KLM Technology Group Practical Engineering Guidelines for Processing Plant Solutions www.klmtechgroup.com Page : 1 of 87 Rev: 02 Rev 1 JUNE 2010 Rev 2 JUNE 2011 KLM Technology Group STORAGE TANK SELECTION AND SIZING (ENGINEERING DESIGN GUIDELINE) Author: Rev 1 Karl Kolmetz Rev 2 Aprilia Jaya Checked by: Karl Kolmetz TABLE OF CONTENT INTRODUCTION Scope 5 General Design Considerations 6 TYPES OF TANKS Fixed Roof Tanks 7 External floating roof tanks 11 Internal floating roof tanks 15 Domed external floating roof tanks 18 Horizontal tanks 20 Pressure tanks 22 Variable vapor space tanks 23 TANK SEALS AND FITTINGS 25 External and Domed External Floating Roof Rim Seals 25 External and Domed External Floating Roof Deck Fittings 32

Engineering Design Guideline Storage Tank Rev 2

Nov 07, 2014

storage tank design

Welcome message from author

This document is posted to help you gain knowledge. Please leave a comment to let me know what you think about it! Share it to your friends and learn new things together.

Transcript

KLM TechnologyGroup

Practical EngineeringGuidelines for Processing

Plant Solutions www.klmtechgroup.com

Page : 1 of 87

Rev: 02

Rev 1 JUNE 2010Rev 2 JUNE 2011

KLM Technology Group

STORAGE TANK SELECTION ANDSIZING

(ENGINEERING DESIGN GUIDELINE)

Author:

Rev 1 Karl KolmetzRev 2 Aprilia Jaya

Checked by:

Karl Kolmetz

TABLE OF CONTENT

INTRODUCTION

Scope 5

General Design Considerations 6

TYPES OF TANKS

Fixed Roof Tanks 7

External floating roof tanks 11

Internal floating roof tanks 15

Domed external floating roof tanks 18

Horizontal tanks 20

Pressure tanks 22

Variable vapor space tanks 23

TANK SEALS AND FITTINGS 25

External and Domed External Floating Roof Rim Seals 25

External and Domed External Floating Roof Deck Fittings 32

KLM TechnologyGroup

Practical Engineering Guidelinesfor Processing Plant Solutions

STORAGE TANK SELECTION ANDSIZING

ENGINEERING DESIGN GUIDELINES

Page 2 of 87

Rev: 02

JUNE 2011

These design guideline are believed to be as accurate as possible, but are very general and not for specific design cases.They were designed for engineers to do preliminary designs and process specification sheets. The final design mustalways be guaranteed for the service selected by the manufacturing vendor, but these guidelines will greatly reduce theamount of up front engineering hours that are required to develop the final design. The guidelines are a training tool foryoung engineers or a resource for engineers with experience.

This document is entrusted to the recipient personally, but the copyright remains with us. It must not be copied,reproduced or in any way communicated or made accessible to third parties without our written consent.

DEFINITIONS 45

NOMENCLATURE 53

THEORY OF THE DESIGN 55

1. Tank Dimension 55

2. Atmospheric storage tank 59

3. Pressure Storage Tank 63

4. Refrigerated Storage 65

5. Emissions Losses 66

A. Total Losses from Fixed Roof Tanks 66

B. Total Losses from Floating Roof Tanks 69

APPLICATION 75

Example 1: Dimension of tank calculate 75

Example 2: Fixed Roof Tank Emission (Cone Roof and Dome Roof) 78

Example 3: Floating Roof Emission Losses 81

REFEREENCES 84

CALCULATION SPREADSHEET 85

Dimension of Tank Spreadsheet.xls 85

KLM TechnologyGroup

Practical Engineering Guidelinesfor Processing Plant Solutions

STORAGE TANK SELECTION ANDSIZING

ENGINEERING DESIGN GUIDELINES

Page 3 of 87

Rev: 02

JUNE 2011

These design guideline are believed to be as accurate as possible, but are very general and not for specific design cases.They were designed for engineers to do preliminary designs and process specification sheets. The final design mustalways be guaranteed for the service selected by the manufacturing vendor, but these guidelines will greatly reduce theamount of up front engineering hours that are required to develop the final design. The guidelines are a training tool foryoung engineers or a resource for engineers with experience.

This document is entrusted to the recipient personally, but the copyright remains with us. It must not be copied,reproduced or in any way communicated or made accessible to third parties without our written consent.

Fixed Roof Tank Emission Losses Spreadsheet.xls 86

Floating Roof Emission Losses Spreadsheet.xls 87

LIST OF TABLE

Table 1: Maximum allowable stress value (f) 56

Table 2: Maximum allowable efficiencies for Arc and Gas welded joints 57

Table 3: Dimension of icr, rc, and sf 58

Table 4: Size of innage and outage of tank 61

Table 5: Nozzle service for tank 62

Table 6: Paint Factors for Fixed Roof Tanks 67

Table 7: Rim-seal loss factor 71

Table 8: Average Clingage Factors (Cs) 72

Table 9: Typical Number of Columns as a Function of Tank Diameter 72

Table 10: Deck-Fitting Loss Factors and Typical Number oF Deck Fitting 78

LIST OF FIGURE

Figure 1: Fixed Roof Tanks 9

Figure 2: Fixed Roof Tanks 2 10

Figure 3: External Floating Roof Tanks 12

Figure 4: External Floating Roof Tanks 2 13

Figure 5: Typical List of Floating Roof Fittings 14

Figure 6: Internal Floating Roof 17

KLM TechnologyGroup

Practical Engineering Guidelinesfor Processing Plant Solutions

STORAGE TANK SELECTION ANDSIZING

ENGINEERING DESIGN GUIDELINES

Page 4 of 87

Rev: 02

JUNE 2011

These design guideline are believed to be as accurate as possible, but are very general and not for specific design cases.They were designed for engineers to do preliminary designs and process specification sheets. The final design mustalways be guaranteed for the service selected by the manufacturing vendor, but these guidelines will greatly reduce theamount of up front engineering hours that are required to develop the final design. The guidelines are a training tool foryoung engineers or a resource for engineers with experience.

This document is entrusted to the recipient personally, but the copyright remains with us. It must not be copied,reproduced or in any way communicated or made accessible to third parties without our written consent.

Figure 7: Dome External Floating Roof 19

Figure 8: Schematics of above-ground horizontal (a) and underground tanks (b) 21

Figure 9: Scheme of Pressure Tank 22

Figure 10: Variable Vapor Space Tanks 24

Figure 11: Vapor mounted primary seals 26

Figure 12: Liquid-mounted and mechanical shoe primary seals 27

Figure 13: Secondary rim seals 29

Figure 14: Access Hatch 32

Figure 15: Gauge float 33

Figure 16: Sample ports 34

Figure 17: Rim vent 35

Figure 18: Deck drains 36

Figure 19: Deck leg 37

Figure 20: Slotted and unslotted guidepoles 38

Figure 21: Vacuum breaker 41

Figure 22: Fixed Roof Support Column 43

Figure 23: Ladder and well 44

KLM TechnologyGroup

Practical Engineering Guidelinesfor Processing Plant Solutions

STORAGE TANK SELECTION ANDSIZING

ENGINEERING DESIGN GUIDELINES

Page 5 of 87

Rev: 02

JUNE 2011

These design guideline are believed to be as accurate as possible, but are very general and not for specific design cases.They were designed for engineers to do preliminary designs and process specification sheets. The final design mustalways be guaranteed for the service selected by the manufacturing vendor, but these guidelines will greatly reduce theamount of up front engineering hours that are required to develop the final design. The guidelines are a training tool foryoung engineers or a resource for engineers with experience.

This document is entrusted to the recipient personally, but the copyright remains with us. It must not be copied,reproduced or in any way communicated or made accessible to third parties without our written consent.

INTRODUCTION

Scope

This design guideline covers the sizing and selection methods of a storage tanksystem used in the typical process industries. It helps engineers understand the basicdesign of different types of storage tank systems and increases their knowledge inselection and sizing.

The selection section contains the explanation for the suitability of types of tanksystem used in processing industries, which are based on the environmentalregulations, location, and process materials involved.

