EAC wins five-year contract extension from National Grid 04 IEC 61850 project delivered for Teesside offshore wind farm 08 High Speed 1 project enters test phase 11 Hybrid HVDC breakers 12 Introducing Symphony Plus 16 New generation recloser 22 Oil reclamation prolongs active life for transformers 26 Power quality issues put to bed 28 Data centre power 30 1 |12 The customer newsletter of ABB Power Products and Power Systems Delivering a power boost for London Underground ™ Power and productivity for a better world ffwd

Welcome message from author

This document is posted to help you gain knowledge. Please leave a comment to let me know what you think about it! Share it to your friends and learn new things together.

Transcript

EAC wins five-year contract extension from National Grid 04IEC 61850 project delivered for Teesside offshore wind farm 08High Speed 1 project enters test phase 11Hybrid HVDC breakers 12Introducing Symphony Plus 16New generation recloser 22Oil reclamation prolongs active life for transformers 26Power quality issues put to bed 28Data centre power 30

1|12The customer newsletter of ABB Power Products

and Power Systems

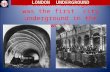

Delivering a power boost for London Underground

™Power and productivity

for a better world

ffwd

Power Products and Power Systems FFWD 1|12 3

Content

2 FFWD 1|12 Power Products and Power Systems

Editorial

Power Products are the key components to transmit and distribute electricity. Thedivision incorporates ABB's manufacturing network for transformers, switchgear,circuit breakers, cables and associated equipment. It also offers all the servicesneeded to ensure products' performance and extend their lifespan.

Power Systems offers turnkey systems and services for power transmission anddistribution grids, and for power plants. Substations and substation automationsystems are key areas. Additional highlights include flexible alternating currenttransmission systems (FACTS), high-voltage direct current (HVDC) systems andnetwork management systems. In power generation, Power Systems offers theinstrumentation, control and electrification of power plants.

Dear reader,Welcome to the first issue of our customer

newsletter for 2012. As you can read in ournewspages, the new year got off to a flyingstart for ABB with the exciting news that ourElectricity Alliance Central (EAC) contract withNational Grid has been extended for a furtherfive years. You can also find out more aboutour EAC projects in the article on page 14.

Another important development is theopening of our new office in East Kilbride thatwill provide the ideal platform for supportingpower infrastructure projects in Scotland. Weare also pleased to welcome our new intakeof apprentices who represent our very realcommitment to the development and trainingvital to support not only ABB’s future growth,but also a healthy economy.

Simply reading through these pagesdescribing major projects and groundbreaking technology, such as the HVDC

hybrid breaker, the true depth and breadth ofABB’s capabilities emerge. They provide asolid foundation for our ambitious growthplans as we look forward to building theadvanced ‘smart’ power networks essentialfor the UK to make the best possible use of itsnew renewable energy resources.

As always, we would be delighted toreceive any feedback on the subjects coveredin this issue, or suggestions for future issues.Please get in touch – we would love to hearfrom you.

In June, we would also be very pleased to see you at the RenewableUK GlobalOffshore Wind 2012 Conference & Exhibitionin London, where ABB is proud to be the core sponsor.

Stephen TrotterDivision Head of ABB Power Systems UK

07New indoor highvoltage substation

ffwd 1/12 • the customer newsletter of ABB Power Products and Power Systems • Subscription Newsletter available as printed or electronic copy. Subscribe online at www.abb.com/ffwd • Contact and feedback [email protected] • Publisher ABB Limited, Power Systems Division, Oulton Road, Stone, Staffordshire ST15 0RS. Phone 01785 825050

Stephen Trotter

ffwd1|12

18Delivering the balance of power

24Substation upgradefor the ‘Chapel inthe Valley’ 33

Supporting MacmillanCancer Support

4 News on major contracts and developments in ABB

8 IEC 61850 project for Teesside offshore wind farm

10 Jon Downs outlines a new approach to smaller substation projects

11 High Speed 1 power quality project

12 Introducing the Hybrid HVDC breaker

14 Leigh Turley reports on ABB’s experience ofworking in National Grid’s substation alliance

16 New Symphony Plus distributed control system24 Substation upgrade for ‘The Chapel in the Valley’24 New connection for SITA

