-

7/28/2019 Geotessili Ing

1/15

EdilfloorEdilfloorProfessionalism and knowledge at 360

Nonwoven geotextile

-

7/28/2019 Geotessili Ing

2/15

Located in Sandrigo since 1979, Edilfloor SpAmanufactures nonwoven geotextiles and geogridsfor application in the geotechnical field andnonwoven technical textiles for industrialapplications. The geocomposites for the acousticinsulation are also part of Edilfloor product range.

Since 30 years, Edilfloor SpA is present in thegeosynthetics market and today its productioncapacity is of about 50 millions of square metres.With a ISO 9001 certified quality system, EdilfloorSpA uses a Strategy for the quality since thebeginning of its activity: from the production tothe sales and to the customer services, its qualitystrategy is the key to success of Edilfloor SpA.

News

EdilfloorEdilfloor

-

7/28/2019 Geotessili Ing

3/15

To supply products and services which cansatisfy customers needs and ideas

To supply products and services creating asurplus value

To improve the technical and human skillsof Edilfloor personnel by respecting their

expectations To improve the internal processes so to get themaximum of the efficiency and of efficacity

To establish and maintain a partnership withthe suppliers so to increase the competitiveadvantages for both parties

To operate respecting the security laws andthe environment

To operate achieving all the results with abehaviour ethically correct and sociallyresponsible

To act with the perspective of thecontinuous improvement so thatEDILFLOOR is recognized as a highquality blend

To be focused on the sales in new marketsfacing the competitors with a highquality/price relation

To increase the range of the EDILFLOORproducts

To expand the commercial and marketingaction in the national and foreign markets

To invest considerably in the technologyinnovation and research

To maintain a dimension that allow thecompany to adapt quickly to the marketand customers changes

Edilfloor main goals Strategy

A key to success has always been the very

strict relationship existing between the

production, the sales personnel and the

management. Those three elements allow

Edilfloor SpA to achieve the most important

result: the customer satisfaction.

Customer

Production

Customer

Satisfaction

Management

Woven geogrids

-

7/28/2019 Geotessili Ing

4/15

GEODREN

DENSITEX

GEOPAV

THERMOFELT

Geotextiles are permeable fabrics which are employedin contact with the soil or any other construction products,in civil engineering or geo-technical works such as road works,railway constructions, tunnels and underground works,reservoirs and dams, shore protection, underground worksand foundations, river banks and canals, landfills, filtration,road pavements.

EDILFLOOR SpA geotextiles are marketed with these brands:

-

7/28/2019 Geotessili Ing

5/15

Geodren PPSTNonwoven geotextile in high quality white polypropylene staples,

needlepunched and calandered. Produced without chemicals or glues.

Geodren PPST PNonwoven geotextile in high quality white polypropylene staples,needlepunched. Produced without chemicals or glues.

Geodren PPEXTNonwoven geotextile in white polypropylene staples, needlepunched andcalandered. Produced without chemicals or glues.

Geodren PPTNonwoven geotextile in multicoloured polypropylene staples,needlepunched and calandered. Produced without chemicals or glues.

Geodren PEITNonwoven geotextile in white polyester staples, needlepunched andcalandered. Produced without chemicals or glues.

Geodren PECTNonwoven geotextile in multicoloured polyester staples, needlepunchedand calandered. Produced without chemicals or glues.

Thermofelt PPEXT2Nonwoven geotextile in white polypropylene staples, needlepunched andthermobonded on both sides. Produced without chemicals or glues.

Thermofelt PET/T1Nonwoven geotextile in high quality white polyester staples, needlepunchedand thermobonded on one side. Produced without chemicals or glues.

GeopavNonwoven geotextile in black high quality polypropylene staples,needlepunched and thermobonded on one side. Produced withoutchemicals or glues.

Nonwoven geotextile

-

7/28/2019 Geotessili Ing

6/15

Roads

The Geodren PP/S/T version is suitable forthe construction of new roads, motorways,yards and heavy traffic areas. It has aremarkable separating, strenghtening andfiltering action and it is usually put on thebuilding site before the laying of the granularmaterial, in order to improve load distributionand to avoid gravel contamination by the soil.

