ICRA LIMITED Page | 1 Corporate Ratings Rohit Inamdar +91 124 4545 847 [email protected] Pratik Singhania +91 124 4545 801 [email protected] Anil Gupta +91 124 4545314 [email protected] Amit Arora +91 124 4545 318 [email protected] ICRA RESEARCH SERVICES Indian Spinning Industry Ability to mantain capacity utilization and contribtion margin to be a challenge for the spinning industry amid declining yarn exports October 2014

ICRA-Indian Spinning Industry-October 2014 (2)

Sep 05, 2015

ICRA-Indian Spinning Industry-October 2014

Welcome message from author

This document is posted to help you gain knowledge. Please leave a comment to let me know what you think about it! Share it to your friends and learn new things together.

Transcript

-

ICRA LIMITED P a g e | 1

Corporate Ratings Rohit Inamdar +91 124 4545 847 [email protected] Pratik Singhania +91 124 4545 801 [email protected] Anil Gupta +91 124 4545314 [email protected] Amit Arora +91 124 4545 318 [email protected]

ICRA RESEARCH SERVICES

ICRA RATING FEATURE

Indian Spinning Industry

Ability to mantain capacity utilization and contribtion margin to be a challenge for the

spinning industry amid declining yarn exports

October 2014

mailto:[email protected]:[email protected]:[email protected]:[email protected] -

ICRA LIMITED P a g e | 2

A. Global Cotton Scenario Cotton production expected to remain higher than consumption in CY 2014/15, increasing the global stock levels to all time high...7 World cotton balance sheet World cotton stock to use ratio vs. Cotlook A Index China cotton balance sheet World less China cotton balance sheet

B. Trend in International Cotton Prices - Expected increase in global cotton availability has resulted in sharp decline in international cotton prices..9 C. Domestic Cotton Scenario Domestic cotton stock position to improve in CY 2014/15 due to decline in exports ....10

Indias cotton balance sheet and estimate for CY 2014/15

India's yearly cotton and cotton equivalent yarn export

Indias monthly cotton consumption and export

D. Outlook on International Cotton Prices- Cotton prices to soften further due to increase in global availability of cotton in CY 2014/15....11 Cotton prices in India and China vs Cotlook A index

E. Outlook on Domestic Cotton Prices- Domestic prices also expected to decline to align with international prices.12

Trend in India's cotton prices

Cotton stock with mills and equivalent days of consumption

F. Domestic Yarn Scenario: Capacity utilization of the industry to remain under pressure in FY 2014-15 due to expected decline in demand from China...13 Monthly yarn production, capacity utilization and inventory levels

Monthly yarn exports

Spread between cotton and PSF prices and share of cotton yarn production in total spun yarn production

G. Outlook on Margins: While the profitability margins were stable in Q1 FY 2014-15, they are expected to moderate going forward....15 Cotton yarn prices in India, China and Pakistan

Cotton yarn spread in India, China and Pakistan

Trend in India's contribution margin in rupee and USD terms

H. Outlook on Indian spinning industry: Stable to Negative for FY 2014-15 ....17 I. Financial performance of listed Indian spinners and outlook for FY 2014-15.....18 Annexure 1: Rating Distribution - ICRA rated Entities Upgrades in 5M FY 2014-15 continue to outpace the downgrades ...19 Annexure 2: RR-TUFS: Investment in standalone spinning projects remain subdued ... 20

Index

-

ICRA LIMITED P a g e | 3

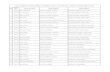

Company Section....21 Ambika Cotton Mills Limited.......22 Bannari Amman Spinning Mills Limited..23 Banswara Syntex Limited..24 Damodar Industries Limited...25 Deepak Spinners Limited .26 Ginni Filaments Limited..27 GTN Industries Limited28 K.P.R. Mill Limited.29 Maharaja Shree Umaid Mills Limited...30 Maral Overseas Limited..31 Nahar Industrial Enterprises Limited.32 Nahar Spinning Mills Limited..33 Nitin Spinners Limited....34 Precot Meridian Limited.35 Rajapalayam Mills Limited...36 RSWM Limited........37 Supreme Tex Mart Limited .38 Super Spinning Mills Limited..39 Sutlej Textiles And Industries Limited .40 Trident Limited.41 TT Limited....42 Vardhman Polytex Limited .43 Vardhman Textiles Limited .44 Winsome Textiles Industries Limited.45 Winsome Yarns Limited..46

-

ICRA LIMITED P a g e | 4

Summary Highlights and Outlook COTTON STOCK POSITION

As global cotton supply outpaces demand, addition to stocks expected to continue for fifth consecutive year leading to all time high stocks at the end of CY1 2014/15; India to emerge as

the worlds largest cotton producer

The global cotton production in CY 2014/15 is expected to remain flat despite a decline in Chinas cotton production as the decline is expected to be offset by an expected increase in

the cotton production in USA. The total cotton production is expected at ~151.1 million bales in CY 2014/15 as against 152.2 million bales in CY2013/14

With expected decline in Chinas cotton production, India is expected to emerge as the largest producer of the cotton in the world with ~25% share in worlds cotton production

The consumption will continue to be driven by China and India and is expected to increase by 3.8% to reach 143.6 million bales; however the consumption would still continue to be

lower than the production which would increase the global stock levels for the fifth consecutive year and reach all time high by end of CY 2014/15, which will be equivalent to ~95% of

annual consumption

Cotton consumption in China to increase due to availability of cotton at market rates from CY 2014/15 which would also limit the imports; imports will only be to meet the shortfall in

production vis--vis consumption

The shift towards the direct subsidy policy from CY 2014/152 would make the domestic cotton available to mills in China at market rates which would increase the cotton consumption

in China which had been declining over the last four years

As the production is expected to continue to remain lower than consumption for CY 2014/15, China would continue to import cotton, though it would be limited to meet only the

shortfall vis--vis consumption. However, if the cotton reserves are liquidated by China, the need for cotton imports would be obviated

Due to limited imports, increase in the cotton stock at the end of the CY 2014/15 is expected to be modest unlike that in the past three years

Decline in cotton imports by China to reduce the exports from India, which would significantly increase the cotton stock position in India compared to the previous years

Due to reduction in demand from China, the raw cotton exports from India are expected to reduce significantly in CY3 2014/15

The cotton production in India in CY 2014/15 is expected to decline modestly due to the late onset of monsoons which is expected to reduce the crop yield, though the decline would

be limited due to higher acreage compared to last year

The domestic consumption of cotton during CY 2014/15 is expected to remain similar to CY 2013/14 as we expect the yarn production levels are unlikely to increase despite growth in

domestic demand as yarn exports are expected to decline. Stable cotton production levels, decline in cotton exports and limited drivers for increase in cotton consumption would

significantly increase the stock position in India compared to that witnessed over the last five cotton seasons, thereby improving raw material availability for the mills

1 Refers to International Cotton Year, which commences from August and ends in July 2 Prior to CY2014/15, Chinese government was procuring cotton directly from farmers at fixed support prices, leading to accumulation of stock with Chinese Government

3 Refers to Indian Cotton Year, which commences from October and ends in September

INDIAN SPINNING INDUSTRY

October 2014

-

ICRA LIMITED P a g e | 5

OUTLOOK ON COTTON PRICES

International cotton prices have declined since announcement by China to terminate its three year old cotton stocking policy and are expected to remain soft on account of increase in

global cotton availability in CY 2014/15

As ICRA Research had noted in this previous note, due to changes in Chinas cotton policy, the international cotton prices have declined since April 2014 after China announced to

terminate its three year old cotton stocking policy. The policy changes would increase Chinas own cotton consumption and reduce the import demand

As the demand from China had resulted in low global stock levels outside China, the global cotton prices remained firm over the last three cotton seasons; however reduction in import

demand from China would increase the global cotton stock levels outside China, thereby putting pressure on international cotton prices

The international cotton prices have already declined by ~24% till August 2014 from that in March 2014 and the December future prices are prevailing further lower by ~9% from

current levels. With the arrival of new crop from October 2014 onwards, the international cotton prices are expected to decline further and may align with the prevailing futures price

The international cotton prices continue to remain sensitive to further changes in Chinas policy, i.e. on release of its cotton reserves, as it would influence the import requirement of

China and thereby the global stock levels outside China and also the prices

Domestic prices are also expected to decline in CY 2014/15 and align with the international prices

Though the international cotton prices had declined since April 2014, the domestic cotton prices had remained firm and had in fact increased till May 2014 on account of tight

domestic stock position due to high levels of cotton and cotton equivalent yarn export in CY 2013/14

While approaching to the new cotton season, revival of monsoons from late July/August 2014 and cautious approach being adopted by players in the textile value chain, the domestic

prices had also been declining since June 2014

With the arrival of new crop, the domestic prices are expected to decline further as it converges with the international cotton prices, given the limited trade restrictions on cotton

import/export and also due to the expectation of increase in the domestic cotton stock levels at the end of CY 2014/15

Domestic cotton prices were already below the Minimum Support Price (MSP) in August 2014 and with expectation of further decline in the prices, the possibility of significant MSP

operations by the government during the CY 2014/15 is fairly high

DOMESTIC YARN SCENARIO

Capacity utilization of the Indian spinning industry is likely to remain under pressure in FY 2014-15 due to expected reduced export demand