18 Delivering the balance of power

20 Creating a new Bulk Supply Point

22 New generation GridShield recloser

26 Reclaiming transformer oil

28 Power quality issues put to bed for Paragon Print & Packaging

30 Data centre power

32 PASS M00

33 Supporting Macmillan

34 GBS platform technology for DolWin2

35 Where to meet ABB this year

Power Products and Power Systems FFWD 1|12 5

News

4 FFWD 1|12 Power Products and Power Systems

News

These enhancements will primarily involve the design, construction andcommissioning of 400 kV, 275 kV and 132 kV transmission substations.

During the contract extension, whichruns until 2017, individual contracts willcontinue to be awarded based upon safety performance, cost, on time delivery performance, project scope andgeographical considerations. It is thereforenot possible to place a total value on thecontract extension.

The EAC was established in 2006 as one of National Grid’s preferred Alliancepartners for substation development and

construction projects. It operates in NationalGrid’s Central region, comprising theMidlands, Greater Manchester andLiverpool. This original award was part of aprogramme worth up to £2.8 billion toupgrade and develop the electricitytransmission network across England and Wales.

Stuart Grattage, Head of Engineering forABB Power Systems in the UK, said:“National Grid’s decision to extend theAlliance contract confirms the success ofour innovative approach where all fourparticipants work together as a truepartnership. This makes the best use of our

individual competencies and shares risk andreward to create an effective team whichsafely and efficiently delivers complexsubstation projects, on time and on budget.”

Most recently, the EAC has been workingon one of the largest ever substationprojects undertaken in the UK, creating areplacement 400 kV substation at Deeside.Not only will this new substation play a vital role in the reinforcement of the highvoltage transmission infrastructure innorthwest England, it will also pave the wayfor the connection of a new high-voltagedirect current (HVDC) power link which isunder construction.

Electricity Alliance Central winsfive-year substation contractextension from National GridThe New Year got off to a flying with the news that National Grid’s Electricity AllianceCentral (EAC), a consortium of ABB, Morgan Sindall and Atkins, has been awardeda five-year contract extension to deliver major enhancements to the UK’s electricaltransmission infrastructure.

Colin has come to ABB after over 15 yearsexperience with the UK energy regulator,where he was most recently Head ofOffshore Transmission Policy at the Office ofGas and Electricity Markets (Ofgem). Hisappointment expands the skills andexpertise that ABB can offer in the UKpower sector.

Colin’s main role is to support ABB inbuilding on its market leading position as asupplier of advanced power transmissionand distribution solutions that are mission-critical to the future development of the UK’senergy infrastructure. This will includedeveloping and extending ABB’s high levelrelationships with key government policymakers, industry bodies and customers topromote the technical and economicadvantages of ABB’s world-leading powersystems technologies. Thanks to his wealthof experience in the power transmissionindustry, Colin is especially well placed topromote, for example, the business case forusing ABB’s high-voltage direct current(HVDC) technology to create the enhancedinfrastructure essential for the effectiveintegration of offshore wind power within the UK grid.

Speaking about his new role, Colin said“This is a great opportunity that enables me

to apply my knowledge, skill and experienceto support the growth of ABB’s UKbusiness. It is an exciting time to work in theUK power sector with the growth ofrenewable generation, the development of smarter networks and the drive towards more efficient production and useof energy.

ABB is a company with a fantastic culture and tradition and I am lookingforward to adding value to ABB and its customers.”

“The UK energy market faces some keytechnical and economic challenges over thenext few years” commented Stephen Trotter, Head of ABB's Power SystemsDivision in the UK. “Colin's appointment willensure that we can work pro-actively withthe various stakeholders – utilities,developers, governmental and nongovernmental organisations and financialinstitutions, understanding the business andregulatory environment and ensuring thatthe market is aware of the value andsolutions ABB can provide across a rangeof technologies – HVDC, energy storage,smartgrids, network protection and control,software, offshore wind, power generation,energy efficiency, rail electrification andtidal/marine.”