Railways

In order to adapt the lines to faster trains, acomplete reliability of the railway structure,also for what concerns life and limitedmaintenance operations, is necessary.Geodren PP/S/T can be used for this purpose,as a separating layer between the foundationground and the ballast layer, placed underthe lines. The geotextile avoids the ballastpenetrating into the soil, that would cause areduction of the railway load capacity and,at the same time, it avoids the foundationground penetrating the ballast layer causinga reduction of the support elasticity.

-

7/28/2019 Geotessili Ing

7/15

Tunnels

For what concerns the construction oftunnels, galleries and under ground structures,Geodren PP/S/T is able to carries out twomain functions: the protection of thegeomembranes and the drainage of thepercolating water. It is very important thatthe water-proofing of a tunnel is done in aprofessional way.

Landfills

Geodren PP/S/T has often been used in thelast few years, also for the construction oflandfills and dams, as a consequence of thefrequent use of geomembranes.The reasons of the success of these newmaterials are represented by their better layingoperations, their more technical reliability, and,above all, their lower costs compared totraditional water-proofing systems done usingconcrete slabs, bitumen, clay layer etc..

Nonwoven geotextile

-

7/28/2019 Geotessili Ing

8/15

Coast-line protection The effects of wave movement

complicate the designing of coast-lineprotective structures. Also in this fieldGEODREN is frequently used,especially as a filter. It is easily layable,also under water, and in this case it isadvisable to use a polyester geotextile.

River banksRiver banks, both natural or artificial,are constantly subject to water action,that becomes particularly dangerous,in the sense of the erosion, in case ofhigh speed current and/or rapid levelchanges. The erosion which takesplace at the foot of the bank can, infact, in time cause problems for whatconcerns the stability of the bank itself,with consequential breakage.Geodren PP/S/T offers many technicaland economical advantages, ifinstalled as a filter and as an anti-erosion system, directly on the bankballast, before the application of theprotective surface elements (rocks,gabions, mattresses ).

el

e le

i

s ila

a

-

7/28/2019 Geotessili Ing

9/15

Under ground structures andfoundations

The under ground cement structures,being more or less porous, need to beprotected against environmentalaggression.The elements that can have a negativeeffect on under ground structures are

water, soil, corrosive substances,biological agents and stray currents.A simple protective covering is nolonger sufficient to protect them, soproducts for a water-proof protectionare required.

RoofingThe geotextile in this application isused as a protection of thewaterproofing membranes in theconstruction of the flat roofs, actingas an anti-puncture protection layer.

Nonwoven geotextile

-

7/28/2019 Geotessili Ing

10/15

In this section we introduce the main functions of theEDILFLOOR geotextiles.

For more technical details, the Design Guide withEdilfloor geosynthetics is available.

-

7/28/2019 Geotessili Ing

11/15

Separation

The aim of the separation function is keeping either two terrain layers ofdifferent granulometric composition or two layers consisting of differentmaterials separated, without preventing water circulation.

FiltrationThe filtration is the function that defines the possibility of a geotextile toact as a filter preventing the migration of the fine particles of the baseterrain and allowing the water to flow out through the surface of thenonwoven geotextile. It has to be designed considering three apparentlycontrasting criteria:The retention requirementThe permeabilityrequirementThe non-retention requirement

ProtectionThe applications in which geotextiles have to fulfil a protection functionare usually constructions of tunnels, dumps, underground constructions,foundations, catchment basins, flat roofs.

In all these cases the geotextile is used for protecting the geomembrane,that fulfils a waterproofing function in the structure.

DrainageDrainage is the geotextile capacity of transporting liquid or gas along itsplane.

ReinforcementThe geotextile reinforcement function with nonwoven geotextiles isobtained through products with an extremely high resistance to tensilestrength and therefore of course unit weight. Fulfilling a reinforcementfunction usually means that the geotextile has to constrict the terrainthus making it less sensitive to deformation under load.

Nonwoven geotextile

-

7/28/2019 Geotessili Ing

12/15

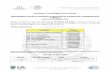

3000

2500

2000

1500

1000

500

0

Max tensile strength(2800 N/20 cm - 14 kN/m)

Energy index:(14 kN/m x 0,58 m) /2 = 4,06

kJ/m

Elongation (58%)

AN EXAMPLE:

Name of the product: GEODREN PPST 200 g/mm2

Max tensile strength (MD/CMD): 14 kN/m - 2800 N/20 cm

Elongation at max load: 58%

Energy index: 4,06 kJ/m

Energy absorption: One of the new concept concerningthe mechanical properties of the geotextiles is the energyindex. This characteristic measures the capability of ageotextile to absorb the energy developed by the forcesin the ground. In this page we can see a picture of astandard tensile test according to EN ISO 10319. Inhorizontal we can read the elongation value measured

in %; in vertical we can read the value of the force appliedin N/20 cm. The energy index is a calculated value andindicates the area under the curve as shown in the imagein this page. Due to the usual nonwoven geotextile curvewe can simplify the calculation as the area of triangle,so the product of the maximum tensile strength multipliedwith the elongation at maximum load divided by two.

