Guidelines for Planning and Construction of Roads in Cyclone Prone Areas CRRI Report – July 2013 Sponsored by National Disaster Management Authority New Delhi Geotechnical Engineering Division Central Road Research Institute is an ISO 9001 Institution

Guidelines for Planning and Construction of Roads in cyclone Prone Areas

Jan 18, 2015

National Disaster Management Authority approached CSIR- CRRI to prepare the ‘Guidelines for Planning and Construction of Roads in Cyclone Prone Areas’.

This task was jointly undertaken by a team from Geotechnical Engg Division and Bridges and Structures Division of CSIR-CRRI.

This task was jointly undertaken by a team from Geotechnical Engg Division and Bridges and Structures Division of CSIR-CRRI.

Welcome message from author

This document is posted to help you gain knowledge. Please leave a comment to let me know what you think about it! Share it to your friends and learn new things together.

Transcript

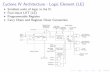

Guidelines for Planning and Construction of

Roads in Cyclone Prone Areas

CRRI Report – July 2013

Sponsored by

National Disaster Management Authority

New Delhi

Geotechnical Engineering Division

Central Road Research Institute is an ISO 9001 Institution

DISCLAIMER

All the data and technical information furnished in this report are based on the literature review and

discussions held with expert members/field engineers and site visits undertaken by CSIR-Central

Road Research Institute (CSIR-CRRI) team. The responsibility of CSIR-CRRI is limited to the

technical and scientific matters contained in this report. All the procedural/ legal/ operational

matters would be responsibility of implementing agencies who would be using this report.

FOREWORD

India has long coastline of about 7500 km including its island territories. Thriving cities and ports

have been built on our coasts. Road network is very vital for providing connectivity to these

population centres. However, road infrastructure in coastal region faces constant threat due to

tropical cyclones. With the technological advancement, many new products and techniques are

now available for civil engineers to provide protection to road infrastructure against cyclone impact.

Keeping in view these issues, National Disaster Management Authority (NDMA) approached CSIR-

CRRI to prepare the ‘Guidelines for Planning and Construction of Roads in Cyclone Prone Areas’.

This task was jointly undertaken by a team from Geotechnical Engg Division and Bridges and

Structures Division of CSIR-CRRI.

The project team is grateful to NDMA for giving us an opportunity to work on this task. Special

thanks are due to Prof Prem Krishna, Prof D.K.Paul and Dr.S.Arunachalam who reviewed the draft

many times and provided valuable suggestions and comments. Acknowledgements are due to

Hon’ble members of ‘Disaster Management Committee’ and ‘Earthwork, Embankment and Ground

Improvement Committee’ of Indian Roads Congress, New Delhi and also to Prof.M.R.Madhav,

Member, Research Council, CSIR-CRRI for many useful comments/suggestions received from

them. The draft report was presented in three workshops held at Visakhapatnam, Bhubaneswar

and at New Delhi and received suggestions/ comments from various officers and engineers of state

disaster management authorities and Public Works Departments. These reviews/comments/

suggestions immensely helped in improving the draft. CSIR-CRRI Team expresses special thanks

to all of them.

(Dr.S.Gangopadhyay) Director, CSIR- CRRI

Draft Preparation Team at CSIR-CRRI

Dr.S.GangopadhyayDirector, CSIR-CRRI

Shri Sudhir MathurChief Scientist & Advisor

Shri U.K.Guru VittalHead, Geotechnical Engg Division (Project Leader)

Dr. Lakshmy Parameswaran Chief Scientist

Dr. Rajeev GargHead, Bridges and Structures Division

(Technical Assistance: Shri J.Ganesh and Dr.Pankaj Gupta)

Expert Committee for Review

Dr.Prem Krishna, FNAEHonorary Visiting Professor, Department of Civil Engineering

Indian Institute of Technology, Roorkee – 247667 (Uttarakhand)

Dr.D.K.PaulDean of Faculty Affairs & Professor, Department of Earth Quake Engg& Head, Centre for Excellence in Disaster Mitigation and Management

Indian Institute of Technology, Roorkee – 247667 (Uttrakhand)

Dr.S.ArunachalamFormerly Advisor (M), SERC, Chennai

Director, Wind Engineering Application CentreJaypee University of Engineering & Technology

A.B. Road, P.B. No. 1, Raghogarh, Dist: Guna (M.P.) - 473226

CONTENTS

Page No

Chapter – 1 Introduction 1

Chapter – 2 Destructions Caused by Cyclones 4

Chapter – 3 Planning of Road Network in Cyclone Prone Areas 8

Chapter – 4 Construction of Road Embankments 11

Chapter – 5 Sea Erosion Control Techniques & River Bank Protection 19

Chapter – 6 Road Pavements in Cyclone Prone Areas 37

Chapter – 7 Mitigation Measures for Culverts and Bridges 42

Chapter – 8 Road Traffic Operations During Evacuation 55

References 59

Annexure – I (Technical Specifications for Geotextile Tubes)

61

LIST OF FIGURES

Figure No. Title Page No1.1 Wind and Cyclone Zones in India (Ref: NDMA) 21.2 Cyclone Hazard and PMSS Map (Ref: BMPTC) 32.1 Effect of Cyclone ‘Aila’ on Embankment 72.2 Another View of Eroded Embankment due to Cyclone ‘Aila’ in West Bengal 74.1 Rill Erosion in Road Embankment 134.2 Deep Cut in Road Embankment Due to Erosion 134.3 Severe Erosion of Road Embankment 134.4 A Type of Polymeric Vertical Drain (Band Drain) 175.1 Provision of Sea Wall and Concrete Tetrapods for Sea Erosion Protection at

Mumbai 21

5.2 Protection Against Sea Erosion by Retaining Wall and Gabions – Puri Konark Road

21

5.3 Another View of Protection Works – Puri Konark Road 215.4 Beach Protection Using Boulder Revetment at Paradip, Odisha 225.5 Another View of Boulder Revetment at Paradip, Odisha 225.6 Masonry Sea Wall Constructed at Sea Coast at Koteshwar, Kori Creek, Gujarat 225.7 Typical Components of a Geotextile Tube 255.8 Geotextile Tube Application for Coastal Protection 265.9 Applications of Geotextile Tubes 275.10 Typical Use of Multiple Geotextile Tubes for Coastal Embankment Construction 275.11 Geotextile Tubes with Gabions as Armour Protection layer 275.12 View of geotextile Tubes Covered with Armour Protection Layer of Gabions 285.13 Shore Reclamation Using Geotextile Bags 295.14 Geotextile Bag 295.15 Use of Gabions for River Bank Protection 306.1 Construction of Roller Concrete Pavement for Rural Roads 386.2 Problem of Sand Dunes Encroaching Road Pavement 416.3 Close up View of Black Top Pavement Abraded by Sand 417.1 Cable Restrainer 497.2 Cable Restrainer Installed in Longitudinal Direction 497.3 Examples of Connecting the Beam Ends of Adjacent Spans 497.4 Connection of Deck to the Substructure 517.5 Cable restrainer between superstructure and substructure 517.6 Typical Details of a Restrainer 527.7 Tying the Restrainer from the Girders Around the Pier 537.8 Reaction Block/Stopper 547.9 Seat Extension to Accommodate Large Longitudinal Displacements 54

LIST OF TABLES

Table No.