The domestic cotton yarn production remained steady in Q1 FY 2014-15 with production increasing by 4.5% over the same period last year

Increase in yarn production and thereby of the capacity utilization of the Indian spinning industry over the last two years was driven by export demand led by China

Due to expected decline in the demand from China, the demand for Indian yarn is likely to decline and may pose pressure on capacity utilization levels which may result in decline in

yarn production during the year unless supported by increase in domestic demand

With reduced export demand and steady growth in the production, the domestic inventory levels for cotton yarn had increased in Q1 FY 2014-15

Margins were stable in Q1 FY 2014-15 compared to that in Q4 FY 2013-14; however expected to decline in Q2 FY 2014-15; subsequently the profitability to remain under pressure due to

expected decline in capacity utilization levels

The average export price of yarn for Indian spinners during 5M FY 2014-15 had been lower by ~5.8% compared to the same period last year in USD terms; however due to rupee

depreciation, the domestic yarn prices in rupee terms had been at similar levels

-

ICRA LIMITED P a g e | 6

The yarn prices have however started declining from August 2014 in rupee as well as USD terms on account of decline in cotton prices and with the expectation of lower cotton prices

in CY 2014/15 and are expected to decline further from the current levels

The contribution margin for the Indian spinners during 5M FY 2014-15 remains lower compared to that over the corresponding period last year due to limited increase in yarn prices

and higher cotton prices during CY 2013-14. The average contribution margin for yarn export during this period was ~USD 1.37/Kg which is lower by ~11.2% over the previous

corresponding period; while the spread for domestic sales was ~Rs. 82/Kg, which was lower by ~4.4%

The EBDITA margin in Q1 FY 2014-15 had been similar to that in Q4 FY 2013-14 at ~15% as the yarn prices were flat during this period and the cotton procurement cost for the mills

remained at similar levels as that in Q4 FY 2013-14

The EBDITA margins of the Indian spinners is however likely to moderate in Q2 FY 2014-15 to ~12% as the yarn prices have declined from August 2014; the extent of impact on

profitability will depend on the quantum of cotton stock and carrying cost held by the mill

Subsequently, from Q3 FY 2014-15 onwards, while the decline in cotton prices is expected to be beneficial for the industry, however reduced export demand will pose pressure on the

capacity utilization levels of the Indian spinners. With expected pressures on capacity utilization, the contribution margins for the mills are also expected to come under pressure, which

would result in downward pressure on the profitability in H2 FY 2014-15

OUTLOOOK ON THE INDIAN SPINNING INDUSTRY

Outlook on the Indian spinning industry is stable with possible downside risk on account of expected reduction in export demand for yarn; Indian spinners to however benefit from lower

cotton cost which shall reduce their funding requirements

The outlook on the Indian cotton spinning industry is stable with possible downside risk on account of risk emanating from changes in Chinas cotton policy for CY 2014/15

The yarn export from India which had increased to ~33% of the total production in FY 2013-14 due to strong demand from China, is expected to be impacted in FY 2014-15. As a result,

the ability of industry to maintain high capacity utilization as well as contribution levels in a declining demand scenario would be a challenge

However, on the positive side, the decline in the domestic cotton prices in CY 2014/15 will reduce the input cost for the industry as well as inventory funding requirements apart from

possible improvement in domestic demand for cotton yarn on account of increased competitiveness as compared to synthetic fibers

Moreover, given the uncertainty on the Chinas policy on liquidation of its huge cotton stock and expectations of sufficient availability of cotton in upcoming season, the mills are

expected to be cautious while stocking cotton during CY 2014/15 to avoid any inventory loss.

Import duty on cotton and cotton yarn in China to remain a key determinant of cotton yarn exports from India

While the cotton consumption in China is likely to increase in CY 2014/15, given its sizeable requirement of cotton yarn, it would continue to meet its requirement either through

cotton and/or cotton yarn imports

If the state reserve of cotton stock is not liquidated, continued duty free import of yarn and/or sustained import duty on cotton imports will be key determinants for ensuring that the

demand for yarn is met through import of yarn, rather than import of cotton

Reduced import duty on cotton and/or levy of import duty on yarn, can partially shift the Chinese demand to cotton from cotton yarn as was the case prior to CY 2011/12

-

ICRA LIMITED P a g e | 7

Global Cotton Scenario Global cotton stock levels expected to reach all time high at the end of CY 2014/15, higher than the initial estimate, though the increase in stock levels would be the lowest compared to that witnessed over the last three years

Sources: ICRA Estimates, Industry data, ICAC, USDA The above data refers to International cotton year which commence from August and ends in July

The global closing cotton stock level for the cotton year ending July 2014 (CY 2013/14) is expected to be higher by ~2% compared to

the previous estimate and reach all time high of ~128.5 million bales which would be equivalent to stock to consumption ratio of 93%

at the end of CY 2013/14 compared to the previous estimate of ~89%. The revision in the global closing stock level for CY 2013/14 is

on account of increase in the production estimate, mainly of India, and decrease in global cotton consumption, mainly in China. For

the CY 2014/15, the global closing cotton stock level is expected to increase for the fifth consecutive year, similar to what was

estimated earlier. While the production is expected to decline by ~0.6% and consumption to increase by ~3.8% in CY 2014/15, the

production would still remain higher than consumption, which would result in increase in global cotton stock levels, whereby the

closing stock is expected to reach all time high of ~136.1 million bales by the end of CY 2014/15.

However, the built up in global cotton stock levels had been reducing over the last three years due to decline in cotton production and

increase in consumption; and the increase in the stock levels in CY 2014/15 would be the lowest compared to that witnessed over the

past three years. While the decline in cotton production in CY 2014/15 is expected to be driven by top two cotton producing

countries, China and India; the extent of decline will be partially offset by the expected increase in cotton production in the third

largest producer, USA, which would keep the decline in total cotton production modest at ~0.6% to ~151.1 million bales. The cotton

production estimate for CY 2014/15 is however higher by ~2% from the previous estimate on account of expected increase in

production in India due to revival of the monsoons from late July/August 2014 and also increase in production in USA which is due to

increase in acreage and improved weather conditions. The increase in the global cotton consumption in CY 2014/15 is expected to be

driven by top two consuming countries, China and India, and is expected to reach 143.6 million bales, which is in line with the earlier

estimate.

The decline in cotton production in China is expected on account of decline in acreage in regions other than Xinjiang (Xinjiang region

accounts for ~50~55% of total cotton production in China) as there was no clarity on the implementation of the direct subsidy policy

in other regions. In April 2014, China had terminated its three year old cotton stocking policy under which it was purchasing cotton at

fixed support price from the farmers and would shift to direct subsidy based policy from CY 2014/15 under which the farmers would

sell cotton at the market price and in case the market price is lower than the government set target price, the difference (subsidy)

would be paid directly to the farmers.

China has set the target prices of Yuan 19,800/ton for CY 2014/15 which is lower than the support price of Yuan 20,400/ton for CY

2013/14 and CY 2012/13 under the cotton stocking policy, though it is equal to the support price for CY 2011/12. As the direct subsidy

policy is to be initially implemented only in Xinjiang region, uncertainty on the market price and whether the direct subsidy policy

would be extended to other regions as well are the key reasons for expected decline in the cotton production in China in CY 2014/15.

-

ICRA LIMITED P a g e | 8

World Cotton Balance Sheet Million bales of 170 Kgs Jul-10 Jul-11 Jul-12 Jul-13 Jul-14 Jul-14E Jul-15E Jul-15E

Estimate as on Sep-14 May-14 % Change Sep-14 May-14

Opening stock 79.5 60.3 64.5 94.1 115.0 115.3 0% 128.5 125.4 Production 131.7 150.0 162.1 157.4 152.0 150.0 1% 151.1 147.9 Trade: (Import/Export) 45.5 45.5 58.8 59.8 51.7 51.7 0% 45.1 46.6 Consumption 152.3 146.9 132.0 136.4 138.3 140.1 -1% 143.6 143.2 Closing Stock 60.3 64.5 94.1 115.0 128.5 125.4 2% 136.1 130.3 Stock to use ratio 40% 44% 71% 84% 93% 89% 95% 91% Sources: ICRA Estimates, Industry data, ICAC, USDA

China Cotton Balance Sheet Million bales of 170 Kgs Jul-10 Jul-11 Jul-12 Jul-13 Jul-14E Jul-14E Jul-15E Jul-15E

Estimate as on Sep-14 May-14 % Change Sep-14 May-14

Opening stock 27.4 18.2 13.6 39.8 64.5 64.5 0% 79.4 76.3 Production 41.0 39.1 43.5 44.8 41.0 41.0 0% 37.8 37.8 Trade: (Import) 14.0 15.4 31.4 26.0 18.1 16.4 10% 10.2 10.9 Consumption 64.0 58.9 48.7 46.1 44.2 45.5 -3% 46.7 47.4 Closing Stock 18.2 13.6 39.8 64.5 79.4 76.3 4% 80.6 77.5 Stock to use ratio 28% 23% 82% 140% 180% 168% 172% 164% Sources: ICRA Estimates, Industry data, ICAC, USDA

The cotton stock level in China is estimated to have increased by ~4% at the end of CY 2013/14 from the initial estimate to ~79.4 million

bales on account of higher imports and decline in consumption. As the shift towards the direct subsidy policy from CY 2014/15 would

make the domestic cotton available to mills in China at market rates, it would increase the domestic consumption of cotton which had

been declining over the past few years due to high domestic cotton prices (higher than global prices) and high import duty on cotton (peak

import duty of 40%), which had resulted in increased yarn imports which had remained duty free. While production (~37.8 million bales) is

expected to remain lower than consumption (~46.7 million bales) in CY 2014/15 as well, the cotton imports would be limited mostly to

meet the shortfall in the domestic production vis--vis consumption, which would keep the increase in cotton stock levels modest unlike

that in the past when most of the domestic cotton was stocked under the governments cotton stocking policy. As a result, cotton stock

levels are expected to increase only modestly by ~1.5% to 80.6 million bales by end of CY 2014/15 which would be equivalent to stock to

consumption ratio of 172% at the end of CY 2014/15 compared to 180% at the end of CY 2013/14. However, China would continue to

account for most of the global cotton stock at ~59% at the end of CY 2014/15 compared to ~62% at the end of CY 2013/14.

