1 Developing an Integrated Shipbuilding Environment for the Ship's Life Cycle Presented by : Ron Wood Dr. Burton Gischner January 25, 2006

Developing an Integrated Shipbuilding Environment for the Ship's Life Cycle

Jan 12, 2016

Developing an Integrated Shipbuilding Environment for the Ship's Life Cycle. Presented by : Ron Wood Dr. Burton Gischner January 25, 2006. Agenda. Interoperability Use of STEP and XML Development of STEP for Shipbuilding - PowerPoint PPT Presentation

Welcome message from author

This document is posted to help you gain knowledge. Please leave a comment to let me know what you think about it! Share it to your friends and learn new things together.

Transcript

-

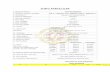

Ship Product Model Data

Ship Structural Envelope

Distribution Systems

Equipment / Subsystems

Life Cycle Maintenance

Miscellaneous

HVACISO AP 227:2005

PipingISO AP 227:2005

Ship ArrangementISO AP 215:2004

Ship Moulded FormsISO AP 216:2003

Ship StructuresISO AP 218:2004

Reference Data LibrariesISO 15926

Common Parts Catalog (CPC)

ElectricalISO AP 212:2001

Mechanical SystemsISO AP 227:2005

Cable TraysISO AP 227:2005

Finite Element AnalysisISO AP 209:2001

Product Config/ GeometryISO AP 203:1994

Product Life Cycle SupportISO AP 239

Systems EngineeringISO AP 233

Computational Fluid DynamicsISO AP 237

Logistics / SparesISO AP 232:2002

Outfit & FurnishingsNSRP 0428:1992

Manufacturing SupportISO APs 224, 238, 240

Standard Approved

Testing Framework

Deployment, integration,testing

Standard In Work

*

Joel Cawley, the head of IBM's Strategic planning unit, Standards don't eliminate innovation, they allow you to focus it. They allow you to focus on where the real value lies, which is usually everything you can add above and around the standard

Quote in "The World Is Flat" by Thomas L. Friedman

*

Development of STEP and XML for Shipbuilding

*

XML = Industry StandardContainer for Data

STEP = ISO StandardLanguage for Data*

DataCompanyAStandardsVirtualShippart(s)CompanyBTransactions of Data Packaged in StandardsXSLT - map data to another XML schemaXML and STEPXML: Accepted format/schema method Web-enablingSTEP: Standards for data expression Standards for geometric exchange

*

ISO Shipbuilding BackgroundEffort of Shipbuilders, Regulatory Bodies, CAD Software Companies, MOD, DOD from Various countries1996 to 1999 U.S. Effort under MariSTEP ProjectFunded under DARPA/MARITECHDARPA (Defense Advanced Research Projects Agency)Prototyped early versions of AP215, 216, 217 and 218Exchanged AP218 data with European SeaSprite ProjectCurrent U.S. effort under NSRP ASE

*

MariSTEP Project1996 - 1999ISDP Export: MariSTEP APs 215, 216, 217, 218GSCAD Import: MariSTEP 218Import and Export:MariSTEP APs 215, 216, 217, 218Import and Export:MariSTEP APs 215, 216, 217, 218Import and Export:MariSTEP APs 215, 216, 217STEPNorthrop GrummanNewport NewsVIVIDElectric BoatCorporationCATIANAVSEA& NGSS - Avondale IndustriesISDP(Intergraph)NGSS - IngallsShipbuildingCvaec Dimension III(CV / PTC / Ciarrai)NASSCOTRIBON(Kockums ComputerSystems)VIVID Export: MariSTEP APs 215, 216, 217, 218GSCAD Import: MariSTEP APs 216, 218First U.S. STEP Shipbuilding Implementation Project

*

Ship APs Now ISO StandardsAP215, ISO TC184/SC4 10303-215 IS "Application protocol: Ship Arrangement". available from Geneva or National Standards bodies as ISO 10303-215:2004. AP216, TC184/SC4 10303-216 IS "Application protocol: Ship Moulded Forms. available from Geneva or National Standards bodies as ISO 10303-216:2003. AP218 ISO TC184/SC4 10303-218 IS "Application protocol: Ship structures". available from Geneva or National Standards bodies as ISO 10303-218:2004. AP227 ISO TC184/SC4/WG3 10303-227 IS Plant Spatial Configuration. available from Geneva or National Standards bodies as ISO 10303-227:2005 Includes all the information needed for the marine industries to exchange information about piping, HVAC and machinery.