All the important parameters used in this guideline are well explained in the definitionsection which helps the reader understand the meaning of the parameters and theterms used.

The theory section includes sizing theory and formulations for the tanking systemsdesign.

In the application section, three cases examples are included by guiding the readerstep by step to do tank sizing.

In the end of this guideline, example specification data sheets for the tank system areincluded which is created based on an industrial example. Calculation spreadsheet isincluded as well and to aid user more understand and to apply the theory forcalculations.

KLM TechnologyGroup

Practical Engineering Guidelinesfor Processing Plant Solutions

STORAGE TANK SELECTION ANDSIZING

ENGINEERING DESIGN GUIDELINES

Page 6 of 87

Rev: 02

JUNE 2011

These design guideline are believed to be as accurate as possible, but are very general and not for specific design cases.They were designed for engineers to do preliminary designs and process specification sheets. The final design mustalways be guaranteed for the service selected by the manufacturing vendor, but these guidelines will greatly reduce theamount of up front engineering hours that are required to develop the final design. The guidelines are a training tool foryoung engineers or a resource for engineers with experience.

This document is entrusted to the recipient personally, but the copyright remains with us. It must not be copied,reproduced or in any way communicated or made accessible to third parties without our written consent.

General Design Considerations

Storage vessels containing organic and non organic liquids and vapors can be foundin many industries, including;

(1) petroleum producing and refining,(2) petrochemical and chemical manufacturing,(3) bulk storage and transfer operations, and(4) other industries consuming or producing liquids and vapors.

Liquids and vapors in the petroleum industry, usually called petroleum liquids orvapors, generally are mixtures of hydrocarbons having dissimilar true vapor pressures.Examples would include jet fuel, diesel, gasoline and crude oil.

Liquids and vapors in the chemical industry, usually called volatile organic liquids andvapor, are composed of pure chemicals or mixtures of chemicals with similar truevapor pressures. Examples would include benzene, styrene, and alcohols).

Liquids and vapors in the bulk storage and transfer operations can be organic orhydrocarbon in nature. Example would include all of the above including acids andbases.

All those chemical should keep in the right storage tank. Design and safety concernhas come to a great concern as reported case of fires and explosion for the storagetank has been increasing over the years and these accident cause injuries andfatalities. Spills and tank fires not only causing environment pollution, there would alsobe severe financial consequences and significant impact on the future business due tothe industry reputation.

KLM TechnologyGroup

Practical Engineering Guidelinesfor Processing Plant Solutions

STORAGE TANK SELECTION ANDSIZING

ENGINEERING DESIGN GUIDELINES

Page 7 of 87

Rev: 02

JUNE 2011

These design guideline are believed to be as accurate as possible, but are very general and not for specific design cases.They were designed for engineers to do preliminary designs and process specification sheets. The final design mustalways be guaranteed for the service selected by the manufacturing vendor, but these guidelines will greatly reduce theamount of up front engineering hours that are required to develop the final design. The guidelines are a training tool foryoung engineers or a resource for engineers with experience.

This document is entrusted to the recipient personally, but the copyright remains with us. It must not be copied,reproduced or in any way communicated or made accessible to third parties without our written consent.

TYPES OF STORAGE TANKS

Seven types of vessels are used to store volatile organic liquids:

1. Fixed-roof tanks;

2. External floating roof tanks;

3. Internal floating roof tanks;

4. Domed external floating roof tanks;

5. Horizontal tanks;

6. Pressure tanks; and

7. Variable vapor space tanks.

The first four tank types are cylindrical in shape with the axis oriented perpendicular tothe foundation. These tanks are almost exclusively above ground. Horizontal tanks(i.e., with the axis parallel to the foundation) can be used above ground and belowground.

Pressure tanks often are horizontally oriented and "bullet" or spherically shaped tomaintain structural integrity at high pressures. They are located above ground.

Variable vapor space tanks can be cylindrical or spherical in shape.

KLM TechnologyGroup

Practical Engineering Guidelinesfor Processing Plant Solutions

STORAGE TANK SELECTION ANDSIZING

ENGINEERING DESIGN GUIDELINES

Page 8 of 87

Rev: 02

JUNE 2011

These design guideline are believed to be as accurate as possible, but are very general and not for specific design cases.They were designed for engineers to do preliminary designs and process specification sheets. The final design mustalways be guaranteed for the service selected by the manufacturing vendor, but these guidelines will greatly reduce theamount of up front engineering hours that are required to develop the final design. The guidelines are a training tool foryoung engineers or a resource for engineers with experience.

This document is entrusted to the recipient personally, but the copyright remains with us. It must not be copied,reproduced or in any way communicated or made accessible to third parties without our written consent.

1. Fixed-Roof Tanks

Of currently used tank designs, the fixed-roof tank is the least expensive to constructand is generally considered the minimum acceptable equipment for storing VOL's(volatile organic liquids). A typical fixed-roof tank, which is shown in Figure 1 below,consists of a cylindrical steel shell with a cone- or dome-shaped roof that ispermanently affixed to the tank shell. Most recently built tanks are of all-weldedconstruction and are designed to be both liquid- and vapor-tight. However, older tanksmay be of riveted or bolted construction and may not be vapor-tight.

A breather valve (pressure-vacuum valve), which is commonly installed on manyfixed-roof tanks, allows the tank to operate at a slight internal pressure or vacuum.Breather vents are typically set at 0.19 kPa (0.75 in. w.c.) on atmospheric pressurefixed-roof tanks. Because this valve prevents the release of vapors during only verysmall changes in temperature, barometric pressure, or liquid level, the emissions froma fixed-roof tank can be appreciable.

For fixed-roof tanks, the nominal capacity is the geometric volume from the bottom ofthe tank up to the curb angle, which is a metallic angle that is welded along theperiphery at the top of the cylindrical portion of the tank.

Additionally, gauge hatches/sample wells, float gauges, and roof manholes provideaccessibility to these tanks and also serve as potential sources of volatile emissions.Breather vents may be called conservation vents, although hardly any conservation ofvapors occurs at such low pressure settings. Generally, the term conservation vent isused to describe a pressure setting of 17 kPa (67 in. w.c.) or less. Vents with settingsgreater than 17 kPa (67 in. w.c.) are commonly called `pressure' vents.

KLM TechnologyGroup

Practical Engineering Guidelinesfor Processing Plant Solutions

STORAGE TANK SELECTION ANDSIZING

ENGINEERING DESIGN GUIDELINES

Page 9 of 87

Rev: 02

JUNE 2011

These design guideline are believed to be as accurate as possible, but are very general and not for specific design cases.They were designed for engineers to do preliminary designs and process specification sheets. The final design mustalways be guaranteed for the service selected by the manufacturing vendor, but these guidelines will greatly reduce theamount of up front engineering hours that are required to develop the final design. The guidelines are a training tool foryoung engineers or a resource for engineers with experience.

This document is entrusted to the recipient personally, but the copyright remains with us. It must not be copied,reproduced or in any way communicated or made accessible to third parties without our written consent.

Figure 1: Fixed Roof Tanks 1.

KLM TechnologyGroup

Practical Engineering Guidelinesfor Processing Plant Solutions

STORAGE TANK SELECTION ANDSIZING

ENGINEERING DESIGN GUIDELINES

Page 10 of 87

Rev: 02

JUNE 2011

These design guideline are believed to be as accurate as possible, but are very general and not for specific design cases.They were designed for engineers to do preliminary designs and process specification sheets. The final design mustalways be guaranteed for the service selected by the manufacturing vendor, but these guidelines will greatly reduce theamount of up front engineering hours that are required to develop the final design. The guidelines are a training tool foryoung engineers or a resource for engineers with experience.

This document is entrusted to the recipient personally, but the copyright remains with us. It must not be copied,reproduced or in any way communicated or made accessible to third parties without our written consent.

