Engineering for Excellence ISGEC John Thompson Sugar Plant & Machinery

Welcome message from author

This document is posted to help you gain knowledge. Please leave a comment to let me know what you think about it! Share it to your friends and learn new things together.

Transcript

Pressure Vessels & Heat Exchangers

Presses: Mechanical & Hydraulic

Castings: Steel & Iron

Contract Manufacturing

Printed in March 2010 Content subject to change, without any prior notice

www.isgec.comwww.isgecgroup.com

ISGECJohn Thompson

IJT

/SP

MB

ro./0

31

0/0

0/D

igitp

Offices

Agents

India : ISGEC John Thompson, A-4, Sector 24, Noida - 201 301 (U.P.) India Tel.: +91-120-330 10 00 to 20Contact: Yogesh MarwahaE-mail: [email protected] (overseas) [email protected] (India)

Chennai • Pune • Mumbai

USA : ISGEC John Thompson North America Office5125 Cochrane Ave., Oakland, California, CA 94618 USA Tel. : +1-510-922-9815Contact: Ashi MalikE-mail: [email protected]

Europe : ISGEC John Thompson Europe OfficeKreiten Strasse 25, 40470 Dusseldorf, Germany Tel.: +49-211-271 63 00Contact: Viren ChadhaE-mail: [email protected]

Across 72 CountriesFor Country specific contact detailsplease write to [email protected]

EPC • Power Plants

Oil / Gas Fired Boilers: Field Assembled & Package Type

Atmospheric Fludised Bed Combustion Boilers

Circulating Fluidised Bed Combustion Boilers

Deaerators

E n g i n e e r i n g f o r E x c e l l e n c e

ISGECJohn Thompson

Sugar Plant&

Machinery

Project Management & Training

We use dedicated teams for Project Management.These include specialists across various functions. We usecentralised ERP (Enterprise Resource Planning) solution fromBaaN and MS Project to control all project activities.

Operational & maintenance personnelfrom customers end undergoing training.

We hold training sessions for our customers,both on site as well as in our office.

The ISGEC Group comprises the heavy engineering divisions

of the Saraswati Industrial Syndicate Ltd., which is a public

company.

The Group has its origins in the Saraswati Sugar Mills, which

was established in 1933, with a sugarcane crushing capacity of

400 Tonnes per day. It has grown into India's largest sugar mill

and now crushes 13,000 Tonnes per day. It is today a

subsidiary company

At the time of the nation's independence, the need for an Indian

Capital Goods Industry was recognized and Isgec was

established in 1946. The initial activity was the manufacture of

spares for sugar mills

In the course of its history, the Company diversified into a range

of engineering products. In 1964 it established a joint venture

with John Thompson of the UK to form ISGEC JOHN

THOMPSON. In 1981, it acquired majority shares in U.P.

STEELS. Both units were subsequently absorbed into the

parent company. Today, the Company has the following

business units across various locations in India - the port town

of Dahej in Gujarat; Yamunanagar & Bawal in Haryana; Noida

& Muzaffarnagar in Uttar Pradesh.

• Isgec

Pressure Vessels & Heat Exchangers

• Isgec

Presses

• Isgec

Iron Castings

• Isgec John Thompson

EPC, Boilers, Sugar Plants, Power Plants

• U.P. Steels

Steel Castings

• ABB, Japan

• Foster Wheeler, China

• Foster Wheeler, USA

• GE Hydro, Canada

• Luk, Germany

Spread over 100 hectares (250 acres), the Company's manufacturing facilities have a shop floor area of over 95,500 square meters (1,14,200 square yards) with world class manufacturing & testing facilities.

Isgec products have been supplied to reputed companies across 74 countries, many of whom have placed repeat orders on us. These include:

• Siemens, Germany

• Sumitomo, Japan

• Valeo, France

• VA Tech Hydro, USA

• Wesfarmers Group, Australia

1 2

ISGEC John Thompson Office at Noida(a suburb of New Delhi), India.

New Plant at the port town of Dahej (Gujarat) India.The shop has been set up especially for the manufacture oflarge equipment for the overseas market.

Main Plantat Yamunanagar (Haryana), India.

