Environment, Health, and Safety 2005 Progress Report

Welcome message from author

This document is posted to help you gain knowledge. Please leave a comment to let me know what you think about it! Share it to your friends and learn new things together.

Transcript

Environment, Health, and Safety

2005 Progress Report

Xerox Environmental, Health, and Safety Policy

Xerox Corporation is committed to the protection of the environment and the health and safety of its employees, customers, and neighbors. Thiscommitment is applied worldwide. The following principles shall govern all business practices in the design, manufacture, procurement, marketing,distribution, maintenance, reuse/recycling, and disposal of products andrelated services:

• Protection of the environment and the health and safety of Xerox employees, customers, and neighbors from unacceptable risks takes priority over economic considerations and will not be compromised.

• Xerox operations must be conducted in a manner that safeguards health,protects the environment, conserves valuable materials and resources, and minimizes risk of asset losses.

• Xerox is committed to designing, manufacturing, distributing, and marketing products and processes to optimize resource utilization and minimize environmental impact.

• All Xerox operations and products are, at a minimum, in full compliancewith applicable governmental requirements and Xerox standards.

• Xerox is dedicated to continuous improvement of its performance in environment, health, and safety.

ABOUT THIS REPORT

Xerox’s 2005 Environment, Health, and Safety Progress Report is the eleventh in a series of annual reports documenting ourprogress toward goals for protecting the environment and safeguarding the health and safety of Xerox employees, customers, and neighbors.

This report reviews worldwide performance during the 2004 calendar year. It also includes some discussion of 2005 goals andactivities. Safety performance and greenhouse gas emissions datacover Xerox operations and subsidiaries during the 2004 timeperiod. Environmental results show full-year performance ofXerox manufacturing, research and development, and equipmentrecovery/recycle operations.

This report supports our continued efforts to maintain an opendialogue with audiences interested in Xerox’s environmental,health, and safety initiatives, including employees, customers,investors, government agencies, non-governmental organizations,and the media. Each year, Xerox strives to enhance the value ofthis report, incorporating international reporting best practicesand feedback from readers. Please send your comments andsuggestions to the Xerox contacts listed on the back cover of thisreport, or visit our web site at www.xerox.com/environment.

Contents

Contents 1

2 To Our StakeholdersA Message from the Chairman and Chief Executive Officer

3 Executive Summary2004 Highlights

4 Policy, Goals, and StrategyIntegration into Xerox Business

8 Waste-Free ProductsSustainable Design for Equipment, Supplies, and Paper

18 Product ShowcaseTranslating Policy into Practice

21 Waste-Free FacilitiesAn Ongoing Commitment

28 Employee Well-BeingHealth and Safety at Xerox

33 Environmental Remediation/Compliance Penalties

34 Employee and Community InvolvementPartnerships for Progress

37 Company ProfileXerox at a Glance

Most Xerox people joined Xerox because of the core values the companystands for. We make the customer our priority among priorities, value diversity, are good stewards of the environment, place a premium on thepeople who work for the company, and invest financial and human capital in the communities in which we work and live.

These values were first articulated by our founder — Joseph C. Wilson — in the early 1960s. They have been nurtured and strengthened ever since andthey have become ingrained in the Xerox culture. In this report, you will readabout our progress in protecting the health and safety of our employees andin preserving our environment. You will see that:• We are making progress and intensifying our efforts to attain benchmark

employee safety levels through the use of Lean Six Sigma quality methodologies.

• We have committed to reduce our absolute greenhouse gas emissions by10 percent from 2002 to 2012 and are on track to do so.

• We have deployed a stringent set of requirements to our paper suppliers to ensure that our paper is sourced from sustainably managed forests.

• We have strengthened our supply chain management to ensure proper control of the chemical content of our products.

• We diverted more than 142 million pounds of waste from landfills last year and saved Xerox several hundred million dollars through benchmarkremanufacturing and parts reuse.

You will read about this and much, much more in the pages that follow.Xerox is recognized as a leader in sustainable development. We are proud tobe listed among the 100 most sustainable companies in the world — proudbut not complacent. We recognize that as good as we may be today, we mustbe even better tomorrow. Our customers expect it, our shareholders demandit, our employees are committed to it, and future generations depend on it.

We do not shrink from these expectations. We welcome and embrace them. To us, employee safety and sustainable development are races with no finishline. Both require leadership and innovation — leadership that sets high expectations and clear direction, and innovation that constantly pushes thefrontier of what is possible.

You have the commitment of all Xerox people that we will continue toimprove — it’s both a part of our heritage and of our future.

2 To Our Stakeholders

To Our Stakeholders A Message from theChairman and Chief Executive Officer

During the past few years, Xerox has rightly received a good deal of praisefor turning the company around and bringing it back from the brink of bankruptcy to the threshold of greatness. We are proud of that, of course,but I believe Xerox people are most proud of the fact that we have simultaneously turned the company around financially and strengthened our core values.

Sincerely,

Anne M. MulcahyChairman and Chief Executive Officer

Goal: Waste-Free Products• Prevented 142 million pounds of material from entering landfills through the

reuse and recycling of Xerox equipment and supplies.

• Enabled energy savings of 48 million therms (1.4 million megawatt hours)through the reuse of parts and the sale of ENERGY STAR® products.

• Ninety-seven percent of eligible new Xerox products met the requirements ofthe international ENERGY STAR and Canada’s Environmental Choice EcoLogo.

• All newly introduced products achieved Xerox’s strict standards limitingemissions of noise, ozone, and dust. In 2005, we launched our first productsthat meet the strict requirements of the European Union’s restriction on the useof hazardous substances directive (RoHS), which goes into effect July 2006.

Goal: Waste-Free Facilities• Pledged to cut greenhouse gas emissions from worldwide operations by

10 percent from 2002 to 2012.

• Recycled 89 percent of non-hazardous solid waste generated in all Xerox facilities, compared with 85 percent in 2003.

• Achieved a 96 percent recycle rate with Xerox’s worldwide equipment recovery and recycle operations.

• Beneficially managed 99 percent of hazardous waste through treatment, recycling, or energy recovery by blending fuels.

• Maintained ISO 14001 certification for global manufacturing sites.

Goal: Safe Workplace and Healthy Workforce• Fell short of our 10 percent year-over-year reduction targets. The Total

Recordable Incident rate was reduced 4 percent while our Day Away FromWork case rate increased by 10 percent. We are now using Lean Six Sigmaquality processes to identify strategies to reach our goal of benchmark safety levels.

• Continued deployment of our emergency preparedness standard worldwide,verifying that all major sites have documented emergency response plans in place.

Executive Summary 3

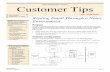

4449 51

544632 698

27

17 16 14

33 3750

12

688

Ener

gy S

avin

gs(M

illio

ns o

f The

rms)

50

40

30

20

10

091 00 01 02 03 04

8

48 1,000

800

600

400

200

0

Avoi

ded

CO2

Emis

sion

s(T

hous

ands

of T

ons)

46

657

Energy Saved in Use (ENERGY STAR)

Energy Saved in Manufacture (Parts Reuse)

Avoided Carbon Dioxide (CO2) Emissions

37

11

38

ENVIRONMENTAL BENEFITS OF PRODUCTENERGY EFFICIENCY PROGRAMS

Executive Summary 2004 Highlights

Xerox maintained good performance toward key environmental, health, and safety goals in 2004 for the benefit of our customers, employees, andneighbors. The following summary of our progress links accomplishments to the goals they support.

NON-HAZARDOUS SOLID WASTE RECYCLE RATE: ALL FACILITIES

Perc

enta

ge R

ecyc

led

95 00 01 02 03 04

100

80

60

40

20

0

807890 92

85 89

//

Per 1

00 E

mpl

oyee

s

3

2

1

096 00 01 02 03 04 05

Target

Total Recordable Incident Day Away From Work Case

2.40

1.05

.57

1.28

.62

1.30 1.19

.56

1.14

.59

1.10

.65

XEROX WORKPLACE INJURY RATES

1.03.60

//

Recently, Xerox discovered an inconsistency in its reporting criteria for DAFW case rates, which has beencorrected. Therefore, the 2003 information reflects achange in numbers from previous reports.