*

The Navy and Shipbuilders Are Using Product Model Data TechnologyProduct Model Data = 3-D CAD + definitions +other documentationContinued investment is key indication of value

*

Implementation of the STEP Standards

*

ISE BackgroundFirst NSRP major systems technology projectPhase 1: Requirements definition and architecture for shipbuilding systems interoperabilityMarch 1999 to December 1999Phase 2: Deployment for Structure & Piping March 2000 to December 2003Phase 3: Deployment for HVAC & CPC InterfacesOctober 2003 to October 2004Phase 4: Arrangements, Electrical, Analysis, Steel Processing January 2005 to April 2006

*

ISE Team Participants

*

ISE Builds tools to Support 2nd Generation IPDEFirst Generation Integrated Product DevelopmentEnvironment (IPDE)2nd Generation IPDE

*

ISE Project ApproachDevelop and demonstrate tools that are low cost can be selectively used by shipyards to support interoperabilitycapitalize on XML and related Internet technologies

Flexibility is criticalallow shipyards to transform their data to/from common information model

Drive development of shipbuilding product data standards (e.g. STEP, PLIB)

Construct a single Shipbuilding Information Model Demonstrate and educate U.S. shipbuilding community

*

ISE architecture represents an innovative, practical solution to the information interoperability challengeAccessible to large and small shipyardsOnly system dependency is Web infrastructureUtilizes open standardsInnovative integration of STEP and XML technologiesSupports sharing of geometry & geometric product modelsPermissive (mediation) architectureLets each enterprise choose its own tool setIncorporated into CAD platforms used by U.S. shipbuilders

*

This ship is used to locate and retrieve torpedoes and missile drones. It has a maximum payload capacity of 42 long tons which includes the deck cargo plus full liquids, full complement, and normal stores.This ship was selected because it is in-service, has a complete set of drawings available for distribution, and is:

Approved for Public Release: Distribution Unlimited.

The ISE Test ShipTWR 841*

*

ISE-2: Moulded Forms, Structure and Pipe

*

Demonstration Storyboard April 10, 2003 LEAPSFlagShipForanSafeHullSupplierParts LibSIMSMARTCAM(IPT)TribonTribonDatabase DeliverablesCAMCAEAutoCADPipeStressCATIACATIA

*

Demo Scenario - Design & AnalysisUserinvokes tool through command FlagShip reads data, performs hydrostatic analysis

*

Demo Scenario: SENER-FORAN v50 STRUCTURAL DETAILED DESIGN and STEP EXPORTFORAN Structural Detailed Design FORAN Preliminary DesignStandardsSeams &Buttsstructure,InternalHull,DecksTWR shipTWR ships structure ready to be exported by FORAN-AP218 STEP Export translatorMidship Section CalculationsSelective STEP Export To ABSFinite Elements CalculationsTo EBTransverse BulkheadsWhole Structure

-

FORAN Definition of Standard Profile Sections and Scantlings

TWR Drawings (6200895-01 in the example)

FORAN TWRs 3D Model (Detail of the Tranverse Bulkhead Fr. no. 12)

Definition of Standard Profiles Sections in FORAN : NORM Module

-

FORAN Definition of Profiles Standard Cut Outs

Definition of Standard Profiles Cut Outs in FORAN : NORM Module

TWR Drawing (6201063-81 )

TWR Drawing (6200895-01 )

FORAN TWRs 3D Model (Details of the Tranverse Bulkhead Fr. no. 12)

-

Definition of Stiffener End Brakets in FORAN : NORM Module

FORAN TWRs 3D Model (Details of the Tranverse Bulkhead Fr. no. 12

FORAN Definition of Stiffener End Brakets

TWR Drawing (6200897-01 )

TWR Drawing (6201063-34 )

TWR Drawing (6201063-39 )

-

Definition of Standard Openings in FORAN : NORM Module

TWR Drawing (6200898-02 )

FORAN Definition of Standard Openings

FORAN TWRs 3D Model (Details of the Openings in Main Deck between frames 13 and 15)

-

TWRs FORAN Steel Production Definition 1- Definition of Butts and Seams : FHULL Module (1/4)

1- Basic Forms either created by FSURF module or AP216-STEP imported

2- Basic Steel Production Lines

3- Butts Definition

4- Seams Definition

-

TWRs FORAN Steel Production Definition 1- Definition of Butts and Seams : FHULL Module (1/4)

1- Basic Forms either created by FSURF module or AP216-STEP imported

2- Basic Steel Production Lines

3- Butts Definition

4- Seams Definition

-

TWRs FORAN Steel Production Definition 3- Definition of Internal Structure and Superstructure : IPANEL Module (3/4)