60

300

552

28

Complete Sugar Plants

Cane Crushing Mills

Boilers

across

Countries

(& major expansions)

Malaysia

BarbadosUK Colombia

Brazil

Guyana

Pakistan

MauritiusUSA

Trinidad &Tobago

Spain

Vietnam

Indonesia

Philippines

Thailand

Tanzania

ZambiaUganda

IndiaNigeria

BangladeshEthiopia

Mozambique

Kenya

Bosnia

Senegal

Liberia

Sudan

Cover Picture:3500 TCD expandable to 5000 TCD with 18 MW Cogeneration Plant executed on a turnkey basis for Daund Sugar Ltd., India

The ISGEC Group comprises the heavy engineering divisions

of the Saraswati Industrial Syndicate Ltd., which is a public

company.

The Group has its origins in the Saraswati Sugar Mills, which

was established in 1933, with a sugarcane crushing capacity of

400 Tonnes per day. It has grown into India's largest sugar mill

and now crushes 13,000 Tonnes per day. It is today a

subsidiary company

At the time of the nation's independence, the need for an Indian

Capital Goods Industry was recognized and Isgec was

established in 1946. The initial activity was the manufacture of

spares for sugar mills

In the course of its history, the Company diversified into a range

of engineering products. In 1964 it established a joint venture

with John Thompson of the UK to form ISGEC JOHN

THOMPSON. In 1981, it acquired majority shares in U.P.

STEELS. Both units were subsequently absorbed into the

parent company. Today, the Company has the following

business units across various locations in India - the port town

of Dahej in Gujarat; Yamunanagar & Bawal in Haryana; Noida

& Muzaffarnagar in Uttar Pradesh.

• Isgec

Pressure Vessels & Heat Exchangers

• Isgec

Presses

• Isgec

Iron Castings

• Isgec John Thompson

EPC, Boilers, Sugar Plants, Power Plants

• U.P. Steels

Steel Castings

• ABB, Japan

• Foster Wheeler, China

• Foster Wheeler, USA

• GE Hydro, Canada

• Luk, Germany

Spread over 100 hectares (250 acres), the Company's manufacturing facilities have a shop floor area of over 95,500 square meters (1,14,200 square yards) with world class manufacturing & testing facilities.

Isgec products have been supplied to reputed companies across 74 countries, many of whom have placed repeat orders on us. These include:

• Siemens, Germany

• Sumitomo, Japan

• Valeo, France

• VA Tech Hydro, USA

• Wesfarmers Group, Australia

1 2

ISGEC John Thompson Office at Noida(a suburb of New Delhi), India.

New Plant at the port town of Dahej (Gujarat) India.The shop has been set up especially for the manufacture oflarge equipment for the overseas market.

Main Plantat Yamunanagar (Haryana), India.

60

300

552

28

Complete Sugar Plants

Cane Crushing Mills

Boilers

across

Countries

(& major expansions)

Malaysia

BarbadosUK Colombia

Brazil

Guyana

Pakistan

MauritiusUSA

Trinidad &Tobago

Spain

Vietnam

Indonesia

Philippines

Thailand

Tanzania

ZambiaUganda

IndiaNigeria

BangladeshEthiopia

Mozambique

Kenya

Bosnia

Senegal

Liberia

Sudan

Cover Picture:3500 TCD expandable to 5000 TCD with 18 MW Cogeneration Plant executed on a turnkey basis for Daund Sugar Ltd., India

horizontal setting mills

• 'A' Frame design head stocks

• Pinionless Mills

• Dewatering Mills for Diffusers

• Various drive combinations:

– AC-VFD with planetary gearbox & Rope Coupling

– DC Motors and Thyristor Panels with Primary Gearbox & Open Gearing

– Hydraulic Drive

– Turbine Drives

• Cane Preparatory Devices

– Cane Knives

– Fibrizers / Shredder options

- Knifed Cane

- Whole Stick Cane Shredder

• King & Queen boltless type

4 Roller Pinionless Mill of size1067mm (42”) x 2135mm (84”) for capacity upto

340 TCH driven by 4 Nos. 160 kW AC motors with VFD,working at Jai Mahesh Sugars in Maharashtra, India.

The mill has achieved power consumption of1.12 kW/TCH against 1.5 kW/TCH in a conventional mill.

We have executed repeat orders for two moresuch mills from the same customer.

