DIGITAL INTEGRATED CIRCUIT (IC) DESIGN Physical Aware Digital System Design W A T Mahesh Dananjaya [email protected] ISaac Intelligent Systems and Advanced Computing

Digital Integrated Circuit (IC) Design

Aug 07, 2015

Welcome message from author

This document is posted to help you gain knowledge. Please leave a comment to let me know what you think about it! Share it to your friends and learn new things together.

Transcript

DIGITAL INTEGRATED

CIRCUIT (IC) DESIGN Physical Aware Digital System Design

W A T Mahesh Dananjaya [email protected]

ISaac Intelligent Systems and Advanced Computing

ISAAC – Intelligent Systems and Advanced Computing

DIGITAL INTEGRATED

CIRCUIT (IC) DESIGN

ISAAC

Intelligent Systems and Advanced Computing

W A T Mahesh Dananjaya

Department of Electronic and Telecommunication Engineering

University of Moratuwa

Sri Lanka

ISAAC – Intelligent Systems and Advanced Computing

Contents

1 Integrated Circuit Design ................................................................................................................ 3

2 Digital Integrated Circuits ............................................................................................................... 5

2.1 Electronic System Level ........................................................................................................... 6

2.2 RTL Design ............................................................................................................................... 6

2.3 Physical Design ........................................................................................................................ 6

3 Physical Design ................................................................................................................................ 6

3.1 VLSI Physical Design ................................................................................................................ 6

3.2 Physical Design Step Nodes .................................................................................................... 8

3.3 Technology Library Support .................................................................................................... 8

3.4 Design Categories Based on the Physical Design Flow ........................................................... 9

3.4.1 Full Custom Design .......................................................................................................... 9

3.4.2 Semi-Custom Design ....................................................................................................... 9

3.4.3 Pre-Cast Designs .............................................................................................................. 9

3.5 Illustration of the Physical Design Steps ............................................................................... 10

3.5.1 Floor Planning ............................................................................................................... 10

3.5.2 Clustering or Partitioning .............................................................................................. 11

3.5.3 Placement ..................................................................................................................... 12

3.5.4 Clock Tree Synthesis (CTS) ............................................................................................ 13

3.5.5 Routing .......................................................................................................................... 15

ISAAC – Intelligent Systems and Advanced Computing

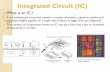

1 Integrated Circuit Design

Integrated circuit design is becoming much more complicated task as design extended across

very large scale integration and technology scaling makes the chip density higher. Therefore

nowadays chip design is concern the optimal tradeoff between various facts such as

performance, power, area etc.

Modern integrated circuits consist of miniaturized electric components built into an

electric network on a monolithic semiconductor substrate by photolithography techniques.

Integrated circuit design has evolved through some eras and nowadays Very Large Scale

Integration (VLSI) is also feasible and available. However there are two major portions of the

IC design in their nature.

USER DESIGNER

ISAAC – Intelligent Systems and Advanced Computing

And also modern IC design compromise to several common stages in both digital and analog

format. But processes carried out by different stages could be varying due to their nature.

General Integrated Circuit Design Steps are as follows whether it is a digital or an analog one.

Integrated Circuits

Analog IC Digital IC

ISAAC – Intelligent Systems and Advanced Computing

2 Digital Integrated Circuits

Digital Integrated Circuits deploys only few discrete states of transistors. Digital

Integrated Circuits nowadays consist of billions of transistors with Very Large Scale Integrity

(VLSI). Digital IC design refer to production of components such as Microprocessors,

Memories (RAM, ROM and FLASH), FPGA, ASIC, SOC, NOC and MPSOCs. Digital design

mostly focuses on

o Logical correctness

o Maximizing circuit density

o Placing circuits in a way so that clock and timing signals can be routed efficiently.

Digital Integrated circuit design flow can be categorized into three main sub domains,

o System Design

o RTL Design

o Physical Design

Then we have a fabrication process that is common for both digital and analog circuits design.

And also this design flow can be classified as three separated design perceptions

o Front-End Design- System Design and RTL design

o Back End Design-Physical Design

Digital Design

Front-End Design

System Design RTL Design

Back-End Design

Physical Design

ISAAC – Intelligent Systems and Advanced Computing

2.1 Electronic System Level

System level functionalities and specifications are completed at this stage. This is the

stage that define overall system functionalities and modular functionalities where designer

finalize what to design. It may be a pseudo model, but most of the time various programming

languages and tools are used to model the system such as C,C++ model, SystemC, System

Verilog transactional level, Simulink and MATLAB. System level modeling with basic

functional cores are the foundation of any digital design. With the support of the programming

languages we have to model the system with algorithms. If it fails we should never go ahead

upon design flow.

2.2 RTL Design

Stage where user specification are mapped into the Register Transfer Level (RTL) description.

This describes the behavior as well as the structure of the digital circuit designs on the chip as

well as interconnection and outputs. Verilog, System Verilog and VHDL are common

languages used for modelling at this stage.