Figure 2: Fixed Roof Tanks 2

KLM TechnologyGroup

Practical Engineering Guidelinesfor Processing Plant Solutions

STORAGE TANK SELECTION ANDSIZING

ENGINEERING DESIGN GUIDELINES

Page 11 of 87

Rev: 02

JUNE 2011

These design guideline are believed to be as accurate as possible, but are very general and not for specific design cases.They were designed for engineers to do preliminary designs and process specification sheets. The final design mustalways be guaranteed for the service selected by the manufacturing vendor, but these guidelines will greatly reduce theamount of up front engineering hours that are required to develop the final design. The guidelines are a training tool foryoung engineers or a resource for engineers with experience.

This document is entrusted to the recipient personally, but the copyright remains with us. It must not be copied,reproduced or in any way communicated or made accessible to third parties without our written consent.

2. External Floating Roof Tanks

A typical external floating roof tank consists of an open-topped cylindrical steel shellequipped with a roof that floats on the surface of the stored liquid, rising and fallingwith the liquid level. The floating roof is comprised of a deck, fittings, and rim sealsystem. Floating roof decks are constructed of welded steel plates and are of threegeneral types: pan, pontoon, and double deck.

Although numerous pan-type decks are currently in use, the present trend is towardpontoon and double-deck type floating roofs. The two most common types of externalfloating-roof tanks are shown in Figures 3 and 4.

Manufacturers supply various versions of these basic types of floating decks, whichare tailored to emphasize particular features, such as full liquid contact, load-carryingcapacity, roof stability, or pontoon arrangement. The liquid surface is covered by thefloating deck, except in the small annular space between the deck and the shell; thedeck may contact the liquid or float directly above the surface on pontoons.

External floating roof tanks are equipped with a rim seal system, which is attached tothe roof perimeter and contacts the tank wall. The rim seal system slides against thetank wall as the roof is raised and lowered. The floating deck is also equipped withfittings that penetrate the deck and serve operational functions. The external floatingroof design is such that evaporative losses from the stored liquid are limited to lossesfrom the rim seal system and deck fittings (standing storage loss) and any exposedliquid on the tank walls (withdrawal loss).

In external floating roof design. the roof is made to rest on the stored liquid and is freeto move with the level of the liquid. These tanks reduce evaporation losses and controlbreathing losses while filling. They are preferred for storage of petroleum productswith a true vapor pressure of 10.3 to 76.5 kPa absolute.

KLM TechnologyGroup

Practical Engineering Guidelinesfor Processing Plant Solutions

STORAGE TANK SELECTION ANDSIZING

ENGINEERING DESIGN GUIDELINES

Page 12 of 87

Rev: 02

JUNE 2011

These design guideline are believed to be as accurate as possible, but are very general and not for specific design cases.They were designed for engineers to do preliminary designs and process specification sheets. The final design mustalways be guaranteed for the service selected by the manufacturing vendor, but these guidelines will greatly reduce theamount of up front engineering hours that are required to develop the final design. The guidelines are a training tool foryoung engineers or a resource for engineers with experience.

This document is entrusted to the recipient personally, but the copyright remains with us. It must not be copied,reproduced or in any way communicated or made accessible to third parties without our written consent.

Figure 3: External Floating Roof Tanks 1

KLM TechnologyGroup

Practical Engineering Guidelinesfor Processing Plant Solutions

STORAGE TANK SELECTION ANDSIZING

ENGINEERING DESIGN GUIDELINES

Page 13 of 87

Rev: 02

JUNE 2011

These design guideline are believed to be as accurate as possible, but are very general and not for specific design cases.They were designed for engineers to do preliminary designs and process specification sheets. The final design mustalways be guaranteed for the service selected by the manufacturing vendor, but these guidelines will greatly reduce theamount of up front engineering hours that are required to develop the final design. The guidelines are a training tool foryoung engineers or a resource for engineers with experience.

This document is entrusted to the recipient personally, but the copyright remains with us. It must not be copied,reproduced or in any way communicated or made accessible to third parties without our written consent.

Figure 4: External Floating Roof Tanks 2

KLM TechnologyGroup

Practical Engineering Guidelinesfor Processing Plant Solutions

STORAGE TANK SELECTION ANDSIZING

ENGINEERING DESIGN GUIDELINES

Page 14 of 87

Rev: 02

JUNE 2011

These design guideline are believed to be as accurate as possible, but are very general and not for specific design cases.They were designed for engineers to do preliminary designs and process specification sheets. The final design mustalways be guaranteed for the service selected by the manufacturing vendor, but these guidelines will greatly reduce theamount of up front engineering hours that are required to develop the final design. The guidelines are a training tool foryoung engineers or a resource for engineers with experience.

This document is entrusted to the recipient personally, but the copyright remains with us. It must not be copied,reproduced or in any way communicated or made accessible to third parties without our written consent.

Figure 5: Typical List of Floating Roof Fittings

KLM TechnologyGroup

Practical Engineering Guidelinesfor Processing Plant Solutions

STORAGE TANK SELECTION ANDSIZING

ENGINEERING DESIGN GUIDELINES

Page 15 of 87

Rev: 02

JUNE 2011

These design guideline are believed to be as accurate as possible, but are very general and not for specific design cases.They were designed for engineers to do preliminary designs and process specification sheets. The final design mustalways be guaranteed for the service selected by the manufacturing vendor, but these guidelines will greatly reduce theamount of up front engineering hours that are required to develop the final design. The guidelines are a training tool foryoung engineers or a resource for engineers with experience.

This document is entrusted to the recipient personally, but the copyright remains with us. It must not be copied,reproduced or in any way communicated or made accessible to third parties without our written consent.

3. Internal Floating Roof Tanks

An internal floating roof tank has both a permanent fixed roof and a floating roofinside. There are two basic types of internal floating roof tanks: tanks in which thefixed roof is supported by vertical columns within the tank; and tanks with a self-supporting fixed roof and no internal support columns. The fixed roof is not necessarilyfree of openings but does span the entire open plan area of the vessel. Fixed rooftanks that have been retrofitted to employ an internal floating roof are typically of thefirst type, while external floating roof tanks that have been converted to an internalfloating roof tank typically have a self-supporting roof.

Tanks initially constructed with both a fixed roof and an internal floating roof may be ofeither type. An internal floating roof tank has both a permanently affixed roof and aroof that floats inside the tank on the liquid surface (contact deck) or is supported onpontoons several inches above the liquid surface (noncontact deck). The internalfloating roof rises and falls with the liquid level. A typical internal floating roof tank isshown in figure below

Contact-type decks include (1) aluminum sandwich panels with a honeycombedaluminum core floating in contact with the liquid; (2) resin-coated, fiberglass-reinforcedpolyester (FRP), buoyant panels floating in contact with the liquid; and (3) pan-typesteel roofs, floating in contact with the liquid with or without the aid of pontoons. Themajority of contact internal floating decks currently in VOL service are pan-type steelor aluminum sandwich panel type. The FRP decks are less common.

Several variations of the pan-type contact steel roof exist. The design may includebulkheads or open compartments around the perimeter of the deck so that any liquidthat may leak or spill onto the deck is contained. Alternatively, the bulkheads may becovered to form sealed compartments (i.e., pontoons), or the entire pan may becovered to form a sealed, double deck, steel floating roof. Generally, construction is ofwelded steel.

Noncontact-type decks are the most common type of deck currently in use, andtypically consist of an aluminum deck laid on an aluminum grid framework supportedabove the liquid surface by tubular aluminum pontoons. The deck skin for thenoncontact-type floating decks is typically constructed of rolled aluminum sheets(about 1.5 meters [m] [4.9 feet (ft)] wide and 0.58 millimeter [mm] [0.023 inches (in)]thick). The overlapping aluminum sheets are joined by bolted aluminum clamping barsthat run perpendicular to the pontoons to improve the rigidity of the frame.

KLM TechnologyGroup

Practical Engineering Guidelinesfor Processing Plant Solutions

STORAGE TANK SELECTION ANDSIZING

ENGINEERING DESIGN GUIDELINES

Page 16 of 87

Rev: 02

JUNE 2011

These design guideline are believed to be as accurate as possible, but are very general and not for specific design cases.They were designed for engineers to do preliminary designs and process specification sheets. The final design mustalways be guaranteed for the service selected by the manufacturing vendor, but these guidelines will greatly reduce theamount of up front engineering hours that are required to develop the final design. The guidelines are a training tool foryoung engineers or a resource for engineers with experience.