//

Vision and GoalsXerox’s environmental, health, and safety policy, established in 1991, provides a solid foundation for the deployment of goals applicable to our global operations. Today, Xerox’s strategic environmental, health, and safety goals are organized into four categories: (1) Safe Workplace and Healthy Workforce,(2) Waste-Free Facilities, (3) Safe Products, and (4) Waste-Free Products.While there is still work to be done, we have made significant advancestoward these goals as shown below.

Policy, Goals, and StrategyIntegration into Xerox Business

The value of responsible corporate citizenship has been firmly embedded in Xerox culture since the company’s inception. We consider protection of the environment and the health and safety of our people to be fundamentalcomponents of our commitment to good corporate citizenship and sustainable growth.

4 Policy, Goals, and Strategy

A RECORD OF PROGRESSVision Goals Performance

Provide Value Safe Workplace Results of the Zero Injury program, initiated in 1997:to Employees & Healthy • 54% reduction in Total Recordable Injury rate.and Society Workforce • 38% reduction in Day Away From Work case rate.

Waste-Free 95% or more hazardous waste managed beneficially since 1999 through Facilities treatment, recycling, or fuels blending.

Improvement in non-hazardous solid waste recycling rate from 56% to 89% since 1999.

31% reduction in water use since 1999.

91% reduction in air emissions from facilities that manufacture Xerox imaging supplies (our most chemically intensive operations) since 1991.

Nearly 6% reduction in company-wide greenhouse gas emissions since 2002.

Provide Value Safe Products Design requirements for materials safety, mechanical and electrical safety, to Customers and ergonomics are integrated into the Xerox product development

process. No product is launched until these criteria are satisfied.

Waste-Free Over 1.6 billion pounds of waste were diverted from landfills since 1991 Products through equipment end-of-life strategies.

Product features such as duplex copying/printing help customers make efficient use of paper. One hundred percent of office and production productsgreater than 30 ppm introduced in 2004 offered duplex capability.

Up to 50% reduction in product energy consumption since 1992.1

Xerox has achieved its goal of minimizing product emissions of ozone and dust. Today’s emission levels are well below the strictest regulatory limits.

1Energy consumption of the Xerox CopyCentre C3545 digital copier compared to the Xerox5343 introduced in 1994. Customer use patterns affect energy consumption.

Xerox Working to Become a Sustainable CompanyIn moving toward a sustainable future, Xerox continues to extend the reach of our environmental, health and safety policies across the product life cycle. In 2004 and 2005, Xerox launched and expanded initiatives that strengthenedsupply chain management and made long-term commitments to further reducethe environmental impact of its operations.

Energy and Greenhouse Gas ReductionsFor our own operations, we have strengthened our commitment to reduceenergy consumption and associated greenhouse gas emissions by adopting a 10 percent absolute reduction in company-wide greenhouse gas emissions by 2012 from a 2002 baseline. See pages 26-27.

Controlling the Chemical Content of Xerox ProductsIn 2004, Xerox issued a new set of environmental, health, and safety requirements for Xerox suppliers to better control the use of chemicals in Xerox products. All new product designs refer to these requirements, and suppliers are expected to verify their compliance. See page 12.

Product Take-Back and RecyclingXerox has operated an extensive equipment take-back and reuse/recycle program for many years. See pages 16-17. With the implementation of theEuropean Union’s Waste Electrical and Electronic Equipment Directive, Xeroxwill continue to operate its European equipment take-back program to enableremanufacturing and parts reuse wherever possible. We will also take advantage, where it makes sense, of European member state collection andrecycling programs.

Paper Supplier RequirementsIn 2003, we began deployment of environmental, health, and safety requirements for companies that provide paper to Xerox for resale. The requirements went into effect over a two-year period with the most stringentrequirements effective in 2005. See pages 14-15.

TransportationServices

Recycling and WasteDisposal Services

Recycling Centers

XeroxCustomers

(Product Use)

Xerox Operations(Research,

Development,Manufacturing,

Remanufacturing, Marketing, Sales,

Distribution, Services)

Company-Wide Commitment to ReduceGreenhouse Gas Emissions

Expanded Environmental, Health, and Safety Supplier Requirements

Material FlowXerox EH&S RequirementsOutsourced Operation

Waste-Free Goals

Xerox Suppliers(Materials & Components

Suppliers, Paper Suppliers,Contract Manufacturing)

ENVIRONMENTAL, HEALTH, AND SAFETY REQUIREMENTS ACROSS THE SUPPLY CHAIN

Xerox applies the same environmental, health, and safety requirements to its suppliers as it does to its own operations. Requirements for suppliers of paper, materials, and components were recently strengthened. A commitment to reduce energy and greenhouse gas emissions was expanded to cover all Xerox operations.

Policy, Goals, and Strategy 5

1.6billion

Pounds of waste divertedfrom landfills since 1991 through equipment end-of-life strategies.

Xerox was named as one of the Global 100 MostSustainable Companies by Corporate Knights Inc. and Innovest Strategic Value Advisors Inc. in 2005.

Governance and Policy DeploymentThe Environment, Health, and Safety organization is charged with ensuringcompany-wide adherence to Xerox’s environmental, health, and safety policy.The governance model we employ to accomplish this task is illustratedbelow. Its central elements include clearly defined goals, a single set ofworldwide standards, and an audit process that ensures conformance tothese requirements. These are crucial for integrating environmental, health,and safety considerations into Xerox business.

StandardsEnvironmental, health, and safety standards are our primary tools for ensuring compliance with corporate policies and goals. Applicable to all operations worldwide, these standards establish specific requirements forproduct safety, materials safety, packaging, environmental management andreporting, workplace safety, emergency response, and asset protection.Xerox employees access these standards via the company’s internal web site.

Operational ProgramsEffective deployment of environmental, health, and safety goals and standardsrelies on full integration into ongoing business practices. Five key programsserve this integration function throughout the company.

Zero Injury ProgramThe Zero Injury program is designed to ensure the safety of Xerox employeesaround the world. Our ultimate goal is benchmark safety performance.Launched in 1997, the program trains managers in safety management andholds them accountable for their organizations’ safety performance. TheEnvironment, Health, and Safety organization develops awareness and

training programs, tracks performance worldwide,and provides guidance as needed to correct deficiencies.

Emergency PreparednessXerox requires each of its operations to have adocumented emergency response plan in placeoutlining actions to be taken in the event of potential emergencies. Training programs ensurethat employees are aware of these plans andunderstand evacuation procedures and rescue and response methods. Routinely scheduled management reviews, drills, and corporate auditsensure that plans comply with Xerox standardsand regulations.

6 Policy, Goals, and Strategy

Policy, Goals, and StrategyIntegration into Xerox Business

CORPORATE REPORTING RELATIONSHIPS

Chairman and Chief Executive Officer

Business Group Operations

Paper, Supplies,and Supply

Chain Operations

Chief Financial Officer

Corporate Controller

Business Ethicsand Compliance

Office

Xerox ManagementAudit Committee

Environment,Health,

and SafetyOrganizationAudit Program

Board of DirectorsAudit Committee

Xerox’s 11-member Board of Directors is 91 percent independent, following a tough 1 percent independence standard.

ENVIRONMENTAL, HEALTH, AND SAFETY GOVERNANCE MODEL

Environmental, Health, and Safety Strategic Goals

Xerox Business Divisions and Operations

Zero Injury Program

ISO 14001 EnvironmentalManagement

Product Development

Process

Supply ChainManagement

Safe Workplace & Healthy Workforce

Waste-FreeFacilities

SafeProducts

Waste-FreeProducts

Environmental, Health, and Safety Corporate Policy

Environmental, Health, and Safety Audit Program

EmergencyPreparedness

Environmental, Health, and Safety Standards

ISO 14001 Environmental Management SystemAll company manufacturing operations employ an ISO 14001-conforming environmental management system to ensure compliance with regulations and Xerox standards, to identify environmental impact, and to set objectivesand performance targets. Our major manufacturing operations have been certified to ISO 14001 since 1997. In 2002, we completed the certification of all current manufacturing operations. New plants are scheduled for certification as they are brought on-line.

Product Development ProcessXerox integrates environment, health, and safety into the earliest stages of Xerox product design and development. Products’ adherence to safety standards, ecolabel criteria, chemical content requirements, and end-of-lifestrategies is reviewed at each major phase of the development process. Failure to meet these requirements can delay product launch.