ExclusiveLicensing Agreement with

Chainless Diffusers • Whole Stick Shredders

Rotary Juice Screens • Continuous Pan

Direct Contact Juice Heaters • Long Tube Evaporators

Chainless Diffuser for turnkey Sugar Plant being set up for HPCL Biofuels, India. We are currently supplying,

on a turnkey basis, 2 such Diffuser Plants, under licence from Bosch

3 4

Mills Diffusers

45" x 90" Mill for Xinavane, Mozambique,under assembly in our Works.

• Complete Boiling House for producing

- Plantation White Sugar

- Raw Sugar

- Household White Sugar (African standard)

- Vitamin A fortified Sugar

• Syrup, Melt and Filtrate Clarification for producing

super white sugar of low ICUMZA

• Refined Sugar of EU – I, II & III; Codex and US Bottlers Grade

• Ion Exchange System with Brine Recovery System

This Process House was supplied to a sugar factory in India. We have

supplied 200 Vacuum Pans, 160 Evaporator Bodies, 180 Juice Heaters and

270 Crystallizers in India and overseas.

30.4 MW Complete Cogeneration Plant supplied on Turnkey basis to Zambia Sugar Plc, (a subsidiary of Illovo Group of South

Africa) Nakambala, Zambia. We are currently executing / have recently executed 7 such Complete Cogeneration Plant projects

for Sugar Mills a various parts of the world.

Kibos Sugar & Allied Ind., Kenya, a 1850 TCD Sugar Plant being expanded to 3000 TCD with 23 MW Cogeneration. We have supplied such Plants, on a turnkey basis, to customers in in India, Vietnam and across Africa

South Africa

Turnkey Solutions

Process House

horizontal setting mills

• 'A' Frame design head stocks

• Pinionless Mills

• Dewatering Mills for Diffusers

• Various drive combinations:

– AC-VFD with planetary gearbox & Rope Coupling

– DC Motors and Thyristor Panels with Primary Gearbox & Open Gearing

– Hydraulic Drive

– Turbine Drives

• Cane Preparatory Devices

– Cane Knives

– Fibrizers / Shredder options

- Knifed Cane

- Whole Stick Cane Shredder

• King & Queen boltless type

4 Roller Pinionless Mill of size1067mm (42”) x 2135mm (84”) for capacity upto

340 TCH driven by 4 Nos. 160 kW AC motors with VFD,working at Jai Mahesh Sugars in Maharashtra, India.

The mill has achieved power consumption of1.12 kW/TCH against 1.5 kW/TCH in a conventional mill.

We have executed repeat orders for two moresuch mills from the same customer.

ExclusiveLicensing Agreement with

Chainless Diffusers • Whole Stick Shredders

Rotary Juice Screens • Continuous Pan

Direct Contact Juice Heaters • Long Tube Evaporators

Chainless Diffuser for turnkey Sugar Plant being set up for HPCL Biofuels, India. We are currently supplying,

on a turnkey basis, 2 such Diffuser Plants, under licence from Bosch

3 4

Mills Diffusers

45" x 90" Mill for Xinavane, Mozambique,under assembly in our Works.

• Complete Boiling House for producing

- Plantation White Sugar

- Raw Sugar

- Household White Sugar (African standard)

- Vitamin A fortified Sugar

• Syrup, Melt and Filtrate Clarification for producing

super white sugar of low ICUMZA

• Refined Sugar of EU – I, II & III; Codex and US Bottlers Grade

• Ion Exchange System with Brine Recovery System

This Process House was supplied to a sugar factory in India. We have

supplied 200 Vacuum Pans, 160 Evaporator Bodies, 180 Juice Heaters and

270 Crystallizers in India and overseas.

30.4 MW Complete Cogeneration Plant supplied on Turnkey basis to Zambia Sugar Plc, (a subsidiary of Illovo Group of South

Africa) Nakambala, Zambia. We are currently executing / have recently executed 7 such Complete Cogeneration Plant projects

for Sugar Mills a various parts of the world.