Title Page No

1.1 Classification of Cyclones 2

2.1 Storm Intensity and Expected Damages 5

4.1 Property Requirements for 3-D Mat 16

5.1 Basic Engineering Parameters for Geotextile Tubes filled with Sand 26

5.2 Geotextile Hydraulic Property Requirements under Different Regimes 31

7.1 Hourly Mean Wind Speed and Pressure at 10m Level for Cyclone Resistant Design of Bridges Situated Within 60 km off the Coast

44

7.2 Transverse Wind Forces Due to Cyclone Acting on Unit Exposed

Frontal Area of Bridge Deck at 10m Level (Plain Terrain)

45

7.3 Qualitative Damage State Descriptions for Typical Cyclone Induced Bridge Damage (FEMA, 2003)

47

LIST OF ABBREVIATIONS

AOS Apparent Opening Size of Geotextile (Also known as O95)

BIS Bureau of Indian Standards

CBP Concrete Block Pavement

CDO Central Dense Overcast (Area immediately surrounding eye region of cyclone)

CRZ Coastal Regulation Zone

DPR Detailed Project Report

ICBP Interlocking Concrete Block Pavement

JGT Jute Geotextile

MDD Maximum Dry Density

MDR Major District Road

MORD Ministry of Rural Development, Government of India

MoRTH Ministry of Road Transport and Highways, Government of India

NH National Highways

NRRDA National Rural Roads Development Agency

ODR Other District Roads

OH Organic Soil having High Liquid Limit

OI Organic Soil having Medium Liquid Limit

OL Organic Soil having Low Liquid Limit

OMC Optimum Moisture Content

PCMS Portable Changeable Message Signs

PMSS Probable Maximum Storm Surge

Pt Peat

PVD Polymeric Vertical Drain/ Prefabricated Vertical Drain

RCCP Roller Compacted Concrete Pavement

RECP Rolled Erosion Control Product

SH State Highways

TRM Turf Reinforcement Mats

VR Village Roads

WMO World Meteorological Organisation

WPS Wireless Priority Service

1

Chapter – 1

INTRODUCTION

A tropical cyclone is a storm system characterised by a large low pressure centre and numerous thunderstorms that produce strong winds and flooding rain. Tropical cyclones feed on heat released when moist air rises, resulting in condensation of water vapour contained in the moist air. The term ‘tropical’ refers to both the geographic origin of these systems, which form almost exclusively in tropical regions of the globe, and their formation in maritime tropical air masses. The term ‘cyclone’ refers to such storms’ cyclonic nature, with counter clockwise rotation in Northern Hemisphere and clockwise rotation in the Southern Hemisphere. Depending on its location and strength, a tropical cyclone is called by many other names, such as hurricane, typhoon, tropical storm, cyclonic storm, tropical depression and simply cyclone. While tropical cyclones can produce extremely powerful winds and torrential rain, they are also able to produce high waves and damaging storm surges. They develop over large bodies of warm water, and lose their strength if they move over land. This is the reason for coastal regions receiving a significant damage from a tropical cyclone, while inland regions are relatively safe from their effect. Heavy rains, however, can produce significant flooding inland, and storm surges can produce extensive coastal flooding up to 40 kilometres from the coastline. Although their effects on human populations can be devastating, tropical cyclones can also relieve drought conditions. They also carry heat and energy away from the tropics and transport it toward temperate latitudes, which make them an important part of the global atmospheric circulation mechanism. As a result, tropical cyclones help to maintain equilibrium in the earth’s troposphere, and to maintain a relatively stable and warm temperature worldwide.

A strong tropical cyclone usually harbours an area of sinking air at the centre of circulation. This area is called ‘eye of the cyclone’. Weather in the eye is normally calm and free of clouds, although sea may be extremely violent. The eye is normally circular in shape, and may vary in size from 3 km to 370 km in diameter. Surrounding the eye is the region called ‘Central Dense Overcast (CDO)’, a concentrated area of strong thunderstorm activity. Curved bands of clouds and thunderstorms trail away from the eye in a spiral fashion. These bands are capable of producing heavy bursts of rain and wind, as well as tornadoes. If one were to travel between the outer edge of a hurricane to its centre, one would normally progress from light rain and wind, to dry and weak breeze, then back to increasingly heavier rainfall and stronger wind, over and over again with each period of rainfall and wind being more intense and lasting longer.

1.1 Classification of Tropical Cyclones

Tropical cyclones with an organised system of clouds and thunderstorms with a defined circulation, and maximum sustained winds of 61 kmph or less are called ‘tropical depressions’. Once the tropical cyclone reaches wind speed of more than 61 kmph, they are typically called a ‘tropical storm’ and assigned a name. When maximum sustained winds reach a speed of 119 kmph, such a cyclone is called a ‘severe cyclonic storm’. The criteria followed by the Meteorological Department of India to classify the low pressure systems in the Bay of Bengal and in the Arabian Sea as adopted by the World Meteorological Organisation (WMO) are given in Table 1.1. Cyclones affect both Bay of Bengal and the Arabian Sea. The areas affected by cyclone in India are shown in Fig 1.1 and 1.2.

1.2 Scope of These Guidelines

These guidelines cover various aspects related to planning and construction of road infrastructure in cyclone prone areas, mainly dealing about preparedness in the eventuality of a cyclone disaster.

2

Table – 1.1 Classification of Cyclones

Type of Disturbances Associated Wind Speed in the CirculationLow Pressure Area Less than 17 knots (< 31 kmph)Depression 17 to 27 knots (31 to 49 kmph)Deep Depression 28 to 33 knots (50 to 61 kmph)Cyclonic Storm 34 to 47 knots (62 to 88 kmph)Severe Cyclonic Storm 48 to 63 knots (89 to 118 kmph)Very Severe Cyclonic Storm 64 to 119 knots (119 to 221 kmph)Super Cyclonic Storm 120 knots and above (222 kmph and above)

Source: India Meteorological Department

Fig – 1.1 Wind and Cyclone Zones in India(Ref: NDMA)

3

Fig – 1.2 Cyclone Hazard and PMSS Map(Ref: BMPTC)

4

Chapter – 2

DESTRUCTIONS CAUSED BY CYCLONES

There are three elements associated with a cyclone, which cause destruction. These have been described below:

2.1 Storm Surge

Cyclones are associated with high-pressure gradients and consequent strong winds. These, in turn, lead to storm surges. A storm surge can be defined as an abnormal rise of sea level near the coast caused by a severe tropical cyclone; as a result of which, sea water inundates low lying areas of coastal regions drowning human beings and live-stock, eroding beaches and embankments, destroying vegetation and reducing soil fertility. Storm surge is the single major cause of devastation from tropical storms. Storm surge is formed due to pushing of sea water towards shore by the force of the winds swirling around the storm. In addition, wind driven waves are superimposed on the storm tide. This advancing surge may happen to combine with the high tides to create the hurricane storm tide, which can increase the average water level to 4.5 m or more. The level of surge in a particular area is also determined by the slope of the continental shelf. Storm surge is inversely proportional to the depth of sea water. A shallow slope off the coast will allow a greater surge to inundate coastal communities. Communities with a steeper continental shelf will not see as much surge inundation, although large breaking waves can still present major problems.

Vulnerability to storm surges is not uniform along Indian coasts. The following segments of Indian coast are most vulnerable to high surges:

a) North Odisha and West Bengal Coastsb) Andhra Pradesh coast between Ongole and Machilipatnamc) Tamilnadu Coast, south of Nagapattinam

The west coast of India is less vulnerable to storm surges than the east coast of India in terms of height of storm surge as well as frequency of occurrence. However, the following segments of western coast are vulnerable to significant surges:

a) Maharashtra coast, north of Harnai and adjoining south Gujarat coast and the coastal belt around the Gulf of Mumbai

b) The coastal belt around the Gulf of Kutch

The world’s highest recorded storm surge was about 12.5m (about 41 ft) and it was associated with the Backergunj cyclone in 1876 near the Meghna estuary in present-day Bangladesh. The Probable Maximum Storm Surge (PMSS) is the highest along the West Bengal coast where it ranges from 9 m to 12.5 m. It reduces to about 3.8 m in Khurda district, Orissa, increasing again to about 8.2 m along the south Andhra Pradesh coast in Krishna, Guntur and Prakasam districts. A small region in south Tamil Nadu around Nagapattinam coast also has higher PMSS of about 8.4 m. Along the west coast; the PMSS varies from about 2 m near Thiruvananthapuram to around 5 m near the Gulf of Khambat in the Saurashtra region of Gujarat. Expected storm surge height in metres along India’s coastline is shown in Fig 1.2.