8- Bulkhead no. 12 Definition

9- Bulkhead no. 16 Definition

10- Other Internal Steel Structure Definition

11- Superstructure Definition

-

TWRs FORAN Steel Production Definition 4- Structure Integration (4/4)

-

*

ISE Process - Detail Piping Design Demonstration on April 10, 2003CATIAV5TribonM2ISE

*

ISE Process for Feeding Analysis Programs from Structural DesignAtlantecTRIBONIntergraphISDPIntergraphIntelliShip

*

ISE Process Design & AnalysisDesign ToolIntegrated process of design, analysis, evaluation of analysis on design Interoperable toolsSingle virtual design & analysis environmentDesign & analysis results both electronic formatDesignerUser performs design & analysis

*

Simulation and Modeling of Shipboard Piping Systems

*

Overview Piping Functional Design*

*

Additional BenefitsValidated As-Built model can be used to:Validate the design and ensure that all requirements are metEvaluate different design alternativesForm a basis for creating an On Board Training System (OBTS) and schoolhouse training systemEvaluate refits and upgrades throughout the lifecycle of the vesselValidate control system algorithmsTest the control system prior to deliveryPerform manning analyses

*

ISE-3: HVAC

*

Washington DCIntegrated Shipbuilding Environment HVAC DemonstrationOctober 2004

*

ELBOWH = 4W = 6Rin = 4Rout = 12DUCTH = 4W = 6L = 86TRANSITIONH1 = 4W1 = 6H2 = 3W2 = 12L = 12Revised Duct for DemoH = 4W = 6L =12ManufacturingTest Case 4

*

Analysis(SIMSMART)Initial HVACDesign(ISDP)Detailed DesignTool1(TRIBON)ManufacturingSister ShipyardDetailed Design(FORAN)AnalysisDetailed DesignTool 2(CATIA)CPCLegend demonstrated discussed Order MaterialCPCParts CatalogCAD ToolISE-3 HVAC Demo (October 2004)CPC

*

ISE-4: Ship Arrangements, Steel Processing, Engineering Analysis and Electrical

*

ISE-4: New NSRP ProjectAwarded January 2005IncludesShip Arrangements (AP215)Steel Processing (AP218, 238, 240) Engineering Analysis (AP209)Electrical (AP212)

*

AP215:2004Ship ArrangementsZone Boundaries Controlling Access Design Authority Cargo Stowage Machinery Compartments Crew Occupancy Common Purpose SpacesStabilityintactdamagedCompartments types properties (shape, coatings,adjacency,access.)Loading conditionsGeneral Subdivision of a Shipinto Spatially Bounded RegionsCargoesassignment to compartmentsweight, centre of gravity*

*

TWR Compartment Overview

Compartment NameCompt #Volume (m^3)Air Handling Room1-8-3-Q9.344559387Ballast Tank #12-6-1-V5.621280313Ballast Tank #21-6-2-V5.621280378Ballast Tank #32-23-6-V10.94196403Ballast Tank #41-23-0-F11.45422363Bosuns Stores2-2-0-A31.1542512Bow Thruster2-5-0-Q29.65740748Chain Locker2-2-0-Q2.128270093CO State Room1-5-2-L15.19818335CPO State Room1-5-1-L15.19818517Crews Berthing2-6-0-L65.55600522Deck Gear1-14-3-A5.256314651Electrical Room1-7-1-Q4.672279696Engine Room2-16-0-E164.4171673Engine Room Exhaust Trunk2-15-1-Q2.803369266Engine Room Supply Trunk2-15-2-Q1.897890198Forepeak2-0-0-V9.703230573Fuel Oil Tank #12-9-1-F7.47810508Fuel Oil Tank #21-9-2-F7.47810645Fuel Oil Tank #32-16-0-F11.87955578Fuel Oil Tank #42-23-2-F4.791415503Fuel Oil Tank #52-9-1-F4.572601083Galley and Mess Area1-9-0-L59.46537759Hold Head2-10-2-L20.57645565Hold Passageway2-8-0-L18.1679584Lazarette2-25-0-Q45.19140913Lazarette Passageway2-23-0-Q6.423977119Linen Locker2-9-1-A2.786579543Lube Oil Tank2-23-4-F0.987812699Main Deck Head1-7-2-L7.00841954Main Deck Passageway1-7-0-L6.371290497Observers Berthing2-10-1-L17.82688618Pilot House01-6-0-C45.87356833Pilot House Passageway1-9-1-L4.014929551Potable Water Tank #12-13-1-W9.928594336Potable Water Tank #22-13-2-W9.928594336Provisions Storeroom2-11-0-A7.495108964Pump Room2-12-0-Q112.0118041Pump Room Passageway2-14-1-Q3.82277429Pump Room Supply Trunk1-14-1-Q0.424752699Void2-2-0-V3.395942412Waste Oil Tank2-15-0-F0.976931207