Kibos Sugar & Allied Ind., Kenya, a 1850 TCD Sugar Plant being expanded to 3000 TCD with 23 MW Cogeneration. We have supplied such Plants, on a turnkey basis, to customers in in India, Vietnam and across Africa

South Africa

Turnkey Solutions

Process House

• Saving Devices - VFDs

- Planetary Gear Boxes - Antifriction Bearings - Energy Efficient Motors - Rope Couplings

• Steam Saving Devices - Direct Contact Heaters - Condensate Flash Recovery - Molasses Conditioning by waste heat of noxious gases - Sugar melting by 4th Effect Vapors - Super heated wash water of centrifugals from condensate flash vessel - Eliminating use of live steam from Process House - Use of Falling Film Evaporators for extensive bleeding

Power

Mills with AC VFD, Planetary Gear Boxes & Rope Couplings.

Energy Saving

5

Sugar Plant Process House at 35% Steam Consumption

2400-0

260-1

R

R

2020-1

255-1

235-1

R

R

217-1

218-1

R

R

210-1

40

40

-140

00-1

210

-1

217

-1

34

10

44

06

44

11

44

10

39

50

32

07

33

07

47

20

-5

R

Travelling Grate • Dumping Grate

natural circulation, single drum, balanced draft, top supported, continuous ash discharge Travelling Grate Boiler. This Boiler for a

30 MW cogeneration plant at Dhampur Sugar Mills, Asmoli, India has been designed for firing bagasse, rice husk and coal. This Boiler is

capable of generating up to 45 MW in condensing mode.We have supplied a Boiler of the same size to Chadha Sugars, India.

170 TPH, 105 kg/sq. cm. (g), 540 Deg. C

Bagasse & BiomassFired Boilers

95 TPH, 62 kg/sq.cm.(g), 500 Deg.C, natural circulation, bi-drum, single pass, balanced draft, top supported, continuous ash discharge Travelling

Grate Boiler designed for firing bagasse at the sugar plant at Mid Siam Sugar Co. Ltd., Thailand supplied and commissioned in 2009.

4 Nos. 150 TPH, 70 kg/sq.cm. (g), 510 Deg. C,Bagasse & Biogas Fired Boilers for a Greenfield 28,000 TCD Cane Sugar Plant with 90 MW Cogeneration facility at Khon Kaen Sugar Power Plant Co. Ltd. (KSL), Thailand.

Condensate Flash Recovery System for 2-3% reduction inSteam consumption at Evaporator Section.

6

• Saving Devices - VFDs

- Planetary Gear Boxes - Antifriction Bearings - Energy Efficient Motors - Rope Couplings

• Steam Saving Devices - Direct Contact Heaters - Condensate Flash Recovery - Molasses Conditioning by waste heat of noxious gases - Sugar melting by 4th Effect Vapors - Super heated wash water of centrifugals from condensate flash vessel - Eliminating use of live steam from Process House - Use of Falling Film Evaporators for extensive bleeding

Power

Mills with AC VFD, Planetary Gear Boxes & Rope Couplings.

Energy Saving

5

Sugar Plant Process House at 35% Steam Consumption

2400-0

260-1

R

R

2020-1

255-1

235-1

R

R

217-1

218-1

R

R

210-1

40

40

-140

00-1

210

-1

217

-1

34

10

44

06

44

11

44

10

39

50

32

07

33

07

47

20

-5

R

Travelling Grate • Dumping Grate

natural circulation, single drum, balanced draft, top supported, continuous ash discharge Travelling Grate Boiler. This Boiler for a

30 MW cogeneration plant at Dhampur Sugar Mills, Asmoli, India has been designed for firing bagasse, rice husk and coal. This Boiler is

capable of generating up to 45 MW in condensing mode.We have supplied a Boiler of the same size to Chadha Sugars, India.

170 TPH, 105 kg/sq. cm. (g), 540 Deg. C

Bagasse & BiomassFired Boilers

95 TPH, 62 kg/sq.cm.(g), 500 Deg.C, natural circulation, bi-drum, single pass, balanced draft, top supported, continuous ash discharge Travelling

Grate Boiler designed for firing bagasse at the sugar plant at Mid Siam Sugar Co. Ltd., Thailand supplied and commissioned in 2009.

4 Nos. 150 TPH, 70 kg/sq.cm. (g), 510 Deg. C,Bagasse & Biogas Fired Boilers for a Greenfield 28,000 TCD Cane Sugar Plant with 90 MW Cogeneration facility at Khon Kaen Sugar Power Plant Co. Ltd. (KSL), Thailand.