5

2.2 Strong Winds/ Squall

Cyclones are known to cause severe damage to infrastructure through high speed winds and gusts. Very strong winds which accompany a cyclonic storm, damage installations, dwellings, communication systems, trees, etc., resulting in loss of life and property. A tropical cyclone damages and destroys structures in two ways. First, many homes are damaged or destroyed when the high speed wind simply lifts the roof of the dwellings. High speed wind moving over the top of the roof creates lower pressure on the exposed side of the roof relative to the attic side. The higher pressure in the attic lifts the roof. Once lifted, the roof acts as a sail and is blown clear of the dwelling. With the roof gone, the walls are much easier to be blown down by the hurricane wind. The second way that wind destroys buildings can also be a result of the roof becoming airborne. The wind picks up the debris (i.e. wood, metal siding, toys, trash cans, tree branches, etc.) and sends them hurling at high speeds into other structures. Based on observations made during damage investigations, researchers have concluded that much of the damage in windstorms is caused by flying debris. Brief details about damages caused by winds of different speed are given in Table 2.1 (Ref: Saffir-Simpson Hurricane Scale – Management of Cyclones: NDMA Guidelines – http://nidm.gov.in/PDF/guidelines/cyclones.pdf)

Table – 2.1 Storm Intensity and Expected Damages

Scale No (Category)

Sustained winds (kmph)

DamageStorm Surge

in m1 119 – 153 Minimal: Unanchored mobile homes,

vegetation and signs1.2 to 1.5

2 154 – 177 Moderate: All mobile homes, roofs, small craft and flooding

1.6 to 2.4

3 178 – 209 Extensive: Small buildings, low lying roads cut-off

2.5 to 3.6

4 210 – 249 Extreme: Roofs destroyed, trees down, roads cut-off, mobile homes destroyed, beach homes flooded

3.7 to 5.5

5 250 or more Catastrophic: Most buildings destroyed, vegetation destroyed, major toads cut-off, homes flooded

More than 5.5

The vertical wind shear in a tropical cyclone environment is also important. Wind shear is defined as the amount of change in the wind velocity direction or speed with increasing altitude. The damages produced by winds are extensive and cover areas occasionally greater than the areas of heavy rains and storm surges which are in general localised in nature. The impact of the passage of the cyclone eye, directly over a place is quite different from that of a cyclone that does not hit the place directly. The latter affects the location with relatively unidirectional winds i.e. winds blowing from only one side, and the lee side is somewhat protected. An eye passage brings with it rapid changes in wind direction, which imposes torques and can twist the vegetation or even structures. Part of structures that were loosened or weakened by the winds from one direction are subsequently severely damaged or blown down when hit upon by the strong winds from the opposite direction. A partial eye passage can also do considerable damage, but damage would be less than a total eye passage.

2.3 Torrential Rains and Inland Flooding

Torrential rainfall (more than 30 cm/hour) associated with cyclones is another major cause of damage. It also creates problems in post cyclone relief operation. Unabated rain gives rise to unprecedented

6

floods. Rainwater on the top of the storm surge may add to the fury of the storm. Rain is the serious problem for the people who become shelterless due to a cyclone. Heavy rainfall resulting from a cyclone would be usually spread over a wide area. As a result, soil erosion also occurs on a large scale. Heavy rains inundate the low-lying ground and cause softening of the soil due to soaking. This contributes to weakening of the embankments, leaning of utility poles or even collapse of pole type structure. Heavy and prolonged rains due to cyclones cause river floods and submergence of low lying areas. River floods occur when the runoff from torrential rains, brought on by landfall of cyclones reach the rivers. Even after the wind has diminished, the flooding potential of cyclonic storms remains for several days. Most of the fatalities due to flooding occur because people underestimate the power of moving water and purposely walk or drive into flooding conditions. It is common to think that stronger the storm the greater the potential for flooding. However, this is not always the case. A weak, slow moving tropical storm can cause more damage due to flooding than a more powerful fast moving hurricane. In addition to the storm surge, tropical cyclones usually cause flash flooding. Flash floods are rapidly occurring events. This type of flood can begin within a few minutes or hours of excessive rainfall. The rapidly rising water can reach heights of 10 m or more and can roll boulders, rip trees from the ground, and destroy buildings and bridges. Urban area floods are also rapid events although not quite as severe as a flash flood. Still, streets can become swift-moving rivers and basements can become death traps as they fill with water. The primary cause is due to the conversion of fields or woodlands to roads and paved parking lots.

It may be mentioned that all the three factors mentioned above occur simultaneously and, the rescue and relief operations for distress mitigation become difficult. So, it is imperative that advance action is to be initiated for relief measures before commencement of adverse weather conditions due to cyclones.

2.4 Effect of Cyclones on Road Infrastructure

From the above discussion, it becomes apparent that cyclonic storms affect human habitations and infrastructure in multiple ways. Providing road connectivity in cyclone prone areas emerges as a vital tool for undertaking rescue and rehabilitation operations. It is also obvious that road infrastructure created in cyclone prone areas need to be designed and constructed to withstand the onslaught of cyclonic storms. The first step would be to identify the road stretches which are vulnerable to effect of cyclonic storm. Principle mode of destruction of road embankments and pavements due to cyclonic storms would be through erosion caused due to storm surge and flooding. The storm water causes damage to the road pavement surface, washes away portions of road at many locations, even breaching portions of embankment. Because of these problems, such road stretches in cyclonic areas become bottle neck and hamper relief operations.

Embankments and road pavements are not much susceptible to damage due to winds. However wind forces affect design of bridge structures. Wind forces also affect certain road furniture like sign boards, electric and telephone poles and trees planted along roadside causing disruptions to traffic flow by uprooting of trees, falling branches of trees, electric/ telephone poles falling in roadway, etc. Keeping these points in view, identified vulnerable road stretches in cyclone prone areas would have to be designed/ constructed to ensure that damage due to storm surge/flooding/winds are minimised or totally alleviated. Impact of a cyclone on road infrastructure may lead to (a) Damage to the roads due to storm surge / flooding (b) Hindrance to traffic movement due to deposition of debris left on roadway (c) Unseating / drifting of bridge superstructure due to storm surge / flooding (d) damages to the bridges due to debris impact. Impact damages can occur due to barge impact, boats, oil rigs, uprooted trees, boulders etc. The impact damage is manifested in the form of span misalignment, damage to fascia girder, fender, pier or pile damage. During cyclone occurrence, bridges may fail due to unseating of individual span, depending on the connection between the bridge deck and pier. The bridge decks with

7

low elevation are likely to fail as a result of excessive longitudinal or transverse movement of bridge deck. Under the storm surge, the bridge decks are subjected to buoyant forces and pounding action of waves. Bearings also suffer damages due to the unseating/drifting of bridge deck. In some bridges, shifting of span due to lateral wave and wind forces often causes damages to the abutments, pier caps, or girders. Damage to parapets on bridge decks, scouring of bridge foundations, erosion of abutment, etc are seen after cyclone disaster. Further details regarding damages caused to bridges due to cyclone are given in Chapter 7. While designing road structure in cyclone prone areas, the above mentioned factors are to be considered and suitable remedial measures described in subsequent chapters are to be provided. Further it is to be noted that usually a package of remedial or protection works are usually fashioned to suit individual site conditions.

CHAPTER – 3

Fig 2.1 – Effect of Cyclone ‘Aila’ on Embankment

Fig 2.2 – Another View of Eroded Embankment due to Cyclone ‘Aila’ in West Bengal

8

Chapter – 3

PLANNING OF ROAD NETWORK IN CYCLONE PRONE AREAS

As in any other part of the country, in a similar manner, the hierarchy of road infrastructure in cyclone prone area would comprise of various categories like National Highways (NH), State Highways (SH), District Roads and Rural Roads. National and State Highways are the arterial roads connecting major cities, ports, state capitals, industrial centres, etc. These roads should provide uninterrupted road communication throughout their length. District roads are intended to act as important roads within a district serving areas of production and markets and connecting with each other or with the main highways of a district. They are further sub-divided into two categories – Major District Roads (MDR) and Other District Roads (ODR). Village Roads (VR) provide connectivity between villages or habitations and District Roads. The term ‘Rural Roads’ is used to denote both ODR and VR. All these types of roads are very important in the overall road network of cyclone affected areas. Effective road connectivity ensures fast deployment of men, materials and machinery to cyclone affected areas and also ensures speedy evacuation of people from vulnerable places to safer areas in the face of an impending disaster threat. Hence the need for development of a reliable road network in the vulnerable areas is very vital to ensure coordination of relief and response in the event of a cyclone. Designation of arterial roads like National Highways and State Highways are based on traffic volume and importance of cities/ towns/ ports to be connected by them.