Supply Chain Environmental, Health, and Safety ManagementXerox extends environmental, health, and safety requirements across its supplychain. Since 1998, Xerox has asked its materials and components suppliers to meet specific environmental, health, and safety requirements. These requirements were strengthened in 2004. Starting in 2003, Xerox extendedadditional requirements to companies who provide paper to Xerox for resale.Supplier initiatives are described in more detail throughout this report.

Audit ProgramA well-established audit program measures our success in implementing environmental, health, and safety goals and targets. Research, manufacturing,and service operations are scheduled for periodic audits. Auditing frequency is based on each operations’ complexity, inherent risk, and past performance.Xerox audit teams evaluate operations against Xerox standards, regulations,and industry guidelines to identify environmental, health, and safety risks andpotential areas of non-compliance. Local managers, with the assistance of auditteams, develop action plans to correct deficiencies. Situations that pose a highrisk of environmental damage, serious injury to employees, or regulatory non-compliance receive special attention from senior management and are trackedfor resolution. The audit program has proven to be an important mechanism for identifying and correcting performance gaps. At the same time, it offers avaluable opportunity to share best practices among facilities.

Policy, Goals, and Strategy 7

BUSINESS ETHICS AND COMPLIANCE

Xerox’s code of conduct is deployed by the XeroxBusiness Ethics and Compliance Office. Annual training gives employees detailed guidance on maintaining a commitment to business ethics. As part of this effort, an annual ethics letter from thecompany CEO helps build employee awareness oftheir responsibilities to the corporate environmental,health, and safety commitment. Each employee mustconfirm his/her understanding of this commitmentthrough a formal acknowledgment process and completion of refresher training. The programincludes a helpline for employees to seek guidanceand raise issues.

ENVIRONMENTAL PLANK OF XEROX’S ETHICS POLICY

Xerox is committed to protecting the environment and the health and safety of its employees, customers,and the communities where it does business. Xeroxwill operate in a manner that conserves naturalresources and will comply with all laws regulatingthese matters.

8 Waste-Free Products

Waste-Free Products Sustainable Design for Equipment, Supplies, and Paper

Xerox made significant progress toward its Waste-Free goals in 2004, conserving both energy and materials throughout the product life cycle.

A number of sustainable product initiatives ensured conservation of energyand materials in 2004:• Programs to remanufacture equipment and reuse or recycle supplies

diverted 142 million pounds of material from landfills.

• Energy-efficient product features enabled energy savings of 37 milliontherms (1.1 million megawatt hours). Parts reuse saved an additional 11 million therms (320,000 megawatt hours).

• All newly introduced products achieved Xerox’s strict standards for minimaluse of hazardous materials and emissions of noise, ozone, and dust.

Xerox engineering teams are incorporating into product designs increasinglychallenging targets for energy efficiency, reuse/recycling, and minimized useof hazardous materials. For example, revised, more stringent standards forenergy efficiency and the chemical content of parts and materials used inXerox products are expected to drive progress in this area.

One measure of success is the number of Xerox products meeting theworld’s most widely recognized environmental certifications: Canada’sEnvironmental Choice EcoLogo; Germany’s Blue Angel; and the internationalENERGY STAR. Ninety-seven percent of Xerox’s eligible product offeringslaunched in 2004 met ENERGY STAR and Environmental Choice EcoLogo criteria. Because Germany’s Blue Angel criteria changed in late 2003, noXerox products currently meet these requirements, but products are beingdesigned to meet them in 2006.

WASTE-FREE PRODUCT GOALS AND INITIATIVES

Waste-FreeProduct Goals

Efficient use of materials and energy

Minimal use of hazardous substances

Low emissions and noise

Sustainable ProductDesign Initiatives

• Energy-efficient design

• Supplies return and recycle programs

• Efficient use of paper

• Equipment remanufactureand parts reuse/recycle

• Recycled content in equipment, supplies, and packaging

• Supply chain management

• Design to Xerox worldwide product environmental performance standards

The Gil Hatch Center for Customer Innovation showcase of digital production printing technologylocated in Webster, New York, opened in 2005.

ENERGY STAR Canada’s Environmental Choice EcoLogo

Germany’s Blue Angel

97120

100

80

60

40

20

0Perc

enta

ge o

f Xer

ox P

rodu

ctM

odel

s In

trodu

ced

95 00 01 02 03 04

64 60

20

98

25

100 100 100 100

20

50

97 97

0

ECOLABEL-QUALIFIED PRODUCTS

Note: Percentages represent the proportion of productmodels introduced in a given year that are eligible forecolabel certification (i.e., within the scope of an ecolabelprogram) and that meet ecolabel criteria.

0//

97

Waste-Free Products 9

Pounds of material divertedfrom landfills through Xeroxequipment remanufactureand supplies reuse/recycleprograms.

Xerox test facilities ensure that products comply with the strictestsafety regulations. Our anechoic chamber in Webster, New York,measures product emissions of, and immunity to, electromagneticradiation.Strategic

Planning

• EH&S DesignStandards • Product Safety

• MaterialsSafety

• EnvironmentalRequirements

• ErgonomicDesign

• Remanufacture/Recycle

• MarketResearch

• CompetitiveTrends

• RegulatoryTrends

• MaterialsAssessments

• RequiredTesting

• SupplierCertifications

STRATEGY/PLANNING

EXECUTION

• Customer/SalesSupport

• CustomerSatisfactionSurveys andFeedback

• ContinuingEngineering

• EnvironmentalMarketing

• CustomerCommunica-tions

• AgencyApprovals

XEROX’S TIME TO MARKET PRODUCT DEVELOPMENT PROCESS

Develop3.3 Demo

3.4Deliver

3.5

Design3.2

Proposal3.1

Integrating Waste-Free Goals into Product DesignXerox recognized early in its drive for Waste-Free Products that the best results — both environmental and financial — are achieved when products are designed from the outset with Waste-Free goals in mind.

Customer feedback, along with a forward-looking view of global trends in technology, regulations, and ecolabels, led us to a comprehensive set of standards that encompass more than Waste-Free goals. The standards also include requirements for electrical and mechanical safety, ergonomics,electromagnetic emissions, fire resistance, and materials safety.

Products being developed undergo a careful review by Xerox business teamsand the Environment, Health, and Safety organization at each stage of Xerox’sTime to Market product development process. These ongoing reviews ensurethat environmental, health, and safety requirements are fully satisfied by allXerox products. Failure to fully meet these requirements can delay the introduction of a new product.

The following pages describe the sustainable product design practices that havebeen most significant in moving Xerox toward its Waste-Free Product goals.

142million

100

Products being developed undergo a careful review by Xerox business teams and the Environment,Health, and Safety organization at each stage of Xerox’s Time to Market product development process.

Design for Energy EfficiencyXerox follows a comprehensive approach to reducing product energy consumption. First, in the design phase, product teams take a systemsapproach to maximizing energy efficiency. Second, during the customer-use phase, features such as automatic power-saver modes lower the energyconsumed. Finally, remanufacture and reuse programs do their part byrequiring less energy than building new parts from raw materials. Together,these initiatives dramatically reduce energy needs, generating cost savingsfor Xerox as well as for its customers — and notable benefits for the environment.

Energy Technology InnovationXerox formalized its commitment to energy-efficient product design in 1993by joining the U.S. Environmental Protection Agency’s ENERGY STAR OfficeEquipment program as a Charter Partner. Since then, the company has introduced more than 290 copier, printer, fax, and multifunction products thathave earned ENERGY STAR status. Ninety-seven percent of eligible Xeroxproducts introduced in 2004 met ENERGY STAR criteria.

A product’s ability to enter a series of power-saver modes, after a specifiedperiod of non-use, is a key factor in winning ENERGY STAR status. Becauseoffice equipment is often inactive for portions of a workday and may be lefton overnight, this power-saver feature substantially reduces energy use.

A systems approach at Xerox coordinates advances in fusing technology and new electronics architectures to make today’s equipment significantlymore energy efficient than comparable 1990 models, even while enhancingfunctionality, such as color capability. For example, the ENERGY STAR-qualifiedXerox CopyCentre C3545 digital color copier consumes 80 percent1 lessenergy than the Xerox 5343, introduced in 1994.

