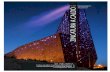

1 HOT DIP GALVANIZING 02 | 2015 Visitor Centre of Château Gruaud-Larose | 3 Formosa – Amphibious House | 6 citizenM Bankside | 10 Number One Riverside | 14 HOT DIP GALVANIZING 02 | 2015 International Magazine ISSN 1363-0148 www.hdgmagazine.co.uk

Welcome message from author

This document is posted to help you gain knowledge. Please leave a comment to let me know what you think about it! Share it to your friends and learn new things together.

Transcript

1

HO

T D

IP G

ALV

AN

IZIN

G

02 |

2015

Visitor Centre of Château Gruaud-Larose | 3 Formosa – Amphibious House | 6 citizenM Bankside | 10 Number One Riverside | 14

HO

T D

IP G

ALV

AN

IZIN

G

02 | 2015 International Magazine

ISSN 1363-0148

www.hdgmagazine.co.uk

2

02 |

2015

HO

T D

IP G

ALV

AN

IZIN

G

2

Editorial

The provision of public

buildings designed and

engineered to the highest

standards has always

been an objective that we

strive for. Sometimes these

ambitions are not realised,

not through lack of effort,

but circumstance. A bus

station, school and new civic

office highlight what can be

achieved.

In Aarau, Switzerland, a bus station forecourt has transformed

a windswept empty square into a space that locals take pride in

proclaiming to be their ‘cloud’. The use of a galvanized facade to

provide a tactile finish by the ingenious placement of perforations

within the steel has created the building block for a school in

Denmark. Its design philosophy has earned it a LEED Gold rating.

A new civic office in Rochdale has created a sustainable and

modern working environment by bringing together a series of

disjointed offices. A new sense of community and transparency has

been engendered.

All these projects help to enhance the interplay between ourselves

and the buildings that help us function on a daily basis.

Iqbal Johal, Editors

Hot Dip Galvanizing – An international journal published jointly

by the galvanizing associations of Germany, Great Britain and Spain.

Edited by: I. Johal, G. Deimel, H. Glinde (Editor in Chief). Published by: Galvanizers Association, Wren’s Court, 56 Victoria Road,

Sutton Coldfield, West Midlands B72 1SY, UK;

Tel: +44 (0) 121 355 8838, Fax: +44 (0) 121 355 8727,

E-Mail: [email protected], Internet: www.galvanizing.org.uk

Distributed in Australia by: Galvanizers Association of Australia,

124 Exhibition Street, Melbourne, Victoria 3000, Australia, Tel: 039 6541266,

Fax: 039 6541136, E-mail: [email protected]

This magazine may not be copied without the written permisson of the editor

© 2015

Photo front cover | Arthur Péquin

3

HO

T D

IP G

ALV

AN

IZIN

G02

| 20

15

1

SparklingGrand CruVisitor Centre of Château Gruaud-Larose

Château Gruaud-Larose in the Saint Julien appellation of Bordeaux has been producing

Grand Cru wines since the 18th century. Four families have passed on their tradition

and success in cultivating the 82 hectare vineyard to produce wine of the highest

quality.

A recent addition to the local terrain has raised the odd eyebrow. Architects Lanoire & Courrian

were asked by the owners to design a new building to sit alongside the existing 18th century

Château to house a visitor centre, boutique and tasting room.

The long low rectangular building set into a natural slope aims to make the most of the expansive

view of parkland and famous vineyards. Constructed predominately out of steel and glass and

topped by a green roof it succeeds in blending with the terrain. This is counterbalanced by a 21

metre observation tower on the edge of the site.

Shimmering in its metallic facade and internal network of galvanized steel, the tower provides

breathtaking views of the vineyards and the nearby Gironde estuary.

1 | The tower provides breathtaking views of the vineyards and Gironde estuary

2 | A network of galvanized steel provides the support structure for the tower

Architect | Lanoire & Courrian Architectes

Photos | Arthur Péquin

Sparklingby Holger Glinde

4

02 |

2015

HO

T D

IP GALVANIZING

The world’s largest air-supported membrane cushion

dominates the newly designed forecourt of the train station

in Aarau. Its organic shape creates a welcoming and open

environment for travellers through the new transport hub.

The centre of Aarau serves as a point of departure, arrival and

transfer for more than 40,000 train and bus travellers every day. Swiss

architects Vehovar Jauslin, in collaboration with engineering consultants

formTL, were given the task of creating an integrated transport hub.

The design of a public space that integrated the various modes of travel

was seen as a crucial factor within their design.

The ‘cloud’, affectionately referred by locals, has become the new

integrating space combining train station forecourt and bus shelter.