Planning a rural road network in a district is carried out in our country based on guidelines provided by Ministry of Rural Development (MORD) and the Indian Roads Congress (IRC). As per the MORD Guidelines, all-weather road access is to be provided to all villages/habitations of population greater than 500 people. The Operations Manual of MORD states that an all weather road is defined as one which is negotiable during all weathers, with some permitted interruptions. Essentially this means that at cross-drainage structures, the duration of overflow or interruption at one stretch shall not exceed 12 hours for ODRs and 24 hours for VRs in hilly terrain, and 3 days in the case of roads in plain terrain. The total period of interruption during the year should not exceed 10 days for ODRs and 15 days for VRs. As per MORD Guidelines, population criteria for providing all weather connectivity has been kept equal to 250 in case of hill States (North-Eastern states, Sikkim, Himachal Pradesh, Jammu & Kashmir and Uttarakhand), desert areas and tribal areas.

The most important issue with the road construction is the alignment of the road. Many issues of drainage, inundation and breaching of road embankment can be tackled at planning stage by choosing the best possible alignment. But in many projects it may not be possible to change the alignment of existing track due to problems like land acquisition, forest area, etc. These are important issues but such issues need to be taken care of by respective state Governments. Moreover, road projects involve huge investment. Hence, it is crucial to give adequate attention at the planning and design stage itself so as to achieve better and economical alignment. For planning road network in cyclone prone areas, following additional points need to be considered:

a) For planning higher category of roads like NH, SH and MDRs, ‘20 Year Road Development Plan’ and ‘Vision 2020 – Road Development Document’ published by IRC/ MoRTH are to be considered. While such arterial roads are necessary to connect main cities and towns, considerations of traffic to be catered and trade/economic importance of cities being connected are also equally essential.Additionally in case of cyclone prone areas, arterial roads required for evacuation in the event of cyclone occurrence need to be identified. Upgradation of such arterial evacuation routes to NH/SH/MDR category depending upon their importance and population being catered by such routes needs to be considered. Width of the important arterial evacuation routes (SH or MDR)

9

should be preferably Two-Lane or atleast they should be of intermediate lane width. While planning the alignment of the rural link roads, it is imperative to connect existing and proposed cyclone shelters in addition to providing connectivity to habitation/ village.

b) Rural link roads in cyclone prone areas are very crucial for evacuation and rescuing of people. Similar to hilly areas and tribal regions, in areas prone for severe cyclone impact (coastal belt of 25 km from the sea), population criteria for providing all weather connectivity can be kept equal to 250 for a habitation to be connected by an all weather road. All weather roads, as already pointed out, may experience interruptions to the traffic due to submergence of a bridge for periods extending from 24 hours to 72 hours. However, roads built in cyclone prone areas need to be designed to reduce the duration of traffic interruption due to flooding. This duration of disruption for roads identified for evacuation (belonging to ODR and VR category) should be preferably not more than 3 hours even after highest flooding expected in that region.

c) The geometric design standards for rural roads are to be followed as per IRC SP – 20, ‘Rural Roads Manual. Roads are always associated with culverts and bridges as the terrain demands, to make them fit throughout the year. Geometric design of NH and SH are to be carried out as per IRC: 73. While selecting the bridge site, factors like (i) permanency of the channel, (ii) presence of high and stable banks (iii) narrowness of the channel and average depth compared to maximum depth, straight reach of the stream, freedom from islands in both upstream side and downstream side, possibility of right angled crossings, good approaches, etc., are to be given adequate attention so as to keep them functional in the event of any disaster.

d) Concerned state agencies who are in charge of the road project should prepare beforehand ‘Hazard Zonation Maps’ of suitable scale, showing extent of cyclone/ flood hazard expected in that region. These maps should indicate vulnerable roads and bridges and risk assessment is to be carried out. In case of failure of bridge/road pavement during a cyclone event, alternate routes should be identified for evacuation/ rescue and relief on these maps. Missing links/ additional infrastructure needs should also be marked on these maps so that they can be attended to during planning process. These state agencies may take assistance from State Disaster Management Authorities and local bodies for preparation and validation of such maps.

e) Construction of roads is to be taken up in such a manner that roads are atleast 500 m away from seashores / coastal regulation zones (CRZ). Intensive protective works to prevent erosion towards seashore side of the road should be planned.

f) The most important consideration for construction of road in the cyclone prone area would be its alignment avoiding inundation of the road under cyclonic rain. Adequate cross drainage works should be provided to prevent such occurrence. Therefore, a survey along the most probable route is needed to ascertain the highest flood level that had occurred during its past history. The free board allowance for different categories of roads is indicated in section 5.6. Provision of minimum free board as per section 5.6 will ensure connectivity even after the cyclonic storm.

g) Rigid pavements are preferable over flexible pavements as there is no appreciable variation in temperature to cause significant thermal stress and resulting distress. Cement concrete pavements withstand flooding/ waterlogging in a better manner than bituminous pavements. Techno-economics of adopting cement concrete pavements vis-a-vis flexible pavement needs to be undertaken before making a final choice.

10

h) Road top level/ alignment are to be decided after taking into account high flood levels and flooding pattern. While fixing the road top levels, special care will have to be taken to cater for rapid changes in underground water table and consequent movement of the soil moisture. This can be achieved by designing and constructing an efficient drainage system. Keeping the road levels above the high flood levels and highest water table need to be ensured. For provision of storm water drainage for roads in urban areas, IRC SP: 50, ‘Guidelines on Urban Drainage’, can be referred to.

i) Preparation of a Detailed Project Report (DPR) for each of the proposed road is a pre requisite for proper evaluation of the project and it ensures timely completion and avoids time and cost over runs.

11

CHAPTER – 4

CONSTRUCTION OF ROAD EMBANKMENTS

Successful performance of an embankment depends as much on adopting standards of good compaction in construction as on careful pre investigations leading to selection of appropriate borrow material and design features of the embankment. Soil is the primary construction material for embankment and also for road subgrade. So soil and construction material survey forms the basic step for preparation of DPR for any road project. While carrying out soil survey along proposed road alignment, representative samples should be collected wherever there is a visible change in soil type. In case the same type of soil continues, at least three representative samples from each kilometre length of road alignment should be collected for laboratory testing.

4.1 Material Specifications for Embankment and Subgrade

The material used in embankments, subgrades, earthen shoulders and miscellaneous backfills shall be soil, moorum, gravel, a mixture of these or any other suitable material approved by the engineer. Such material shall be free from organic materials like logs, stumps, roots, rubbish or any other ingredient likely to deteriorate or affect the stability of the embankment/subgrade. The following material shall be considered unsuitable for embankment: Materials from swamps, marshes and bogs, peat, log, stump and perishable material, any soil

classified as OL, OI, OH or Pt in accordance with IS: 1498 The fill soil to be used should have liquid limit less than 70 and plasticity index less than 45 Materials having salts which may result in leaching in the embankment

Expansive clay exhibiting marked swell and shrinkage properties (‘free swell index’ exceeding 50 when tested as per IS: 2720–Part 40) shall not be used as fill material. Where expansive clay with free swell index less than 50 is used as a fill material, subgrade and top 500 mm portion of the embankment below subgrade shall be non-expansive in nature. The soil to be used as embankment fill or subgrade should also meet maximum dry density and other requirements as specified in MoRTH Specifications (in case of NH/SH works) or MORD Specifications (in case of rural roads).

4.2 Design of Embankments

The cyclone impact occurs in the form of erosion of road embankments. Apart from preventing erosion, the designer has to ensure stability of road embankments. For details regarding design of road embankment IRC: 75 can be referred to. Failure of embankments may be due to either inadequate bearing capacity or due to deep seated shear failure. The objective of the stability analysis is to ensure that embankment does not face any risk of shear failure. Generally in the slip circle method failure plane is assumed to be circular. A particular circle gives the minimum factor of safety. Calculation of factor of safety of different circles until the critical circle is located is a very time consuming process. Available software may provide quick solutions.