In 2004 alone, Xerox ENERGY STAR equipment in customer locations aroundthe world — several million machines — enabled energy savings of 37 milliontherms (1.1 million megawatt hours). These energy savings translate into an avoidance of nearly 595,000 tons of carbon dioxide emissions. By remanufacturing equipment with reused parts in 2004, Xerox saved an additional 11 million therms of energy (320,000 megawatt hours) and prevented 62,000 tons of carbon dioxide emissions from entering the atmosphere. In total, the energy saved in 2004 through ENERGY STAR product features and equipment remanufacturing was enough to light nearly1.1 million U.S. homes for a year.

1This calculation assumes that customers do not manually power off equipment at the end of each workday.

Waste-Free Products Sustainable Design for Equipment, Supplies, and Paper

10 Waste-Free Products

The annual energy consumption of the ENERGYSTAR-qualified Xerox CopyCentre C3545 digitalcolor copier is 80 percent1 less than that of theXerox 5343, introduced in 1994.

Note: Energy savings from parts reuse is the differencebetween energy required to build new parts and energyrequired to process parts for reuse (refer to footnote on page 17 for more details). Annual energy savings fromENERGY STAR features are calculated by comparing theannual energy consumption of Xerox ENERGY STAR-qualified product types to non-ENERGY STAR counterparts.Savings are aggregated across the estimated number ofXerox ENERGY STAR-qualified machines in customer locations worldwide. Energy reductions are translated intoavoided carbon dioxide emissions using conversion factorsfrom the U.S. Environmental Protection Agency, the U.S.Department of Energy, and the International Energy Agency.

4449 51

544632 698

27

17 16 14

33 3750

12

688

Ener

gy S

avin

gs(M

illio

ns o

f The

rms)

50

40

30

20

10

091 00 01 02 03 04

8

48 1,000

800

600

400

200

0

Avoi

ded

CO2

Emis

sion

s(T

hous

ands

of T

ons)

46

657

Energy Saved in Use (ENERGY STAR)

Energy Saved in Manufacture (Parts Reuse)

Avoided Carbon Dioxide (CO2) Emissions

37

11

38

ENVIRONMENTAL BENEFITS OF PRODUCTENERGY EFFICIENCY PROGRAMS

//

Production SystemsXerox’s production systems offer a wide range of features that provide high-capacity and print-on-demandcapability for Xerox customers. Energy management insuch technologically complex systems is challengingdue to the products’ large number of individual subsystems. Xerox’s Nuvera 100/120 DigitalCopier/Printer was designed from the ground up to meet ENERGY STAR and Environmental Choice EcoLogospecifications. It provides copying, scanning, and printing capability for mid-production applications of up to 500,000 images per month. The product’s unique integrated printer controller optimizes the energy consumption of each subsystem, reaching power-savinglevels previously achieved only by much-lower-speedmachines. The product is designed to reach power-saving sleep-mode levels of fewer than 70 watts after a period of non-use. To accomplish this, the machine’spower consumption must be reduced by 90 percentfrom its standby mode. The integrated printer controllercoordinates the reduction in power consumption, turning off each subsystemwhile ensuring the machine’s ability to “wake up” quickly.

Power consumption in other modes of operation have also been reduced. For example, the Xerox Nuvera 100/120 Digital Copier/Printer operates atstandby power levels that have been reduced by 60 percent when compared to earlier Xerox offerings in this class, and operates at run-mode levels thathave been reduced by up to 30 percent.

Multifunction BenefitsXerox multifunction systems further reduce the amount of energy required to provide customers with copy, print, fax, and scan capabilities by combiningthe functions of multiple products into one machine. The annual energy consumption of a Xerox WorkCentreor WorkCentre Pro multifunction system is approximately 50 percent less than the combined annualenergy consumption of the individual ENERGY STAR-qualified copier, fax, and printers it replaces. Energy savings increase to 73 percent if a multifunction systemreplaces individual products that have not earned theENERGY STAR.

Waste-Free Products 11

➡

XEROX MULTIFUNCTION SYSTEMS: INHERENT ENVIRONMENTAL BENEFITS

50% reductionAnnual energy consumption of an office copier, four laserprinters, and a fax: 1422 kWh

Annual energy consumption of a multifunction system:706 kWh

The low-sleep-mode power consumption of the ENERGY-STAR-qualified Xerox Nuvera Digital Copier/Printer is achieved by turningoff this feature-rich product’s subsystems when not in use.

XEROX NUVERA DIGITAL COPIER/PRINTER

User-Interface DisplaySleep Power: 0 Watts

Printer ControllerSleep Power: 68 Watts

Feeder ModuleSleep Power: 0 Watts

Fuser SubsystemSleep Power: 0 Watts

Finisher ModuleSleep Power: 0 Watts

ENVIRONMENTAL, HEALTH, AND SAFETYREQUIREMENTS FOR XEROX MATERIALS ANDCOMPONENTS SUPPLIERS (UPDATED IN 2004):

• Comply with applicable government environmental,health, and safety regulations.

• No ozone-depleting substances in manufacturing or processing of parts/materials supplied to Xerox.

• No toxic heavy metals — including cadmium, mercury, hexavalent chromium, or lead — in packaging.

• No use of asbestos, azo-colorants, benzene, hexachlorobenzene, ozone-depleting substances,polybrominated biphenyls, polybrominated diphenyl ethers, polychlorinated terphenyls, or polychlorinated biphenyls in parts/materials supplied to Xerox.

• By July 1, 2006, eliminate cadmium, hexavalentchromium, mercury, and lead from parts/materialssupplied to Xerox — except where exemptions areallowed by the European Union RoHS Directive.1

• Restricted use of 21 additional substances in Xeroxconsumables. Approval for use requires a Xerox-conducted safety assessment.

• Mark plastic parts with recycling codes, as definedby ISO standards.

Waste-Free Products Sustainable Design for Equipment, Supplies, and Paper

12 Waste-Free Products

Low Emissions and NoiseXerox designs its products to strictly control emissions of chemicals and noise,consistent with the criteria of the world’s strictest ecolabels. As a result, currentproducts have achieved chemical emission levels that are well below global regulatory requirements — often at or near the detection limit of our measurementequipment — and are considered to have a negligible impact on customers’ workenvironments. Since 1991, ozone and dust emissions from office and productioncopying and printing systems have decreased by more than 50 percent. FutureXerox products will be developed to maintain these low levels.

Sophisticated noise prediction models developed by Xerox noise experts makeit possible to identify potential noise sources in the earliest stages of productdesign, even before prototypes are available for testing. This modeling technology has proven to be a cost-effective way of designing low-noise equipment. State-of-the-art acoustical instrumentation facilitates troubleshootingand enhances advanced product development.

Minimal Use of Hazardous SubstancesXerox has long worked toward minimizing the use of hazardous substances in our products. Xerox has well-established requirements that govern productdesign and materials selection. Xerox toxicologists conduct a comprehensiveassessment of new materials in our products to ensure conformance with these criteria. They include compliance with applicable global registration, hazard communication, and waste handling and disposal considerations. The requirements prohibit the use of materials that:• Are carinogenic, mutagenic, or cause adverse developmental or reproductive

effects

• Pose a toxicity hazard to humans or aquatic species

• Can cause a permanent adverse impact to the skin, eyes, or respiratory system

• Have the potential to generate hazardous waste

Concern about the use of hazardous materials in electronics has promptedmany countries around the world to consider restricting the use of certain substances. Most notably, the European Union will require electronic productssold after July 1, 2006, to be free of lead, mercury, cadmium, hexavalentchromium, and certain brominated flame retardants unless feasible alternativesare unavailable. In 2004, Xerox issued updated requirements for Xerox suppliers to better control the use of chemicals in our products. All new product designs refer to these requirements and suppliers are expected to verify their compliance with these strict requirements.

In 1999, Xerox banned the use of the targeted flame retardants in our products.We have also made very good progress in eliminating the use of mercury.Remaining uses — mercury-containing lamps that scan images and back-lightuser displays — will be phased out as alternatives become available. The elimination of lead — used in virtually all electronic components — is a particularly challenging task for the electronics industry. Questions of reliabilityand functionality of lead-free components are serious concerns for companiessuch as Xerox who produce high-performance production-level equipment.Despite these challenges, Xerox is committed to reducing the use of these materials to compliant levels for new products in 2006.

