Gas Dynamics of Turbine Cascades P M V Subbarao Professor Mechanical Engineering Department Its Group Performance, What Matters.……

Gas Dynamics of Turbine Cascades P M V Subbarao Professor Mechanical Engineering Department Its Group Performance, What Matters.……

Jan 15, 2016

Welcome message from author

This document is posted to help you gain knowledge. Please leave a comment to let me know what you think about it! Share it to your friends and learn new things together.

Transcript

Gas Dynamics of Turbine Cascades

P M V SubbaraoProfessor

Mechanical Engineering Department

Its Group Performance, What Matters.……

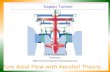

Turbine Blade on A Disk

Introductory Remarks

• The science of gas dynamics is becoming more and more applied to turbines.

• It is of interest to inquire how far the knowledge of aerofoil mechanics is applicable to steam and gas turbines.

• Almost all steam turbine blades have much greater curvature than basic aerofoils.

• This is a necessity for utilizing the entire pressure difference of steam/gas in a practicable number of stages.

The Influence of Neighbors

The group of Aerofois

• An important point to be examined is whether the crowding together of steam/gas turbine blades has effects similar to those noticed in aeroplane practice.

• A biplane is stated to have less lifting effect than a monoplane of the same wing surface.

• The biplane arrangement is analogous to the circumferential pitching of steam/gas turbine blades.

• Additional wing surfaces in series (one behind the other), analogous to avoiding of pressure compounding in a turbine.

• The reasons for grouping may have some bearing on turbine blading efficiency.

Influence of Neighboring aerofoils

The Group Behavior

Steps in Analysis of Blade Cascades

Nomenclature of Turbine Cascades

More Geometrical Specifications of Arrangement of A Cascade

Vr1

Vr2

More Geometrical Specifications of Arrangement of A Cascade

Ub

Geometrical Details of A Cascade

The Cascade

Solidity: the first Step in Cascade Design

• One of the important aspects of cascade design is the selection of the blade solidity.

• Defined as the ratio of chord or axial chord to blade spacing.

• A minimum allowable value is usually desired from the standpoint of reducing weight, cooling flow, and cost.

• An increase in the blade spacing eventually results in decreased blade efficiency due to separated flow.

• An optimum solidity cascade should be a fully attached flow with maximum blade spacing.

• The gas dynamic factors affecting solidity are

• The requirements of velocity diagram

• The blade loading

Related Documents