New Head of Regulatory Affairsand Technology for the UK

In October 2011 we were pleased to say‘you’re hired’ to the latest class of talentedyoungsters to join our successful ABBPower Systems apprentice scheme. Wereceived a record number of applications for our 2011 apprentice programme and the applicants faced a tough selection process.

The new apprentices are now hard atwork, both at our offices in Stone,Staffordshire and studying at Newcastle-Under-Lyme College. At the same time weare already starting the process for thisyear’s apprentice intake.

‘You’re hired’ - new apprentice class of 2011

We are delighted to report that Colin Green has joined ABB in the new role of Headof Regulatory Affairs and Technology for the UK.

Colin Green

Power Products and Power Systems FFWD 1|12 7

News

6 FFWD 1|12 Power Products and Power Systems

News

ABB has won a major orderfrom E.ON UK, to supply thepower export cables forHumber Gateway offshorewind farm.

Power export cable for HumberGateway offshore wind farm

The contract includes 2 x 14 km circuits of132 kV 3-core AC submarine cable, withintegrated fibre optics and accessories, thatwill connect Humber Gateway, one of theUK’s largest offshore wind farms, to themainland grid.

When completed, in spring 2015,Humber Gateway will consist of a 73 turbinearray that will generate up to 219 MW ofelectricity, enough energy to power up to170,000 homes. The wind farm will belocated 8 km off the East Yorkshire coast,just north of the mouth of the river Humber.

The cable will be manufactured by ABB’sfactory in Karlskrona, Sweden, with deliveryscheduled during the summer of 2013.

East Kilbride office establishedABB’s new office in East Kilbride nowprovides a local hub in Scotland for ourPower Systems division. This effective localpresence will enable customers in Scotlandto access ABB’s state-of-the-art solutions tosupport the major investments they aremaking to expand and upgrade Scotland’selectricity transmission, distribution andrenewable energy systems.

The office, at the Technology Centre onthe Scottish Enterprise Technology Park inEast Kilbride, will be the base for a number

of new ABB roles working on the full projectdelivery – from inception, tendering anddesign through to commissioning andhandover – of the many multi-million poundschemes crucial to upgrade and enhanceScotland’s high-voltage power transmissionand distribution infrastructure to integratethe country’s fast-increasing level ofrenewable energy generation.

The positions created initially in ABB’sEast Kilbride office will require considerableadditional labour market resource and

support, both directly from ABB and withinour wider supply chain, to be based onconstruction sites throughout Scotland.Although this is the first ABB Power Systemsoffice in Scotland, ABB already has anestablished and thriving business inAberdeen, serving mainly the oil and gasindustries, as well as service personnellocated throughout Scotland. ABB is also amajor investor in Aquamarine Power, a waveenergy technology company with headoffices in Edinburgh.

New indoor high voltage substationcompleted for Northern Powergrid

The project has reinforced grid reliability andensured security of supply for the majorpopulation centre served by the Tynemouthsubstation by replacing outdoor AIS (air

insulated switchgear) equipment that wasnearing the end of its service life. The use ofABB’s state-of-the-art compact ELK GISequipment enabled the new substation to be

built indoors, within a purpose-designedbuilding that occupies around one quarter ofthe space required by the old substation.

Reinforcing our UK sales operationWe are pleased to announce that David Hughes, who was a wealth of experience in ABB’s UK operations, has been appointedas our new Head of Front End Sales (FES) UK. He takes over the role from Richard Oulton who has moved to ABB’s High-VoltageMarketing & Sales function in Zurich.

ABB has handed over Northern Powergrid’s new 132 kV indoor GIS (gas insulatedswitchgear) substation at Tynemouth following the successful on-time completionof a turnkey design and build project.

delivery. In fact, the whole process fromdesign, engineering, building the panels,carrying out the FAT (factory acceptancetest) and shipping them to site wasaccomplished in just three months.”