“From the beginning, we wanted to create a spatial atmosphere

under the roof that resembles a clearing in the woods. In order to

greet the passengers in a bright and friendly environment, a very

light, diaphanous material was selected,” explains architect Mateja

OrganiccloudAarau municipal bus station

1

2

by Holger Glinde

5

HO

T D

IP G

ALV

AN

IZIN

G

02 |

2015Vehovar. “We chose an air-supported membrane

cushion made of the synthetic material ETFE.

Such membrane roofs are not only easily designed

in various forms, but are also extremely light,

durable, weather-resistant and self-cleaning. The

expansive cushion is held up from within by a

freeform steel construction. An irregular network

of steel cables across the outer surfaces gives form

to the air cushion. The necessary utility lines for

drainage, lighting, recirculating air and measurement

technology run invisibly inside the construction. Thus

the roof appears light and airy instead of looking like

a technical installation. For all the materials used, we

paid attention to the issue of sustainability.”

Steel structure

The steel structure consists of a free-formed, flat

steel frame, which is 7 metres high and stands

on 11 filigree steel uprights and covers an area

of 1,000m2. The uprights, which are inclined at 8

degrees for optical reasons, are clamped into a

steel table, and their bases are hinged into the roof

of the underground car park. The uprights’ star-

shaped heads are integrated into the flat frame,

formed from rectangular tubes, by means of rigid

high-tensile joints. Stainless steel cables up to 41

metres long stretch from edge to edge and, together

with the nodes at the cable intersections, form a

three-dimensional cable network. All the ancillary

equipment drainpipes, power cables and air hoses

are neatly hidden within the structural frame.

Corrosion prevention

The entire steel table structure, consisting of

uprights and rigid table sections, was hot dip

galvanized and painted. This makes it possible to

exclude expensive maintenance work on corrosion

prevention in relation to the steel structure

throughout the projected service life, which is 50

years.

ETFE-foil panels

The upper blue foil and the lower clear foil forming

the EFTE panel are imprinted using air bubbles.

Thanks to the visual complexity of the cable network

forming the roof and the steel structure within, there

is a continuously changing interplay of light and

shade, of the visible and the concealed, by day and

night. The foil panel maintains standards in relation

to air tightness, and remains inflated even if there is

a 24-hour loss of power.

The bus station roof in Aarau has not only set new

standards for the creation of long-term municipal

functional structures but also received the approval

of the local population.

Aarau municipal bus station

1 | The world’s largest air-supported membrane cushion roof

2 | Air bubbles imprinted in ETFE panels create visual complexity

3 | Galvanized filigree steel structure

3

Architect | Vehovar JauslinEngineer | formTLPhotos | Niklaus Spoerri

6

02 |

2015

HO

T D

IP G

ALV

AN

IZIN

G

Rising to the challengeFormosa - Amphibious House

In many ways the house designed by Baca Architects and Techniker is ordinary –

triumphantly ordinary. It’s an elegant ordinary house with a pitched roof structure

and concrete basement. The industrial weatherscreen skin of zinc shingles wraps the

glazed facade to fully exploit the magnificent views of the River Thames. It is the

views that hold the secret to what makes this house so special and it is what lies

beneath this house that makes it extraordinary – it is the UK’s first amphibious house.

Its special position on an island in the Thames means that the downside of those spectacular

views is that the house sits in Flood Zone 3b, classified as Functional Floodplain. Planning

permission could only be granted for a new structure, to replace the dilapidated existing building,

by demonstrating that it can deal with the inevitable floods – a floor level 2 metres above ground

level was required. A new house would need to be either flood resilient, to cope with flood water

entering the building, or flood resistant, preventing flood water from entering the building. The

amphibious house is a unique solution that will rise and fall with the floodwater, and so will never

be flooded internally. Water can occupy the footprint of the house as if it was not there – the

water simply sits beneath it.

Baca Architects are specialists in waterfront and water architecture. They apply award-winning

research to find answers to the threat posed by flooding, designing accommodation that interacts

intelligently with water. Techniker, under the direction of Matthew Wells, has a reputation for

non-standard structural design, they approach design challenges with imagination and a holistic

understanding of architectural aspirations. Amphibious houses have been built before, typically

on mini piles, but not in this country and the design team felt the problem was not insoluble. To