Despite the increase in cotton consumption in China in CY 2014/15, given the sizeable requirement of cotton yarn, it would continue to

meet a part of its requirement through import of cotton/cotton yarn. Prior to implementation of the cotton stocking policy in CY 2011/12,

China had an annual cotton consumption of ~58~64 million bales. As a result, with expected consumption of 46.7 million bale of cotton in

CY 2014/15, the balance requirement of cotton/cotton yarn would continue to be met through imports, the proportion of which may

however vary in CY 2014/15 compared to that in CY2013/14 depending on the import duty structure on cotton and cotton yarn. However,

the above assumption of import of cotton and cotton yarn would be contingent on the policy on liquidation of cotton stock by China from

its reserves as release of cotton at import parity prices (including import duty) would obviate the need to import any cotton/cotton yarn in

CY 2014/15.

he

Sources: ICRA Estimates, Industry data, ICAC, USDA The above data refers to International cotton year which commence from August and ends in July

-

ICRA LIMITED P a g e | 9

Trend in international cotton prices Expected increase in global cotton availability due to change in Chinas cotton policy has resulted in sharp decline in international cotton prices

Cotlook A: Jan-14 Feb-14 Mar-14 Apr-14 May-14 Jun-14 Jul-14 Aug-14 Dec-14 (F) Jun-Aug 14 Mar-May 14 Jun-Aug 13

Cotlook (Cents/Pound) 90.96 94.05 96.95 94.20 92.71 90.90 83.84 74.00 67.44 82.91 94.62 92.80 Cotlook ($/kg) 2.01 2.07 2.14 2.08 2.04 2.00 1.85 1.63 1.49 1.83 2.09 2.05 YoY Change 6% 5% 3% 2% 0% -2% -9% -20% -23% -11% 1% 11% Cotlook A is an index representative of the level of offering prices on the international raw cotton market. It is an average of the cheapest five quotations from a selection (at present numbering nineteen) of the principal upland cottons traded internationally

The Cotlook A Index which had remained range-bound at ~USD 2/Kg over last three cotton seasons, had been declining since April 2014 after the announcement by China to discontinue its

three year old cotton stocking policy, which had supported the global prices over this period, despite the rising global stock levels. China had been purchasing its domestic cotton at support

prices which were higher than the international prices and most of the global cotton stock was being built up in China which is estimated to have accumulated cotton stock equivalent to ~62%

of the global stock at the end of CY 2013/14. Due to higher prices, the cotton stock in China was not available to the mills in China which had relied on import of cotton/cotton yarn from other

countries to meet their requirement. This had resulted in tight global cotton position outside China and had kept the global prices firm. However with shift to direct subsidy policy in China from

CY 2014/15, the global availability of cotton would improve (world less cotton stock to demand ratio expected to increase to 39% at end of CY 2014/15 compared to 33% in the previous year)

and this has resulted in decline in the international cotton prices. In addition to the cotton policy change in China, increase in estimate global cotton production in CY 2014/15 had also

contributed to the decline in the international cotton prices. The Cotlook A Index which was at USD 2.1/Kg in March 2014 had declined by 24% to USD 1.6/Kg in August 2014 and the December

futures are prevailing lower by further ~9% at ~USD 1.5/Kg.

-

ICRA LIMITED P a g e | 10

Indian Cotton Scenario Domestic cotton stock position to improve in CY 2014/15 due to decline in exports which is expected on account of reduced demand from China

The domestic stock position at the end of cotton year which ends in September 2014 (CY 2013/14) is expected to improve from the previous

estimate with closing stock of ~3.3~3.6 million bales which would be equivalent to stock to consumption ratio of ~11~12% at the end of CY

2013/14 compared to the previous estimate of ~6~8%. The improvement in the domestic stock position had been driven by revision in the

production estimate for CY 2013/14 by ~7% in line with the revision in the production estimate by Cotton Advisory Board (CAB). The revision

in the production estimate by CAB was anticipated while making the previous estimate in the backdrop of high levels of exports during the

year, which would have otherwise reduced the closing stock levels to the lowest level since the last two decades. Despite the improvement

in the expected stock position, it would continue to remain tight with stock of only ~1.5 months of consumption at the end of CY 2013/14.

The cotton production in CY 2014/15 is expected to be ~38~39 million bales, which is a modest decline of ~3% over CY 2013/14. While the

cotton acreage is higher by ~10% at 12.5 million hectare, expected reduction in yield due to scattered and late onset of the monsoons is

expected to result in decline in the production in CY 2014/15. The cotton exports are expected to decline significantly by ~40% in CY

2014/15 on account of reduced demand from China as the cotton prices in China are expected to align with the international prices on

import parity basis (including import duty) which would reduce the cotton imports by China. While the yarn exports are also expected to

decline due to decline in demand from China as it increases the consumption of its domestic cotton, improvement in the domestic demand

in India and shift towards cotton yarn due to decline in price differential between cotton and polyester fiber prices is expected to keep the

cotton consumption at similar levels as that in CY 2013/14. As a result, due to reduced exports, the closing stock levels are expected to

increase significantly to ~6.5~7.5 million bales, which would increase the stock to consumption ratio to ~24%, the highest since last five

cotton seasons.

Indian Cotton Balance Sheet Mn bales of 170 kgs CY10 CY11 CY12 CY13 CY14 CY14 CY14 CY15

Actual Actual Actual Actual

Provisional as on July 2014

ICRAs Revised Estimates (Sep-14)

ICRAs Earlier Estimates (May-14)

ICRAs Estimate (Sep-14)

Opening stock 7.2 4.1 4.6 4.0^ 3.5 3.5 3.5 3.3~3.6 Production 30.5 33.9 35.3 36.5 39.0 39.0~40.0 36.5~37.5 38.0~39.0 Imports 0.6 0.2 1.2 1.5 0.8 0.7~0.9 1.0~1.5 0.8~1.0 Consumption 25.9 26.0 25.3 28.3 28.7 28.6~29.2 29.2~29.7 28.6~29.2 Exports 8.3 7.7 12.9 10.1 11.4 11.4~11.6 10.0~10.5 6.5~7.5 Closing Stock 4.1 4.6 2.9^ 3.5 3.2 3.3~3.6 1.8~2.3 7.0 Stock to use ratio 16% 18% 11% 12% 11% 11~12% 6~8% 24% Sources: ICRA Estimates, CCI, Cotton Advisory Board of India (CAB); The above data refers to Indian cotton year (CY) which commence from October and ends in September ^During April 2013, CAB revised its opening stock estimates for CY2013

Monthly cotton consumption and exports Mn bales of 170 kgs Jan-14 Feb-14 Mar-14 Apr-14 May-14 Jun-14 9M CY 14 9M CY 13 % Change CY 13

Cotton Consumption 2.52 2.32 2.51 2.42 2.46 2.42 21.86 20.36 7% 28.32 Cotton Exports 2.06 1.42 1.31 0.92 0.65 0.36 11.23 9.48 18% 10.14 Sources: Textile Commissioner, USDA

Sources: ICRA Estimates, Industry data, USDA, Textile Commissioner, Cotton Advisory Board of India; Cotton Corporation of India, Ministry of Agriculture, Government of India. The above data refers to the Indian cotton year which commences in October and ends in September

-

ICRA LIMITED P a g e | 11

Outlook on International Cotton Prices (CY 2014/15) - International cotton prices to soften further on account of increase in global availability of cotton; Chinas policy on sale of its cotton reserves remains key driver for the international cotton prices

Sources: ICRA Estimates, Industry data, Cotton Outlook Limited Cotton prices are for ginned cotton.