4.3 Important Considerations for Embankment Construction

(a) Fill material should conform to MoRTH/ MORD Specifications depending on road classification. Borrow pit excavation should be located at a distance atleast 5 m away from the toe of embankment. Top soil should not be used as fill material. Top soil should be spread back on the excavated land or used for covering the side slopes of the embankment.

12

(b) After clearing the site, limits of the embankment are to be marked by fixing batter pegs and marking toe lines on both sides at regular intervals as guides. Where ever feasible, stagnant water, if any, from the roadway (embankment foundation area) should be removed.

(c) After removing the topsoil / unsuitable material, the ground surface should be loosened upto a minimum depth of 150 mm by ploughing or scarifying and compacted to the specified density. For embankment construction over ground not capable of supporting equipment, successive loads of embankment fill material should be spread in a uniformly distributed layer of adequate thickness to support equipment and to construct the lower portion of the embankment. In case of soft sub-soil areas (marine clay sub-soil), ground improvement measures may be necessary to prevent failure of embankment. Expert advice should be obtained in such cases and specified foundation treatment should be carried out in a manner and to the depth as specified. Brief details of ground improvement techniques are given in section 4.5.

(d) The soil should be spread over the entire width of the embankment in layers not exceeding required loose layer thickness. The moisture content of the fill material spread for compaction should be within ±2 per cent of the optimum moisture content of the soil. Clayey soils should be compacted at moisture content slightly higher than OMC (upto 2 per cent above OMC).

(e) Each layer of fill material should be compacted using rollers to meet the specified compaction requirements. Adequate quality control and field tests as per MoRTH/ MoRD specifications are needed to ensure this.

(f) The top 50 cm of the embankment (in case of NH and SH) or 30 cm (in case of rural roads) which forms the subgrade should be built to specification requirements of the subgrade.

For further details/ specifications, reference may please be made to ‘MoRTH Specifications for Road and Bridge Works’ or ‘MoRD Specifications for Rural Roads’ and ‘IRC 36 – Recommended Practice for Construction of Earth Embankment and Subgrade for Road Works’.

4.4 Embankment Slope Protection against Soil Erosion

Road embankments experience a high degree of damage due to erosion from torrential rains which accompany cyclones and hence erosion protection of embankment slopes should receive special attention in such areas. Soil erosion is the process of detachment and transportation of soil particles by wind or water. Cohesionless soil particles may get blown away by wind (Aeolian) erosion. However erosion due to surface run-off would be the principal cause for failure of road embankments in the aftermath of a cyclone disaster. The kinetic energy of falling raindrops causes detachment of soil particles which are subsequently carried away by surface run-off. Nature of soil and impact of rain drops are determinant factors in the erosion process. Silty and sandy types of soils are more susceptible to erosion than clayey soils. Distress in the form of rills to gullies and finally to erosion ditches develop when intensity of rainfall is high and the slope is steep. These problems will impair slope stability if not controlled with proper protective measures. The surface protection of embankment against action of rain and wind is usually achieved by promoting vegetation growth. Whenembankments are constructed using non-cohesive material, cover of 0.3 to 0.6 m thick cohesive material can be given. In case of high embankments, a system of kerb channel and median drains coupled with chutes should be provided to drain off the rain water from the road embankments. Different engineering measures which may be adopted for erosion protection of roads built in cyclone prone areas are briefly described below. For more details, IRC: 56, ‘Recommended Practices for Treatment of Embankment and Roadside Slopes for Erosion Control’ can be referred to.

13

Fig 4.1 – Rill Erosion in Road Embankment

Fig 4.2 – Deep Cut in Road Embankment Due to Erosion

Fig 4.3 – Severe Erosion of Road Embankment

14

4.4.1 Slope protection by simple vegetative turfing

Vegetation is ideal for erosion control because it is relatively inexpensive to establish and maintain and it presents aesthetically appealing look. Vegetation on the embankment side slopes provides adequate canopy interception to the falling rain drops and saves the soil from splash erosion, while the mass of litter and Rhizomes act as speed breakers for running water on the slope. Mechanical function of plant is to reinforce the soil by binding the loose soil particles with its fibrous root system.

However, planting of tree species which grow considerably big/tall should not be permitted alongside the road in cyclone prone areas. During cyclones, such trees may get uprooted/ braches may snapwhich may cause obstruction to movement of traffic and may even lead to accidents. Moreover, roots of big trees may tend to loosen the structure of the embankment when shaken by wind storm which would cause cracks in the embankment. Shrubs, thorny bushes and short grass growing on the slope of embankments provide good protection against erosion and such vegetation should be promoted. Tree plantation should be carried out in areas beyond road land (Right of way) width. Generally the side slopes and unpaved shoulders in the top portion of the embankment should be turfed with grass sods and this turfing should extend beyond the toe on the country-side and the river side by 6.0 meters and 3.0 meters respectively. This is as per existing practices of some cyclone prone states.

Simple vegetative turfing method should be adopted where the soil has enough nutrients and the environmental conditions are conducive to promote vegetation growth. The density of sowing is of great importance. In general, while sowing a mixture of grass and legume plants, seed rate would be normally 15 gm/m2. Prior to sowing, the soil surface should be adequately prepared. On highly erodible slopes where seeding or sprigging is liable to be washed down before they have had time to take root. In such circumstances, it is advisable to go for special techniques such as the ones recommended in the succeeding paragraphs.

4.4.2 Transplantation of readymade turfs of grass

‘Sodding’ technique which involves bodily transplantation of blocks of turfs of grass (with 5-8 cm of soil covering the grass roots) from the original site to the barren slopes to be treated can be adopted in locations where ensuring grass growth would require considerable time. The sod to be used for transplantation should consist of dense, well-rooted growth of permanent and desirable grasses, indigenous to the locality where it is to be used, and it should be practically free from weeds or other undesirable matter. Thickness of the sod should be as uniform as possible, with some 50-80 mm or so of soil covering the grass roots depending on the nature of the sod, so that practically all the dense root system of the grasses is retained in the sod strip. The completed embankment side slopes should be scarified to a depth of about 25 mm and application of fertiliser/ manure should be carried out. After the sods have been laid in position, the surface shall be cleaned of loose sod, a thin layer of top soil shall be scattered over the surface of top dressing and the area thoroughly moistened by sprinkling with water. For further details MoRTH Specifications for Road and Bridge Works, Clause 307 and 308 can be referred to.

4.4.3 Application of mulch

The term ‘mulch’ refers to any loose or soft organic material, e.g. straw with cowdung or wood shavings mixed with cowdung or saw dust and dung mixture, etc laid down on the slopes to protect the roots of plants. In the case of embankments which are less than 3 m high, where the severity of the erosion problem is not of a high order, the mulch application would be very helpful for vegetation growth even in

15

infertile slopes. The approximate thickness of mulch cover should be about 2.5 cm. The organic mulch covering the soil slopes can be held in place and made resistant to being washed downhill or being blown away by pegging them down with bamboos, at suitable intervals, in a grid pattern. Cellulose based fibrous mulches can be hydraulically spray applied with the seed. These ‘spray-on’ mulch systems (also called Hydro-mulching or Hydro-seeding) are somewhat more resistant to erosion than dry applied systems but they are relatively costlier also.

4.4.4 Promotion of vegetative turfing by using jute/ coir netting

Growth of appropriate vegetation on exposed soil surface is facilitated by use of natural (agro based) geotextiles such as open weave jute geotextiles (JGT) or coir netting. Such nettings laid on slopes provides a cover over exposed soil lessening the probability of soil detachment and at the same time reduces the velocity of run-off, the main agent of soil erosion. Natural geotextiles bio-degrade within one to three years. In spite of this, agro based geotextiles facilitate rapid growth of dense vegetationduring its service life. Once dense vegetation develops on the slope, plant cover would prevent erosion and it would be self sustaining. Hence biodegradability of jute/ coir nettings cannot be considered as a drawback in areas which experience adequate precipitation to ensure green vegetation cover throughout the year. For more details and specifications of this technique, IS: 14986 ‘Guidelines for application of Jute Geotextile for rain water erosion control in road and railway embankments and hill slopes’, IS: 15869 ‘Open weave coir Bhoovastra-Specification’ and IS 15872 ‘Application of coir geotextiles (coir woven Bhoovastra) for rain water erosion control in roads, railway embankments and hill slopes-Guidelines’ may be referred to.