1

by Iqbal Johal

7

HO

T D

IP G

ALV

AN

IZIN

G02

| 20

15create an innovative house with a means of raising and lowering itself

should be relatively easy based on Archimedes’ principle. In fact with

this amphibious house, Formosa, the design team’s first solution was

for a house on a steel pontoon. But then, explains Wells, “We started

to investigate what could be done with an ordinary house”. The house

was given a waterproof concrete basement, the equivalent of a ship’s

hull, and positioned within a concrete tank as a wet dock. Guide posts

or ‘dolphins’ are required for when water comes into the dock as the

house is then buoyed up. Two waterproofing systems are used to

ensure the basement hull is watertight: there are both internal tanking

and waterproof concrete. The concept for Formosa is a free-floating

pontoon set between four galvanized steel dolphins. Permanent vertical

guideposts allow the house to rise up by 2.5 metres, more than enough

to cope with an extreme flood event. Flexible pipes allow all services to

remain clean and operational in the event of a flood. Inhabiting both the

flotation unit and the roof space has enabled the architects to squeeze

in three storeys of accommodation in place of the existing single storey

house within the maximum height allowed by the planners. The result

is an ‘ordinary’ house in which the only real additional cost comes from

the construction of the two foundation systems.

Creativity and innovation

Engineering intelligence to ensure stability when the house floats was

then applied. The first consideration is that the house should have

a low centre of gravity. This is achieved via the concrete basement

which weighs around 150 tonnes, in contrast to the timber super-

structure which weighs only 45 tonnes. While having a low centre of

gravity is essential, it is not sufficient. The resulting load is applied

through the geometrical centre of the plan so the house’s tendency to

tilt is minimised. This allows the dolphins to cope with the large lateral

forces. The two long sides of the house sit against the edges of the

dock, and four 7 metre galvanized steel dolphins guide the structure

up and down. Control gears are provided to also help with preventing

lateral movement, (tilting), these are formed by steel rectangular tubes

divided from the dolphins by hardwood blocking to enable a smooth

slide. Holes to the base of the dock allow any flooding in so there isn’t

a rush of water. Floodwater rises up from the ground rather than

flowing in across the surface from the river. The house is balanced by

the use of ‘suitcase weights’, as used in tractors, to balance outplaced

internally in the corners of the base of the hull, supported on hooks,

each weighing 23kg. The design of this unique house means the

owners can return and occupy the house with all services working as

soon as the flood waters recede. 3

2

1 | Galvanized dolphins on the two side elevations act as guides during times of flooding

2 | Archimedes’ principle in action: the house slowly rises with the ingress of floodwater

3 | The UK’s first amphibious house ‘Formosa’

Architect | baca ArchitectsEngineer | TechnikerPhotos | Tim Crocker (1),

baca Architects (2)Fremantlemedia (3)

8

02 |

2015

HO

T D

IP GALVANIZING

North Star School, Denmark

The Nordstjerneskolen (North Star School) in the Danish town of Frederikshavn is

a Public-Private Partnership Project. The durability of the materials, the minimizing

of energy use and the importance of flexible design, which could also cope with the

demands of the future, were key factors within the planning approval process for the

project.

In terms of the Danish construction regulations, the school was listed as ‘low energy class 2020’,

which roughly corresponds to LEED Gold. The two-storey school building, which has a total area of

14,000m2, accommodates 1,200 pupils, divided into kindergarten, primary and secondary schools.

All classrooms have access to daylight and are naturally air-conditioned. In designing the school

complex, the architects ARKINORD A/S and Arkitema Architects wanted to create surroundings in

which teaching, learning and social activities could be linked with one another.

Five star Perforation

1 | Detailed imagery has been made possible by innovative technology

2 | Galvanizing provides protection throughout the facade, even around the perforation edge

1

by Holger Glinde

9

HO

T D

IP G

ALV

AN

IZIN

G

02 |

2015

Architect | ARKINORD A/S and Arkitema Architects

Photos| RMIG 2

The design of the school is based on the

concept of a star shape with each arm

accommodating different age groups. At

the centre of the star is a common square

that forms the focal point for the School. All

departments can be accessed through it and

it forms the heartbeat of school activities

from teaching, learning and social gatherings.

Each point of the star makes up a department

for two grades, each with its own identity

and furnishings, designed for the age group

it houses. In this way the large number of

children are accommodated within a scale

that appears natural, safe and inspiring.

Metal facade with individual perforations

The design for each of the facades of

the school was inspired by the compass

orientation of each arm of the star. The

western arm represents the USA and Great

Britain, while the others depict views of

Scandinavia, Africa, the Middle East and the

North Pole. Giant graphic images of symbols

from all over the world form an individual

facade cladding. The facade consists of 2mm

thick sheet steel, which creates graphic

images by means of thousands of perforations

of various sizes that is subsequently hot dip

galvanized. A technology developed by the

perforated plate manufacturer RMIG makes it

possible to convert artistic patterns, drawings

and even photos into individual perforated

facade surfaces.