This document is entrusted to the recipient personally, but the copyright remains with us. It must not be copied,reproduced or in any way communicated or made accessible to third parties without our written consent.

The deck skin seams can be metal on metal or gasketed with a polymeric material.The pontoons and clamping bars form the structural frame of the floating deck. Deckseams in the noncontact internal floating roof design are a source of emissions.Aluminum sandwich panel contact-type internal floating roofs also share this designfeature. The sandwich panels are joined with bolted mechanical fasteners that aresimilar in concept to the noncontact deck skin clamping bars. Steel pan contactinternal floating roofs are constructed of welded steel sheets and therefore have nodeck seams. Similarly, the resin-coated, reinforced fiberglass panel decks have noapparent deck seams. The panels are butted and lapped with resin-impregnatedfiberglass fabric strips.

The internal floating roof physically occupies a finite volume of space that reduces themaximum liquid storage capacity of the tank. When the tank is completely full, thefloating roof touches or nearly touches the fixed roof. Consequently, the effectiveheight of the tank decreases, thus limiting the storage capacity. The reduction in theeffective height varies from about 0.15 to 0.6 m (0.5 to 2 ft), depending on the typeand design of the floating roof employed.

All types of internal floating roofs, like external floating roofs, commonly incorporaterim seals that slide against the tank wall as the roof moves up and down. Circulationvents and an open vent at the top of the fixed roof are generally provided to minimizethe accumulation of hydrocarbon vapors in concentrations approaching the flammablerange. Flame arresters are an option that can be used to protect the vessel from fire orexplosion. When these are used, circulation vents are not provided. Tank ventingoccurs through a pressure-vacuum vent and flame arrestor.

The design features of internal floating roof can be summary as follow

1. A truly vapor tight metal to metal clamp beam develops the full strength of thedeck skin itself

2. A patented pivot joint eliminates stress at pontoon ends by allowing flexurewhere it is needed

3. Pontoon saddles support the clamp beams on the pontoon and distribute theconcentrated load to assure against localized buckling

4. Bolted connections are corrosion resistant 300 series stainless steel fixings

5. Reduces emissions from fixed roof tanks by up to 97% & meets VOC controland Environmental Protection Standards

KLM TechnologyGroup

Practical Engineering Guidelinesfor Processing Plant Solutions

STORAGE TANK SELECTION ANDSIZING

ENGINEERING DESIGN GUIDELINES

Page 17 of 87

Rev: 02

JUNE 2011

These design guideline are believed to be as accurate as possible, but are very general and not for specific design cases.They were designed for engineers to do preliminary designs and process specification sheets. The final design mustalways be guaranteed for the service selected by the manufacturing vendor, but these guidelines will greatly reduce theamount of up front engineering hours that are required to develop the final design. The guidelines are a training tool foryoung engineers or a resource for engineers with experience.

This document is entrusted to the recipient personally, but the copyright remains with us. It must not be copied,reproduced or in any way communicated or made accessible to third parties without our written consent.

Figure 6: Internal Floating Roof

KLM TechnologyGroup

Practical Engineering Guidelinesfor Processing Plant Solutions

STORAGE TANK SELECTION ANDSIZING

ENGINEERING DESIGN GUIDELINES

Page 18 of 87

Rev: 02

JUNE 2011

These design guideline are believed to be as accurate as possible, but are very general and not for specific design cases.They were designed for engineers to do preliminary designs and process specification sheets. The final design mustalways be guaranteed for the service selected by the manufacturing vendor, but these guidelines will greatly reduce theamount of up front engineering hours that are required to develop the final design. The guidelines are a training tool foryoung engineers or a resource for engineers with experience.

This document is entrusted to the recipient personally, but the copyright remains with us. It must not be copied,reproduced or in any way communicated or made accessible to third parties without our written consent.

4. Domed External Floating Roof Tanks

Domed external floating roof tanks have the heavier type of deck used in externalfloating roof tanks as well as a fixed roof at the top of the shell like internal floating rooftanks. Domed external floating roof tanks usually result from retrofitting an externalfloating roof tank with a fixed roof. A typical domed external floating roof tank isshown in Figure 7.

As with the internal floating roof tanks, the function of the fixed roof is not to act as avapor barrier, but to block the wind. The type of fixed roof most commonly used is aself supporting aluminum dome roof, which is of bolted construction. Like the internalfloating roof tanks, these tanks are freely vented by circulation vents at the top of thefixed roof. The deck fittings and rim seals, however, are basically identical to those onexternal floating roof tanks.

Aluminum dome roof have some advance features :

1. The Clear Span design eliminates the need for interior support structures whilehigh strength aluminum alloys and corrosion resistant materials provide for a longservice life.

2. Properly designed tension rings ensure that the lateral force generated by thedome is not translated to the tank shell, eliminating the need for additional tankshell reinforcement or modifications.

3. Beams are designed with an extruded continuous threaded bolting slot. Thisbolting slot provides more thread engagement area and more pull resistance thanin conventional designs.

4. The overlapping panels naturally shed water and are secured in place with apatented Batten Bar and hidden gasket system. This deign allows the roof panelsto flex while keeping sheets from puckering and bolts from leaking.

5. Aluminum Dome reduces wind induced vapor losses, aids in odor abatement andprovides significant emission credits.

6. Floating roof and seal maintenance are drastically reduced due to the lack ofrainwater and UV exposure.

KLM TechnologyGroup

Practical Engineering Guidelinesfor Processing Plant Solutions

STORAGE TANK SELECTION ANDSIZING

ENGINEERING DESIGN GUIDELINES

Page 19 of 87

Rev: 02

JUNE 2011

These design guideline are believed to be as accurate as possible, but are very general and not for specific design cases.They were designed for engineers to do preliminary designs and process specification sheets. The final design mustalways be guaranteed for the service selected by the manufacturing vendor, but these guidelines will greatly reduce theamount of up front engineering hours that are required to develop the final design. The guidelines are a training tool foryoung engineers or a resource for engineers with experience.

This document is entrusted to the recipient personally, but the copyright remains with us. It must not be copied,reproduced or in any way communicated or made accessible to third parties without our written consent.

Figure 7: Dome External Floating Roof

KLM TechnologyGroup

Practical Engineering Guidelinesfor Processing Plant Solutions

STORAGE TANK SELECTION ANDSIZING

ENGINEERING DESIGN GUIDELINES

Page 20 of 87

Rev: 02

JUNE 2011

These design guideline are believed to be as accurate as possible, but are very general and not for specific design cases.They were designed for engineers to do preliminary designs and process specification sheets. The final design mustalways be guaranteed for the service selected by the manufacturing vendor, but these guidelines will greatly reduce theamount of up front engineering hours that are required to develop the final design. The guidelines are a training tool foryoung engineers or a resource for engineers with experience.

This document is entrusted to the recipient personally, but the copyright remains with us. It must not be copied,reproduced or in any way communicated or made accessible to third parties without our written consent.

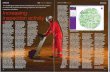

5. Horizontal Tanks

Horizontal tanks are constructed for both above-ground and underground service.Figures 8 present schematics of typical underground and above-ground horizontaltanks. Horizontal tanks are usually constructed of steel, steel with a fiberglassoverlay, or fiberglass-reinforced polyester. Horizontal tanks are generally smallstorage tanks with capacities of less than 75,710 L (20,000 gallons).

Horizontal tanks are constructed such that the length of the tank is not greater than sixtimes the diameter to ensure structural integrity. Horizontal tanks are usually equippedwith pressure-vacuum vents, gauge hatches and sample wells, and manholes

to provide accessibility to these tanks. In addition, underground tanks may becathodically protected to prevent corrosion of the tank shell. Cathodic protection isaccomplished by placing sacrificial anodes in the tank that are connected to animpressed current system or by using galvanic anodes in the tank. However, internalcathodic protection is no longer widely used in the petroleum industry, due tocorrosion inhibitors that are now found in most refined petroleum products.

The potential emission sources for above-ground horizontal tanks are the same asthose for fixed-roof tanks. Emissions from underground storage tanks are mainlyassociated with changes in the liquid level in the tank. Losses due to changes intemperature or barometric pressure are minimal for underground tanks because thesurrounding earth limits the diurnal temperature change and changes in thebarometric pressure would result in only small losses.