4.4.5 Erosion control using two dimensional (2–D) synthetic geogrids/ Geosynthetic nettings

Geosynthetic nettings/ geogrids can be used for promoting vegetation growth on barren slopes in a manner similar to biodegradable nettings. Under erratic weather conditions, successful vegetation growth and its sustenance depends on un-seasonal rainfall and hence longer life of reinforcing material would be required for ensuring vegetation growth apart from contribution from the mesh towards reduction in velocity of surface runoff. Agro based nettings may fail to provide erosion prevention in areas which experience repetitive change in climate, prolonged drought in particular. Use of polymer geogrid mesh provides a permanent protection as it is not biodegradable, long lasting and has almost unfailing success rate for vegetation growth, year after year.

4.4.6 Three dimensional erosion control mat / Rolled erosion control products

Relying upon vegetation growth alone may be sometimes very unpredictable and unreliable as it may be extremely difficult to achieve 100 per cent vegetation coverage, leaving exposed areas vulnerable to erosion. Furthermore, vegetation may sometimes dry up or become diseased, reducing its erosion control capability. Reinforced vegetation (or reinforced grass) is a better method that can be adopted for enhancing slope stability and erosion control. Such erosion control products are usually three dimensional mats, having multi-filamented materials of specified thickness. Such materials are known as Rolled Erosion Control Products (RECPs)/ 3-D Mats and also as ‘Turf Reinforcement Mats (TRM). While mats made using natural fibres last for one to two years, polymeric mats are used in situations where such products are required to last for a longer time. 3-D mats having a wide ranging variety of strength are available. The material used for manufacturing these mats also varies. Hence following general specifications are given (Table 4.1) for guidance. However, field conditions like harsh areas/ high survivability requirements may warrant use of 3-D mats with tensile strength as high as 35 kN/m or even more.

16

Table – 4.1 Property Requirements for 3-D Mat

3-D Mat Property Specified value* Test MethodMinimum Tensile Strength 2 kN/m ASTM D 5035UV Stability (Min % tensile strength

retention)80% ASTM D 4335 (500 hour

exposure)Minimum thickness 6.5 mm ASTM D 6525Mass per unit area (Minimum) 250 gm/ m2 ASTM D 3776

* Minimum Average Roll Values, machine direction only for tensile strength test

4.4.7 Preformed polymer geosynthetic cells or webs

Often, embankments are to be constructed in areas where vegetation may be difficult to establish and erosion problem might be severe due to water bodies. It may also be not possible to mitigate potential erosive forces that are likely to overcome the strength of the root system. In such cases ‘Geosynthetic Cells’ can be adopted. However, geosynthetic cells would be relatively more costly than all other techniques outlined above.

4.5 Ground Improvement Techniques

Often problems like slip failure of road embankment or high degree of unevenness of road pavements which occur in coastal roads can be traced to inadequate consolidation of clayey sub-soil found in such locations. Such problems in the coastal and delta areas arise due to low shear strength and high compressibility of soft clay sub-soils which are commonly referred to as marine clays. In severe cases, road embankments may even fail or pavement surface may experience unacceptable levels of settlements stretching over considerable period of time. Improvement of the load response behaviour of such soft sub-soil becomes necessary if the embankments are to be built economically and serviceability levels are to be kept high. Accelerating the consolidation process by providing vertical drains has been widely adopted for road embankment construction in such marine clay areas.

4.5.1 Ground improvement using vertical drains

Vertical drains have been in use for more than half a century to promote rapid consolidation of thick soft clay deposits like marine clays, where preloading alone will be insufficient. Sand drains were the earliest type of vertical drains used for consolidation of soft clay layer. Installation of sand drains is usually done by drilling boreholes in soft clay and back filling the borehole using sand of specified gradation. The major problem in this case would be formation of cavities due to bulking of sand. Polymeric vertical drains (PVD) which are also known as ‘Band drains’ have now virtually replaced sand drains/ sand wick technique for ground improvement.

4.5.2 Band drains (PVD)

Band drains consists of a plastic/polymeric core formed to create channels or paths which are surrounded by a thin geotextile filter jacket. Typically the size of band drains is 10 cm in width and 3 to 9 mm in thickness. The primary use of band drains is to accelerate consolidation and to greatly decrease the settlement time of embankments over soft soils. By doing so, band drains also accelerate the rate of strength gain of the in-situ soils. Band drains are used in consolidation situations where soil to be treated is a moderate to highly compressible soil with low permeability and fully saturated in its natural state. The soil should be either normally consolidated or under consolidated prior to loading. The loading should exceed maximum past consolidation pressure for the band drains to be beneficial.

17

Band drains are generally installed by displacement methods. The mandrels used with band drains are hollow and normally rectangular or trapezoidal in cross section. The mandrel covers and protects the band drain material during installation. All installation methods employ some form of anchoring system (generally using a disposable end shoe) to hold the drain in place when mandrel is withdrawn. Commonly used methods employ an installation mast (called ‘Stitcher’) which contains the material reels, mandrel and provision for providing installation force. Added to this is a carrier, which is a crawler excavator or crawler crane, depending somewhat on the depth of installation. Usually for drain installation depth upto 20 m, the mast can be mounted on a crawler excavator. Drains requiring depth greater than 20 m most often require an installation mast mounted to a crane to provide stability. The most important criteria for method of installation is the size of the installing mandrel. The mandrel should be kept to a minimum size, usually not greater than 80 cm2 unless larger size is required for penetrating to greater depth. Although equipment is available to work over slopes, a level granular surface containing no large obstructions is ideally required for band drain installation. Sufficient head room is also required for its installation. A thumb rule for head room required would be 3 m longer than depth of installation. Band drains have been installed upto 60 m depth, by using specialised equipment.

It is essential to recognise that band drains serve no structural function. By providing a shorter drainage path, it provides a faster release of excess pore pressure, thereby resulting in faster settlement and quicker strength gain through consolidation. For sites with a stability problem, the soil will initially have the same strength with or without the band drains installed. Further band drains do not play any role in secondary consolidation. Therefore in cases where secondary consolidation is expected to be significant, it is necessary to provide excess surcharge and/or extended waiting periods prior to final construction. It is not recommended to install band drains where pre-drilling is necessary for installation. A drainage layer of coarse sand or gravel is provided above the ground to drain off water from band drains. Generally sand layer is provided for a thickness of 0.5 to 1.0 m.

4.5.3 Stone columns

Stone columns comprise of boreholes of designed diameter made at specified distance apart in the soft soil, which are then back filled using stone aggregates and compacted. The diameter of stone columns varies from about 0.4 m to 0.7 m and their spacing varies from 1.5 m to 3.5 m. This method is used in soft subsurface soils to both accelerate settlement and provide sufficient increase in strength to

Fig – 4.4 A Type of Polymeric Vertical Drain (Band Drain)

18

minimise settlement and prevent deep seated shear failure. However stone column technique would be comparatively costlier than providing polymeric vertical drains. Hence stone column technique is selectively adopted to support structures which are sensitive to large amount of settlement or in cases where it is also required to increase the bearing capacity of the sub-soil. At locations where undisturbed shear strength of clayey soil (Su) is lower than 15 kPa, providing stone columns may result in considerable wastage of stone aggregates and Geosynthetic encased stone columns may be adopted in such places. IS 15284 (Part 1) provides guidelines for design and construction of stone columns.

4.5.4 Instrumentation and monitoring

Field instrumentation such as piezometers, settlement platform, settlement gauges and inclinometers are used to monitor performance of band drains and possibly control the rate of embankment construction and/or surcharge. It is important that both the designer and the instrumentation personnel have a full appreciation of the instrumentation being installed. Generally settlement measuring devices of different types like settlement platforms, deep settlement points or horizontal deflection devices are used to measure only the rate and total amount of consolidation. An inclinometer is used to measure horizontal deflection with depth and as a warning device against potential failure. The pore pressure devices (piezometers) are used for both calculation of achieved consolidation rate and excessive build up of pore pressure which are an indication of potential failure. Proper selection of instrumentation devices and the frequency of monitoring a project are important. For simple projects where stability is of no concern, and time is not the critical factor, only surface settlement platforms, which are relatively easy to install, are needed. In situations where stability is critical, pore pressure measurements and measurements of horizontal deformations (using inclinometer) are also necessary. The monitoring can be done daily or once in two/three days during loading period depending on rate of loading. The periodicity of taking the readings from the instruments can then be reduced to once a week or ten days gradually after loading is over. The design of PVD system and monitoring of consolidation using instrumentation are a specialised job and hence advice of geotechnical consultants is to be obtained in these tasks.

