellow

NASA In-Space Inspection Technology Workshop

(ISIW 2014) Johnson Space Center, Houston

© 2014 HALLIBURTON. ALL RIGHTS RESERVED. 2

In-EarthIn-Space

Context

© 2014 HALLIBURTON. ALL RIGHTS RESERVED. 3

Exploration Drilling

© 2014 HALLIBURTON. ALL RIGHTS RESERVED. 44© 2011 HALLIBURTON. ALL RIGHTS RESERVED.

© 2014 HALLIBURTON. ALL RIGHTS RESERVED. 5

Oil Well Integrity

• Well Integrity: NORSOK D-010 and API Std 65 (1 & 2)

• Well Reliability as KPI

API RP 65-2: “Barriers contribute to total systemreliability; total system reliability is the probability ofbarrier success, or one minus the probability that allbarriers to uncontrolled flow along a particular path willfail simultaneously.”

“Application of technical, operational and organizational

solutions to reduce the risk of uncontrolled release offormation fluids throughout the entire life cycle of thewell.”

© 2014 HALLIBURTON. ALL RIGHTS RESERVED. 6

Wellbore IntegrityWellbore Integrity

Casing IntegrityCasing Integrity

Cement SheaathIntegrity

Cement SheaathIntegrity

Annular IntegrityAnnular Integrity

Junction IntegrityJunction Integrity

Data IntegrityData Integrity

6

Total Well Integrity Ecosystem

Engineering

+ Inspection

Structural Integrity

Structural Integrity

© 2014 HALLIBURTON. ALL RIGHTS RESERVED. 7

Challenge

Surface

Sub-surface

© 2014 HALLIBURTON. ALL RIGHTS RESERVED. 8

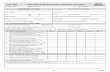

PrimaryMechanical

• Barriers SecondaryOperational

Well barriers schematic

for Drilling PhaseSource: NORSOK D-10 lit-1

primary barrier is the fluid column in the well

secondary barrier is the last set

Well Integrity - Basics

© 2014 HALLIBURTON. ALL RIGHTS RESERVED. 9

How this is done?

Interconnect• Monitor• Inspect• Engineering• Intelligent

© 2014 HALLIBURTON. ALL RIGHTS RESERVED. 10

Barrier performance change with time

Barrier Design

(Casing, Casing

joint, Liner Hanger)

Simulation -1

Design & Run

Changing Well Conditions

Stress

Levels

Reliability

Results

Simulation -2

Accelerated

Test

How this is done?

Inspection

Results

Well Integrity issues

BarrierAnalysis

3

2

1

4

Source: Bibek Das and Robello Samuel

© 2014 HALLIBURTON. ALL RIGHTS RESERVED. 11

Simulation Design

Casing Wear

model

[API TR 5C3]

Casing Wear due

to rotating

drillstring

[period of rotation]

Reduced Casing

strength

[tensile, collapse,

burst]Test for Failure

Tensile

Stress model

[API TR 5C3]

Burst model

[API TR

5C3]

Collapse

model

[API TR

5C3]

Operations:

Internal & External

Pressure

[stress]

next

period o

f ro

tation

Representative

Failure ModelAccelerated Test

next

occurr

ence o

f casin

g p

ressure

model

applicability

Reliability Model

Source: Bibek Das and Robello Samuel

© 2014 HALLIBURTON. ALL RIGHTS RESERVED. 12

depth

Reliability Mathematics

)(1)( tFtR −=

∫=t

dssftF0

)()(

An acceleration factor is calculated as compared to the use conditions

tu = AF x ts

( ) ( )AF

tfAF

tf su1)( =

Source: API RP 2A

Source: Bibek Das and Robello Samuel

© 2014 HALLIBURTON. ALL RIGHTS RESERVED. 1313© 2011 HALLIBURTON. ALL RIGHTS RESERVED.

Engineering Health diagnostic System

If the triaxial

stress exceeds

the yield

strength, a

yield failure is

indicated.

The triaxial

safety factor is

the ratio of the

material’s yield

strength to the

triaxial stress.

© 2014 HALLIBURTON. ALL RIGHTS RESERVED. 14

Anomaly Diagnostic

• Extend inspection to potential barrier failures and maintenance schedule

Engineering, operational and organizational solutions to reduce risk of uncontrolled release of formation fluids throughout the life cycle of a well

Well Integrity - Inspection

© 2014 HALLIBURTON. ALL RIGHTS RESERVED. 15

Real Time Integrity Inspection

Real Time Verification

DecisionSpace®InSite® Direct

© 2014 HALLIBURTON. ALL RIGHTS RESERVED. 16

Identify Real Time Asset Inspection

© 2014 HALLIBURTON. ALL RIGHTS RESERVED. 1717© 2011 HALLIBURTON. ALL RIGHTS RESERVED.

Risk Analysis

© 2014 HALLIBURTON. ALL RIGHTS RESERVED. 1818© 2011 HALLIBURTON. ALL RIGHTS RESERVED.

Quantum Data

Monitoring

Engineering

DataAnalytics

© 2014 HALLIBURTON. ALL RIGHTS RESERVED. 1919© 2011 HALLIBURTON. ALL RIGHTS RESERVED.

Erosion Corrosion Collapse Burst

Max

Average

Max

Min

Max

Min

Max

Min

actualTrend

Inspection Dash Board

Source: SPE 164230

© 2014 HALLIBURTON. ALL RIGHTS RESERVED. 20

Comprehensive WIM System

Full Integrated Analysis

Engineering Inspection Analytice

Erosion Corrosion Collapse Burst

Max

Average

Max

Min

Max

Min

Max

Min

actualTrend

© 2014 HALLIBURTON. ALL RIGHTS RESERVED. 21

How can we use the “quantum data”?

Inspection needs

© 2014 HALLIBURTON. ALL RIGHTS RESERVED. 22

How are we going to use the “quantum data”?

Well Integrity Summarization =

Data Informed + Engineering Guided

Inspection needs

i

n

i

m

j

jref∑ ∏= =

=

1 1

. πλλ

∏=

=b

k

kwell RR1

ψ

© 2014 HALLIBURTON. ALL RIGHTS RESERVED. 23

Winning Work In The Exploration Race

Dr.Robello Samuel

Halliburton Fellow

Related Documents