Xerox’s noise chamber and precision instruments evaluateproduct noise emissions from Xerox products and componentsto ensure conformance with company standards.

1 European Union Directive 2002/95/EC on the restrictions of the useof hazardous substances in electrical and electronic equipment(RoHS). The Directive allows the use of targeted materials whenthere is no alternative or where the negative environmental, health,or safety impacts caused by substitution outweigh the benefits.

17.8 17.418.3

00 01 02 03 04

16.313.8

Mill

ions

of P

ound

s

20

15

10

5

0

Toner ContainersWaste TonerCartridges11.2

XEROX GREEN WORLD ALLIANCE:TOTAL WASTE DIVERTED FROM LANDFILLS

Waste-Free Products 13

Xerox Supplies Reuse and Recycling: The Green World AllianceThe Xerox Green World Alliance reuse/recycle program for imaging suppliesmakes up a central element of its strategy to achieve Waste-Free Product goals. This partnership with Xerox customers resulted in more than 3.2 million cartridges and toner containers being returned in 2004. Xerox remanufacturedor recycled more than 90 percent by weight of the cartridges and toner containers returned in 2004.

Xerox also processed 2 million pounds of post-consumer waste toner forreuse. The plastic bottles customers utilized to return waste toner to Xerox —more than 100,000 in number — were recycled. At the same time, Xerox continued its practice of designing toner containers to incorporate post-consumer recycled plastic, achieving an average of 26 percent recycled contentfor toner bottles sold in 2004.1

Well-Established Collection and Reprocessing MethodsPrepaid postage labels and packaging from new supplies allow customers toreturn spent materials to Xerox for reuse and recycling. And return labels fortoner containers are available from Xerox upon request.

Returned products are cleaned, inspected, and then remanufactured or recycled. Remanufactured cartridges, containing an average of 90 percentreused/recycled parts, are built and tested to the same performance specifications as new products. Similarly, waste toners qualified for reuse may account for 25 percent of the weight of new toner, without compromisingtoner functionality. The reuse of waste toner saves several million dollars in raw material costs each year.

For one of Xerox’s most popular product families, a closed-loop recyclingprocess enables scrap plastic parts from returned cartridges to be re-ground,re-qualified, and molded into the same parts. These parts, made of 100 percentrecycled plastic, are used in manufacturing new cartridges. Each year Xeroxrecycles more than 115,000 pounds of post-consumer plastic scrap in thismanner.

Recent Upgrades Strengthen Green World Alliance• An updated web site makes it possible for customers to download return

labels directly from the site rather than request them by phone or e-mail.

• A European web page added in 2004 enabled expansion of the supplies recycling program in 14 European countries.

• A number of new cartridges and waste toners, including color toners, werequalified for remanufacture.

• For black waste toners not suitable for remanufacture, efforts continued toidentify reuse options. One such option involves reprocessing waste toner as a colorant in newly built plastic parts.

1This figure is based on North American sales.

Xerox return programs for supplies — The Green World Alliance —diverted 13.8 million pounds of material from landfills worldwide in 2004.

Xerox Green World Alliancewww.xerox.com/gwa

0.62.0

Waste-Free Products Sustainable Design for Equipment, Supplies, and Paper

14 Waste-Free Products

Paper Sourcing RequirementsAs one of the largest distributors of cut-sheet paper, Xerox recognizes itsobligation to reduce the environmental impact of paper. Starting with thesource of the fiber used to make the paper, through its manufacture and use, Xerox strives to minimize the environmental impact while meeting itscustomers’ exacting business needs.

In 2000, Xerox adopted an environmental position on sourcing paper. Theposition states that our goal is to source paper from companies committed tosound environmental, health, and safety practices and sound environmentalmanagement. In support of this position, in 2003 we issued a set of stringent requirements for companies who provide paper to Xerox for resale. Therequirements, which went into effect over a two-year period, cover all aspects of papermaking, from forest management to production of finishedgoods. The requirements are now included in our new supplier qualificationprocess, and existing Xerox paper suppliers worldwide must meet these newrequirements to continue doing business with Xerox.

Suppliers must also submit detailed documentation, on an annual basis, verifying conformance. More than 75 percent of our paper suppliers, representing in excess of 90 percent of the paper Xerox supplies to its customers, have committed to meeting these requirements. In 2005, stringent requirements for demonstrating sustainable forest managementwent into effect, and, as of this publication, suppliers representing 90 percentof Xerox paper have met these additional requirements.

Key ElementsKey elements of the requirements include:• Commitment to compliance with all applicable environmental, health, and

safety regulatory requirements, including forestry codes of practice andregulations governing legal harvesting of wood.

• An effective mill environmental management system and objectives for continual improvement in environmental performance above and beyondregulatory compliance.

• An effective procurement process that:– Ensures the exclusion of illegally harvested wood raw materials.– Ensures the exclusion of wood raw materials derived from forest areas

of significant ecological or cultural importance, unless certified to aXerox-accepted sustainable forest management standard.

– Encourages all suppliers of wood raw materials to practice sustainableforest management.

• Strict limits on the use of hazardous materials, including exclusion of elemental chlorine, in the processing and content of Xerox papers.

XEROX POSITION ON PAPER SOURCING

Xerox Corporation sources its paper from companies committed to sound environmental,health, and safety practices and sustainable forest management in their own operations andthose of their suppliers. Our intent is to protectthe health and integrity of forest ecosystems, conserve biological diversity and soil and waterresources, safeguard forest areas of significantecological or cultural importance, and ensure sustainable yield. Companies must be committedto compliance with all applicable environmental,health, and safety regulatory requirements in thecountries where they operate.

Xerox extends financial support to NatureServe and The Nature Conservancy. NatureServe develops tools to help forest managers identify plant and animal species and ecological communities requiring protection. The Nature Conservancy is an international organization dedicated to preserving the diversity of life on Earth.

Waste-Free Products 15

Forest Areas Needing ProtectionWe recognize that one of the biggest challenges paper companies face inmeeting these requirements will be to demonstrate they are safeguarding forest areas of significant ecological or cultural importance. Therefore, wefully support multistakeholder efforts to develop information sources andtools to help suppliers identify these areas on their own forestlands and in their procurement of wood raw materials from third-party lands. We encourage our suppliers to take full advantage of these resources as part of their sustainable forestry efforts.

Recycled PaperIncorporating recycled content in our products is another important wayXerox reduces the environmental impact of its paper products. Xerox recycled papers use post-consumer waste in place of new pulp to conservenatural resources. For every ton of recycled fiber used, paper manufacturersavoid the use of 3.5 tons of virgin fiber.1 This not only saves trees butreduces pressure on natural forests.

Recycled products are designed for optimal performance in Xerox equipmentand are required to meet the same strict performance specifications as virgin products. We offer multipurpose papers with up to 100 percent post-consumer recycled content. And our transparencies, tabs, coloredpapers, and several premium products designed especially for digital colorprinting applications contain 20 to 30 percent recycled content.

In 2004, Xerox expanded its recycled product offerings. Our MultipurposePastel, Premium Inkjet, and Premium Laser papers were converted from virgin content to 30 percent post-consumer waste. And we intend to continueexpanding recycled product offerings in 2005.

Efficient Use of PaperXerox equipment and software are designed with features that allow customers to make efficient use of paper. Reliable two-sided (duplex) printingis featured in Xerox office equipment. Software products such as DocuShare®,FlowPort®, FreeFlow® SMARTsend®, and FreeFlow Digital Workflow Collection help Xerox customers reduce paper consumption by facilitatingelectronic data management, scan to e-mail, print-on-demand, and distribute-then-print workflows. 1Paper Task Force Recommendations for Purchasing and Using Environmentally Preferable Paper, UpdatedLifecycle Environmental Charts (2002).

Xerox strives to minimize the environmentalimpact of paper while meeting its customers’ exacting business needs.