2.3 Physical Design

Stage of the chip designs according to the predefined set of guide lines. This takes the RTL

design, technology libraries provided with relevant technology cells, course of constraints and

design the chip. This stage defines the chip which gates to use, how much area need, where to

place cells and how to wire them together in a limited area. Then the designers can analyses

performance, speed, cost and area. But physical design flow doesn’t affect the functionalities

at all.

3 Physical Design

3.1 VLSI Physical Design

VLSI physical designs process is lying between synthesis process and fabrication

process. The design come out from the physical design layer can be directly used to fabrication

process. Although physical design is organized as a single component, it consist of several

different and significant design steps. Physical design steps belong to back-end design stage

and it is totally depends on the results given by synthesis process. And also tech library support

is paramount important for the physical design stage to reserve area, power and lesser cross

talks. Clustering, floor planning, placing, routing, clock tree synthesis (CTS) are the major

ISAAC – Intelligent Systems and Advanced Computing

physical design steps. Following diagram illustrate the position of physical design in the

common ASIC design flow.

Design Specification

Architectural Design

RTL Modeling

Synthesis

Physical Design

Layout sign off

Fabrication

Package and Test

ISAAC – Intelligent Systems and Advanced Computing

3.2 Physical Design Step Nodes

3.3 Technology Library Support

There are two part of the technology libraries that are used by two different design stages, front-

end and back end, of the development cycle. LIB part of the technology library is used for the

synthesis process which basically the front end design. And the LEF (Layout Exchange

Format) is used for the physical design flow which is basically the back end design consist of

clustering,

Partitioning and Clustering

Floor Planning

Placement

Clock Tree Synthesis

Signal Routing

Timing Closure

ISAAC – Intelligent Systems and Advanced Computing

3.4 Design Categories Based on the Physical Design Flow

Although two main categories exist in the past nowadays designers identify three major

categories of the design.

o Full Custom

o Semi-Custom

o Precast

3.4.1 Full Custom Design

Designers have the complete flexibility for their layout (physical) design. There are no

predefined cells to be used for the design. As a example ASIC designs are vulnerable for

full custom designs. There any cells that obey to DFM can be used dynamically according

to designers specifications admitted with the tech libraries.

3.4.2 Semi-Custom Design

Pre-defined library cells are used which have been tested with DFM (Design for

Manufacturability). Designers have the flexibility in placement and routing. Size of the

cells depends on the design specifications and requirements of the designers. IP cores are

the emerging semi-custom designs. As an example ARM cores.

Semi-custom designs are becoming significant to electronic revolution in the recent

history as it fasten the manufacturing and design process as well as reducing time to market.

Semi-custom designs are popular because design companies are supported to face the

competition with other companies.

There are two types of semi-custom designs.

o Fabricated

o Fables

ARM cores are fabless cores and some cores are fabricated and sometimes they are used for

the SOC (System on Chip) design.

3.4.3 Pre-Cast Designs

Pre cast means designers cannot define any physical layer content and cells to be used.

They have been specified with the relevant technologies. Designers only have access to the

modelling level and synthesis level with limited specifications with general components. No

technology libraries that are specified by the designers, are going to be used for the physical

ISAAC – Intelligent Systems and Advanced Computing

layout. Most of the time reconfigurable technologies such as FPGAs are categorizing into this

specific group. This technologies are based on the trial and error approach and used for research

and academic purposes. But in the recent history they have been deployed for some commercial

level applications.

3.5 Illustration of the Physical Design Steps

3.5.1 Floor Planning

Floor plan is the physical plan of the chip. In other way it is the initial phase of the physical

synthesis process. In the floor plan phase,

o Physical plan of the chip

o Size of the die

o Boundaries and core area

o Wire tracks

o Pin locations

o Positioning of blocks/macros on the die

Is carrying out according to the input constraints given by the designers.

ISAAC – Intelligent Systems and Advanced Computing

Initial Process of the physical design is to convert synthesized logic cells into structures of

actual physical dimensions in the way that they suit to place to achieve best functionality. Floor

planning is the process of identifying physical structures and allocate area and other resources

to optimize the performance and chip size and also to decide the I/O structure and the aspect

ratio. Based on the area and the physical hierarchy floor plan will be designed and optimized.

This is the phase of identifying hard macros to the design used in design, memory and other IP

cores and placement requirements and routing possibilities. Therefore we need some input and

constraints to plan the floor.

o Size of the chip

o Aspect Ratio: Horizontal routing resources and vertical routing resources

o Core Utilization: Standard cell area and core area

o Technology: .lib or tech file

o Power

o I/O constraints

This phase of better floor planning need to avoid the unnecessary wastages in chip/die

area and also to avoid routing congestions. Actual main concern when doing floor plan is the

tradeoff between area and the speed. This because due to placement potential and routing

resources available for routing. Best floor planed design may lead to less connection lengths,

reduction in area, shorter interconnect distances, modules/structures of the design to be much

closer, faster end-to-end signal flow paths and less routing resources to be used. This well

planned floor will cause to consistent and compromised placing and routing time. Especially

in routing when data path designing it causes to less interventions and congestions.

