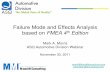

FMEA Objective, scope and goal(s): Key Date: System: Potential Subsystem: Failure Mode and Effects Analysi Component: Design Design Lead: Core Team: rev 1.0 42303 Item / Function 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 © TLC, 2003 Potential Failure Mode(s) Potential Effect(s) of Failure S E V Potential Cause(s)/ Mechanism(s) of Failure P R O B Current Design/Process Controls D E T R P N

FMEA Analysis

Oct 31, 2014

Automotive core tools FMEA refernce.

Welcome message from author

This document is posted to help you gain knowledge. Please leave a comment to let me know what you think about it! Share it to your friends and learn new things together.

Transcript

FMEA Objective, scope and goal(s):

Key Date:

System: PotentialSubsystem: Failure Mode and Effects Analysis (FMEA)Component: Design

Design Lead:

Core Team:

rev 1.0 42303

Item / Function

0 0 0 0

0 0 0 0

0 0 0 0

0 0 0 0

0 0 0 0

0 0 0 0

0 0 0 0

0 0 0 0

0 0 0 0

0 0 0 0

0 0 0 0

0 0 0 0

0 0 0 0

0 0 0 0

0 0 0 0

0 0 0 0

0 0 0 0

0 0 0 0

0 0 0 0

0 0 0 0

0 0 0 0

0 0 0 0© TLC, 2003

Potential Failure Mode(s)

Potential Effect(s) of Failure

SEV

Potential Cause(s)/

Mechanism(s) of Failure

PROB

Current Design/Process

Controls

DET

RPN

FMEA Type: Design

Potential FMEA Number: Failure Mode and Effects Analysis (FMEA) Prepared By:

FMEA Date:

Revision Date:

Page: of

Action Results

Actions Taken

New

Sev

New

Pro

b

New

Det

New

RP

N

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

Recommended Action(s)

Responsibility & Target

Completion Date

Design FMEA Ex.

Page 3

Key Date:

System:

Subsystem:

Component:

Design Lead:

Core Team:

Item / Function

Seals

Compression set

Potential Failure Mode(s)

Coolant containment. Hose connection. Coolant fill. M

Sensor mount. Seal

Sensor mount. Seal

Loosen during sensor assembly/service

Sensor mount. Seal

Damaged internal thread

Sensor mount. Seal

Damaged external thread

Coolant containment. Hose connection. Coolant fill. M

Crack/break. Burst. Side wall flex. Bad seal. Poor hose rete

Design FMEA Ex.

Page 4

System:

Subsystem:

Component:

Design Lead:

Core Team:

Item / Function Potential Failure Mode(s)

Stress crack

Stress crack

Stress crack

Corrosion

Corrosion

Puncture

Coolant containment. Hose connection. Coolant fill. M

Crack/break. Burst. Side wall flex. Bad seal. Poor hose rete

Coolant containment. Hose connection. Coolant fill. M

Crack/break. Burst. Side wall flex. Bad seal. Poor hose rete

Hold fluid, flow path, Heat transfer structure

Hold fluid, flow path, Heat transfer structure

Hold fluid, flow path, Heat transfer structure

Hold fluid, flow path, Heat transfer structure

Hold fluid, flow path, Heat transfer structure

Hold fluid, flow path, Heat transfer structure

Design FMEA Ex.

Page 5

System:

Subsystem:

Component:

Design Lead:

Core Team:

Item / Function Potential Failure Mode(s)

Seam fail

Burst fail

Plugged

Ballooning

© TLC, 2003

Hold fluid, flow path, Heat transfer structure

Hold fluid, flow path, Heat transfer structure

Hold fluid, flow path, Heat transfer structure

Hold fluid, flow path, Heat transfer structure

Design FMEA Ex.

