-

8/12/2019 E-Line_DK

1/11

www.eae.com.tr

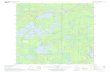

Underfloor Ducting systems

for wiring management of Power,

Data, Audio-Visual, Alarm,

Telephone facilities for Business Centres,

Bank, Offices, Conference Halls, Hotels, etc.

T E

ME 04

IEC 60439-2 sISO

9001

14001

NTALE MM AN NO AR GI EV MNE E

ND

TN SA YY STI TL EA MU SQ

EAEhasfullrighttomakeanyrevisionsorchancesonthiscataloguewithoutanypriornotice.

Cakmakli Mahallesi, 2. Cadde,

119. Sokak, No:12 34522

Kirac-Hadimkoy-Istanbul-TURKEY

Tel: +90 (212) 886 23 90

Fax: +90 (212) 886 24 20

ULATANITIM/

E.E./

A.A./

6124066

Catalogue09/00-Ing.

2.0

00Pcs

13/05/2008

-

8/12/2019 E-Line_DK

2/11

w w w . e a e . c o m . t r

-

8/12/2019 E-Line_DK

3/11

CONTENTS

General Description

D Junction Box System Installation Layout

D Product Selection Table

B Junction Box System Installation Layout

B Product Selection Table

Accessories

A Junction Box System Installation Layout

A Product Selection Table

Underfloor Ducting System Installation

Coat Wire Application

2-3

4-5

6-7

8-9

10-11

12-13

14

15

16

16

-

8/12/2019 E-Line_DK

4/11

E L E K T R K

E DKLINE E DKLINE

35 906

96 976

96 977

96 482

3

Underfloor Ducting Systems

E-Line Underfloor Ducting system is a modular and modern cable managementsystem that brings solutions for any changes in connection with wiring at the time ofnstallation or in future, and thus proves to be a good support to meet any requirementhat may arise during operation.

E-line Underfloor Ducting Systems ensures aesthetic, safe and reliable cablemanagement by eliminating the wiring-related confusion caused in the working environments.

Applicable Fields

Banks

Shopping Centres

Modern offices

HotelsHospitals

Conference Halls

Course Buildings

Cinema and Theatre Halls

Touristic facilities

Elevated floor

Similar spaces.

Significant Advantages

Easy Planning

Possibility of multiple outlet

Easy and quick cable ducting

Robust and sound construction

Elasticity cable ducting

Decorative appearance

Easy and functional use

Safe cable ducting

E-Line ; adapts itself easily to anymodifications or capacity increasein the working environment of the office.

Access to the system is very easy. Possible needs in future aremet easily thanks to wide ducts and flexible outlet boxes.Systems capacity is increased without any negativeeffect on decoration.

Underfloor Ducting Systems

Output Junction Box

Cover that can be fitted in both directions

Lockable Cable protection covers

Capacity of 16 different outputs

Easy to use

Decorative appearance

Accessories making it easy for

socket and cable installation

Robust and sound construction

Junction Box

Easy conformance to projects

Ability of 4-directional outlets

Adjustment possibility

before and after alum

Smooth adjustment capability

up to 7-10 cm heights

Fitting output box feature

Robust and functional construction

Fast and easy installation

Output Junction Box N

Output Junction BoxN

Connection Junction Box K

Junction Box Cover Set M

-

8/12/2019 E-Line_DK

5/11

E DLINE

E L E K T R K

5

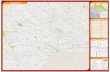

Junction Box SystemInstallation Layout

Co nnectionJunctionBoxK(450x450)

96977

ConnectionJunctionBox

96979 K(360x360)

OutputJunctionBoxM(450x450)

35821

OutputJunctionBox35820 M(360x360)

OutputJunctionBox96976 N(450x450)

OutputJunctionBox96978 N(360x360)

-

8/12/2019 E-Line_DK

6/11

-

8/12/2019 E-Line_DK

7/11

E BLINE

E L E K T R K

9

OutputJunctionBoxM(360x360)

35819

OutputJunctionBoxN-2(360x720)

35818

OutputJunctionBoxN(360x360)

96482

Junction Box SystemInstallation Layout

-

8/12/2019 E-Line_DK

8/11

-

8/12/2019 E-Line_DK

9/11

-

8/12/2019 E-Line_DK

10/11

-

8/12/2019 E-Line_DK

11/11

E DKLINE

14

16

1

2

3

4

COAT WIRE APPLICATION;

Underloor Ducting systems, in case the screed thickness is small,

before pouring the screed " Rabitz wire" (thin grid wire) should be

applied. In this application a thin cement mortar layer has to be

poured upon the duct and then Rabitz grid shold be laid, then

another cement mortar layer should be poured on the Rabitz grid,finally the regular screed should be poured, after that the

application is complete.

Installation Instructions / Coat Wire Application

Pull a rope suitable to the system

Cut the resin according to the channel width

Yield the resin for the duct inser tion

Install the duct into the inlet of the junction box

Completing the connection

Attachment of the Ducts

Attach the supplementary components to thetab of the duct

Install the other duct to the supplementarycomponent

Perform level adjustment of the junction boxat the gauge

Perform level adjustment of the attachment atthe gauge

Apply smoothing alum

1- Pull the rope according to duct layout and alum heights described in the project.

2- Begin installation first from the junction boxes.

3- If construction conditions are suitable, smoothing alum should be applied

onto the mat concrete

4- After that, perform installation of Sub Channels and Junction Boxes with water gauge.

5- If smoothing alum is not applied, ensure that the upper point of thejunction box, channels and outlet windows are at the same level.

6- Initially fix the system to the ground from specific points.

7- Install the transparent plastic protective covers of the junction boxes.

8- While applying alum, ensure that the system installer electricity technician is present.

9- Install the output boxes after the ground covering has been completed.