The international cotton prices had been declining since April 2014 after the announcement by China on termination of its three year old

cotton stocking policy and shift towards direct subsidy policy which is expected to make the cotton available to mills in China at market

rates, reducing their import requirement for cotton and cotton yarn. As the import demand from China had resulted in low global stock

levels outside China, which had kept the global cotton prices firm over the last three cotton seasons, reduction in import demand from

China would increase the cotton stock levels outside China, which shall result in softening in the international prices. As the cotton from

new cotton season CY 2014/15 shall be available from end of September/October 2014, the international cotton prices have already

declined by ~24% till August 2014 from the price in March 2014 and the December future price are prevailing further lower by ~9%. The

international cotton prices are expected to align with the future price at ~USD 1.5/Kg for CY 2014/15 compared to ~USD 2.0/Kg which had

prevailed over the last three cotton season. Moreover, as the global cotton position turns surplus from CY 2014/15, the international

prices shall be driven by the prices in the main consuming country, i.e. China unlike the prices in the previous cotton seasons when the

prices were driven by the prices in the main supplying country i.e. India, as the global stock position (excluding China) was tight.

As the international prices shall be driven by the prices in China, they remain sensitive to Chinas policy on release of cotton from its

reserves which hold ~62% of global cotton stock. Release of cotton from the reserves at prices such that it is lower than the landed cost of

imported cotton (international cotton price plus import duty), would further reduce the import demand from China from the current

estimate. This would increase stock levels outside China, which shall in turn lead to further decline in the international prices.

Mar-14 Apr-14 May-14 Jun-14 Jul-14 Aug-14 11M CY 14 11M CY 13 % Change

Cotton Prices (USD/Kg) 1.93 1.96 2.00 1.98 1.95 1.84 1.92 1.88 2% % change YoY -3% -1% 4% 2% -2% -10% Sources: Textile Commissioner, ICRA research

-

ICRA LIMITED P a g e | 12

Outlook on Domestic Cotton Prices (CY 2014/15) - Domestic prices also expected to decline to align with international prices and also due to improvement in domestic stock position

Sources: ICRA Estimates, Industry data, Cotton Advisory Board of India; Cotton Corporation of India. Cotton prices are for ginned cotton

Though the international cotton prices had declined since April 2014, the domestic cotton prices had remained firm and had increased till

May 2014 in both dollar and rupee terms on account of tight domestic stock position due to high levels of cotton and cotton equivalent

yarn export. The pending cotton arrivals as on June 2014 was ~3.0 million bales while the cotton stock with the mills was ~5.1 million

bales, resulting in total availability of ~8.1 million bale of cotton till end of CY 2013/14, which was just sufficient to meet the cotton

requirement.

However, the domestic prices had been declining since June 2014 as the new cotton season approaches, to align with the international

prices and also easing of production concerns for CY 2014/15 after recovery of monsoon from late July/August 2014. The domestic cotton

prices in August 2014 was USD 1.8/Kg which is lower by ~8% compared to the price in May 2014 and lower by ~10% on YoY basis. The

domestic cotton prices in August 2014 was Rs. 111.8/Kg in rupee terms which is lower by ~9% compared to the price in May 2014 and

lower by ~13% on YoY basis.

The domestic prices are expected to decline further as it converges with the international cotton prices, given the limited trade

restrictions on cotton import/export and also due to the expectation of increase in the domestic cotton stock levels at the end of CY

2014/15. With domestic cotton prices already below the Minimum Support Price (MSP) in August 2014 and with expectation of further

decline in the prices, the possibility of significant MSP operations by the government during the CY 2014/15 is high.

The decline in the cotton prices would however reduce the funding requirement for the Indian spinning mills who typically stock their

cotton requirements for the entire season during the harvest season which is till March. Moreover, given the susceptibility of the cotton

prices on Chinas policy on liquidation of its cotton reserve, the spinning mills are likely to adopt a cautious approach whi le stocking

cotton for the CY 2014/15.

Mar-14 Apr-14 May-14 Jun-14 Jul-14 Aug-14 11M CY 14 11M CY 13 % Change

Cotton Prices (Rs./Kg) 117.99 118.20 123.27 118.23 117.12 111.79 117.58 105.29 12% % change YoY 10% 10% 16% 6% -2% -13% Cotton Prices (USD/Kg) 1.93 1.96 2.00 1.98 1.95 1.84 1.92 1.88 2% % change YoY -3% -1% 4% 2% -2% -10% Sources: Textile Commissioner, ICRA research

-

ICRA LIMITED P a g e | 13

Decline in demand from China has reduced the cotton yarn exports from India which has increased the domestic inventory levels as the production has remained steady

The domestic cotton yarn production continued to remain steady with production increasing by 4.5% during Q1 FY2014-15 over the

same period last year, though it has moderated from the growth of 9.8% witnessed in FY 2013-14. The increase in the production had

been driven by improved capacity utilization of the mills which had operated at an average of ~96% utilization level during this period

compared to utilization level of ~92% in the same period last year.

As the spinning mills have been operating at high utilization levels, the pace of growth is likely to slow down going forward, even if

the current demand sustains, as also reflected in stagnation in the production volumes since September 2013.

The increase in the production and thereby of the capacity utilization (from ~80% in FY 2011-12 to ~95% in FY 2013-14) of the Indian

spinning industry over the last two years was primarily on account of substantial increase in the export demand, primarily from

China, which was driven by high cotton prices in its domestic market and import restrictions on cotton, thereby making it cheaper to

import cotton yarn rather than cotton.

As the cotton prices in China has eased since April 2014 due to reduction in the reserve auction price (to Yuan 17,250/ton from Yuan

18,000/ton earlier) and expectation of lower prices in CY 2014/15 with shift to direct subsidy policy, the demand of yarn from China

has witnessed a decline in Q1 FY 2014-15 due to increase in its domestic production as also reflected in decline in yarn exports from

India by ~5.6% in Q1 FY 2014-15 over the same period last year. The export registration for yarn in volume terms in Q1 FY 2014-15

has reduced by ~18% on YoY basis and by ~21% on QoQ basis with the proportion of yarn export registration to total yarn production

declining to ~29% in Q1 FY 2014-15 as compared to ~36% in Q4 FY 2013-14.

Despite the decline in yarn exports, the domestic yarn production had remained steady which along with relatively flat domestic

demand has resulted in increase in the domestic yarn inventory levels in Q1 FY 2014-15 which has increased to ~13 days as compared

to ~11 days in Q4 FY 2013-14 and Q1 FY 2013-14.

2.9 3.1 3.5 3.1 3.6 3.9 1.0

1.0 1.11.2

1.21.3

1.4

0.3

1.41.5

1.51.5

1.371.3

0.3

19% 19%20%

24%

31%33%

27%

15%

20%

25%

30%

35%

0.0

1.0

2.0

3.0

4.0

5.0

6.0

7.0

Mar-09 Mar-10 Mar-11 Mar-12 Mar-13 Mar-14 3M Mar-15

Pro

du

ctio

n -

Mill

ion

To

ns

Trend in Yarn Production and Exports

Cotton Yarn Blended Spun Yarn

Man Made filament Yarn % Cotton Yarn Export (RHS)

Sources: ICRA Estimates, Industry data, Ministry of Textiles, Textile Commissioner

-

ICRA LIMITED P a g e | 14

Capacity utilization of the Indian spinning mills is likely to decline in FY 2014-15 due to reduced export demand unless supported by increase in domestic demand

With the expectation of further easing of cotton prices in China with the arrival of new cotton in CY 2014/15, the demand for Indian

yarn is likely to decline and may pose pressure on capacity utilization levels which may result in decline in yarn production during the

year unless supported by increase in domestic demand.

Around 20% reduction in export demand in FY 2014-15 (as per the trend during Q1 FY 2014-15) without corresponding pick up in the

domestic demand may result in decline in capacity utilization of the spinning mills to ~90% compared to ~95% in the previous year.

Given the substantial nature of fixed overheads, the decline in the capacity utilization would also result in moderation in the

profitability.

Within spun yarn*, which accounts for most of the domestic yarn production at ~80% in FY 2013-14, the share of cotton yarn vs blended

yarn has ranged from ~74% to 76% over the last two years depending upon the price differential between the cotton and polyester fiber.

The proportion of cotton yarn in total spun yarn production during Q1 FY 2014-15 had declined to 74.2% from 74.7% in Q4 FY 2013-14 on

account of increase in the price differential between cotton and polyester fiber to ~Rs. 22.1/Kg from ~Rs. 19.8/Kg.

*Spun yarn refers to yarn manufactured on spindles/rotors

70%

75%

80%

85%

90%

95%

100%

300

320

340

360

380

400

420

440

460

480

Apr-13 Jul-13 Oct-13 Jan-14 Apr-14 Jul-14

Pro

du

ctio

n -

Mill

ion

Kg

Trend in Total Spun Yarn Production and Capacity Utilisation

Spun Yarn Production Capacity Utilisation (RHS)

Sources: ICRA Estimates, Industry data, Ministry of Textiles, Textile Commissioner

-

ICRA LIMITED P a g e | 15

Spread between yarn and cotton prices during 5M FY 2014-15 remain lower over the previous period on account of higher cotton prices

2.5

3.0

3.5

4.0

4.5

Apr-12 Aug-12 Dec-12 Apr-13 Aug-13 Dec-13 Apr-14 Aug-14

US$

/Kg

International Cotton Yarn Prices

China India Pakistan

0.4

0.6

0.8

1.0

1.2

1.4

1.6

1.8

2.0

Apr-12 Aug-12 Dec-12 Apr-13 Aug-13 Dec-13 Apr-14 Aug-14

US$

/Kg

Cotton Yarn Spread - US$/Kg

China India Pakistan

Sources: ICRA Estimates, Industry data, Ministry of Textiles, Textile Commissioner The above data refers to the Indian financial year which begins in April and ends in March

The average export price of yarn for Indian spinners price during 5M FY 2014-15 had been lower by ~5.8% compared to the same period

last year; however due to rupee depreciation, the domestic yarn prices in rupee terms had been at similar levels.

