Flexible manufacturing system Seminar Report

Oct 16, 2015

Each process in FMS is controlled by a dedicated computer (FMS cell computer).

Flexible Manufacturing Systems (FMS)

FLEXIBLE MANUFACTURING SYSTEMPRESENTED BYPRANAV PANDEY

UNDER THE GUIDANCE OF

ASST. PROF. IRFAN PASHATECHNICAL SEMINARONFMS consists of a group of processing work stations interconnected by means of an automated material handling and storage system and controlled by integrated computer control system.

FMS is called flexible because it is capable of processing different work parts simultaneously at the workstation and quantities of production can be adjusted with respect to demand patterns.

WHAT IS FLEXIBLE MANUFACTURING SYSTEM?2This definition is from the Russell and Taylor Ops. Mgmt. text used in this class.FLEXIBILITY MEANING A manufacturing system must possess these three capabilities in order to be flexible:

The ability to identify and distinguish among different incoming part processed by the system.

Quick changeover of operating instructions.

Quick changeover of physical setup.

3Every situation will differ. Sometimes you may be required to implement only robotics or manufacturing technology. These are only suggestions as to making a FMS work.BASIC COMPONENTS OF FMS

a) Workstations: Workstations are computer numerical control (CNC) machine tools that perform machining operation on work parts. The various workstations are:Machining centersLoad and unload stationsAssembly work stationsInspection stations , etc.b) Automated Material Handling and Storage system: These are used to transport work parts and subassembly parts between the processing stations. Functions:Handling a variety of work part configurations.Temporary storage.Convenient for loading and unloading of work parts.

c) Computer Control System: It is used to coordinate the activities of the processing stations and the material handling system in the FMS.Functions:Control of each work station.Distribution of control instruction to work stations.Production control.Traffic control.

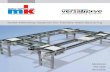

TYPES OF FMS Flexible manufacturing systems can be distinguished according to the number of machines in the system, they are a) Single machine cell b) Flexible manufacturing cell c) Flexible manufacturing systema) Single Machine Cell: It consists of one CNC machining centre combined with a parts storage system for unattended operation. The cell can be divided to operate in a batch mode, a flexible mode, or a combination of both.b) Flexible manufacturing cell(FMC): It consists of two or three processing work stations combined with a part handling system. The part handling system is connected to a load/unload station. The handling system usually includes a limited parts storage capacity.c) Flexible manufacturing system (FMS): It has four or more processing stations connected mechanically by a common parts handling system and electronically by a distributed computer system.

TYPES OF FMS LAYOUT The different types of FMS layouts are:

a) In-line type

b) Loop type

c) Ladder type

d) Open-field type

e) Robot- centered type

Work flow-one directionPROCAUTPROCAUTPROCAUTPROCAUTPROCAUTLOAD UNLD MANWork inPROCAUTPROCAUTPROCAUTPROCAUTPROCAUTWork outWork flow-both directions Basic in-line configuration with one directional work flowIn-line with transfer at workstations to allow back flow on primary handling systemInline Configuration PROCAUTPROCAUTPROCAUTPROCAUTPROCAUTPROCAUTLOADWork flowLOOP CONFIGURATIONLADDER CONFIGURATIONLOAD UNLD MANPROCAUTPROCAUTPROCAUTPROCAUTWork flowOPEN-FIELD CONFIGURATION

ROBOT-CENTERED CONFIGURATIONChallenges with FMSDetermining if FMS is the best production system for your company (economically and socially)

High costs associated with implementing FMS

Day to day maintenance of FMS operations13These challenges must never be overlooked when deciding whether or not to implement a FMS system. In order to get the best possible results you must answer the these questions within your own firms.AIMS OF FMSThe principle Aims of FMS are:To reduce costs.To Decrease Lead Times.To Increase machine utilization.To Decrease Work in Progress.Better utilization of the production equipment.Reduction of piece part unit costs.To increase Technical Performance.Shorter lead times/delivery times.Determination of production capacities.To increase quality.

Advantages of using FMSTo reduce set up and queue timesImprove efficiencyReduce time for product completionUtilize human workers betterProduce a variety of Items under one roofImprove product qualityProduce more product more quickly

Disadvantage of using FMS Limited ability to adapt to changes in product or product mix Expensive, costing millions of dollars Sophisticated manufacturing systems

CONCLUSIONWe can concluded that it is system, which reduces the manual work with the help of automation.

It is also help us to understand the concept of automation as it is the requirement of today globalize world.

By using the flexible manufacturing system we can save 65 to 75% time over general manufacturing system.

Flexible Manufacturing System improve the quality of product by maximum utilization of equipments and resources at minimum cost.

THANKYOU

![Flexible Manufacturing Systems [F.M.S] · PDF fileFigure 2: - Block Diagram of a Flexible Manufacturing Cell (F.M.C.), Courtesy Flexible Manufacturing systems in Practice, Bonneto](https://static.cupdf.com/doc/110x72/5a9e4e527f8b9a077e8b7393/flexible-manufacturing-systems-fms-2-block-diagram-of-a-flexible-manufacturing.jpg)