KLM TechnologyGroup

Practical Engineering Guidelinesfor Processing Plant Solutions

STORAGE TANK SELECTION ANDSIZING

ENGINEERING DESIGN GUIDELINES

Page 21 of 87

Rev: 02

JUNE 2011

These design guideline are believed to be as accurate as possible, but are very general and not for specific design cases.They were designed for engineers to do preliminary designs and process specification sheets. The final design mustalways be guaranteed for the service selected by the manufacturing vendor, but these guidelines will greatly reduce theamount of up front engineering hours that are required to develop the final design. The guidelines are a training tool foryoung engineers or a resource for engineers with experience.

This document is entrusted to the recipient personally, but the copyright remains with us. It must not be copied,reproduced or in any way communicated or made accessible to third parties without our written consent.

(a)

(b)

Figure 8: schematics of typical above-ground horizontal (a) and underground tanks (b)

Product dischargeProduct delivery line

Fit pipeVent line

Float vent valve in ventline for over protection

Dielectric bushing providingelectrical insulation betweentank and all connecting lines

Cathodic monitoring system

Access manway

Striker plate below fill pipe

Submergedproduct deliverypump

Sacrificial anodes

Cathodically-processed epoxycoasted steel

Compacted bed of sand or gravel

KLM TechnologyGroup

Practical Engineering Guidelinesfor Processing Plant Solutions

STORAGE TANK SELECTION ANDSIZING

ENGINEERING DESIGN GUIDELINES

Page 22 of 87

Rev: 02

JUNE 2011

These design guideline are believed to be as accurate as possible, but are very general and not for specific design cases.They were designed for engineers to do preliminary designs and process specification sheets. The final design mustalways be guaranteed for the service selected by the manufacturing vendor, but these guidelines will greatly reduce theamount of up front engineering hours that are required to develop the final design. The guidelines are a training tool foryoung engineers or a resource for engineers with experience.

This document is entrusted to the recipient personally, but the copyright remains with us. It must not be copied,reproduced or in any way communicated or made accessible to third parties without our written consent.

6. Pressure Tanks

Two classes of pressure tanks are in general use: low pressure (2.5 to 15 psig) andhigh pressure (higher than 15 psig). Pressure tanks generally are used for storingorganic liquids and gases with high vapor pressures and are found in many sizes andshapes, depending on the operating pressure of the tank. Pressure tanks areequipped with a pressure/vacuum vent that is set to prevent venting loss from boilingand breathing loss from daily temperature or barometric pressure changes.

The pressure tank allows the pump to run occasionally instead of every time a faucetis opened. The basic system is often enhanced, either by necessity or for improvedperformance, with a constant pressure delivery system.

Figure 9: Scheme of Pressure Tank

KLM TechnologyGroup

Practical Engineering Guidelinesfor Processing Plant Solutions

STORAGE TANK SELECTION ANDSIZING

ENGINEERING DESIGN GUIDELINES

Page 23 of 87

Rev: 02

JUNE 2011

These design guideline are believed to be as accurate as possible, but are very general and not for specific design cases.They were designed for engineers to do preliminary designs and process specification sheets. The final design mustalways be guaranteed for the service selected by the manufacturing vendor, but these guidelines will greatly reduce theamount of up front engineering hours that are required to develop the final design. The guidelines are a training tool foryoung engineers or a resource for engineers with experience.

This document is entrusted to the recipient personally, but the copyright remains with us. It must not be copied,reproduced or in any way communicated or made accessible to third parties without our written consent.

7. Variable Vapor Space Tanks

Variable vapor space tanks are equipped with expandable vapor reservoirs toaccommodate vapor volume fluctuations attributable to temperature and barometricpressure changes. Although variable vapor space tanks are sometimes usedindependently, they are normally connected to the vapor spaces of one or more fixedroof tanks. The two most common types of variable vapor space tanks are lifter rooftanks and flexible diaphragm tanks. Lifter roof tanks have a telescoping roof that fitsloosely around the outside of the main tank wall. The space between the roof and thewall is closed by either a wet seal, which is a trough filled with liquid, or a dry seal,which uses a flexible coated fabric.

Flexible diaphragm tanks use flexible membranes to provide expandable volume.They may be either separate gasholder units or integral units mounted atop fixed rooftanks. Variable vapor space tank losses occur during tank filling when vapor isdisplaced by liquid. Loss of vapor occurs only when the tank's vapor storage capacityis exceeded.

KLM TechnologyGroup

Practical Engineering Guidelinesfor Processing Plant Solutions

STORAGE TANK SELECTION ANDSIZING

ENGINEERING DESIGN GUIDELINES

Page 24 of 87

Rev: 02

JUNE 2011

These design guideline are believed to be as accurate as possible, but are very general and not for specific design cases.They were designed for engineers to do preliminary designs and process specification sheets. The final design mustalways be guaranteed for the service selected by the manufacturing vendor, but these guidelines will greatly reduce theamount of up front engineering hours that are required to develop the final design. The guidelines are a training tool foryoung engineers or a resource for engineers with experience.

This document is entrusted to the recipient personally, but the copyright remains with us. It must not be copied,reproduced or in any way communicated or made accessible to third parties without our written consent.

Figure 10: Variable Vapor Space Tanks

KLM TechnologyGroup

Practical Engineering Guidelinesfor Processing Plant Solutions

STORAGE TANK SELECTION ANDSIZING

ENGINEERING DESIGN GUIDELINES

Page 25 of 87

Rev: 02

JUNE 2011

These design guideline are believed to be as accurate as possible, but are very general and not for specific design cases.They were designed for engineers to do preliminary designs and process specification sheets. The final design mustalways be guaranteed for the service selected by the manufacturing vendor, but these guidelines will greatly reduce theamount of up front engineering hours that are required to develop the final design. The guidelines are a training tool foryoung engineers or a resource for engineers with experience.

This document is entrusted to the recipient personally, but the copyright remains with us. It must not be copied,reproduced or in any way communicated or made accessible to third parties without our written consent.

Types of Floating Roof Perimeter Seals

External and Domed External Floating Roof Rim Seals

Regardless of tank design, a floating roof requires a device to seal the gap betweenthe tank wall and the deck perimeter. A rim seal, or in the case of a two-seal system,the lower (primary) rim seal, can be made from various materials suitable for organicliquid service. The basic designs available for external floating roof rim seals are

(1) mechanical (metallic) shoe seals,

(2) liquid-filled seals, and

(3) (vapor or liquid mounted) resilient foam-filled seals.

Figures below depict these three general types of seals.

One major difference in seal system design is the way in which the seal is mountedwith respect to the liquid surface. Figure below shows a vapor space between theliquid surface and rim seal, whereas in second Figure, the seals rest on the liquidsurface. These liquid-filled and resilient foam-filled seals are classified as liquid- orvapor-mounted rim seals, depending on their location.

Mechanical shoe rim seals are different in design from liquid-filled or resilient foam-filled rim seals and cannot be characterized as liquid- or vapor-mounted. However,because the shoe and envelope combination precludes contact between the annularvapor space above the liquid and the atmosphere (see below), the emission rate of amechanical shoe seal is closer to that of a liquid-mounted rim seal than that of avapor-mounted rim seal.

KLM TechnologyGroup

Practical Engineering Guidelinesfor Processing Plant Solutions

STORAGE TANK SELECTION ANDSIZING

ENGINEERING DESIGN GUIDELINES

Page 26 of 87

Rev: 02

JUNE 2011

These design guideline are believed to be as accurate as possible, but are very general and not for specific design cases.They were designed for engineers to do preliminary designs and process specification sheets. The final design mustalways be guaranteed for the service selected by the manufacturing vendor, but these guidelines will greatly reduce theamount of up front engineering hours that are required to develop the final design. The guidelines are a training tool foryoung engineers or a resource for engineers with experience.

This document is entrusted to the recipient personally, but the copyright remains with us. It must not be copied,reproduced or in any way communicated or made accessible to third parties without our written consent.