Page 6

FMEA Objective, scope and goal(s):

FMEA Type: Design

Potential FMEA Number: Failure Mode and Effects Analysis (FMEA) Prepared By:

Design FMEA Date:

Revision Date:

Page: of

Action Results

Actions Taken

New

Sev

New

Pro

b

New

Det

0

0

Leak 8 Gasket material 7 1 56

8 2 Added rib. 1 16

5 2 1 10

4 3 1 12

Leak 8 Over pressure 8 1 64

Potential Effect(s) of Failure

Sev

Potential Cause(s)/

Mechanism(s) of Failure

Prob

Current Design/Process

Controls

DET

RPN

Recommended Action(s)

Responsibility & Target

Completion Date

Pressure cycle w/cold shock.

Use imported material

Leak. Fall inside tank

Fitting not held in place

Implement holding rib in design. New fitting design. Prototype validation.

J.P. Aguire 11/1/95

Cannot install sensor

Damaged during installation or transportation

Cannot install wire nut

Damaged during shipment to piracicaba

Damaged fitting not used by Piracicaba

Burst, validation pressure cycle.

Test included in prototype and production validation testing.

J.P. Aguire 11/1/95 E. Eglin 8/1/96

Design FMEA Ex.

Page 7

Potential FMEA Number: Failure Mode and Effects Analysis (FMEA) Prepared By:

Design FMEA Date:

Revision Date:

Page: of

Action Results

Actions Taken

New

Sev

New

Pro

b

New

DetPotential

Effect(s) of Failure

Sev

Potential Cause(s)/

Mechanism(s) of Failure

Prob

Current Design/Process

Controls

DET

RPN

Recommended Action(s)

Responsibility & Target

Completion Date

Failed mount 5 Vibration 9 3 135 J.P. Aguire

Hose leak 6 5 2 60

0 Operator instruction

0

8 7 Thermal cycle 1 56 E. Eglin 8/1/96

0

8 7 5 280 Coolant ordered

8 10 1 80 E. Eglin 8/1/96

Vibration w/road tapes

Obtain GMB vibration road tape.

Overpressure. Poor clamp

Burst, validation pressure cycle w/GMB clamps.

Obtain GMB clamps and clamping specification.

J.P. Aguire 12/1/95

Air conditioning does not work. Sudden refrigerant loss.

Air conditioning does not work. Sudden refrigerant loss.

Leak. Loss of heat transfer.

Wicking. Material strength

Included in Product Specification

Air conditioning does not work. Sudden refrigerant loss.

this is a test while dan is here

Leak. Loss of heat transfer.

Coolant quality. Contamination. Environment - int/ext.

SWAT, service simulation. Coolant evaluation.

Brazilian coolant to be evaluated. Zince lined tubes may need to be released. Simulated service test w/GMB coolant to be performed.

J.P. Aguirre 11/1/95

Leak. Loss of heat transfer.

External damage. Coolant velocity. No reinf sawcut.

Leak test. Simulated service.

100% cores tested in production. Simulated service included in Product Specificatin.

Design FMEA Ex.

Page 8

Potential FMEA Number: Failure Mode and Effects Analysis (FMEA) Prepared By:

Design FMEA Date:

Revision Date:

Page: of

Action Results

Actions Taken

New

Sev

New

Pro

b

New

DetPotential

Effect(s) of Failure

Sev

Potential Cause(s)/

Mechanism(s) of Failure

Prob

Current Design/Process

Controls

DET

RPN

Recommended Action(s)

Responsibility & Target

Completion Date

5 Environment - int/ext. 1 1 5 E. Eglin 8/1/96

8 2 Burst/leak pressure 5 80 GMB 12/1/95 Study originated

8 7 1 56 Coolant ordered

5 9 8 360 GMB 12/1/95

0

0

0

Leak. Loss of heat transfer.

SWAT, service simulation.

Included in Product Specification.

Leak. Loss of heat transfer.

Over pressure contamination.

GMB to study engine cleanliness.

Loss of heat transfer. Leakage due to increase flow velocity

Contamination. Coolant quality.