Condensate Flash Recovery System for 2-3% reduction inSteam consumption at Evaporator Section.

6

• Complete automation of sugar plants, power plants, sugar refineries and ethanol plants

- Centralized control - DCS based - Individual stations - DCS based - Individual automations PLC based

Control & Automation

7 8

125 KLPD San Carlos Bio Ethanol Plant, Philippines set up by Bronzeoak Philippines Inc. (a subsidiary of Bronzeoak, U.K.). We have supplied Milling, Clarification and Raw Syrup Concentration Plants as well as multi-fuel fired Travelling Grate Boiler for this Project. Poyry, UK were the Project Engineers. We are currently supplying a 16 MW Cogeneration Plant to JGC, Philippines (a subsidiary of JGC, Japan) for Green Future Innovations Inc., a 150 KLPD Greenfield Cane Juice to Ethanol Plant being set up in Philippines..

in partnership with leading ethanol plant suppliers

• Milling Plant for Feed Stock – Sugar Cane

and Sweet Sorghum

• Clarification Plants

• Raw Syrup Concentration Plants

• Fermentation and Distillation Plants

• Boilers and Turbo Sets

/ Diffuser s

Bio-Ethanol

Control Room at Kenana Sugar Co., Sudan. We have replaced stand alone Control System for8 Boilers with state-of-the-art DCS. We also set up a stand by Control Room.

Centralised Control Room for Sugar Plant with Cogeneration facilityat Daund Sugar, India.

A Centralised Control Room for a Cogeneration Plant in Kenya.

• Complete automation of sugar plants, power plants, sugar refineries and ethanol plants

- Centralized control - DCS based - Individual stations - DCS based - Individual automations PLC based

Control & Automation

7 8

125 KLPD San Carlos Bio Ethanol Plant, Philippines set up by Bronzeoak Philippines Inc. (a subsidiary of Bronzeoak, U.K.). We have supplied Milling, Clarification and Raw Syrup Concentration Plants as well as multi-fuel fired Travelling Grate Boiler for this Project. Poyry, UK were the Project Engineers. We are currently supplying a 16 MW Cogeneration Plant to JGC, Philippines (a subsidiary of JGC, Japan) for Green Future Innovations Inc., a 150 KLPD Greenfield Cane Juice to Ethanol Plant being set up in Philippines..

in partnership with leading ethanol plant suppliers

• Milling Plant for Feed Stock – Sugar Cane

and Sweet Sorghum

• Clarification Plants

• Raw Syrup Concentration Plants

• Fermentation and Distillation Plants

• Boilers and Turbo Sets

/ Diffuser s

Bio-Ethanol

Control Room at Kenana Sugar Co., Sudan. We have replaced stand alone Control System for8 Boilers with state-of-the-art DCS. We also set up a stand by Control Room.

Centralised Control Room for Sugar Plant with Cogeneration facilityat Daund Sugar, India.

A Centralised Control Room for a Cogeneration Plant in Kenya.