Figure `11: Vapor mounted primary seals

KLM TechnologyGroup

Practical Engineering Guidelinesfor Processing Plant Solutions

STORAGE TANK SELECTION ANDSIZING

ENGINEERING DESIGN GUIDELINES

Page 27 of 87

Rev: 02

JUNE 2011

These design guideline are believed to be as accurate as possible, but are very general and not for specific design cases.They were designed for engineers to do preliminary designs and process specification sheets. The final design mustalways be guaranteed for the service selected by the manufacturing vendor, but these guidelines will greatly reduce theamount of up front engineering hours that are required to develop the final design. The guidelines are a training tool foryoung engineers or a resource for engineers with experience.

This document is entrusted to the recipient personally, but the copyright remains with us. It must not be copied,reproduced or in any way communicated or made accessible to third parties without our written consent.

Figure 12: Liquid-mounted and mechanical shoe primary seals

Mechanical Shoe Seal.

A mechanical shoe seal, also known as a "metallic shoe seal" (Figure above), ischaracterized by a metallic sheet (the "shoe") that is held against the vertical tank wall.Previously the regulations did not specify a height for mechanical shoe seals;however, shoe heights typically range from 75 to 130 centimeters (cm) (30 to 51 in.).

KLM TechnologyGroup

Practical Engineering Guidelinesfor Processing Plant Solutions

STORAGE TANK SELECTION ANDSIZING

ENGINEERING DESIGN GUIDELINES

Page 28 of 87

Rev: 02

JUNE 2011

These design guideline are believed to be as accurate as possible, but are very general and not for specific design cases.They were designed for engineers to do preliminary designs and process specification sheets. The final design mustalways be guaranteed for the service selected by the manufacturing vendor, but these guidelines will greatly reduce theamount of up front engineering hours that are required to develop the final design. The guidelines are a training tool foryoung engineers or a resource for engineers with experience.

This document is entrusted to the recipient personally, but the copyright remains with us. It must not be copied,reproduced or in any way communicated or made accessible to third parties without our written consent.

The shoe is connected by braces to the floating deck and is held tightly against thewall by springs or weighted levers. A flexible coated fabric (the "envelope") issuspended from the shoe seal to the floating deck to form a vapor barrier over theannular space between the deck and the primary seal.

Liquid-Filled Seal

A liquid-filled rim seal (Figure above) may consist of a tough fabric band or envelopefilled with a liquid, or it may consist of a flexible polymeric tube 20 to 25 cm (8 to 10in.) in diameter filled with a liquid and sheathed with a tough fabric scuff band. Theliquid is commonly a petroleum distillate or other liquid that will not contaminate thestored product if the tube ruptures. Liquid-filled rim seals are mounted on the liquidproduct surface with no vapor space below the seal.

Resilient Foam-Filled Seal

A resilient foam-filled rim seal is similar to a liquid-filled seal except that a resilientfoam log is used in place of the liquid. The resiliency of the foam log permits the sealto adapt itself to minor imperfections in tank dimensions and in the tank shell. Thefoam log may be mounted above the liquid surface (vapor-mounted) or on the liquidsurface (liquid-mounted). Typical vapor-mounted and liquid-mounted seals arepresented in the Figures above respectively.

Secondary Seals on External Floating Roofs

A secondary seal on an external floating roof consists of a continuous seal mountedon the rim of the floating roof and extending to the tank wall, covering the entireprimary seal. Secondary seals are normally constructed of flexible polymericmaterials. Figure below depicts several primary and secondary seal systems. Analternative secondary seal design incorporates a steel leaf to bridge the gap betweenthe roof and the tank wall. The leaf acts as a compression plate to hold a polymericwiper against the tank wall.

A rim-mounted secondary seal installed over a primary seal provides a barrier forvolatile organic compound (VOC) emissions that escape from the small vapor spacebetween the primary seal and the wall and through any openings or tears in the sealenvelope of a metallic shoe seal (Figure below). Although not shown in Figure below,a secondary seal can be used in conjunction with a weather shield as described in thefollowing section.

KLM TechnologyGroup

Practical Engineering Guidelinesfor Processing Plant Solutions

STORAGE TANK SELECTION ANDSIZING

ENGINEERING DESIGN GUIDELINES

Page 29 of 87

Rev: 02

JUNE 2011

These design guideline are believed to be as accurate as possible, but are very general and not for specific design cases.They were designed for engineers to do preliminary designs and process specification sheets. The final design mustalways be guaranteed for the service selected by the manufacturing vendor, but these guidelines will greatly reduce theamount of up front engineering hours that are required to develop the final design. The guidelines are a training tool foryoung engineers or a resource for engineers with experience.

This document is entrusted to the recipient personally, but the copyright remains with us. It must not be copied,reproduced or in any way communicated or made accessible to third parties without our written consent.

Another type of secondary seal is a shoe-mounted secondary seal. A shoe-mountedseal extends from the top of the shoe to the tank wall (Figure below). These seals donot provide protection against VOC leakage through the envelope. Holes, gaps, tears,or other defects in the envelope can permit direct exchange between the saturatedvapor under the envelope and the atmosphere. Wind can enter this space throughenvelope defects, flow around the circumference of the tank, and exit saturated ornearly saturated with VOC vapors.

Figure 13: Secondary rim seals

KLM TechnologyGroup

Practical Engineering Guidelinesfor Processing Plant Solutions

STORAGE TANK SELECTION ANDSIZING

ENGINEERING DESIGN GUIDELINES

Page 30 of 87

Rev: 02

JUNE 2011

These design guideline are believed to be as accurate as possible, but are very general and not for specific design cases.They were designed for engineers to do preliminary designs and process specification sheets. The final design mustalways be guaranteed for the service selected by the manufacturing vendor, but these guidelines will greatly reduce theamount of up front engineering hours that are required to develop the final design. The guidelines are a training tool foryoung engineers or a resource for engineers with experience.

This document is entrusted to the recipient personally, but the copyright remains with us. It must not be copied,reproduced or in any way communicated or made accessible to third parties without our written consent.

Weather Shield

A weather shield may be installed over the primary seal to protect it from deteriorationcaused by debris and exposure to the elements. Though the USA EPA does notaccept the installation of a weather shield as equivalent to a secondary seal, there area large number of existing tanks not affected by high VOC’s that have thisconfiguration. Typically, a weather shield is an arrangement of overlapping thin metalsheets pivoted from the floating roof to ride against the tank wall. The weather shield,by the nature of its design, is not an effective vapor barrier. For this reason, it differsfrom the secondary seal. Although the two devices are conceptually similar in design,they are designed for and serve different purposes.

Internal Floating Roof Rim Seals

Internal floating roofs typically incorporate one of two types of flexible, product-resistant rim seals: resilient foam-filled seals or wiper seals. Similar to those employedon external floating roofs, each of these seals closes the annular vapor spacebetween the edge of the floating deck and the tank shell to reduce evaporative losses.They are designed to compensate for small irregularities in the tank shell and allowthe roof to freely move up and down in the tank without binding.

Resilient Foam-Filled Seal

A resilient foam-filled seal used on an internal floating roof is similar in design to thatdescribed for external floating roofs. Resilient foam-filled seals are shown in Figuresabove. These seals can be mounted either in contact with the liquid surface (liquid-mounted) or several centimeters above the liquid surface (vapor-mounted).

Resilient foam-filled seals work because of the expansion and contraction of a resilientmaterial to maintain contact with the tank shell while accommodating varying annularrim space widths. These seals consist of a core of open-cell foam encapsulated in acoated fabric. The elasticity of the foam core pushes the fabric into contact with thetank shell. The seals are attached to a mounting on the deck perimeter and arecontinuous around the roof circumference.

Polyurethane-coated nylon fabric and polyurethane foam are commonly usedmaterials. For emission control, it is important that the mounting and radial seal jointsbe vapor-tight and that the seal be in substantial contact with the tank shell.