The domestic yarn price in August 2014 was Rs. 195/Kg while the yarn export price was USD 3.2/Kg. While the yarn prices in USD and local

currency terms in both China and Pakistan had been lower during 5M FY 2014-15 over the corresponding previous period by ~4~6%, the

rupee prices of yarn in India had been flat.

The yarn prices have however started to decline from August 2014 on account of decline in cotton prices and with the expectation of lower

cotton prices in CY 2014/15, the yarn prices are expected to decline from the current levels from October/November 2014. The yarn prices

(in USD) in the three major yarn producing countries i.e. China, India and Pakistan had been declining since April 2014 with the decline in

the international cotton prices after the announcement by China to shift to direct subsidy based policy which is expected to improve the

global cotton availability from CY 2014/15.

The export spread (difference between yarn and cotton prices) for the Indian spinners during 5M FY 2014-15 remains lower compared to

that over the corresponding period last year as the decline in the yarn prices (in USD terms) had been more than that in the cotton prices.

The average spread during this period was ~USD 1.37/Kg which is lower by ~11.2% over the previous corresponding period.

The average spread in rupee terms (~Rs.82/Kg during 5M FY 2014-15) had also been lower compared to the previous corresponding period,

though the decline had been lower at ~4.4% due to rupee depreciation. The average exchange rate during 5M FY 2014-15 was Rs. 60/USD

compared to ~Rs. 58/USD in the previous year with rupee depreciating by ~3.9% over this period.

-

ICRA LIMITED P a g e | 16

Margins in Q1 FY 2014-15 were stable due to stable yarn prices, though likely to moderate in Q2 FY 2014-15

While the spread in Q1 FY 2014-15 in rupee terms (Rs. 81.7/Kg) was higher by ~4% and in USD terms (USD 1.4/Kg) by ~9% compared to that in Q4 FY 2013-14 (Rs. 78.8/Kg and USD 1.3/Kg

respectively), the profitability had been at similar levels as the yarn prices were flat during this period while the average cotton procurement cost for the mills remained at similar levels as

that in Q4 FY 2013-14 because mills typically stock cotton during the harvest season till March 2014 for the remaining period of the cotton year. The yarn prices had moderated with the

decline in the cotton prices in Q2 FY 2014-15, however due to higher cost cotton procured during the cotton harvest season, the profitability of the Indian spinners is expected to moderate

from that witnessed in Q1 FY 2014-15. Moreover decline in the capacity utilization levels due to slowdown in the export demand would also have an impact on the profitability in Q2 FY

2014-15.

Mar-14 Apr-14 May-14 Jun-14 Jul-14 Aug-14 5M-FY 15 5M-FY 14 % Change

Cotton Yarn Prices (Rs./Kg) 196 202 200 198 200 195 199 201 -1% % change YoY 2% 0% 4% 0% -2% -6% Cotton Yarn Prices (USD/Kg) 3.17 3.37 3.32 3.35 3.33 3.23 3.32 3.53 -6% % change YoY -10% -9% -7% -4% -3% -5% Contribution (Rs./Kg) 78.06 83.79 81.56 79.87 83.18 82.98 82.28 86.05 -4% % change YoY -7% -11% -5% -7% -2% 5% Contribution (USD/Kg) 1.24 1.41 1.32 1.37 1.38 1.39 1.37 1.55 -11% % change YoY -21% -19% -20% -12% -3% 2% Source: Textile Commissioner, ICRA research

-

ICRA LIMITED P a g e | 17

Outlook on Indian spinning industry: Stable with possible downside risk on account of expected reduction in export demand for yarn which would put pressure on the capacity utilization and contribution margin of the Indian spinners; Indian spinners to however benefit from low cotton cost which shall reduce their funding requirements

Due to increase in cotton prices during CY 2013/14 (from Q3 FY 2013-14 onwards) with relatively modest increase in yarn realization, the contribution margin of the Indian spinners had

reduced since onset of new cotton season. As a result, the profitability of the Indian spinners had declined in H2 FY 2013-14, though it remained robust. The profitability in Q1 FY 2014-15 was

stable as that in Q4 FY 2013-14 as the domestic yarn prices were stable while the cotton procurement cost remained at similar levels as that in Q4 FY 2013-14 due to stocking of cotton by the

spinning mills during the harvest season which ends in March.

The profitability is however likely to moderate in Q2 FY 2014-15 as the yarn prices have declined with decline in cotton prices while the cotton procurement cost shall remain at similar level

to that in the last quarter. Moreover, as the yarn demand from China is expected to reduce, the capacity utilization of the Indian spinners would be under pressure which would result in

downward pressure on the profitability in H2 FY 2014-15 given the substantial overheads and also on account of oversupply in the market.

The outlook on the Indian cotton spinning industry is stable with possible downside risk on account of risk emanating from the changes in the Chinas cotton policy for CY 2014/15, which is

already evident in reduced prices of cotton futures. As against the average of USD 2.0/Kg of Cotlook A price for CY 2013/14, the Cotlook A futures for December 2014 are currently prevailing at

USD 1.49/Kg, which will also result in decline in the domestic cotton prices as it converges closer to the international prices, given the limited trade restrictions on cotton import/export and

expected improvement in the domestic stock levels at the end of CY 2014/15. The domestic cotton prices in August 2014 has already fallen below the Minimum Support Price (MSP) and given

the expectation of further reduction in the cotton prices in CY 2014/15, the possibility of substantial support operations under MSP by the government is fairly high. Since the decline in cotton

prices will coincide with the beginning of cotton season, when the stocks with the mills are lowest, the risk of inventory losses for mills (as happened in FY 2011-12) is low.

The decline in cotton prices will be beneficial for industry as it will reduce the input cost as well as inventory funding requirements apart from improving demand for cotton yarn on account of

increased competiveness with respect to synthetic fibers which shall result in fiber substitution. However as the increase in the capacity utilization and thereby of yarn production over the last

two years was driven by the demand from China which had resulted in yarn export from India reaching all time high of 33% of domestic production in FY 2013-14, the export volumes of Indian

yarn will be adversely impacted as China increases the consumption of its domestic cotton stocks to meet its yarn demand. As a result, the ability of industry to maintain high capacity

utilization as well as profit contribution levels in a declining demand scenario would be a challenge.

Around 20% reduction in export demand in FY 2014-15 (as per the trend during Q1 FY 2014-15) without corresponding pick up in the domestic demand may result in decline in capacity

utilization of the spinning industry to ~90% compared to ~95% in the previous year. Moreover, given the uncertainty on the Chinas policy on liquidation of its huge cotton stock, the mills are

expected to be cautious while stocking cotton during CY 2014/15 to avoid any inventory loss. Liquidation of cotton stock by China at prices which are lower than the landed cost of imported

cotton (including import duty) would further lower Chinas import demand of cotton from the current estimate, which would further depress the international cotton prices and could result in

inventory loss for those players who stock substantial cotton inventory.

Though the cotton prices in China are likely to decline from CY 2014/15 which would increase its domestic yarn production, however given its significant requirement of cotton and cotton

yarn, China, to an extent would continue to remain dependent on import of cotton/cotton yarn to meet its requirement, if the huge cotton stock is not liquidated. As a result, continued duty

free imports of yarn as well as continuance of the import duty on cotton imports will be critical to ensure that the Chinese yarn demand is met through import of yarn, rather than import of

cotton. Reduced import duty on cotton by China will shift the Chinese yarn demand from import to its domestic sources, which was the practice prior to CY 2011/12.

-

ICRA LIMITED P a g e | 18

Financial performance had remained steady in Q1 FY 2014-15; however it is expected to moderate going forward on account of profitability pressure due to reduced demand

The financial performance of the Indian spinning industry was stable in Q1 FY 2014-15 as compared to that in Q4 FY 2013-14 as the

yarn production and spread between the yarn & cotton prices remained steady. However, decline in yarn prices in Q2 FY 2014-15

with high cost carry forward cotton stock from the CY 2013/14 and decline in the export demand is likely to result in moderation in

the profitability and debt coverage for the full year FY 2014-15 as compared to the previous year. Due to leveraged capital structure

arising out of capital intensity (fixed as well as working capital) and tendency to leverage on account of interest subsidies available

on term debt, the financial profile of the industry remains vulnerable to cyclical moderations in profitability.

Revenue Growth: For the ICRAs sample set of 22 large cotton spinners, revenues had increased by 11% in Q1 FY 2014-15 (YoY) as

against an increase of ~5% in cotton yarn production and ~2% increase in sales realizations witnessed by the industry. The revenue

growth in Q1 FY 2014-15 is similar to the revenue growth witnessed in Q4 FY 2013-14 on YoY basis. The revenue growth has

however moderated from that in the previous quarters due to moderation in the production growth on account of the capacity

constraints as the industry has been operating at high utilization levels. However ability to prevent de-growth in the backdrop of

expected moderation in export demand and decline in yarn prices will remain a key challenge for domestic industry. The revenues

for the companies in ICRA sample set had declined by ~2% in Q1 FY 2014-15 on QoQ basis and is expected to decline by ~8~10% in

FY 2014-15 driven by expected decline in production as well as yarn realizations.