Hot dip galvanizing not only enhances the

optical and tactile properties of the facade, but

also provides lasting and robust protection.

This extends into protecting the areas inside

and around the edges of the perforations.

10

02 |

2015

HO

T D

IP GALVANIZING

1

11

HO

T D

IP G

ALV

AN

IZIN

G

02 |

2015

‘A collection of innovative concepts, citizenM is a hotel driven

by one desire: to create affordable luxury for the people.’

citizenM, Bankside, is a six-storey modular hotel built over

a single storey traditional steelwork podium. The design

included offices, a boutique bar and restaurant.

CitizenM have invested whole heartedly in the concept of off-site,

prefabricated modular construction. They recognise the benefits this

offers them in terms of speed of construction and long term building

performance. Peter Dann designed bespoke volumetric galvanized

light gauge steel frames to create the hotel’s modular bedrooms. Cold

formed sections are rolled to the engineer’s specific requirements

using pre-galvanized sheet metal. The sections are then cut to length

and welded together in a factory environment to form 3D frames

that incorporate the floor, ceiling, walls, door openings and services

penetrations necessary for each bedroom.

Hot rolled, hot dip galvanized sections are welded into the light gauge

skeleton where necessary to stiffen the frame and to carry specific

high concentration loadings such as cladding, mechanical & engineering

plant and transfer structure. The welded light gauge steel frame

arrangement provides a lightweight, dimensionally accurate and stiff

structure into which room finishes can be pre-installed prior to delivery

to site.

The properties of the steel frame are such that there is minimal flexure

of the frame during delivery and lifting and when installed on site there

is minimal onward axial shortening under load. This, combined with

the lack of shrinkage in the structural components, provides a robust

building structure that protects the pre-installed room finishes and

minimises building maintenance. Welded light gauge steel structures

typically provide enhanced protection against disproportionate

collapse due to their high degree of connectivity between structural

components. The galvanized steel structural frame provides a building

fabric that will far outlast the standard recommendations for building

design life.

ModularhotelCitizenM Bankside, London

1 | A mix of offices, restaurant and bars combine to offer a desirable hotel

2 | Prefabricated off-site, the bedroom suites are craned into place

3 | citizenM is a hotel driven by one desire: to create affordable luxury for the people

Engineer | Peter DannPhotos | citizenM

by Iqbal Johal

3

2

12

02 |

2015

HO

T D

IP GALVANIZING

Artistic CelebrationFrei Otto, Pritzker Prizewinner 2015

The two news reports came in quick succession. On

9th March, 2015, the architect Frei Otto died at the

age of 89. One day later, the Pritzker Prize committee

announced that the visionary had been awarded the

Pritzker Prize for 2015. Otto is the second German who

has been awarded ‘the architect’s Nobel Prize’.

In stating their reasons for giving him the award, the Jury declared

that Otto was not just an architect, but also “an explorer, an

inventor, a pattern-finder, an engineer, an environmental activist,

and the creator of some unforgettable buildings and projects”.

Otto’s own comment about himself, “I’ve not built much. But I

did dream up lots of ‘castles in the air’”. He was one of the most

important architects and architectural theorists of the twentieth

century. His greatest claim to fame was that he brought lightness

into architecture. Roof structures, such as the star wave tent at

the Tanzbrunnen Park in Cologne, which dates from 1957, the

cable net roofs for the Olympic site in Munich, or the aviary of

the Hellabrun zoo, are already part of architectural history. The

Institute for Light Plane Load-Bearing Structures which he founded

in 1964 at the University of Stuttgart, and which now carries on

his work under the direction of Werner Sobek, is famous all over

the world.

1

by Holger Glinde

13

HO

T D

IP G

ALV

AN

IZIN

G

02 |

2015

Frei Otto was one of the initial thinkers behind sustainable construction

and also used hot dip galvanized steel in his building projects to good

effect. These include the house in Warmbronn where he lived, the aviary

of the Hellabrunn zoo, which dates from 1980, or the very recently

erected group of bridges in Mechtenberg and Schwarzbach in the Ruhr.

Frei Otto is the first Pritzker Prize winner who will not accept the award

in person, as the prize is awarded to architects who are still alive. Otto

learned that he had been honoured with the prize before he died, and

said “I never did anything to earn this prize. Winning prizes is not my

life’s ambition. I am trying to help poor people. But what can I say? I’m

very happy.”