GMB coolant to be evaluated. GMB to study engine cleanliness.

J.P. Aguirre 11/1/95

Leak. Loss of heat transfer.

Over pressure contamination.

GMB to study engine cleanliness. Clustomer profile to be determined.

Design FMEA Ex.

Page 9

Action Results

New

RP

N

0

0

0

0

0

0

0

Design FMEA Ex.

Page 10

Action Results

New

RP

N

0

0

0

0

0

0

0

0

Design FMEA Ex.

Page 11

Action Results

New

RP

N

0

0

0

0

0

0

0

Severity Criteria

Page 12

System FMEA Severity Rating

Effect SEVERITY of Effect Ranking

10

9

Very High 8

High System inoperable with equipment damage 7

Moderate System inoperable with minor damage 6

Low System inoperable without damage 5

Very Low System operable with significant degradation of performance 4

Minor System operable with some degradation of performance 3

Very Minor System operable with minimal interference 2

None No effect 1

Hazardous without warning

Very high severity ranking when a potential failure mode affects safe system operation without warning

Hazardous with warning

Very high severity ranking when a potential failure mode affects safe system operation with warning

System inoperable with destructive failure without compromising safety

Severity Criteria

Page 13

General SEVERITY RANKING TABLE

Rank Category External and Internal Effect

10 Liability Failure will affect safety or compliance to law

9 Catastrophic customer impact

Moderate to major reliability failures

Reliability / End user recalls

Reputation Premature end-of-life (wear out)

at risk Increased early life failures

Intermittent functionality

Major customer impact

8 Minor reliability failures

7 Customer line impact / lines down

Impacts the yield of customer

Customer Wrong package / part / marking

quality Products performing marginally

inconveniences Involved customer's special handling

Damaged the customer's equipment

6 Product assembly error

5 Equipment cross contamination

Internal yield Damaged to down stream equipment

or special Major yield hit

4 handling Significant line yield loss

required Minor yield hit

3 Low line yield loss

2 Special internal handling, effort or annoyance

1 Unnoticed Unnoticed either internally or externally

Severity Criteria

Page 14

Prob. of Failure Criteria

Page 15

PROBABILITY of Failure Failure Prob Ranking

Very High: Failure is almost inevitable >1 in 2 10

1 in 3 9

High: Repeated failures 1 in 8 8

1 in 20 7

Moderate: Occasional failures 1 in 80 6

1 in 400 5

1 in 2,000 4

Low: Relatively few failures 1 in 15,000 3

1 in 150,000 2

Remote: Failure is unlikely <3.4 in 1,000,000 1

Detectability Criteria

Page 16

Detection Likelihood of DETECTION by Design Control RankingCannot Detect 10

Very Remote 9

Remote 8

Very Low 7

Low 6

Moderate 5

Moderately High 4

High 3

Very High 2

Almost Certain 1

Design control cannot detect potential cause/mechanism and subsequent failure mode

Very remote chance the design control will detect potential cause/mechanism and subsequent failure mode

Remote chance the design control will detect potential cause/mechanism and subsequent failure mode

Very low chance the design control will detect potential cause/mechanism and subsequent failure mode

Low chance the design control will detect potential cause/mechanism and subsequent failure mode

Moderate chance the design control will detect potential cause/mechanism and subsequent failure mode

Moderately High chance the design control will detect potential cause/mechanism and subsequent failure mode

High chance the design control will detect potential cause/mechanism and subsequent failure mode

Very high chance the design control will detect potential cause/mechanism and subsequent failure mode

Design control will detect potential cause/mechanism and subsequent failure mode

RPN InterpretationRPN NumberHigh Due to prob. of failureHigh Due to severityHigh Due to detectionModerate Due to detectionModerate Due to prob. of failureModerate Due to severityLow All

Change design or process Change design or process Change process control/test methodConsider improving present control/test methodConsider changing design or process Consider changing design or process Maintain present status

Related Documents