4.6 Embankment Construction in Waterlogged Areas

When embankment construction is to be undertaken through an existing pond, dewatering and slush removal should be taken up before placing the embankment fill. In case dewatering is not considered to be feasible and embankment is to be constructed under water, only acceptable granular material shall be used. Acceptable granular material should consist of well graded, hard durable particles with maximum particle size not exceeding 75 mm. The material should be non plastic having coefficient of uniformity not less than 10. The material placed in standing water shall be deposited by end tipping without compaction.

Other methods which can be adopted in water logged areas include – Depressing the water table by using geotextile wrapped aggregate drains (also known as trench drains), raising the embankment height and providing a capillary cut off. Custom made synthetic drains made of polymeric materials are also available which can be used in place of aggregate trench drains. For more details regarding embankment construction in waterlogged/ salt infested areas or in areas where ground water table is very high, IRC: 34, ‘Recommendations for road construction in areas affected by waterlogging, flooding and/or salts infestation’ may be referred.

19

Chapter – 5

SEA EROSION CONTROL TECHNIQUES & RIVER BANK PROTECTION

Coastal beach erosion occurs in various forms around the world. This phenomenon gets more acute during cyclones and in-turn causes damage to infrastructure facilities including roads. This is due to severity of waves and storm surge which result in coastal erosion. The basic approach to mitigate coastal erosion related problems is to provide suitable cover to the soil. The measures to control coastal erosion can be categorised as structural and soft/ non-structural. These can be taken up together or separately also. Structural measures used for arresting coastal erosion are sea wall, revetment (rock armour, gabion mattress or precast concrete block revetment systems), offshore breakwater, groynes, etc. Soft measures generally adopted to prevent coastal erosion are artificial nourishment of beaches, vegetative cover such as mangrove plantation, etc. Instead of providing rock armour layer, latest and environmental friendly technologies which make use of geosynthetics for construction of armour protection layer can also be adopted.

5.1 Wave Generation in Sea

Waves are caused by a disturbance of the water surface. Such disturbances become more prominent during cyclones because of wave surge and high speed winds. Most waves are generated by wind. After waves are formed, they can propagate across the surface of the sea for thousands of miles. When waves break on a shoreline or coastal structure, they have fluid velocities and accelerations that can impart significant forces. The wave period of individual waves remains constant through the transformations until breaking but the direction of propagation and the wave height can change significantly. As a wave moves into shallower water the wavelength decreases and the wave height increases. Waves break at two general limits:

In deepwater, waves can become too steep and break when the wave steepness defined as, H/L, approaches 1/7 (where H = Height of the wave i.e., distance between crest of the wave and water surface, L = Wave length defined as distance between two successive wave crests).

In shallow water, waves break when they reach a limiting depth (d) of water.

This depth-limited breaking is important in the design of coastal revetments protecting highways. For an individual wave, the limiting depth is roughly equal to the wave height and lies in the range given below:

0.8 < Maxd

H

> 1.2 ........... Equation 5.1

A practical value of wave height which can be considered when there is mild sandy slope offshore is:

MaxdH

≈ 0.8 ........... Equation 5.2

5.2 Systems for Protection of Coastline Against Sea Erosion

The systems adopted for protection against water erosion comprise of two different parts – the outer revetment or armour layer to absorb the hydraulic energy of velocity of water flow and/or the wave energy; and the inner part of filter layer. Revetment systems in the form of rip-rap blocks, prefabricated concrete elements or gabion mattresses or RCC/stone masonry walls are most commonly used as

20

armour layer. The function of inner filter layer is to prevent soil particles from being eroded and to allow free escape of internal water simultaneously. Conventionally several layers of granular material with well designed grain size distribution and thicknesses are used for this purpose. Geotextiles can be successfully adopted to replace such granular filter material. They are now being increasingly adopted owing to various technical advantages, cost benefits, ease of installation, faster completion of the project and superior long term performance of the system. Fig 5.1 to 5.6 show photos of protection measures adopted at various locations in India for protection of sea coast.

5.2.1 Bulkheads and revetments

The distinction between revetments, seawalls, and bulkheads is one of functional purpose. Revetments are layers of protection on the top of a sloped surface to protect the underlying soil. Seawalls aredesigned to protect beach against large wave forces. Bulkheads are designed primarily to retain the soil behind a vertical wall in locations with less wave action. Bulkheads are mostly adopted where wave heights are very small. Seawalls are more common where wave heights are quite large. Revetments are often common in intermediate situations such as on bay or lake shorelines. Seawalls can be rigid structures or rubble-mound structures specifically designed to withstand large waves. Vertical sheet pile seawalls with concrete caps are common but require extensive marine structural design. A more common seawall design type is a rubble-mound that looks very much like a revetment with larger stones to withstand the design wave height. Thus, the two terms, seawalls and revetments, can be used interchangeably with the former typically used for the larger wave environments.

5.2.2 Seawall

Seawall is useful in case of protection of specific area from erosion due to waves and storm surges. Seawalls are constructed along the coast adopting stone masonry technique or using reinforced cement concrete. Seawall can be constructed using gabions also when wave heights are low, typically less than about 1.0 m. Seawalls constructed using gabions are permeable and flexible; thereby they would be able to withstand differential settlement without loss of its structural integrity. Provision of filter layer behind the seawall is essential to prevent piping of sand and subsequent destabilisation of structure. Sometimes a combination of sea wall constructed using masonry or reinforced cement concrete is further protected on sea side using gabions or concrete blocks/ tetrapods. Design of the masonry or gabion seawalls is to be carried out in a manner similar to design of retaining walls, to ensure stability against overturning, sliding, excessive foundation pressure (bearing capacity failure) and water uplift. Additionally ‘Wave flume studies’ may also have to be adopted to arrive at satisfactory design of stone, rock and/or concrete armour units.

5.2.3 Breakwater

Breakwaters are coastal structures constructed to protect an area from the effects of waves. Breakwaters are adopted to protect a ship berthing area, to train and prevent silting of the entrance of river mouths or to prevent erosion of coastlines. However, adverse effects are observed on down drift side and it should be avoided unless their main purpose is to protect a specific area at the cost of adjoining areas. An off-shore breakwater may be constructed to prevent beaches or coastlines from erosion by wave activity. The off-shore breakwaters are submerged structures located at certain distance offshore in order to dissipate wave energy before they reach shoreline. The broken waves would not be having the energy to erode the beach or coastline and the coastline may even increase in extent as a result of accretion. It is an expensive option and needs regular maintenance.

21

Fig – 5.1 Provision of Sea Wall and Concrete Tetrapods for Sea Erosion Protection at Mumbai

Fig – 5.2 Protection Against Sea Erosion by Retaining Wall and Gabions – Puri Konark Road

Fig – 5.3 Another View of Protection Works – Puri Konark Road

22

Fig – 5.4 Beach Protection Using Boulder Revetment at Paradip, Odisha

Fig – 5.5 Another View of Boulder Revetment at Paradip, Odisha

Fig – 5.6 Masonry Sea Wall Constructed at Sea Coast at Koteshwar, Kori Creek, Gujarat

23

5.2.4 Soft Structural/ Non-structural measures – Artificial nourishment of beaches

Beach nourishment may be adopted for protection and beach development. Combination of nourishment of beaches with seawall/ groynes will create beach in front of protected area and eliminate leeside erosion.

5.2.5 Vegetation cover

Plantation of mangroves and palm trees can be taken up for beach protection. Vegetation cover can restrict sand movement and erosion.

5.2.6 Artificial reef balls

A reef ball is a designed artificial reef used to restore ailing coral reefs and to create new fishing and scuba diving sites. Reef balls are the only type of artificial reefs that can be floated and towed behind a boat. Reef balls are made of a special grade marine environment resistant concrete and are designed to mimic natural reef systems. They are also used widely to create habitats for fish and other marine and fresh water species. Reef balls are made in many sizes to best match the natural reef system which is being mimicked.