KLM TechnologyGroup

Practical Engineering Guidelinesfor Processing Plant Solutions

STORAGE TANK SELECTION ANDSIZING

ENGINEERING DESIGN GUIDELINES

Page 31 of 87

Rev: 02

JUNE 2011

These design guideline are believed to be as accurate as possible, but are very general and not for specific design cases.They were designed for engineers to do preliminary designs and process specification sheets. The final design mustalways be guaranteed for the service selected by the manufacturing vendor, but these guidelines will greatly reduce theamount of up front engineering hours that are required to develop the final design. The guidelines are a training tool foryoung engineers or a resource for engineers with experience.

This document is entrusted to the recipient personally, but the copyright remains with us. It must not be copied,reproduced or in any way communicated or made accessible to third parties without our written consent.

Wiper Seals

Wiper seals are commonly used as primary rim seals for internal floating roof tanks.This type of seal is depicted in Figures above. Wiper seals generally consist of acontinuous annular blade of flexible material fastened to a mounting bracket on thedeck perimeter that spans the annular rim space and contacts the tank shell. Themounting is such that the blade is flexed, and its elasticity provides a sealing pressureagainst the tank shell. Such seals are vapor-mounted; a vapor space exists betweenthe liquid stock and the bottom of the seal. For emission control, it is important thatthe mounting be vapor-tight, that the seal extend around the circumference of the roof,and that the blade be in substantial contact with the tank shell.

Three types of materials are commonly used to make the wipers. One type consists ofa cellular, elastomeric material tapered in cross section with the thicker portion at themounting. Rubber is a commonly used material. All radial joints in the blade arejoined. A second type of wiper seal construction uses a foam core wrapped with acoated fabric. Polyurethane on nylon fabric and polyurethane foam are commonmaterials. The core provides the flexibility and support, while the fabric provides thevapor barrier and wear surface. A third type of wiper seal consists of overlappingsegments of seal material (shingle-type seal). Shingle-type seals differ from the wiperseals discussed previously in that they do not provide a continuous vapor barrier.

Secondary Seals for Internal Floating Roof Tanks

Secondary seals may be used to provide some additional evaporative loss controlover that achieved by the primary seal. The secondary seal is mounted to an extendedvertical rim plate, above the primary seal, as shown in Figure above. Secondary sealscan be either a resilient foam-filled seal or an elastomeric wiper seal.

For a given roof design, using a secondary seal further limits the operating capacity ofa tank due to the need to maintain contact with the tank shell or keep the seal frominterfering with IFRT fixed-roof rafters when the tank is filled. Secondary seals are notcommonly used on internal floating roof tanks that are not affected by the EPAregulations.

KLM TechnologyGroup

Practical Engineering Guidelinesfor Processing Plant Solutions

STORAGE TANK SELECTION ANDSIZING

ENGINEERING DESIGN GUIDELINES

Page 32 of 87

Rev: 02

JUNE 2011

These design guideline are believed to be as accurate as possible, but are very general and not for specific design cases.They were designed for engineers to do preliminary designs and process specification sheets. The final design mustalways be guaranteed for the service selected by the manufacturing vendor, but these guidelines will greatly reduce theamount of up front engineering hours that are required to develop the final design. The guidelines are a training tool foryoung engineers or a resource for engineers with experience.

This document is entrusted to the recipient personally, but the copyright remains with us. It must not be copied,reproduced or in any way communicated or made accessible to third parties without our written consent.

TYPES OF FLOATING ROOF DECK FITTINGS

External and Domed External Floating Roof Deck Fittings

Numerous fittings penetrate or are attached to an external floating roof deck. Thesefittings accommodate structural support components or allow for operational functions.These fittings can be a source of emissions in that they must penetrate the deck.Other accessories are used that do not penetrate the deck and are not, therefore,sources of evaporative loss. The most common fittings relevant to controlling vaporlosses are described in the following sections.

Access Hatches.

An access hatch consists of an opening in the deck with a peripheral vertical wellattached to the deck and a removable cover to close the opening as shown in Figurebelow. An access hatch is typically sized to allow workers and materials to passthrough the deck for construction or servicing. The cover can rest directly on the well,or a gasketed connection can be used to reduce evaporative loss. Bolting the cover tothe well reduces losses further.

Figure 14: Access Hatch

KLM TechnologyGroup

Practical Engineering Guidelinesfor Processing Plant Solutions

STORAGE TANK SELECTION ANDSIZING

ENGINEERING DESIGN GUIDELINES

Page 33 of 87

Rev: 02

JUNE 2011

These design guideline are believed to be as accurate as possible, but are very general and not for specific design cases.They were designed for engineers to do preliminary designs and process specification sheets. The final design mustalways be guaranteed for the service selected by the manufacturing vendor, but these guidelines will greatly reduce theamount of up front engineering hours that are required to develop the final design. The guidelines are a training tool foryoung engineers or a resource for engineers with experience.

This document is entrusted to the recipient personally, but the copyright remains with us. It must not be copied,reproduced or in any way communicated or made accessible to third parties without our written consent.

Gauge Float Wells

Gauge floats are used to indicate the level of stock within the tank. These usuallyconsist of a float residing within a well that passes through the floating deck, as shownin Figure below. The float is connected to an indicator on the exterior of the tank via atape passing through a guide system. The float rests on the stock surface within thewell, which is enclosed by a sliding cover. Evaporation loss can be reduced bygasketing and/or bolting the connection between the cover and the rim of the well. Thecable passes through a bushing located at the center of the cover. As with similardeck penetrations, the well extends into the liquid stock on noncontact floating decks.

Figure 15: Gauge float

Gauge Hatch/Sample Ports

Gauge hatch/sample ports provide access for hand gauging the level of stock in thetank and for taking samples of the tank contents. A gauge hatch / sample port consists

KLM TechnologyGroup

Practical Engineering Guidelinesfor Processing Plant Solutions

STORAGE TANK SELECTION ANDSIZING

ENGINEERING DESIGN GUIDELINES

Page 34 of 87

Rev: 02

JUNE 2011

These design guideline are believed to be as accurate as possible, but are very general and not for specific design cases.They were designed for engineers to do preliminary designs and process specification sheets. The final design mustalways be guaranteed for the service selected by the manufacturing vendor, but these guidelines will greatly reduce theamount of up front engineering hours that are required to develop the final design. The guidelines are a training tool foryoung engineers or a resource for engineers with experience.

This document is entrusted to the recipient personally, but the copyright remains with us. It must not be copied,reproduced or in any way communicated or made accessible to third parties without our written consent.

of a pipe sleeve through the deck and a self-closing gasketed cover, as shown inFigure below. Gauge hatch/sample ports are usually located under the gauger’splatform, which is mounted on the top of the tank shell. The cover may have a cordattached so that it can be opened from the gauger’s platform. A gasketed coverreduces evaporative losses.

Figure 16: Sample ports

Rim Vents

Rim vents are found on tanks equipped with a rim seal system that creates a vaporpocket, such as a mechanical shoe seal or double wiper seal system. The rim vent isconnected to the rim vapor space by a pipe and releases any excess pressure orvacuum that is present (Figure below). The rim vapor space is bounded by the floatingdeck rim, the primary-seal shoe, the liquid surface, and the primary-seal fabric. Rimvents usually consist of weighted pallets that rest on the gasketed surface.

KLM TechnologyGroup

Practical Engineering Guidelinesfor Processing Plant Solutions

STORAGE TANK SELECTION ANDSIZING

ENGINEERING DESIGN GUIDELINES

Page 35 of 87

Rev: 02

JUNE 2011

These design guideline are believed to be as accurate as possible, but are very general and not for specific design cases.They were designed for engineers to do preliminary designs and process specification sheets. The final design mustalways be guaranteed for the service selected by the manufacturing vendor, but these guidelines will greatly reduce theamount of up front engineering hours that are required to develop the final design. The guidelines are a training tool foryoung engineers or a resource for engineers with experience.

This document is entrusted to the recipient personally, but the copyright remains with us. It must not be copied,reproduced or in any way communicated or made accessible to third parties without our written consent.