Profitability margins: The profitability margin in Q1 FY 2014-15 remained comfortable at ~15% and was at similar levels as that in Q4

FY 2013-14. The profitability is however expected to decline to ~12% in Q2 FY 2014-15 on account of decline in yarn prices. For full

year FY 2014-15, ICRA expects the profitability of companies in ICRA sample set to decline to ~13% compared to ~17% in FY 2013-14

as the inventory gain realized during H1 FY 2013-14 would not be available this year and expected reduction in demand.

Debt Coverage: While the operating profitability was stable in Q1 FY 2014-15, the increase in the interest expense by ~13% on QoQ

basis had resulted in moderation in the interest coverage from 3.5 times in Q4 FY 2013-14 to 3.0 times in Q1 FY 2014-15. While in

quantity terms the cotton inventory has not changed significantly in March 2014 vs March 2013, however increased prices of cotton

as well as yarn has increased amounts of working capital borrowings leading to increase in interest expense, which couled with

decline in absolute operating profits had resulted in decline in interest coverage. With expected profitability pressures in FY 2014-15,

the debt coverage indicators are expected to moderate, however, lower cotton prices would reduce the funding requirement and

limit moderation in the debt coverage.

Sources: Aggregate financials for 22 large cotton spinning companies which are listed on stock exchanges;

Sources: Aggregate financials for 22 large cotton spinning companies which are listed on stock exchanges; The above 12 Month data refers to the period which commences in April and ends in March The above data refers to the quarterly financial performance as reported by these companies to the stock exchanges

-

ICRA LIMITED P a g e | 19

Annexure 1: Rating Distribution - ICRA rated Entities Upgrades in 5M FY 2014-15 continue to outpace the downgrades due to improved operating and financial position

While assessing the credit profile of spinning companies, ICRA factors in attributes which include:

a) Scale of operations and extent of modernization of manufacturing facilities: Yarn being a commoditized product results in limited pricing power, hence larger scale of operations, modernized facilities helps in reducing wastages/improving yields and improving economies of scale, thereby resulting in better cost structure and fundamentally improves the ability to compete in commoditized market

b) Capacity Utilization levels: As reflected in the average utilization of ~95% for the spinning industry, high capacity utilization is of utmost importance so as to reduce the fixed capital cost per unit of production, given the capital intensive nature of the sector. The track record of maintaining high utilization levels/ fast ramp up of new capacities is considered a positive attribute for the entities being rated

c) Level of Integration: Higher levels of integration lead to lower cyclicality in profitability margins as the entitys exposure to intermediate goods in the value chain is lower. For example, an integrated fabric manufacturer witnesses a lower volatility in profit margins than a standalone spinner. Integrated operations also help in reducing overheads related to sales, transportation, packaging, taxes at intermediate stages etc.

d) Diversified product portfolio: Better value addition with higher share of value added yarns can improve pricing power to an extent and hence considered as a positive attribute e) Distribution and selling network: Diversity in customer profile and markets helps to reduce adversities in a particular market and capitalize on opportunities in other markets f) Working capital management: Given the seasonal nature of cotton availability, the working capital intensity of the business remains high. Prudent stocking of cotton in relation to

orders in hand, outlook on cotton availability and prices is an important factor to mitigate the inventory holding risks g) Financial Profile: Spinning companies are usually highly leveraged, both because of capital intensive nature of the industry, investment incentives available as well as large stocking

requirement due to seasonal nature of procurement. Owing to high leverage, high working capital requirements and exposure to cyclical trends in the industry, financial flexibility in terms of availability of unutilized working capital limits, ability to stock cotton during harvest season and ability to refinance/raise fresh borrowings are key factors for measuring financial flexibility

h) Scale of projects and ability to fund: Given the availability of investment incentives, the players have a tendency to leverage and continuously undertake new projects. The scale of these new projects and ability to fund the same are also key constraining factors for the credit profile.

i) Eligibility under Investment incentives: Availability of investment incentives under schemes such as TUFS improves the return on capital indicators and supports the projects profitability. Approvals at the time of being rated reduces the ambiguities related to availability of the incentives and can be a supporting factor for the credit profile

j) While ICRA tends to achieve rating

While ICRA tends to achieve rating stability by rating entities through the cycles, sharp correction in cotton prices leading to high inventory losses resulted in sizeable rating downgrades in FY12, the spillover effects of which continued in H1-FY13 too. Subsequently, with the improvement in profitability and accruals in FY 13 which continued in FY 14 as well, upgrades in FY14 have significantly outpaced the downgrades with the number of upgrades at almost the similar levels as downgrades in FY12. With improvement in financials, the pace of upgrades continues to remain high during 5M FY 15, however with expected profitability pressures; this is unlikely to continue in near future. Rating migration of ICRA-rated spinning companies

FY 2010 FY 2011 FY 2012 FY 2013 FY 2014 5M FY 2015

Total Downgrades in Textile sector 16 32 120 80 35 14 Total Upgrades in Textile sector 5 0 19 32 111 62 Downgrade to upgrade ratio 3.20 - 6.32 2.50 0.32 0.23 Total Downgrades in spinning sector 8 15 81 38 11 4 Total Upgrades in spinning sector 2 0 8 12 66 28 Downgrade to upgrade ratio 4.00 - 10.13 3.17 0.17 0.14

-

ICRA LIMITED P a g e | 20

Annexure 2: RR-TUFS: Investment in standalone spinning projects remain subdued due to reduction in benefits as the scheme focuses on capacity creation in down-stream sectors

Sources: ICRA Estimates, Ministry of Textiles, Textile Commissioner, The above data refers to the Indian financial year which commences in April and ends in March

The R-TUFS scheme was modified in October 2013 to Revised Restructured TUFS (RR-TUFS) to incentivize investments in

downstream capacities in the weaving, processing and garmenting sectors to achieve balanced growth across the value

chain as most of the investments under the previous TUFS schemes had been mostly in the spinning sector. While significant

investment in the spinning sector was made as reflected in the domestic spinning capacity not only being sufficient to meet

the domestic requirements but also able to export ~33% of the yarn production, the investments in the other sectors had

lagged.

Due to reduction in the incentives available to standalone spinning projects under RR-TUFS, the incremental investment in

the standalone spinning projects has remained subdued. The share of standalone spinning projects approved under RR-TUFS

was only ~23% of the total projects approved as on September 2014, which has declined from a share of 30% in May 2014.

The moderation is also evident in only 30% of the total subsidy earmarked for standalone spinning projects utilized till

September 2014 (increased from 24% in May 2014) compared to 81% utilization of the total subsidy earmarked for other

sectors which include weaving, processing and garmenting (43% in May 2014), indicating shift towards integrated projects

and standalone downstream sectors as these projects offer higher fiscal benefits as compared to standalone spinning

projects.

Though the benefits under RR-TUFS have been reduced for standalone spinning projects, it is compensated by the incentives

available under investment schemes announced by the various state governments such as Gujarat, Madhya Pradesh,

Maharashtra and Rajasthan and incremental additions should largely be concentrated in these states only.

The pace of investments in the integrated projects and down-stream sectors have picked up significantly over the last few

months and with only ~19% of the sanctioned subsidy available for these sectors as on September 2014 for the rest of the

12th

five year plan, the government would have to increase the subsidy available under RR-TUFS to maintain the pace of

investment in the textile sector.

The subsidy caps and their utilization under RR-TUFS are as mentioned below: Rs in Billion Sector

Subsidy Cap for fresh investment

under RR-TUFS

Subsidy available as on September

2014

Subsidy available as on

May 2014

% subsidy utilized as on September 2014 out of total

subsidy earmarked

% subsidy utilized as on May 2014 out of total

subsidy earmarked

% Share of sector in subsidy approved under RR-TUFS till

September 2014

% Share of sector in subsidy approved under RR-TUFS till May 2014

A B C (A-B)/A (A-C)/A % breakup of (A-B) % breakup of (A-C)

Spinning 4.75 3.30 3.63 30% 24% 9% 12% Others* 18.88 3.65 10.69 81% 43% 91% 88% Total 23.63 6.96 14.32 71% 39% 100% 100% * The sectoral caps have been removed in RR TUFS while retaining the share of standalone spinning at ~20% of the total subsidy for fresh investment

-

ICRA LIMITED P a g e | 21

Company Section

-

ICRA LIMITED P a g e | 22

AMBIKA COTTON MILLS LIMITED

ACML Ambika Cotton Mills Limited was incorporated in 1988 by Mr P.V. Chandran and commenced production of cotton yarn from January 1990 with an installed capacity of 6,048 spindles. The company was subsequently converted into a public limited company in September 1994. As on March 31, 2014, the company had a total installed capacity of 109,872 spindles across four manufacturing units in Tamil Nadu. The company also has 27.4 MW captive wind power generation capacity in Tamil Nadu which was increased from the earlier capacity of 15.4 MW in FY 2011 at an investment of Rs. 0.73 billion. The captive wind power met around 72% of the power requirement of the spinning units and has supported high capacity utilization of the spinning units, given the power shortage in the state. umore than half of the power requirements of its manufacturing units The company focuses on value add speciality yarn such as compact and elitwist yarn with presence across a wide count range from 24s to 140s which has resulted in consistent high operating profitability for the company. Out of the total capacity of 109,872 spindles, ~92% of the capacity is for manufacturing of value add compact yarn. As the company mostly manufactures high count yarn, it utilizes high proportion of long staple cotton, which is mostly imported (such as Supima from USA and Giza from Egypt). During FY 2014, it imported 82% of its total raw material requirement compared to 61% in FY 2013 and 33% in FY 2012. The proportion of export sales have increased steadily over the years and in FY 2014, exports accounted for ~62% of the total sales of the company, given the healthy export demand and companys product portfolio of value add premium yarn. Most of the exports are to East Asian and South East Asian countries which accounted for ~78% of the total exports of the company followed by South Asia which accounted for 12% and Europe which accounted for ~9% of total exports in FY 2014 with the balance 1% being contributed from other various countries.