Equipment Remanufacture and Parts ReuseXerox pioneered the practice of converting end-of-life electronic equipmentinto new products and parts. We developed a comprehensive process for taking back end-of-life products from customers in the early 1990s, establishing a remanufacture and parts reuse program that fully supports our Waste-Free initiatives. Ninety percent of Xerox-designed product modelsintroduced in 2004 were developed with remanufacturing in mind.

Our approach to managing products at end-of-life translates into significantenvironmental and financial benefits. It prevents millions of pounds of wastefrom entering landfills each year — 128 million pounds in 2004 alone. Plus,the practice of reusing parts reduces the amount of raw material and energyneeded to manufacture brand-new parts, generating several hundred milliondollars in cost savings each year. We estimate that in 2004, energy savingsfrom parts reuse totaled 11 million therms (320,000 megawatt hours) —enough energy to light more than 250,000 U.S. homes for a year.

Designing for ReuseXerox has been able to maximize the end-of-life potential of products andcomponents by incorporating reuse considerations into the design process.Machines are designed for easy disassembly and contain fewer parts. Partsare designed for durability over multiple product life cycles. Parts are alsoeasy to reuse or recycle and are coded with disposition instructions. As aresult, equipment returned to Xerox at end-of-life can be remanufactured —rebuilt to as-new performance specifications, often reusing 70 to 90 percentof machine components by weight, while meeting performance specificationsfor equipment with all new parts.

Xerox has further extended its ability to reuse parts by designing productfamilies around modular product architectures and a common set of corecomponents. These advances offer Xerox multiple options for giving new life

to old equipment. A returned machine can be rebuiltas the same model through remanufacture, convertedto a new model within the same product family, orused as a source for parts for next-generation models.

Improved processes for forecasting equipment returnsfrom customers have allowed Xerox to increasinglyrely on previous generations of equipment as a sourcefor components for products in development. Xeroxproducts with designs based on previous models may have 60 percent of their parts in common with previous equipment. As the pace of technologicalinnovation has shortened product life cycles, our ability to reuse parts across product generations has become increasingly important.

Waste-Free Products Sustainable Design for Equipment, Supplies, and Paper

16 Waste-Free Products

Since its inception in the early 1990s, Xerox’s equipment remanufacture and parts reuse/recycle program has kept nearly 1.6 billion pounds of waste out of landfills — the equivalent of more than 2.3 million machines. This is enough material to fill the Empire State Building nearly four times.

Build Product

Process Parts for Reuse(Equipment Remanufacture

or Conversion)

Recycle Parts

Recycle Materials(Third Party) Sort/Inspect

Dismantle

Return to Xerox

Customer Use

Deliver

Fabricate New Parts

Alternative Uses DisposalGoal: Zero to Landfill

Raw Materials

XEROX EQUIPMENT RECOVERY AND PARTS REUSE/RECYCLE PROCESS

Waste-Free Products 17

Ensuring Product QualityXerox has developed unique processes and technologies to ensure that allXerox products, regardless of their reused or recycled part content, meet the same specifications for performance, appearance, quality, and reliability.Signature Analysis is one such technology. It enables Xerox engineers todetermine the life expectancy of motors and other electromechanical components. Using this technology, we test new parts to determine a “signature” — an acceptable range for the noise, heat, or vibration thatelectromechanical parts produce while in use. We then test the same characteristics in parts from returned equipment. Only those parts havingsignatures consistent with those of newly built parts are approved andprocessed for reuse.

Xerox has been using Signature Analysis technology in its equipment disassembly and remanufacture operations since 1994. Prior to its introduction, the reuse potential of returned parts was predetermined basedon average life expectancy data. Some parts were consistently scrapped,while others were consistently approved for reuse. Today, using SignatureAnalysis, we are able to identify unacceptable parts that might otherwise have been approved for reuse, improving equipment reliability and customersatisfaction. Xerox also identifies many useful parts that would otherwisehave been scrapped, reducing unnecessary waste and eliminating costsassociated with the purchase of new parts.

The full integration of equipment remanufacture and partsreuse processes with traditional manufacturing operations is another critical element of Xerox’s strategy for ensuringconsistent quality for all products. Machines with reused orrecycled parts are built on the same manufacturing lines as

newly manufactured equipment, and they undergo the same rigorous qualityassurance tests. As a result, products with reused or recycled parts carry the same Xerox guarantees, warranties, and service agreements as Xeroxequipment made from all new parts.

Meeting Customer RequirementsCustomer acceptance of reused and recycled parts was a significant challenge for Xerox’s program throughout the 1990s. Today, with more than

a decade of proof, we find that far fewercustomers share the misperception thatproducts with reused or recycled parts areinferior to those built from all new parts.Xerox continues to educate customersabout the quality and reliability of reusedparts. And, whenever necessary, we promote environmentally responsible purchasing policies and practices that eliminate barriers to reuse by focusing on the quality and performance of productsregardless of recycled content.

Xerox uses Signature Analysis testing technology to determine the usable life of parts fromreturned equipment.

PRODUCTS DESIGNED FOR REMANUFACTURE

Perc

enta

ge o

f Xer

ox

Prod

uct M

odel

s

00 01 02 03 04

100

80

60

40

20

0

10090

100 10090

Note: Percentages are the proportion of Xerox-designed product models introduced each year that are designed for remanufacture.

Note: These data cover the remanufacture andreuse/recycle of Xerox equipment and parts atXerox facilities and those of our contract officeequipment manufacturer, Flextronics.

1 Energy savings represent the difference between theenergy required to build new parts and the energyrequired to process parts for reuse, assuming an average machine composition of 60 percent plastic and40 percent steel. Energy savings calculations encompass“feedstock energy” (the energy content of the petroleumand coal raw materials converted to plastic and steel,respectively) and energy required to process and transport materials throughout the life cycle. Life cycleenergy data was obtained from Franklin Associates, Ltd.Energy savings were converted into avoided emissions of carbon dioxide using a U.S. energy profile and emissions factors calculated by the U.S. EnvironmentalProtection Agency and Department of Energy. Feedstockenergy was excluded from this conversion.

WASTE DIVERTED FROM LANDFILLS THROUGH PARTS REUSE/RECYCLE

Mill

ions

of P

ound

s

91 00 01 02 03 04

200

150

100

50

0

142

49

149 143 139 128

30

98

//

1716

14100

9279

8

9 87

8 12

6

67

Ener

gy S

avin

gs(M

illio

ns o

f The

rms)

20

10

091 00 01 02 03 04

150

100

50

0Av

oide

d CO

2Em

issi

ons

(Tho

usan

ds o

f Ton

s)

46

62

Feedstock Energy Saved

Process and Transport Energy Saved

CO2 Emissions Avoided

5

6

6

REDUCTIONS IN ENERGY AND CO2 EMISSIONSFROM PARTS REUSE

8

4

4

711

//

Parts Recycled

PartsReused

1

18 Product Showcase

Xerox Nuvera 100/120 Digital Production System

Xerox iGen3 Digital Production Press

Xerox iGen3 Digital Production PressCompared to traditional offset printing presses, the Xerox iGen3 creates little waste, emits 80 percent less noise, and neither generates hazardouswaste1 nor uses hazardous materials. Up to 97 percent of the parts in thisthree-ton machine and 80 percent by weight of the waste it generates can bereused or recycled. This 80 percent figure includes the machine itself, emptytoner bottles, waste developer, and packaging.

1According to applicable national waste regulations.

Xerox Nuvera Digital Print-on-Demand and Publishing SolutionsModular architecture and new technologies in the Xerox Nuvera 100/120 DigitalProduction System and Digital Copier/Printer, introduced in 2004, extend thelife of machine components and make efficient use of materials and energy. For example, during the imaging process, a cloud of toner is suspended overthe photoreceptor where the fine particles adhere only to the properly chargedarea of the belt. This ability to develop an image without contact extends the lifeof the photoreceptor and the developer.

In addition, innovative cleaning technologies minimize wear to the photoreceptor and extend the belt’s life by 200 percent. Because the system’sfull-width array scanner captures light so efficiently, a lower-power xenon lamp replaces the typical mercury-containing lamp.

Digital Production TechnologyInnovative design features coupled with digital technology make Xerox-designed production printing systems the environmentally preferable choice.

• Non-toxic dry inks deliver nearly 100 percenttransfer efficiency to reduce potential for waste.