Figure 17: Rim vent

Deck Drains

Deck drains permit removal of rainwater from the surface of floating decks. Two typesof floating roof drainage systems are currently used: closed and open. Closeddrainage systems carry rainwater from the surface of the deck to the outside of thetank through a flexible or articulated piping system or through a flexible hose systemlocated below the deck in the product space. Since product does not enter this closeddrainage system, there is no associated evaporative loss. Open drainage systems,consisting of an open pipe that extends a short distance below the bottom of the deck,permit rainwater to drain from the surface of the deck into the product. Since thesedrainpipes are filled with product to the product level in the tank, evaporative lossoccurs from the top of the open drainpipes. Two types of roof drains are commonlyused in open drainage systems: flush drains and overflow drains. Flush drains (Figure

KLM TechnologyGroup

Practical Engineering Guidelinesfor Processing Plant Solutions

STORAGE TANK SELECTION ANDSIZING

ENGINEERING DESIGN GUIDELINES

Page 36 of 87

Rev: 02

JUNE 2011

These design guideline are believed to be as accurate as possible, but are very general and not for specific design cases.They were designed for engineers to do preliminary designs and process specification sheets. The final design mustalways be guaranteed for the service selected by the manufacturing vendor, but these guidelines will greatly reduce theamount of up front engineering hours that are required to develop the final design. The guidelines are a training tool foryoung engineers or a resource for engineers with experience.

This document is entrusted to the recipient personally, but the copyright remains with us. It must not be copied,reproduced or in any way communicated or made accessible to third parties without our written consent.

below) have a drain opening that is flush with the top surface of the double deck. Theypermit rainwater to drain into the product.

Overflow drains (Figure below) consist of a drain opening that is elevated above thetop surface of the deck, thereby limiting the maximum amount of rainwater that canaccumulate on the deck and providing emergency drainage of rainwater. They arenormally used in conjunction with a closed drainage system. Some open deck drainsare equipped with an insert to reduce the evaporative loss.

Figure 18: Deck drains

Deck Legs

Deck legs prevent damage to fittings underneath the deck and allow for tank cleaningor repair by holding the deck at a predetermined distance from the tank bottom. Thesesupports consist of adjustable or fixed legs attached to the floating deck as shown in

KLM TechnologyGroup

Practical Engineering Guidelinesfor Processing Plant Solutions

STORAGE TANK SELECTION ANDSIZING

ENGINEERING DESIGN GUIDELINES

Page 37 of 87

Rev: 02

JUNE 2011

These design guideline are believed to be as accurate as possible, but are very general and not for specific design cases.They were designed for engineers to do preliminary designs and process specification sheets. The final design mustalways be guaranteed for the service selected by the manufacturing vendor, but these guidelines will greatly reduce theamount of up front engineering hours that are required to develop the final design. The guidelines are a training tool foryoung engineers or a resource for engineers with experience.

This document is entrusted to the recipient personally, but the copyright remains with us. It must not be copied,reproduced or in any way communicated or made accessible to third parties without our written consent.

Figure below. For adjustable deck legs, the load-carrying element passes through awell or sleeve in the deck.

Figure 19: Deck leg

Slotted and Unslotted Guide Poles and Wells

Anti-rotation devices are used to prevent floating roofs from rotating and potentiallydamaging roof equipment and rim seal systems. A commonly used antirotation deviceis a guide pole that is fixed at the top and bottom of the tank (Figure below). The guidepole passes through a well in the deck. Rollers attached to the top of the well ride onthe outside surface of the guide pole to prevent the floating roof from rotating.

KLM TechnologyGroup

Practical Engineering Guidelinesfor Processing Plant Solutions

STORAGE TANK SELECTION ANDSIZING

ENGINEERING DESIGN GUIDELINES

Page 38 of 87

Rev: 02

JUNE 2011

These design guideline are believed to be as accurate as possible, but are very general and not for specific design cases.They were designed for engineers to do preliminary designs and process specification sheets. The final design mustalways be guaranteed for the service selected by the manufacturing vendor, but these guidelines will greatly reduce theamount of up front engineering hours that are required to develop the final design. The guidelines are a training tool foryoung engineers or a resource for engineers with experience.

This document is entrusted to the recipient personally, but the copyright remains with us. It must not be copied,reproduced or in any way communicated or made accessible to third parties without our written consent.

The guide pole well has a sliding cover to accommodate limited radial movement ofthe roof. The sliding cover can be equipped with a gasket between the guide pole andthe cover to reduce evaporative loss. The guide pole well can also be equipped with agasket between the sliding cover and the top of the well to reduce evaporative loss.Openings at the top and bottom of the guide pole provide a means of hand-gaugingthe tank level and of taking bottom samples.

In the slotted guide pole/sample well application, the well of the guide pole isconstructed with a series of drilled holes or slots that allow the product to mix freely inthe guide pole and thus have the same composition and liquid level as the product inthe tank. Evaporative loss from the guide pole can be reduced by modifying the guidepole or well, or by placing a removable float inside the pole. Deck fitting factors forslotted guide poles without pole sleeves were determined from test data on fittingswhere the float top or float wiper was positioned at or above the sliding coverelevation.

Tests were not conducted with floats where the top of the float or wiper was below thesliding cover elevation (“short” floats); emissions from such a configuration areexpected to be somewhere between those for guide poles with and without floats,depending upon the float height. When a pole sleeve is used, the evaporative loss willnot be affected by the height of the float within the well, since the purpose of the polesleeve is to restrict the flow of vapor from the vapor space below the deck into theslotted guide pole.

KLM TechnologyGroup

Practical Engineering Guidelinesfor Processing Plant Solutions

STORAGE TANK SELECTION ANDSIZING

ENGINEERING DESIGN GUIDELINES

Page 39 of 87

Rev: 02

JUNE 2011

These design guideline are believed to be as accurate as possible, but are very general and not for specific design cases.They were designed for engineers to do preliminary designs and process specification sheets. The final design mustalways be guaranteed for the service selected by the manufacturing vendor, but these guidelines will greatly reduce theamount of up front engineering hours that are required to develop the final design. The guidelines are a training tool foryoung engineers or a resource for engineers with experience.

This document is entrusted to the recipient personally, but the copyright remains with us. It must not be copied,reproduced or in any way communicated or made accessible to third parties without our written consent.

Figure 20: Slotted and unslotted guidepoles

KLM TechnologyGroup

Practical Engineering Guidelinesfor Processing Plant Solutions

STORAGE TANK SELECTION ANDSIZING

ENGINEERING DESIGN GUIDELINES

Page 40 of 87

Rev: 02

JUNE 2011

These design guideline are believed to be as accurate as possible, but are very general and not for specific design cases.They were designed for engineers to do preliminary designs and process specification sheets. The final design mustalways be guaranteed for the service selected by the manufacturing vendor, but these guidelines will greatly reduce theamount of up front engineering hours that are required to develop the final design. The guidelines are a training tool foryoung engineers or a resource for engineers with experience.

This document is entrusted to the recipient personally, but the copyright remains with us. It must not be copied,reproduced or in any way communicated or made accessible to third parties without our written consent.

Vacuum Breakers

The purpose of a vacuum breaker is to allow for the exchange of vapor and airthrough the floating roof during filling and emptying. Vacuum breakers are designed tobe activated by changes in pressure or liquid level, or strictly by mechanical means.

Mechanical vacuum breakers are activated when the deck is either being landed on itslegs or floated off its legs to equalize the pressure of the vapor space across the deck.This is accomplished by opening a deck penetration that usually consists of a wellformed of pipe or framing on which rests a cover (Figure below). Attached to theunderside of the cover is a guide leg long enough to contact the tank bottom as theexternal floating deck approaches the tank bottom. When in contact with the tankbottom, the guide leg mechanically opens the breaker by lifting the cover off the well.When the leg is not contacting the bottom, the penetration is closed by the coverresting on the well.

The closure may or may not have a gasket between the cover and neck. Since thepurpose of the vacuum breaker is to allow the free exchange of air and/or vapor, thewell does not extend appreciably below the deck. The gasket on the underside of thecover, or conversely on the upper rim of the well, provides a small measure ofemission control during periods when the roof is free floating and the breaker isclosed.

KLM TechnologyGroup

Practical Engineering Guidelinesfor Processing Plant Solutions

STORAGE TANK SELECTION ANDSIZING

ENGINEERING DESIGN GUIDELINES

Page 41 of 87

Rev: 02

JUNE 2011