Welcome message from author

This document is posted to help you gain knowledge. Please leave a comment to let me know what you think about it! Share it to your friends and learn new things together.

Transcript

HONDA establish in 1999 at Manesar ( Haryana ) HONDA is a Japanese Public Multinational . HONDA is a largest motorcycle manufacturing company. HONDA deals with 2-wheeler, 4-wheeler and power

products.Honda motorcycle and scooter India (HMSI)Honda Siel Cars India Ltd (HSCI)Honda Siel Power Products Limited (HSPP)

First plant of HSMI in Manesar (Haryana). Second plant in Tapukara ,Dist.:-Alwar, Rajasthan Third plant in Narsapura, Bengaluru Forth plant in Ahmadabad ,Gujarat

My training is at HSMI Manesar in frame Assembly

PRODUCTSHonda AVIATORHonda ACTIVA(110;125;ACTIVA I;3G)Honda DioHonda dream neoHonda ShineHonda CBF StunnerHonda CB Unicorn Dazzler Honda YugaHonda Unicorn 150Honda CB triggerHonda CBR 150R Honda CBR 250R Honda Unicorn 160 (new model)Honda CBR 650 (new model)

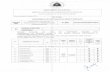

HR (Human Resource and Development)

IR(Industrial relation) A/F(Frame assemble) A/E(Engine assembly) Paint Shop P I (Part inspection) Utility Maintenance BOP Weld Steel machining

Aluminum machining SafetyPurchaseCasting PPC(Production planning)VQ (Vehicle quality) LogisticStoreFinance R & DTechnical center SQA

Raw material Press

BOP WELD CASTING

PAINT PAINT SHOPENGINE

ASSEMBLYBOP

FRAME ASSEMBLY

VQ

LOGISITICS

DISPATCH

MACHINING

The term PI refers to a pre-inspection in which the product manufactured in manufacturing process is inspected before it is transferred to the assembly line in order to obtain the final product output.

There are three assembly Line. ◦ The first line is for Activa only.◦ The second is in Motorcycle plant where both scooter and

motorcycle are assembled.◦ The third is for the new model line and only meant for only

motorcycles.

I worked on frame assembly line 3 that assembled new models.

Modals at Frame Assembly line 3

A/F FRAME ASSEMBLY

KYJM CBR 250KSPP

K-38 KPPR CBR 150

First principle inspection is the inspection in which the parts are inspected with the help of measuring instruments so as to ensure the part is accurate as per the working standards.

Measuring instruments like Vernier Caliper, Height Gauge, V-Block etc

Gauge inspection is the inspection tool used to check a work piece against its allowed tolerances.

The gauge has two tests; the check involves the work piece having to pass one test (Go) and fail the other (No Go).

It is used in the manufacturing industry to ensure interchangeability of parts between processes, or even between different manufacturers.

It is defines as the examination of the material, component or a product for condition of non conformance using light and eyes alone or with conjunction with various aids.

Visual inspection is commonly employed to support other NDT methods.

Several Characteristics about the part being examined may be determined which include dimensional conformance, the presence of discontinuities, general fit and wear.

CMM is defined as Co-ordinate Measuring Machine. This machine is imported from Japan which is used to

inspect the co-ordinates of the part randomly. A coordinate measuring machine (CMM) is a device

for measuring the physical geometrical characteristics of an object. This machine may be manually controlled by an operator or it may be computer controlled.

A machine which takes readings in six degrees of freedom and displays these readings in mathematical form is known as a CMM

Sorting (seiro)Stabilize (seiton)Systematic Cleaning (seiso)Standardizing (seiketsu)Self-Discipline (shitsuke)

The Project is to improve the DPR (direct pass ratio) of model K-38 (Unicorn 160). DPR is improved by reducing the defects. By removing of defects DPV (defects per vehicle) decreases. Unicorn 160 is a new model on line the mass production of which was started in Jan 2015. As it is a new model and as per HMSI every single part of new model is inspected so as to get high production i.e. improved DPR

Scratches on parts Rear light switch spring open Handle movement hard Fuel tank not set Part miss Part fitment N/G Nut free

Root cause

Loading in marshal Loading Unloading from marshal Strip pasting Tail lighting putting

Fitment on frame

Problem Category Why 1

Scratch generation due to man/method

Improper Handling

Mishandling of parts during loading and offloading

Awareness not present for defect generation

Scratch generation due to Tool & Jigs

Machine Scratch generation from Socket of Gun

FUEL TANK SCRATCH

Root cause

Fuel tank loading in the paint area.

Fuel tank leakage testing

Fuel tank unloading from marshal

Problem Category Why 1

Scratch generation due to man/method

Improper Handling

Mishandling of F/Tanks during loading and unloading

Scratch generation due to Jig and Fixtures

Machine

Scratch generation at the time of fitment oil gauge, nob & Uncovered Fuel Tank Leakage Testing Container

Countermeasures

92% defects of fuel tank scratch reduced

SIDE COVER SCRATCH

Root Cause Countermeasure

change the loading position of the side cover

85% defects of fuel tank scratch reduced

Thread of the component damage at the time of nut tightening.

Root cause Nut taper tightening

85% defects of stem nut reduced

Related Documents