• Emissions of chemicals such as ozone anddust are strictly controlled to the same levelsof Xerox office machines, well below regulatory requirements.

• Digital print-on-demand technology reducespaper use and excess inventory by making iteconomical to print books and brochures asthey are ordered.

• Every part that is lifted, pushed, or pulled during machine assembly, operation, or servicehas been engineered and evaluated to minimizerisk to Xerox employees and customers.

Product ShowcaseTranslating Policy into Practice

Xerox introduced a number of products and supplies in 2004 and 2005 with environmental features demonstrating its latestadvances toward Waste-Free Product goals. Each new generation of products offers increasing functionality while conservingenergy and materials throughout the product life cycle.

Solid Ink Color MultifunctionIn 2005, Xerox introduced its first solid ink multifunction product, theWorkCentre C2424. Xerox also launched its fourteenth generation of solid inkprinters — the Phaser 8500/8550. Solid ink devices use unique formulationswhich are solid blocks of ink at room temperature. During the printing process,these sticks are melted and jetted through piezoelectric print heads. Images areprinted onto a rotating drum and offset onto paper in a single pass of the printengine, achieving nearly 100 percent ink transfer efficiency.

This simplified process requires significantly fewer supplies and maintenanceitems compared to laser machines, conserving valuable material resources.Solid ink printing also generates 95 percent less waste during use than a typicalcolor laser product. Fewer consumables translate into lower operating costs,increased reliability, and easier use.

DocuColor 8000 Digital PressWe designed the DocuColor 8000 Digital Press with the environment in mind.In addition to meeting Xerox noise and emissions levels, its high-speed belt-nip fuser conserves energy. Color adjustment features allow use of a widerange of recycled papers and other media types. Plus, these machines are remanufactured and designed for recycle and reuse to save valuable resources.

Emulsion Aggregation TonerEmulsion aggregation technology, a breakthrough process for producing colorand black toner, took over eight years to develop and carries more than 100patents. The process builds toner particles to any desired shape or size using a chemical method. By contrast, traditional toner manufacturing involvesmechanical grinding of large particles of solid colored plastic into smaller ones,followed by a classification process to sort out the desired size.

The extremely small size and round shape of emulsion aggregation toner particles make it possible to more uniformly charge the particles and transferthem efficiently and uniformly to receive paper. As a result, the system usesabout 50 percent less toner per printed page and significantly reduces tonerwaste — all while producing sharper color images and fine lines.

In addition, emulsion aggregation toners exhibit image fixing capability at lowtemperatures, thus reducing energy consumption per page.

The latest Xerox products to use emulsion aggregation tonersinclude the Xerox CopyCentre C123/C128 copiers, the WorkCentreM123/M128 (above), and the WorkCenter Pro 123/128 multifunction system.

Product Showcase 19

DocuColor 8000 Digital Press

The WorkCentre C2424 isXerox’s first multifunctionproduct featuring solid ink.

20 Waste-Free Products

Into the FutureXerox’s research and development efforts are aimed at reinventing Xeroxmachines and systems, rethinking how people work, and redefining “the document.” Each of these areas is preparing Xerox for the sustainable product designs and solutions of the future.

Efficient Use of Materials and EnergyThe company is a leader in developing Micro-Electro-Mechanical Systems(MEMS), which integrate electronics and mechanical systems to enable more intelligent systems based on sensing, control, and adaptive processes. Suchadvances will enable Xerox engineers to replace costly precision mechanicalparts with electronics and modern controls, thus reducing the cost andimproving the performance of Xerox marking engines. Development effortsare also focusing on system architectures and efficient fuser designs todirectly reduce the energy required by Xerox products. These efforts shouldresult in smaller machines with fewer and longer-life parts for more efficientuse of materials and energy.

Innovative MaterialsIn the materials area, Xerox is pioneering applications of nanotechnology for use in printing and copying. Nanotechnology is the science of building materials and devices from elements in the nanometer-or-less size range.Emulsion aggregation toner, introduced by Xerox in 2002, is one example. It uses a process to grow micron-size particles from smaller nanometer-sizeconstituents. This toner uses an estimated 25 percent less energy to manufacture than traditional toner. And because it is water-based and avoidsthe use of organic solvents commonly required to make particles in this sizerange, it is environmentally advantaged.

Xerox is also pioneering the development of solid ink technology. The inherent environmental benefits of solid ink include the efficient use of materials, typically producing 95 percent less waste than a comparable laser printer. We are currently researching innovative inks and print headsthat will enhance the energy efficiency attributes of this technology.

Documents of the FutureXerox is expanding the boundaries of today’s document. One area of researchlooks at how to create alternative document viewing media, such as electronic paper, which preserves desirable attributes of paper — portability,thinness, and low cost — while imparting the benefits of digital systemssuch as reuse and storage. Xerox established its first commercial venturemarketing SmartPaper technology, via its subsidiary Gyricon LLC, in 2003.

Waste-Free Products Sustainable Design for Equipment, Supplies, and Paper

Innovation and invention prepare Xerox for the sustainable productdesigns and solutions of the future.

Xerox researchers developed the Optical MEMS (Micro-Electro-Mechanical Systems) switch. Research in MEMSwill result in smaller machines that make more efficient use of materials and energy.

SmartPaper contains millions of small two-color beadssealed in a thin layer of transparent plastic. When voltage is applied to the surface, the beads rotate toshow one color or the other, producing an image.

Xerox’s Oklahoma City, Oklahoma facility is granted membership to the U.S. Environmental Protection Agency’sNational Environmental Performance Track Program.

The Dundalk Chamber of Commerce presents the BusinessExcellence Award to the Dundalk, Ireland, facility.

ISO 14001 Environmental Management SystemAll company manufacturing operations are certified to the ISO 14001environmental management system standard to ensure continuous environmental performance improvement, to identify environmental impact, and to set reduction targets and maintain compliance with regulations andXerox standards.

The ISO 14001 system requires the integration of environmental planning and program management with day-to-day business activities. This process encourages the application of innovative engineering solutions, creative partnerships, and employee involvement. In 2004, changes were made to the ISO 14001 standard. Xerox anticipates having all certified facilities in conformance with these revisions in 2006.

Proactive Programs Achieved National and Local RecognitionThe ISO 14001 approach has led to the development of programs that proactively reduce or prevent adverse environmental impact, and some havegained national recognition. For example, Xerox’s manufacturing facility inOklahoma City, Oklahoma, was granted membership into the U.S. EnvironmentalProtection Agency’s National Environmental Performance Track Program. The program awards facilities that voluntarily exceed regulatory requirements,implement systems for improving environmental management such as ISO 14001, work with their communities, and set three-year environmental performance improvement goals. Only facilities with a record of sustained compliance with environmental requirements are eligible to participate.

Xerox manufacturing sites have also gained recognition from local communities.The Xerox Technology Park in Dundalk, Ireland, won the Dundalk Chamber ofCommerce Business Excellence Award for its environmental performance. The award, sponsored by Vhi Healthcare, demonstrates Xerox’s continued commitment to the protection of the environment.

Waste-Free Facilities 21

Waste-Free FacilitiesAn Ongoing Commitment

Since the early 1990s, Xerox has managed environmental performance in its manufacturing operations to an internal benchmark known as Waste-FreeFactory. Our commitment to the goals of this initiative, along with globalimplementation of an ISO 14001 environmental management system, has driven environmental performance improvements for over a decade.

XEROX RESEARCH AND MANUFACTURINGSITE OPERATIONS

Type of Operation Locations

Research, Technology, Canada, United Kingdom,and Development United States, France

Manufacturing, Brazil, Canada, Engineering, Egypt, India, Ireland, and Assembly Mexico, Netherlands,

Spain, United Kingdom, United States

ABOUT ENVIRONMENTAL PERFORMANCE RESULTS

Environmental performance data in this section represent total quantities for Xerox’s manufacturing, research and development, andequipment recovery/recycle operations located in 11 countries aroundthe world. Energy consumption and greenhouse gas emissions arereported across all company operations. Starting in 2002, these data— with the exception of solid waste figures — do not include Xeroxoffice equipment manufacturing operations outsourced in late 2001 to Flextronics, a global electronics manufacturing services company.Unless otherwise noted, all numbers represent worldwide totals andare reported in generally accepted international metrics.