-

7/28/2019 Geotessili Ing

13/15

Kly = Kilo-Langley = 1000 Langley(Langley is a unit of irradiation energy)1 Kly=1 Kcal/cm2

Lab test with corindone

Lab test with porphiry

Prove in sito con porfido

NORTHERNEUROPE

CENTRALEUROPE

SOUTHERNEUROPE

70-80 klyMedium exposure

per year

Durability withstandard PP raw

materials(50% of the initial strength)

Durability with UVtreated PP raw materials

(50% of the initial strength)

REGION MIDDLEEAST

1 year

3 years

1 year

3 years

80-100 kly

6 months

2 years

120-140 kly

6 months

2 years

160-180 kly

100%

80%

60%

40%

20%

0%

GTN GGW1 GGW2 GGE

87.0 %

97,6 %92,4 %

43,1 %

70,2 % 71,1 %

91,6 %97,8 % 97,6 % 99,7 % 97,8 %

99,8 %

Damage during installation: This is one of themost delicate stages affecting the performanceof a geotextile once it has been laid. A specificregulation EN ISO 10722-1 defines theprocedures of the test on the damage sufferedby the geotextile when it is being laid.GEODREN PPST results are very good evencompared to other geosynthetic materials,since the reduction of their mechanicalperformances after installation is very limited,which means that the mechanical and hydraulic

features of these geotextiles are preservedeven at the moment of installation. In fact theelongation of our nonwoven geotextiles allowsthe product to adapt to the irregularity of thesurface without breaking. We show youhereafter a comparison chart between differentgeosynthetic materials with the results of thedamage during installation on different soilsand laying conditions for the products listedhere below. The testing has been made by anindependent laboratory.

GTN: GEODREN PP/S/T 500P g/m2 .GGW1: Woven geogrid, in high tenacitypolyester yarns coated PVCGGW2: Woven geogrid, in high tenacity

polypropyleneGGE: Mono-directional extruded geogrid, inpolypropylene

The UV resistance of polypropylene staple:The breaking strength of PP raw materials isreduced by UV exposure. The reduction of thebreaking strength depends on exposure time,exposure intensity, temperatures, chemical andmechanical influences. Therefore exact valuesof the impact cannot be forecast.The reduction of the breaking strength ismeasured in number of years which pass until

the breaking strength has reached 50% of itsoriginal value. Our experience and Lab test onXenotest 1200 provide following values for PPraw materials:

Nonwoven geotextile

The quality control: All EDILFLOOR geotextiles,independent of the quality of the raw materialused, are top-quality in their category. This isdue above all to the fact that the quality systemwith which the company operates complieswith the requirements of the regulation UNI EN

ISO 2001:2000, better known as VISION 2000.

Edilfloor wide range: GEODREN productsmeet the different performance needs accordingto the application in which they will be used.This line includes polypropylene and polyestergeotextiles manufactured with both top-qualityf ibres and recycled f ibres, white or

multicoloured.

-

7/28/2019 Geotessili Ing

14/15

Edilfloor SpA wants to act in the geosynthetic sector withthose main goals:

The satisfaction of customer needs and expectations

The continuous improvement of the internal organizationprocess so to get the maximum level of efficiency andefficacy

The contribution of all Edilfloor employees to define theimprovement plan

The development of an effective quality culture in all internalprocesses

The correctness and seriousness in all the relationships withthe suppliers and all the people that co-operate with Edilfloor

The respect for the community values and for the environment

Nonwoven geotextile

EMPA

-

7/28/2019 Geotessili Ing

15/15

EDILFLOOR SpA

Via L. Da Vinci, 15 (Z.A.) - 36066 Sandrigo (Vicenza)

Tel. +39 0444 750350 - Fax +39 0444 657246

e-mail:[email protected] - http://www.edilfloor.com

EdilfloorEdilfloor