Major Customers

International Indian

9 10

• Compagnie Sucrerie Senegalise (CSS) , Senegal

• San Carlos Bioenergy, Philippines

• BISCOM, Philippines

• Butali Sugar, Kenya

• Transmara Sugar, Kenya

• Kibos Sugar & Allied Industries, Kenya

• Consolidated Farming Ltd., Zambia

• Wonji Shoa Sugar, Ethiopia

• Sudanese Sugar, Sudan

• Kenana Sugar Co., Sudan

• Phung Hiep Sugar, Vietnam

• Bien Duong Sugar, Vietnam

• Medine Sugars, Mauritius

• Xinavane Sugar, Mozambique

• Lopez Sugar, Philippines

• SONEDCO, Philippines

• Caroni, Trinidad & Tobago

• HPCL Biofuels

• Daund Sugar

• Core Green Sugars & Fuels

• Bajaj Hindusthan

• Dwarkesh Sugar

• Haidergarh Chini Mills

• Akbarpur Chini Mills

• Dhampur Sugar

• Ramgarh Chini Mills

• Mawana Sugar Works

• EID Parry

• Triveni Sugar

• Empee Sugars & Chemicals

• Titawi Sugar

• Mankapur Chini Mill

• Jai Mahesh Sugars

• Vishwanath Sugars

12000 TCD Sugar Plant, Bajaj Hindusthan, Uttraula, India

2500 TCD Sugar Plant, Consolidated Farming Ltd., Zambia.

13000 TCD Sugar Plant, Mawana Sugar Works, India.

170 TPH, 87 kg / sq.cm. (g), 515 Deg C Bagasse Fired Travelling Grate Boiler supplied by us on a turnkey basis to Mumias Sugar Co., Kenya for their 34 MW Cogeneration Plant. We have supplied / are supplying 30 such boilers to customers across various parts of the world.

Major Customers

International Indian

9 10

• Compagnie Sucrerie Senegalise (CSS) , Senegal

• San Carlos Bioenergy, Philippines

• BISCOM, Philippines

• Butali Sugar, Kenya

• Transmara Sugar, Kenya

• Kibos Sugar & Allied Industries, Kenya

• Consolidated Farming Ltd., Zambia

• Wonji Shoa Sugar, Ethiopia

• Sudanese Sugar, Sudan

• Kenana Sugar Co., Sudan

• Phung Hiep Sugar, Vietnam

• Bien Duong Sugar, Vietnam

• Medine Sugars, Mauritius

• Xinavane Sugar, Mozambique

• Lopez Sugar, Philippines

• SONEDCO, Philippines

• Caroni, Trinidad & Tobago

• HPCL Biofuels

• Daund Sugar

• Core Green Sugars & Fuels

• Bajaj Hindusthan

• Dwarkesh Sugar

• Haidergarh Chini Mills

• Akbarpur Chini Mills

• Dhampur Sugar

• Ramgarh Chini Mills

• Mawana Sugar Works

• EID Parry

• Triveni Sugar

• Empee Sugars & Chemicals

• Titawi Sugar

• Mankapur Chini Mill

• Jai Mahesh Sugars

• Vishwanath Sugars

12000 TCD Sugar Plant, Bajaj Hindusthan, Uttraula, India

2500 TCD Sugar Plant, Consolidated Farming Ltd., Zambia.

13000 TCD Sugar Plant, Mawana Sugar Works, India.

170 TPH, 87 kg / sq.cm. (g), 515 Deg C Bagasse Fired Travelling Grate Boiler supplied by us on a turnkey basis to Mumias Sugar Co., Kenya for their 34 MW Cogeneration Plant. We have supplied / are supplying 30 such boilers to customers across various parts of the world.

• AUTOLISP for auto generation of drawings and bill of materials

• SUGARS for sugar process design

• STAAD PRO for structural design

• Solid WORKS for 3D modeling

• COSMOS for finite element analysis (FEA)

• CAESAR-II for piping stress analysis

• PRO STEEL for 3D Modeling of structure

• VIEWING – Navsio Works Viewer

• PLM for Document Control

• CFD for Flow & Combustion Study

International Codes for design and fabrications

PD 5500 : 2003, BS, IS, NEMA, etc.

12000 TCD Sugar Plant with ZERO Discharge

12

Design Capabilities

3D Sketch of a Travelling Grate Boiler. Such computer aided simulation of boiler

construction and assembly helps us to identify and avoid potential fouling of boiler

parts and structural members, confirm easy accessability to boiler parts and eliminate

reworks during construction.

This picture represents the computer aided flowmodelling technique used by us to predict the

flue gas flow pattern, velocity and temperatureprofile inside the boiler.

We get our designs validated byindependent experts such as IIT, Delhiand Sugar Research International, Australia.

Sugar R search & Innovation

eQl

v

ueens and Uni ersity of Technology

SUGAR RESEARCH

IN ERNATIONAL

T

Rwevie of a 45”x90” inclined set dewatering

J

mill design for ISEC ohn Thompson

G

fCon idential

by

GA Kent and DA Kenny

April 2008

5

Project N . 469-3732

o

edJ

R esign of ournal Bearing for Sugar Cane Crushing Mills

forn

M/s. ISGEC Joh Thompsonc

n

A-4, Se tor 24, Noida - 201 301, U.P., I dia

Rnde

by: Dr. .K. Pa y

tConfiden ial

Indian Institute of Tech ology, Delhin1

Hauz Khas, New Delhi - 1 0 016, IndiaMay-2009

FEA analysis of45" x 90" Mill assembly

showing permissibledisplacement.