Sources: ICRA Research, Companys Annual Report, Quarterly Results filing with stock exchanges, BSE, NSE

Fact Sheet

Incorporation 1988 Geographical Revenue Mix FY14 Plant Location Tamil Nadu Domestic 38% Exports 62% Installed Capacities % Product Revenue Mix FY14

Spinning 109,872 spindles Yarn 88% Weaving - Fabric 1% Processing - Garments 0% Garmenting - Others 11% Retailing - Total (Rs billion) 4.77

Chairman cum Managing Director Mr. P.V. Chandran Bankers IDBI, Bank of Nova Scotia, BOB, Corporation Bank, Axis

Bank Auditors L. Venkatasubbu & Co

Standalone(Rs. Billion) FY 12 FY 13 FY 14

Operating Income 3.89 3.98 4.77 YoY Growth (%) 19% 2% 20% OPBDIT 0.78 0.87 1.04 Interest Charges 0.20 0.19 0.13 PAT 0.24 0.31 0.48 Earnings per Share 40.65 52.74 81.94 Dividend per Share 5.00 9.50 12.50 Net Fixed Assets 3.10 2.91 2.89 Total Assets 4.43 4.30 4.66 Total Debt 1.52 0.94 1.00 Tangible Net worth 1.96 2.20 2.60

OPBDIT/OI (%) 20% 22% 22% PAT/OI (%) 6% 8% 10% ROCE (%) 12% 16% 19%

Total Debt/Net Worth 0.78 0.43 0.39 TOL/TNW 1.24 0.95 0.79 OPBDIT/Interest 3.90 4.50 8.07 NCA/Total Debt 33% 62% 80% Total Debt/OPBDITA 1.94 1.08 0.96 Debtor (Days) 10 6 4 Inventory (Days) 106 115 140

ICRA Ratings Long Term NA Short Term NA Outlook NA

Shareholding Pattern (%) Promoters 48.63% FIIs 0.00% DIIs 7.00% Public: Individuals 31.20% Public: Others 13.17%

Price Performance

Closing Price (Rs.) 453.8 Market Cap (bn) 2.7 52W H/L (Rs.) 556.75/232.15 3M 12M ACML (%) 14% 86% BSE 500 (%) 4% 38% CNX Nifty 500 (%) 4% 39%

Stock Movement

0

100

200

300

400

500

600

Oct

-13

No

v-1

3

De

c-1

3

Jan

-14

Feb

-14

Mar

-14

Ap

r-1

4

May

-14

Jun

-14

Jul-

14

Au

g-1

4

Sep

-14

Rs/

Shar

e

Price- Rs/share Standalone(Rs. billion) Q1 FY13 Q2 FY13 Q3FY13 Q4FY13 Q1FY14 Q2FY14 Q3FY14 Q4FY14 Q1FY15 Q1 FY13 Q2 FY13 Q3FY13 Q4FY13 Q1FY14 Q2FY14 Q3 FY14 Q4 FY14 Q4 FY12 Q1 FY13 Q2 FY13 Q3FY13 Q4FY13 Q1FY14 Q2FY14

Operating Income 0.89 1.04 0.94 1.10 1.07 1.25 1.28 1.18 1.21 0.89 1.04 0.94 1.10 1.07 1.25 1.28 1.18 0.92 0.89 1.04 0.94 1.10 1.07 1.25 Growth (%) - YoY 5% -2% 20% 20% 20% 36% 7% 14% 5% -2% 20% 20% 20% 36% 7% 5% -2% 17% 17% 16% OPBDIT 0.20 0.24 0.21 0.22 0.21 0.27 0.30 0.26 0.27 0.20 0.24 0.21 0.22 0.21 0.27 0.30 0.26 0.16 0.20 0.23 0.21 0.22 0.21 0.27 PAT 0.05 0.09 0.08 0.08 0.08 0.14 0.15 0.10 0.13 0.05 0.09 0.08 0.08 0.08 0.14 0.15 0.10 0.03 0.05 0.09 0.08 0.08 0.08 0.14 OPBDIT/OI (%) 22% 23% 22% 20% 19% 21% 23% 22% 23% 22% 23% 22% 20% 19% 21% 23% 22% 17% 22% 22% 22% 20% 19% 21% PAT/OI (%) 6% 9% 9% 8% 8% 12% 12% 9% 11% 6% 9% 9% 8% 8% 12% 12% 9% 3% 6% 9% 9% 8% 8% 12% OPBDITA/Interest 3.25 4.87 5.20 5.83 7.57 8.08 11.28 9.54 12.99 3.25 4.87 5.20 5.83 7.57 8.08 11.28 9.54 3.09 3.25 4.68 5.20 5.83 7.57 8.08

-

ICRA LIMITED P a g e | 23

BANNARI AMMAN SPINNING MILLS LIMITED

Bannari Amman Spinning Mills Ltd (BASML) was incorporated in 1989 as Shiva Textile and was renamed to BASML in FY 1991. BASML is part of one of the prominent industrial groups in South India, The Bannari Amman Group which has business activities in Sugar, Textiles, Distilleries, Education, etc. BASML is an integrated textile manufacturer which presence in spinning, weaving/knitting, processing and garmenting. The companys manufacturing facilities are located in the state of Tamil Nadu (TN).

The spinning unit with installed spinning capacity of 144,240 spindles is located in Dindigul, Tamil Nadu (TN), which has capacity to produce ~60 Ton of yarn per day. In FY 2014, the yarn production volume stood at 20,700 MT, which was higher by ~18% on YoY basis. The spinning operations are supported by captive windmill power capacity of 29.95 Mega Watt (MW). Almost 50% of the revenues of the spinning unit were from exports.

The weaving unit of BASML has 135 looms and is located near Palladam, TN. The unit manufactures wide-width cotton fabric. During FY 2014, the fabric production stood at 7.62 million meters, which was high by ~24% on YoY basis. Moreover, 1672 MT of knitted fabric was also manufactured in FY 2014 which was higher by 9% on YoY basis. Almost 22% of sales of knitted fabric were from exports.

In addition, the company has a fabric processing unit near Annur, TN with capacity to process 24 Lakh meter of fabric p.a. to produce coated fabric, canvas and breathable water proof fabric.

The garment division of BASML manufactured 0.75 million pieces of garments in FY 2014 which was higher by ~53% on YoY basis and accounted for ~5% of BASMLs FY 2014 revenues. Almost 98% of the revenues from this division were from exports.

Standalone(Rs.billion) Q1FY13 Q2Y13 Q3FY13 Q4FY13 Q1FY14 Q2FY14 Q3FY14 Q4FY14 Q1FY15

Operating Income 1.35 1.36 1.46 1.46 1.46 1.87 1.75 1.92 1.73 Growth (%) - YoY 7% 51% 34% 9% 38% 20% 32% 18% OPBDIT 0.30 0.32 0.27 0.27 0.34 0.36 0.27 0.21 0.26 PAT 0.08 0.09 0.06 0.05 0.10 0.12 0.06 0.03 0.06 OPBDIT/OI (%) 22% 24% 18% 19% 23% 19% 15% 11% 15% PAT/OI (%) 6% 7% 4% 3% 7% 7% 4% 1% 3% OPBDITA/Interest 3.57 3.49 3.04 2.34 3.56 3.98 3.02 2.02 2.58

Sources: ICRA Research, Companys Annual Report, Quarterly Results filing with stock exchanges, BSE, NSE

Fact Sheet

Incorporation 1989 Geographical Revenue Mix FY14 Plant Location Tamil Nadu Domestic 58% Exports 42% Installed Capacities % Product Revenue Mix FY14

Spinning 144,240 spindles Yarn 62% Weaving 135 looms Fabric 21% Processing 2.4 mmpa^ Garments 5% Garmenting Not Available Others 12% Wind Power 29.95 MW^ Total (Rs billion) 7.00

Chairman and Managing Director Mr. S.V. Arumugam

Bankers Allahabad Bank, Bank of Maharashtra, Corporation Bank, IDBI, Indian Bank, ICICI, Karur Vysya, OBC, IOB

