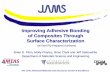

EV Group Europe & Asia/Pacific GmbH DI Erich Thallner Strasse 1 4782 St. Florian am Inn Austria +43 7712 5311 0 Contact [email protected] www.EVGroup.com Printed on paper from sustainable sources. Data, design and specifications may not simultaneously apply; or depend on individual equipment configuration, process conditions and materials and may vary accordingly. EVG reserves the right to change data, design and specifications without prior notice. All trademarks, logos, website addresses or equipment names are registered trademarks and/or the property of EV Group or their respective owners. © EV Group (EVG). All rights reserved. V19/01 ■ Substrate size up to 300 mm ■ Lamination speed from 1 mm/s up to 10 mm/s ■ Roller pressure from 5 N/cm2 up to 50 N/cm2 ■ Heating up to 120 °C Technical Data Features ■ Room-temperature bonding ■ Encapsulation of biological materials ■ Ultra-thin adhesive layer ■ Excellent uniformity over large areas ■ Parallel processing on wafer scale ■ No alignment necessary ■ Compatible with a wide range of materials Introduction EVG®820 Lamination System Adhesive Transfer for Microfluidics Adhesive bonding found widespread use in sealing of microfluidic devices either in the form of pressure sensitive tapes or liquid UV-curable adhesives. As a room- temperature process, it allows the encapsulation of biological materials. In addition, adhesive bonding can compensate a certain surface roughness caused for example by thin-film electrodes. A challenge usually represents the selective deposition of adhesive to minimize or avoid adhesive within the microfluidic channels which otherwise can influence biological reactions. The adhesive transfer process is an elegant solution for microfluidic devices where micro-channels stay free of adhesive without the need for alignment. A liquid UV-curable adhesive is spin-coated onto an adhesive transfer foil which is then laminated onto the microstructured substrate. By releasing the transfer foil, the adhesive will remain only on the heightened structures and can be subsequently bonded by UV-curing. The EVG820 lamination system offers the adhesive transfer of ultra-thin layers in the order of a few microns thickness with excellent uniformity over large areas. Combined with EVG´s spin coating and bonding equipment, this process enables completely new possibilities for microfluidic manufacturing. 2) Transfer Adhesive 3) Detach Transfer Foil 4) Bonding (UV-curing) 5) Bonded Substrate 1) Spin-coating Adhesive on Transfer Foil Spin-on Adhesive Adhesive Transfer Foil Conventional Adhesive Bonding Adhesive Transfer Bonding

Welcome message from author

This document is posted to help you gain knowledge. Please leave a comment to let me know what you think about it! Share it to your friends and learn new things together.

Transcript

EV Group Europe & Asia/Pacific GmbHDI Erich Thallner Strasse 14782 St. Florian am InnAustria+43 7712 5311 0

Contact

www.EVGroup.com

Prin

ted

on p

aper

from

sus

tain

able

sou

rces

. Dat

a, d

esig

n an

d sp

ecifi

catio

ns m

ay n

ot s

imul

tane

ousl

y ap

ply;

or d

epen

d on

indi

vidu

al e

quip

men

t con

figur

atio

n, p

roce

ss c

ondi

tions

and

mat

eria

ls a

nd m

ay v

ary

acco

rdin

gly.

EVG

rese

rves

the

right

to c

hang

e da

ta, d

esig

n an

d sp

ecifi

catio

ns w

ithou

t prio

r not

ice.

All

trad

emar

ks, l

ogos

, web

site

add

ress

es o

r equ

ipm

ent n

ames

are

regi

ster

ed tr

adem

arks

and

/or t

he p

rope

rty

of E

V G

roup

or t

heir

resp

ectiv

e ow

ners

. ©

EV

Gro

up (E

VG).

All

right

s re

serv

ed. V

19/0

1

■ Substrate size up to 300 mm ■ Lamination speed from 1 mm/s

up to 10 mm/s ■ Roller pressure from 5 N/cm2

up to 50 N/cm2 ■ Heating up to 120 °C

Technical Data

Features

■ Room-temperature bonding ■ Encapsulation of biological

materials ■ Ultra-thin adhesive layer ■ Excellent uniformity over large

areas ■ Parallel processing on wafer

scale ■ No alignment necessary ■ Compatible with a wide range

of materials

Introduction

EVG®820Lamination SystemAdhesive Transfer for Microfluidics

Adhesive bonding found widespread use in sealing of microfluidic devices either in the form of pressure sensitive tapes or liquid UV-curable adhesives. As a room-temperature process, it allows the encapsulation of biological materials. In addition, adhesive bonding can compensate a certain surface roughness caused for example by thin-film electrodes. A challenge usually represents the selective deposition of adhesive to minimize or avoid adhesive within the microfluidic channels which otherwise can influence biological reactions.

The adhesive transfer process is an elegant solution for microfluidic devices where micro-channels stay free of adhesive without the need for alignment. A liquid UV-curable adhesive is spin-coated onto an adhesive transfer foil which is then laminated onto the microstructured substrate. By releasing the transfer foil, the adhesive will remain only on the heightened structures and can be subsequently bonded by UV-curing.

The EVG820 lamination system offers the adhesive transfer of ultra-thin layers in the order of a few microns thickness with excellent uniformity over large areas. Combined with EVG´s spin coating and bonding equipment, this process enables completely new possibilities for microfluidic manufacturing.

2) Transfer Adhesive

3) Detach Transfer Foil

4) Bonding (UV-curing)

5) Bonded Substrate

1) Spin-coating Adhesive on Transfer Foil

Spin-on Adhesive

Adhesive Transfer Foil

ConventionalAdhesive Bonding

Adhesive TransferBonding

Related Documents