3.5.2 Clustering or Partitioning

Partitioning is the process of dividing chip into sub-blocks. After synthesis process the

logic cells are matched into a millions and billions of semiconductor layer devices. Designing

the physical layer with placing and routing becomes a critical problem in complex ICs.

Therefore as a pragmatic remedy designers divide the complete design problem into different

sub problems by partitioning the physical layout according to few paramount important factors.

Divided the synthesized logic cells into separate partitions in such a way that each partition has

a separate set of logic cells and minimum connections from it to outside partitions. Number of

connections are the basic concern here because placing and routing is basically depends on the

number of cells and routes they have. With this partitioning strategy floor planning, placing

ISAAC – Intelligent Systems and Advanced Computing

and routing also becomes sub system problem and we only need to optimize those things within

the cluster/partitions. Therefore it is easier to placement and routing. Then we can integrate

them into build the complete physical layout or top level module.

3.5.3 Placement

Placement is the process of placing each and every physical cell inside the physical

layout according to the floor plan specifications. In this phase standard cells of each

frame/platform are placed using partitioned Design Exchange Format (DEF). In this step all

cells placed within rows of the chip area/die and also route channels between rows to

interconnect them.

o Standard Cell placement of each frame/platform using partitioned DEF

o Scan re-routing based on location of scan flops

o Parasitic extractions

Those are the few steps in this stage. And also there are some optimizations carrying out at

this stage.

o Static Time Analysis (STA) with ideal clock and estimated wire parasites based on

placement

o Fix timing issues

Placement process is based on the hierarchical view and dependencies between cells according

to their functions and layout. Placement process is optimized according to the physical

resources. Placement stage consist of four major phases.

o Pre-Placement Optimization

o In Placement Optimization

o Post- Placement Optimization (PPO) before clock tree synthesis (CTS)

o PPO after CTS

Pre-Placement Optimization: Optimize the netlist before placement. HFN are collapsed. It can

also downsize the cells.

In-Placement Optimization: Re-optimize the logic based on virtual route VR.in this stage

various functions are carrying out.

o Cell sizing

ISAAC – Intelligent Systems and Advanced Computing

o Cell moving

o Cell Bypassing

o Net Splitting

o Gate Duplication

o Buffer Insertion

o Area Recovery

Optimization performs iteration of set up fixing, increment timing and congestion driven

placement.

Post Placement Optimization: This is done before CTS performs netlist optimization with ideal

clock. It can fix setup, hold, max trans/cap violation. This process include optimization based

on global routing.

Post Placement Optimization: This is carrying out after CTS optimizations timing with

propagated clock. It tries to preserve clock skew.

3.5.4 Clock Tree Synthesis (CTS)

Clock is the caliber behind the sequential digital designs. Building a clock throughout

a complex design and synchronize the clock signal is paramount important to have a good

performance. Therefore building the clock tree is important. Buffer insertion in clock path so

that all sequential elements receive the clock at the same time. This is very crucial for faster

timing closure.

CLK

ISAAC – Intelligent Systems and Advanced Computing

Importance and goal of having CTS is to minimize skew and insertion delay.

After CTS hold slack should improve. Clock tree begins at defined clock source and

ends at stop pins of flops. There are 2 types of stop pins.

o Ignore pins

o Sync Pins

If clock is divided then separate skew analysis is required. Another important parameter is that

area overhead by clock shielding so that the noise is not coupled to other signals. Therefore we

can optimized the CTS by shielding the clock which is known as Clock Tree Optimization

(CTO). This also can be achieved by optimizing,

o Buffer sizing

o Gate sizing

o Buffer relocation

o Level adjustments

o HFN synthesis

We try to improve setup slack in pre-placement, in placement and post placement optimization

before CTS stages while neglecting hold slack. In post placement optimization after CTS hold

slack is improved

3.5.4.1 Clock Tree Constraints

o Clock insertion Delay: consideration of propagation of clocks from clock source

to flop.

o Clock Skew: Difference in propagation time due to various reasons such as

Bandwidth differences to the sequential flops in the same tree hierarchy.

o Maximum Transition Time: Clock is alternative signal that transition various

upon internal capacitance of pins and wires.

o Clock Tree Power

3.5.4.2 Clock Tree Power

There are typical reasons to have varying power on clock process upon cells.

o Clock Gating Cells

o Minimum number of clock components before clock gating elements

o Improving clock latency

ISAAC – Intelligent Systems and Advanced Computing

3.5.5 Routing

Routing is the process of establishing connection between placed components on the

physical layer via top metal layers. There are lots ways to do the routing in the design. Better

routing prevent the congestions and interventions from other signal. There are two major

routing scenarios.

o Global Routing

o Detailed Routing

Global routing allocates routing resources that are used for connections. Detailed routing assigns

routes to specific metal layers and routing tracks within the global routing resources.

Related Documents