Auditors M/s P N Raghavendra Rao & Co

^ mmpa Million meter per annum, MW Mega Watt

Standalone(Rs. Billion) FY 12 FY 13 FY 14

Operating Income 4.60 5.60 7.00 YoY Growth (%) -16% 22% 25% OPBDIT 0.34 1.13 1.18 Interest Charges 0.33 0.38 0.38 PAT -0.16 0.27 0.32 Earnings per Share -10.39 17.34 20.04 Dividend per Share 0.00 2.00 2.00 Net Fixed Assets 4.64 4.42 4.40 Total Assets 6.93 6.94 8.10 Total Debt 4.16 3.82 4.48 Tangible Net worth 1.86 2.12 2.41 OPBDIT/OI (%) 7% 20% 17% PAT/OI (%) -4% 5% 5% ROCE (%) 0% 12% 12% Total Debt/Net Worth 2.17 1.78 1.84 TOL/TNW 2.70 2.26 2.35 OPBDIT/Interest 1.03 2.98 3.11 NCA/Total Debt 5% 16% 15% Total Debt/OPBDITA 12.36 3.37 3.80 Debtor (Days) 26 29 35 Inventory (Days) 90 79 121

ICRA Ratings Long Term NA Short Term NA Outlook NA

Shareholding Pattern (%) Promoters 55.55% FIIs 0.00% DIIs 1.13% Public: Individuals 28.68% Public: Others 14.64%

Price Performance

Closing Price (Rs.) 142.0 Market Cap (bn) 2.2 52W H/L (Rs.) 155.1/105 3M 12M BASML (%) 14% 35% BSE 500 (%) 4% 38% CNX Nifty 500 (%) 4% 39%

Stock Movement

0

20

40

60

80

100

120

140

160

180

No

v-1

3

De

c-1

3

Jan

-14

Feb

-14

Mar

-14

Ap

r-1

4

May

-14

Jun

-14

Jul-

14

Au

g-1

4

Sep

-14

Oct

-14

Rs/

Shar

e

Price- Rs/share

-

ICRA LIMITED P a g e | 24

BANSWARA SYNTEX LIMITED

ACML Banswara Syntex (BSL) was initially incorporated as a joint venture company between Rajasthan State Industrial Development & Investment Corporation Ltd. (RIICO) and Mr. R.S. Toshniwal with its manufacturing facilities located at Banswara in state of Rajasthan. Later in 1982, Mr Toshniwal purchased the entire stake of RIICO.

BSL is an integrated textile player with presence in manufacturing of blended, wool & cotton spun yarn, fabric (including technical fabric) and readymade garments. While the spinning, weaving and processing capacities of BSL are located in Banswara Rajasthan, its garmenting facilities are located across four units in Daman and one unit in Surat (Gujarat).

The company also has one joint venture, Treves Banswara Pvt. Ltd, which produces laminated knitted and woven textiles for internal furnishing of buses, trains and automobiles.

For FY 2014, the synthetic yarn production stood at 30.1 million Kg (YoY decline of 3%). The fabric production stood at 36 mn meter which was similar to that in FY 2013. The garment production was up by 28% in FY 2014 and stood at 3.26 million pcs. The power requirements of the manufacturing units located at Banswara are almost met entirely through captive power plant of 33MW, which operated at Plant load factor of ~98.1% during FY 2014.

The increase in revenues in FY 2014 by ~10% was driven by increase in from garment and fabric sales with sales from yarn remaining almost flat. The overall exports were also flat during FY 2014, though the exports of fabric and garments had increased during the year.

The company incurred capex of Rs. 0.53 billion in FY 2014 towards addition of 30 looms, increase in garmenting capacity and addition of balancing equipments in the processing unit. In FY 2015, the company plans to incur capex of ~Rs. 0.25 billion which would be towards increase in the garmenting capacity and addition of balancing equipments in dyeing and spinning units.

Sources: ICRA Research, Companys Annual Report, Quarterly Results filing with stock exchanges, BSE, NSE

Fact Sheet

Incorporation 1976 Geographical Revenue Mix FY14 Plant Location Rajasthan, Daman Domestic 57% Gujarat Exports 43% Installed Capacities % Product Revenue Mix FY14

Spinning 152,264 spindles Yarn 37% Weaving 413 looms Fabric 41% Processing 11,880 MT p.a.

50.0 mmpa ^ Garments 15%

Garmenting 4.5 Mn pcs p.a. Others 6% Power 33 MW^ Total (Rs billion) 12.12

Chairman Mr. R. S. Toshniwal Managing Director Mr. R. K. Toshniwal Bankers BOB, BOI, PNB, Union Bank of India Auditors Kalani & Company ^ mmpa Million meter per annum, MW Mega Watt

Standalone(Rs. Billion) FY 12 FY 13 FY 14

Operating Income 9.24 10.96 12.12 YoY Growth (%) 14% 19% 11% OPBDIT 1.30 1.47 1.77 Interest Charges 0.75 0.82 0.81 PAT 0.15 0.12 0.27 Earnings per Share 10.06 8.15 17.13 Dividend per Share 1.50 1.50 3.00 Net Fixed Assets 4.88 5.15 5.14 Total Assets 10.22 10.77 11.22 Total Debt 6.85 6.78 6.96 Tangible Net worth 1.75 1.89 2.13 OPBDIT/OI (%) 14% 13% 15% PAT/OI (%) 2% 1% 2% ROCE (%) 12% 12% 14% Total Debt/Net Worth 3.91 3.59 3.27 TOL/TNW 4.89 4.76 4.30 OPBDIT/Interest 1.73 1.79 2.18 NCA/Total Debt 8% 9% 11% Total Debt/OPBDITA 5.26 4.61 3.93 Debtor (Days) 53 51 46 Inventory (Days) 136 123 118

ICRA Ratings Long Term NA Short Term NA Outlook NA

Shareholding Pattern (%) Promoters 55.23% FIIs 13.58% DIIs 0.03% Public: Individuals 19.08% Public: Others 12.08%

Price Performance

Closing Price (Rs.) 80.9 Market Cap (bn) 1.3 52W H/L (Rs.) 88.9/44 3M 12M BSL (%) 2% 80% BSE 500 (%) 4% 38% CNX Nifty 500 (%) 4% 39%

Stock Movement

0102030405060708090

100

No

v-1

3

De

c-1

3

Jan

-14

Feb

-14

Mar

-14

Ap

r-1

4

May

-14

Jun

-14

Jul-

14

Au

g-1

4

Sep

-14

Oct

-14

Rs/

Sh

are

Price- Rs/share Standalone(Rs. billion) Q1 FY13 Q2 FY13 Q3FY13 Q4FY13 Q1FY14 Q2FY14 Q3 FY14 Q4 FY14 Q1 FY15

Operating Income 2.78 2.67 2.55 2.63 3.12 2.83 3.06 3.27 3.00 Growth (%) - YoY 27% 9% 30% 12% 6% 20% 24% -4% OPBDIT 0.37 0.37 0.36 0.36 0.38 0.38 0.45 0.47 0.40 PAT 0.07 0.03 0.04 0.02 0.03 0.04 0.07 0.08 0.05 OPBDIT/OI (%) 13% 14% 14% 14% 12% 13% 15% 14% 13% PAT/OI (%) 3% 1% 1% 1% 1% 1% 2% 2% 2% OPBDITA/Interest 1.80 1.81 1.86 1.70 1.79 1.74 2.26 2.44 2.02

-

ICRA LIMITED P a g e | 25

DAMODAR INDUSTRIES LIMITED

ACML Damodar Industries Limited (DIL) was initially incorporated at Damodar Threads Limited (DTL) in 1987 and is promoter by Mr Arun Biyani and his brothers. In FY 1993, the company came out with an IPO and in FY 2013 the name of the company was changed to DIL from DTL. DIL is mainly engaged in manufacturing of yarn (both cotton and blended) and derives almost its entire revenue from the spinning activities. The company has four manufacturing units out of which three are in Dadra & Nagar Haveli and one is in Daman. A significant proportion of the yarn production is exported and share of exports in overall revenues stood at 68% during FY 2014. The exports were up by ~26% during FY 2014. In FY 2012, DIL had started manufacturing fabric on outsourcing basis and in the same year had also started a FMCG division wherein it sells the products under the brand Calves N Leaves. The revenues of DIL have witnessed strong growth in FY 2014 by 26%, however majority of the revenue growth was driven by increase in trading activity which had increased by 36%. As against 49% of revenues from trading sale (~Rs 2.86 billion) in total revenues of Rs 5.82 billion in FY 2013; the trading sales increased to Rs 3.88 billion (~53% of revenues) in FY 2014 leading to strong revenue growth. The revenues from sale of in-house manufactured yarn increased from Rs 2.97 billion to Rs 3.46 billion, which is a growth of ~17%. Owing to high share of the trading volumes, the profit margins have remained modest and at similar levels as against sharp improvement witnessed by other industry players in FY 2013 and FY 2014.

Sources: ICRA Research, Companys Annual Report, Quarterly Results filing with stock exchanges, BSE, NSE

Fact Sheet

Incorporation 1987 Geographical Revenue Mix FY14 Plant Location Daman Domestic 32% Dadra & Nagar Haveli Exports 68% Installed Capacities % Product Revenue Mix FY14

Spinning Not Available Yarn 98% Weaving - Fabric 2% Processing - Garments - Garmenting - Others - Retailing - Total (Rs billion) 7.35