69 71

168

5377

54 62

180

58 63

Met

ric T

ons

91 00 01 02 03 04

700

600

500

400

300

200

100

0

Supplies Operations Worldwide

636

//

Note: In late 2001, Xerox outsourced most of its office product manufacturing operations to Flextronics. Air emissions from these transferred operations are excluded from Xerox totals starting in 2002. This change in reporting accounts for nearly all of the reduction in air emissions between 2001 and 2002.

AIR EMISSIONS

3

2004 AIR EMISSIONS: DISTRIBUTION BY TYPE

25%Dichloromethane

<1% Other RegulatedPollutants

62% OtherVolatile OrganicCompounds

13% Particulates

Waste-Free FacilitiesAn Ongoing Commitment

22 Waste-Free Facilities

Air EmissionsXerox facilities released 63 metric tons of chemicals and particulates to the air in2004, a 1 percent increase from 2003. The increase came primarily from higherproduction of Xerox imaging supplies.

Over 90 Percent Reduction Since 1991The majority of Xerox’s air emissions come from operations that manufactureXerox imaging supplies — toners, inks, and photoreceptors. With a firm commitment to our Waste-Free Factory goals, these facilities have made tremendous progress in reducing air emissions over the last decade.

Reduction, reuse, and recycling strategies put in place by supplies operationsbetween 1991 and 1996 were responsible for reducing air emissions by 87 percent during that period. Since that time, production level declines andcontinuous improvements in our processes have resulted in an additional 4 percent reduction by supplies operations, for a total of 91 percent reductionfrom 1991 levels.

High-Priority Target for ReductionThe single largest component of Xerox’s air emissions is dichloromethane (methylene chloride), a necessary solvent for the manufacture of organic photoreceptors. Efficiency improvements in manufacturing, along with state-of-the-art emission control technologies, have resulted in a 97 percentreduction of dichloromethane emissions to the air since 1991.

Whereas a third of the dichloromethane waste generated was released to the airin 1991, only 3 percent is released today. The remainder is captured for on-sitereuse or off-site recycling. To date, we have not been able to identify a suitablereplacement chemical, but the reduction of dichloromethane emissions to the airremains a priority.

DICHLOROMETHANE MANAGEMENT: U.S. FACILITIES

Perc

enta

ge o

f Was

te G

ener

ated

Released to Air Reused or Recycled

100

80

60

40

20

0

33

67

97

1991 2004

Waste-Free Facilities 23

Hazardous WasteXerox strives to minimize hazardous waste generation and to find disposalsolutions that are environmentally benign. Ninety-nine percent of hazardouswaste generated in 2004 was beneficially managed through treatment, recycling, or energy recovery through fuels blending. The remaining 1 percent was incinerated or disposed in landfills permitted to accept hazardous waste.

Increasing Production Requires Greater EffortWorldwide hazardous waste volumes increased by 19 percent between 2003and 2004. This change was driven primarily by increases in the production of advanced-technology print heads for solid ink printers and associatedprocess wastewater. This wastewater is treated by adjusting the pH levelthrough a neutralization process. After treatment, the water is discharged intolocal sanitary sewers. In 2005, we are identifying opportunities to reduce thevolume of hazardous waste generated in our operations. For example, betterseparation of process wastewaters will reduce the amount of wastewaterrequiring treatment as hazardous waste.

A large proportion of Xerox’s hazardous waste — over 80 percent — was theprocess wastewater mentioned above. The remaining hazardous waste generated in 2004 was primarily organic solvent waste. Captured usingsophisticated reclamation systems, organic waste is sent off-site for recyclingor energy recovery. Off-site recycling converts waste into reusable products.

Xerox Applies Innovative SolutionsReducing the generation of hazardous waste remains a priority and requiresinnovative engineering solutions. Xerox’s Webster, New York, photoreceptorplant recently improved its solvent reclamation system. Originally installed in1995, the system reclaims over 98 percent of the waste solvent used in thephotoreceptor coating operation. Reclaimed solvent is either reused in thesame process or recycled off-site.

Until 2002, only 50 percent of the reclaimed solvent was pure enough for in-process reuse. An innovative enhancement to the reclamation processincreased the reusable portion to 70 percent, reducing the hazardous wastegenerated by 45 percent and the chemicals purchased by over 40 percent.This project has won the statewide 2004 Industry Award for PollutionPrevention from the New York Water Environmental Association.

99percent

Beneficially managed hazardous waste throughtreatment, recycling, orenergy recovery throughfuels blending.

HAZARDOUS WASTE GENERATED

Thou

sand

s of

Met

ric T

ons

00 01 02 03 04

20181614121086420

9.8

4.7

12.3

15.2

18.3

Xerox’s Webster, New York photoreceptor plant received the statewide2004 industry award for pollution prevention from the New YorkWater Environmental Association.

2004 HAZARDOUS WASTE MANAGEMENT

89% TreatedOn-Site

4% Fuels Blended

3% Treated Off-Site

2% Recycled Off-Site 1% Recycled On-Site

1% Disposed

Note: Increases in hazardous waste primarilyreflect production increases at Xerox’s solid inkfacility. The hazardous waste generated from thisprocess is treated on-site and then discharged as non-hazardous wastewater.

2004 NON-HAZARDOUS SOLID WASTE MANAGEMENT

57% EquipmentWaste Reused or Recycled

32% ProcessWaste Reused or Recycled

2% EquipmentWaste Disposed9% Process

Waste Disposed

Waste-Free FacilitiesAn Ongoing Commitment

24 Waste-Free Facilities

Thou

sand

s of

Met

ric T

ons

EQUIPMENT WASTE: EQUIPMENT RECOVERY/RECYCLE OPERATIONS

95 00 01 02 03 04

60

40

20

0

Reused or Recycled Disposed

19

5

34

2

4550

2

49

2

45

23//

Non-Hazardous Solid WasteXerox’s Waste-Free Factory initiative has focused our efforts on reducing theamount of non-hazardous solid waste generated by Xerox operations andresponsibly managing the waste that cannot be eliminated. Xerox recycled 89 percent of its non-hazardous solid waste in 2004, up from 85 percent in 2003.

In addition to typical solid waste generated from manufacturing, construction,and maintenance, Xerox manages end-of-life machines returned to Xeroxequipment recovery/recycle facilities. Returned equipment that cannot bereused through remanufacturing, which we classify as “equipment waste,”makes up over 50 percent of the waste managed by Xerox operations.

Because of the unique challenges of managing returned equipment containingelectronic waste, the following two solid waste sections present results separately for equipment recovery/recycle operations that handle equipmentwaste and for manufacturing operations that handle process waste.

Equipment Recovery/Recycle OperationsEquipment that reaches the end of its useful life is returned to Xerox equipmentrecovery/recycle facilities. To maximize environmental and financial benefits,Xerox first evaluates returned equipment for its reuse potential. Products suitable for reuse undergo the rigorous equipment remanufacture processesdescribed on pages 16 and 17 of this report. For more than a decade, this practice has given new life to the equivalent of more than 2.5 million copiers,printers, and multifunction systems, while diverting hundreds of millions ofpounds of potential waste from landfills.

Returned products that cannot be remanufactured are designated as equipmentwaste. Xerox equipment recovery/recycle operations disassemble thesemachines, removing parts that can be processed for reuse according to stringent standards for quality and performance. The remaining componentsare recycled or disposed. Of the 47,000 metric tons collected in 2004, Xeroxwas able to reuse or recycle 96 percent.

Xerox also carefully manages suppliers that provide recycling and waste disposal services. An audit process ensures that vendor practices are safe,environmentally sound, and compliant with regulations. Xerox requires thesecompanies to document the final disposition of materials, including electronicscrap, sent to their facilities.

Xerox manages thousands of end-of-life machinesthat customers return each year to our equipment recovery/recycle facilities.

NON-HAZARDOUS SOLID WASTE RECYCLE RATE: ALL FACILITIES

Perc

enta

ge R

ecyc

led

95 00 01 02 03 04

100

80

60

40

20

0

807890 92

85 89

//

Mill

ions

of L

itres

00 01 02 03 04

4,000

3,000

2,000

1,000

0

3,2183,1462,960

2,487 2,442

Waste-Free Facilities 25