11

• AUTOLISP for auto generation of drawings and bill of materials

• SUGARS for sugar process design

• STAAD PRO for structural design

• Solid WORKS for 3D modeling

• COSMOS for finite element analysis (FEA)

• CAESAR-II for piping stress analysis

• PRO STEEL for 3D Modeling of structure

• VIEWING – Navsio Works Viewer

• PLM for Document Control

• CFD for Flow & Combustion Study

International Codes for design and fabrications

PD 5500 : 2003, BS, IS, NEMA, etc.

12000 TCD Sugar Plant with ZERO Discharge

12

Design Capabilities

3D Sketch of a Travelling Grate Boiler. Such computer aided simulation of boiler

construction and assembly helps us to identify and avoid potential fouling of boiler

parts and structural members, confirm easy accessability to boiler parts and eliminate

reworks during construction.

This picture represents the computer aided flowmodelling technique used by us to predict the

flue gas flow pattern, velocity and temperatureprofile inside the boiler.

We get our designs validated byindependent experts such as IIT, Delhiand Sugar Research International, Australia.

Sugar R search & Innovation

eQl

v

ueens and Uni ersity of Technology

SUGAR RESEARCH

IN ERNATIONAL

T

Rwevie of a 45”x90” inclined set dewatering

J

mill design for ISEC ohn Thompson

G

fCon idential

by

GA Kent and DA Kenny

April 2008

5

Project N . 469-3732

o

edJ

R esign of ournal Bearing for Sugar Cane Crushing Mills

forn

M/s. ISGEC Joh Thompsonc

n

A-4, Se tor 24, Noida - 201 301, U.P., I dia

Rnde

by: Dr. .K. Pa y

tConfiden ial

Indian Institute of Tech ology, Delhin1

Hauz Khas, New Delhi - 1 0 016, IndiaMay-2009

FEA analysis of45" x 90" Mill assembly

showing permissibledisplacement.

11

Approvals:

• ISO 9001:2000

• Marking for Gap Frame Presses

• ASME ‘U2’, ‘U’ & ‘S’ Stamps

• National Board, USA ‘R’ Symbol

• National Board, USA ‘NB’ Mark

• Lloyd’s Approved Class-I Manufacturer of Pressure Vessels

• Lloyd’s Approved Foundry

• Department of Transportation (DOT), USA approval for

Liquefiable Gas Containers

• Manufacturing License for Boilers and Pressure Vessels,

China (SQL)

Testing Facilities:

• Radiography upto 200 mm thickness

• Helium Leak Testing

• Mechanised Ultrasonic Testing

• Positive Material Identification (PMI)

• Metallurgical Microscope of 2000x with photography facility

• 22 Channel Spectroscope

0 0• Impact Testing up to -196 C (-320.8 F)

Quality, Health & Safety

Site Activities

13 14

Infrastructure

Shown here is a picture of one of the 10 Pressure Vessel Bays, across 2 locations with a crane lifting capacity of 300 Tonnes. We have 14 Bays for building

Mechanical Equipment and 5 Foundry Bays at 3 sites.

• Shop Area : 95,500 sq. m. (10,28,000 sq. ft.)

• Maximum Crane Capacity : 300 Tonnes

• Maximum Weight of Job (Single Piece) : 750 Tonnes

• Maximum Size of Stress Relieving Furnace : 20m x 8m x 8m

• Maximum Size of Boring Machine : 16m x 4.5m x 2.4m

• Large Floor Type Boring Machines : 11 Nos.

Manufacturing FacilitiesCoastal Plant at Dahej (Gujarat) India Yamunanagar Plant (Haryana) India

A Vacuum Column weighing 575 Tonnes and an Atmospheric

Column weighing 390 Tonnes were fabricated at site and installed

by us for the Crude and Vacuum Distillation Unit of the Indian Oil

Panipat Refinery. One Column was of 10 m (33’) diameter

and the other had a length of 70 m (230’).

Mill & Process House under execution. Boiler under execution.