*

Steel Processing Steel Processing StagesScantling DesignDetailed Design3D Neutral Manufacturing2D Neutral Piece Parts2D Shipyard Piece PartsCADInformation ModelsFunctionsProduction PlanningPiece PartDevelopmentManufacturing DefinitionNestingNCDrawings &Reports Moulded Forms & Lines Preliminary scantlings Structural systems Unit Breakdown Structural Part Definition Structural Part Relationships Seams Features Assembly breakdown Assembly order Welds Bevels Bending lines Flat pattern parts Marking Lines Shipyard specific parts Added material Marking lines, Labeling Tabs Manufacturing Aids

*

ISE Steel Processing System OverviewAP216/218EB-specificMfg Data(AP/216/218/238)NG SS-specificMfg Data(AP/216/218/238)NCNCSteel ProcessingSystemDesign definition with neat geometryConnectivity/part relationships and structural hierarchyProductionPlanningPiece PartDevelopmentManufacturingDefinitionNestNestReports,Dwgs, etc.Reports,Dwgs, etc.Manufacturing definition with explicit geometryJoint/Edge preparationsEnd cutsAdded/Removed materialMarking linesCAD

*

Generate 2D Nesting Part Objects

*

Engineering Analysis Task OverviewXML Mediation Addresses CAD-CAE Interoperability with Ship APsShip CAD ToolsSTP (Express) FilesXML FilesA Mediation Example from 2003 NSRP ISE-2 DemosXSLTInteroperabilityCAE Analysis Tools

*

Engineering Analysis Demo Plans

*

AP209 Analysis

*

AP 212:2001 Electrical Design and InstallationElectrotechnical Plant Plant, e.g., Automobile Unit, e.g., Engine Control System Subunit, e.g., Ignition SystemElectrotechnical Systems Buildings Plants Transportation SystemsEquipment Coverage Power-transmission Power-distribution Power-generation Electric Machinery Electric Light and Heat Control SystemsData Supporting Terminals and Interfaces Functional Decomposition of Product 3D Cabling and Harnesses Cable Tracks and Mounting Instructions

*

Electrical Task OverviewValidatesReportsAP 212 DataConversionAP212XMLSchemasAP212XMLFileAP 212XML SchemaImplementa-tionElectrotechnicalComponentData InterfacesSTEPPart 28

KnowledgeBaseDatabasesElectrotechnical Data SourcesInitialXMLFileISO 10303AP212

*

AP212 Electrical

*

ISE 4 Possible Demo ScenarioInitial DesignDetail DesignManufacturingLifecycle SupportTRIBONISDPLEAPSLEAPSElectrical(KSS/KM)Engineering AnalysisFORANPreliminary ArrangementFeed Mfg from ISDPModifyArrangementNavyResponseCenterPartnership YardFORANRepair ShipyardEarly StageElectrical DesignSuggestDesignChangesSubmit DesignApproveChangesSubmitNavyChangesFinal Product Model Delivered to Navy GDEBNGSSSteel Processing

*

STEP Shipbuilding Implementation ForumA Testing Forum for the STEP Shipbuilding APs has been establishedIt is being run under the auspices of the NSRP Systems Technology PanelIt will test and validate implementations of the STEP Shipbuilding APsForum began in 2004 with AP216 testing

*

SummaryISE-1,2 & 3 have successfully demonstrated the potential of standards based data exchange to LEAN design and construction processes for HVAC, moulded forms, structures and piping.ISE-4 is looking at Electrical, Ship Arrangements, Steel Processing, AnalysisWeb site: http://www.isetools.org/Two major challenges lie ahead of us:Commercialization of this technologyContinuing to prototype standards based data exchange in other application areas such as product life cycle

*

ConclusionsThese testing, modeling, and simulation efforts are part of an attempt to develop a suite of product model data exchange tools that will enable U.S. Shipyards to become more productive These efforts revolve around implementation of the ISO 10303 STEP Shipbuilding standardsThe APs that enable these exchanges have completed their development and approval as International StandardsThe focus is now shifting to testing and validating their implementations

*

Conclusions (contd)In order to increase the availability and lower the price of production ready tools:The ship owner / operator needs to insist that data be delivered in a system neutral formatThe shipbuilder needs to insist that STEP functionality be an integral part of productThe next challenge is to move this technology into the mainstream and that the technology is mature enough to transition into commercial CAD and Product Modeling products

*

DISCUSSION

When you move from 2-d data to 3d data in assemblies the difference is even more dramatic.

Related Documents