1 | Frei Otto, Pritzker Prizewinner 2015

2 | The Aviary at Hellabrunn Zoo

3 | Series of bridges in Mechtenberg and Schwarzbach in the Ruhr

Photos | The Pritzker Architecture Prize (1), Frei Otto (2), Christine Kanstiger (3)

2

3

Casehistory: The Aviary at Hellabrunn Zoo

The Aviary at Hellabrunn Zoo was completed in 1980 covering an area

of 5000m². The project was a collaboration between Frei Otto with

Jörg Gribl and Ted Happold. A recent inspection carried out by the

Institute Feuerverzinken in July 2015, found the galvanized pylons to

be in excellent condition after 35 years’ service. With recorded coating

thicknesses of 220 microns, the galvanized coating will continue to

provide protection for many decades to come.

14

02 |

2015

HO

T D

IP GALVANIZING

1

1 | Cantilevered walkway follows the sinuous facade

2 | Galvanized clamps hold the glass fins in place

3 | 33 individual buildings unified into a single, fluid location alongside the river Roch

After a successful design competition, FaulknerBrowns Architects were commissioned

by Rochdale Metropolitan Borough Council to design a new civic office to help achieve

three strategic objectives: rationalisation of their estate from thirty-three buildings into

one; provision of an environment which delivers ‘new ways of working’ and quality

public space incorporating a new library and customer service centre; creation of a

sense of community engagement and social transparency.

All of these objectives on their own would have challenged the design team; combined, they

provided a unique opportunity to develop a special building within the challenging context of an

economic downturn. Offering a new sustainable and modern working environment, the brief for

the project was perhaps most radical in that it was underpinned by a desire by the client to bring

just under 1,700 employees together, in one building, as opposed to 33 individual buildings. A

key driver and resultant outcome of this approach was to deliver a building which is BREEAM

‘Excellent’ utilising the architecture and its engineering to achieve cost savings and efficiencies

FluidUnificationNumber One Riverside, Rochdale

by Iqbal Johal and Steve McIntyre

15

HO

T D

IP G

ALV

AN

IZIN

G

02 |

2015from an operational and maintenance perspective – the building saves

over £1m per annum on energy alone. These savings have only been

achieved through the adoption of an integrated design solution which

harnesses all of the buildings engineering and environmental systems.

Transforming a previously dislocated and loosely connected

organisation into one singular and unified entity gave the opportunity

for the Council to adopt both new ways of working and also new ways

of thinking. Coupled with an aspiration to improve and regenerate the

immediate public realm and riverside area of a town centre suffering

from a lack of investment, the design agenda had clear and defined

aspirations from the outset.

The innovative arrangement of building floor plates not only offers

workspaces that engage with one another but it also promotes a

building form that engages with the external environment and riverside

setting. The physical manifestation of weaving floor plates creates a rich

internal workplace which accommodates a variety of work settings.

Technical Application

The fluid shapes which are expressed in the building’s form were

developed in parallel with the building’s environmental strategy. The

building elevations respond to their orientation – the riverside elevation

adopts a series of cast low-iron u-profile glass fins which span floor to

floor and offer passive solar gain control to the office accommodation.

The spacing of these fins are compressed and expanded to reinforce

the building’s fluid form.

A galvanized sub-structure was developed to support this facade

system which included a sinuous access walkway which follows the line

of the River Roch. The glass fin galvanized clamp detail was designed

to ensure that it would hold each glass unit independently. The detail

which was developed ensures the glass units are held at the base and

head within an individual neoprene and silicone-filled shoe detail which

helped to create a simple and elegant connection detail.

The maintenance walkways were integrated into this riverside elevation

and were carefully detailed to reinforce the character of this elevation. It is

composed of 1,200mm wide galvanized walkway units that are supported

from cantilevered steel support arms which span 1.48 metres. Meticulous

care was taken in the design and integration of each component of

this elevation to allow the whole façade system to be connected back

through a profiled aluminium recess channel. The primary support fins are

8mm thick which support a secondary steel arm which carries the main

walkway and provides support to the head and base of the glass fins.

The galvanized finish compliments the surrounding palette of materials

which has been created through the use of glass and glass reinforced

concrete panels which adopt white and grey tones to create a powerful

and contemporary architectural design solution.

Photos | DEGES (1); Max Muszermann (2)

3

2

Architect | FaulknerBrowns ArchitectsPhotos| Hufton+Crow

Galvanizing Delight

RIVA 1, a new office and private apartment complex at Phoenix lake

in Dortmund offers luxurious living along a lakeside setting. Architects

Schamp and Schmaloer have created simple, elegant cubic forms to

characterise what will be an expanding district. Artist Michael

Stratmann has interwoven a modernist interpretation on Moorish art

to form one of the entrance ways to the complex. Combinations of

galvanized steel and galvanized and powder coated steel help to

define the entrance.

Related Documents