Out of these measures, depending on the techno-economic viability, any suitable measure can be adopted, while a combination of these measures usually gives optimum results.

5.3 Design of Coastal Rip-rap Against Wave Attack

Rip-rap can be used for protection from four different types of hydraulic situations: direct rainfall impacts, overland flow, stream or river currents, and waves. This section addresses only wave attack. IRC:89 provides procedures for the design of riprap revetments for channel bank protection on larger streams and rivers where the active force of the flowing water exceeds the bank material’s ability to resist movement. Brief details of the same are provided in section 5.6. Flow in a stream or river is unidirectional and typically aligned parallel to the banks. Waves produce oscillatory velocities and accelerations that can be in almost any direction on a revetment. In such situations, it is recommended that ‘Hudson’s equation’ be used to estimate stone size for revetments subject to wave action. This involves determining the design wave height (as per equation 5.1) and using Hudson’s equation to size the stones to be used for rip-rap. This approach can lead to designs with larger stones and narrower stone gradations than designs for non-wave situations. The difference is due to the higher forces caused by waves. Situations where riverine and wave flows are also significant, the design engineer should consider both design approaches and develop a conservative design. A simplified version of Hudson’s equation for calculating required median weight for the outer, or armour layer, stones is:

θcot 280H

W3

50 ........... Equation 5.3

Where, W50 = Median weight of armour stone in kgsH = Design wave height in mΘ = Slope

The range of recommended slopes for revetments is up to 2:1 (horizontal:vertical) or flatter. Hence cotΘwould be equal to 2 for a 2:1 slope and cotΘ=3 for a 3:1 slope. Apart from armour stone, either graded aggregate filter layers or preferably geotextile needs to be placed below armour to prevent piping

24

failure. Selection of geotextile can be carried out as per IRC SP:59. A typical rip-rap gradation for coastal revetment with a median weight W50 = 350 kgs, will have 50 per cent of stones weighing between 100 kgs to 350 kgs, 30 per cent weighing between 350 kgs to 700 kgs, and 20 per cent weighing between 700 kgs to 1350 kgs. Thus, the recommended coastal revetment gradation precludes the smaller stones and allows for some larger stones as compared to gradation adopted for river bank protection. These smaller stones are typically not included in coastal revetments because of their tendency to move in response to wave action. Further it may be noted that the construction of a revetment, while it protects the upland, does not address the underlying cause of erosion. The depths at the toe of the revetment will likely increase if the erosion process continues. The presence of a revetment or seawall can increase the vertical erosion at its base. A common practice to overcome toe erosion is to extend revetment beyond the slope inside water and provide toe protection. A commonly proposed alternative to rubble mound revetments is a concrete block revetment, which are also known as 'Tetrapods'. Some of these have physical interlocking between individual blocks also. Many such concrete blocks which have a patented shape are also available. These are essentially unreinforced concrete objects designed to resist the wave action. If the intensity of wave action is severe, then additional layers of armour protection would be required. In such cases, ‘Tetrapods’ can be placed over stone blocks.

5.4 Use of Geosynthetic Products as Revetment

Coastal and waterways protection applications comprised the earliest use of geosynthetics. Over the last 40 years, there have been numerous coastal and waterway protection projects that have utilised geosynthetics. Geosynthetics can be used as components of coastal and waterway protection measures in two different ways – they can be used as filters within coastal and waterway protection structures and they can also be used to create revetment systems (containers) to act as mass-gravity protection works. During the construction of structural measures to control sea erosion, problem generally faced is the non availability of construction materials like big size boulders, sand, etc., within reasonable and cost effective distance. This problem can be sorted to a great extent by using geosynthetic revetment systems. The most universal and widely used geotextile containers are well-known, ubiquitous sand bags which are seen world over for shoring up flood defences in times of natural calamity. The dominant geosynthetic material used for making revetment systems is geotextiles, which are robust and permeable materials. Three types of geoetextile revetment systems differentiated by geometrical shape are available. They are geotextile tubes, geotextile containers and geotextile bags. Geotextile tubes are tubular containers that are filled in-situ on land or in water. Geotextile containers are large volume containers that are filled above water and then deposited into the submarine environment. Geotextile bags are small volume containers that are filled on land or above water and then pattern-placed either near water or below water level. The geotextile revetment systemshave the following advantages:1. They are resistant to chemical attacks occurring in usage, especially to alkalies and acids.2. Geotextiles are quite durable when exposed to elements of nature like – Sun, precipitation, etc.

However, ultraviolet radiation reduces their strength in long term. Hence they need to be treated to enhance their ultraviolet resistance if they are going to be exposed to sun during their service life.

3. They are resistant to organic attacks like bacteria and fungus and are not attractive to rats or termites.

Geotextile containers behave as mass-gravity elements that can resist hydraulic forces. For these applications, the geotextile skin should have specific mechanical, hydraulic and durability requirements.Distinction must be made between those applications where the geotextile containment is required for only temporary use and those applications that require long term performance. For temporary works the requirements of the geotextile container itself is fairly basic as it only has a short life over which it has to

25

perform, however for long term applications, the performance requirements of the geotextile container are more severe. With regard to long term performance, distinction must also be made according to type of hydraulic environment acting on the geotextile container. For example, the action of still water, or intermittent water flows, will have a different effect on the geotextile container than the action of breaking waves.

5.4.1 Geotextile tubes

Geotextile tubes are large cylindrical structures made using high strength woven geotextile material which are then filled with dredged material in-situ. Geotextile tubes may be used for a range of coastal and waterway protection applications where barrier type, mass-gravity, structures are required. Thedredged material is usually pumped in a slurry form from nearby area and consists of a mixture of sandy soil and water. The geotextile tube, being permeable, enables the excess water to pass the geotextile skin while the fill attains a compacted, stable mass within the tube. For coastal and waterway applications the type of fill used is sand, or a significant percentage would be sand. The reasons being – sand can be compacted to a good density by hydraulic means, sand has good internal shear strength which gets further improved by the presence of confining geotextile tube skin, and this type of fill once compacted, will not undergo settlement, which would change the shape of the filled up geotextile tube The tube is filled by direct coupling to a hydraulic pumping system conveying dredged material. Designed with appropriately sized openings called ‘Filling Ports’, the geosynthetic tubes retains fill material while allowing water to permeate through tube wall. After dewatering typically very little consolidation will occur in case of pure sands while it may be as much as 70 per cent in case of tube that has been filled with fine grained organic material. Openings called, fill ports are provided in geotextile tubes at a spacing of about 8 to 10 m for filling dredged material. Special high strength seaming techniques are adopted in their manufacturing process to resist pressure during pumping action. Geotextile tubes permanently trap granular material in both dry and underground construction. Geotextile tubes are generally about 1 m to 3 m in diameter, though they can be custom made to any size depending on their application. Geotextile tubes ranging in diameters from 1.5 m to 5.0 m are available for coastal and waterway protection applications. Stacking of geotextile tubes one over other can also be made to construct structures of higher heights. Geotextile tubes may be used for a range of coastal and waterway protection applications where barrier type, mass gravity structures are required. Geotextile tubes can be used for construction of groynes, off-shore breakwater, etc. When geotextile tubes are used as off-shore breakwater structures, the dimensions of geotextile tubes are to be chosen in such a way that waves break over the geotextile tubes.

Geotextile tubes are normally described in terms of either a theoretical diameter, D or a circumference, C. While these two properties represent the fundamental characteristics of geotextile tubes they are not of direct interest when it comes to engineering parameters for coastal and waterway protection

Fig – 5.7 Typical Components of a Geotextile Tube

26

applications where the geotextile tube in its filled condition is of prime importance. When the geotextile tube has been filled with sand, it assumes an oval shape. The width of the oval tube and its height are of importance from engineering performance point of view. Table 5.1 lists relationships between the fundamental geotextile tube characteristics and engineering parameters. The relationships are applicable to geotextile tubes that have a maximum strain of about 15 per cent, low unconfined creep, and are filled to maximum capacity with sand. It is also assumed that the foundation beneath the tube is a flat, solid surface.