Approvals:

• ISO 9001:2000

• Marking for Gap Frame Presses

• ASME ‘U2’, ‘U’ & ‘S’ Stamps

• National Board, USA ‘R’ Symbol

• National Board, USA ‘NB’ Mark

• Lloyd’s Approved Class-I Manufacturer of Pressure Vessels

• Lloyd’s Approved Foundry

• Department of Transportation (DOT), USA approval for

Liquefiable Gas Containers

• Manufacturing License for Boilers and Pressure Vessels,

China (SQL)

Testing Facilities:

• Radiography upto 200 mm thickness

• Helium Leak Testing

• Mechanised Ultrasonic Testing

• Positive Material Identification (PMI)

• Metallurgical Microscope of 2000x with photography facility

• 22 Channel Spectroscope

0 0• Impact Testing up to -196 C (-320.8 F)

Quality, Health & Safety

Site Activities

13 14

Infrastructure

Shown here is a picture of one of the 10 Pressure Vessel Bays, across 2 locations with a crane lifting capacity of 300 Tonnes. We have 14 Bays for building

Mechanical Equipment and 5 Foundry Bays at 3 sites.

• Shop Area : 95,500 sq. m. (10,28,000 sq. ft.)

• Maximum Crane Capacity : 300 Tonnes

• Maximum Weight of Job (Single Piece) : 750 Tonnes

• Maximum Size of Stress Relieving Furnace : 20m x 8m x 8m

• Maximum Size of Boring Machine : 16m x 4.5m x 2.4m

• Large Floor Type Boring Machines : 11 Nos.

Manufacturing FacilitiesCoastal Plant at Dahej (Gujarat) India Yamunanagar Plant (Haryana) India

A Vacuum Column weighing 575 Tonnes and an Atmospheric

Column weighing 390 Tonnes were fabricated at site and installed

by us for the Crude and Vacuum Distillation Unit of the Indian Oil

Panipat Refinery. One Column was of 10 m (33’) diameter

and the other had a length of 70 m (230’).

Mill & Process House under execution. Boiler under execution.

Pressure Vessels & Heat Exchangers

Presses: Mechanical & Hydraulic

Castings: Steel & Iron

Contract Manufacturing

Printed in March 2010 Content subject to change, without any prior notice

www.isgec.comwww.isgecgroup.com

ISGECJohn Thompson

IJT

/SP

MB

ro./0

31

0/0

0/D

igitp

Offices

Agents

India : ISGEC John Thompson, A-4, Sector 24, Noida - 201 301 (U.P.) India Tel.: +91-120-330 10 00 to 20Contact: Yogesh MarwahaE-mail: [email protected] (overseas) [email protected] (India)

Chennai • Pune • Mumbai

USA : ISGEC John Thompson North America Office5125 Cochrane Ave., Oakland, California, CA 94618 USA Tel. : +1-510-922-9815Contact: Ashi MalikE-mail: [email protected]

Europe : ISGEC John Thompson Europe OfficeKreiten Strasse 25, 40470 Dusseldorf, Germany Tel.: +49-211-271 63 00Contact: Viren ChadhaE-mail: [email protected]

Across 72 CountriesFor Country specific contact detailsplease write to [email protected]

EPC • Power Plants

Oil / Gas Fired Boilers: Field Assembled & Package Type

Atmospheric Fludised Bed Combustion Boilers

Circulating Fluidised Bed Combustion Boilers

Deaerators

E n g i n e e r i n g f o r E x c e l l e n c e

ISGECJohn Thompson

Sugar Plant&

Machinery

Project Management & Training

We use dedicated teams for Project Management.These include specialists across various functions. We usecentralised ERP (Enterprise Resource Planning) solution fromBaaN and MS Project to control all project activities.

Operational & maintenance personnelfrom customers end undergoing training.

We hold training sessions for our customers,both on site as well as in our office.

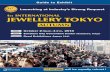

Related Documents

![IJT DOCWebinar[1].ppt - USCIB · Weekly "Pearl TV: 5 TV stations 28 programs Nov 25 Watch, Precious Metal & Optical Industry Newspaper Central](https://static.cupdf.com/doc/110x72/601e2520e1273356c67e60e9/ijt-docwebinar1ppt-uscib-weekly-pearl-tv-5-tv-stations-28-programs-nov.jpg)