Flexible open system architectureThe adoption by ABB of the IEC 61850standard offers significant technicaladvantages through its flexible open systemarchitecture. These include a standardizedmodel of the IEDs and their data andcommunication services, full interoperabilitybetween electrical devices from differentvendors, reduced cabling and effectivefuture-proofing of the infrastructure bymaking it easy to extend and update asneeds change.

The protection and control system forWarrenby substation is based on IEDs from ABB’s Relion® family of equipmentdeveloped specifically to implement the core values of the IEC 61850 standard. Theyinclude Relion RET 650, RET 630 and RET 615 transformer protection and control devices. As an example of the ease of integration with third-partyequipment, the scheme incorporates anAVC (automatic voltage control) devicesupplied by another manufacturer.

One of the key technical challengessolved by ABB in designing the system was to ensure that it meet the needs of theengineering recommendation G59, that setsout the standards required for theconnection of a generating plant to thedistribution systems of a licensedDistribution Network Operator (DNO).

Rigorous FATThe rigorous FAT for the Warrenby panels was carried out at ABB’s uniqueautomated System Verification Simulator(SVS) based at Stone, Staffordshire. Ratherthan carrying out manual switching ofequipment to simulate the operation ofsubstation plant, the SVS is able to duplicate the whole substation within the test laboratory. It runs automated, self-monitoring test sequences to provide ahigh level of rigour and repeatability as wellas a full audit trail.

“Teesside Offshore Wind Farm is a vitalreference project that confirms ABB’scapability to deliver IEC 61850 substationprojects” concludes Andy Osiecki. “It isproof positive that this key new developmentin substation design is now making thetransition from the laboratory to practicalreal-world applications.”

Power Products and Power Systems FFWD 1|12 9

Network Management

8 FFWD 1|12 Power Products and Power Systems

Network Management

The project for Warrenby substation, the wind farm’s onshore connectionconstructed by Morrison Utility Services, isa significant development as ABB’s first UKimplementation of the global IEC 61850standard that represents a major stepforward in simplifying the integration ofintelligent electronic devices (IEDs).

The offshore wind farm at Redcar,Teesside consists of 27 turbines producing

power exported by 33 kV subsea cables toWarrenby, where it will be stepped up by twogrid transformers to 66 kV so it can be fedinto the regional and national grids via theNorthern Powergrid network.

Complete protection and control systemMorrison Utility Services, the UK’s leadingutility service provider, awarded ABB thecontract to provide the complete protection

and control system for Warrenby substation.According to Andy Osiecki, ABB’s GeneralManager for Power System NetworkManagement, “the Teesside Offshore WindFarm project has been a significantchallenge, working not only with a newcustomer, but also a whole new technicalapproach that effectively required us to startfrom a blank sheet of paper, and alsocombined with the need to ensure fast-track

IEC 61850 substation protectionand control scheme delivered forTeesside Offshore Wind FarmABB has delivered a state-of-the-art substation protection and control system,based on the IEC 61850 international standard for substation automation, for EDFEnergy Renewables’ Teesside Offshore Wind Farm.

Safety by design features include special feet to improve cabinetstability during assembly.

Power Products and Power Systems FFWD 1|12 11

Rail

10 FFWD 1|12 Power Products and Power Systems

Substations

This involves running real trains – a Eurostarand an Hitachi Class 395 – on arepresentative section of the network toconfirm the capability of the ABB equipmentto prevent voltage drop issues on thetraction power catenary supply.

The 68 mile (109 km) High Speed 1 route, from the Central London terminal atSt Pancras International to the ChannelTunnel at Dover, is used by Eurostar trainsoperating the international high speed routes between London, Paris and Brussels as wellas high speed domestic trains that provide a commuter service betweenLondon and Kent.

The High Speed route is supplied withpower on the 2 x 25 kV principle usingautotransformers. Its nominal line voltage istherefore 25 kV. There are, however, somesections of the line where it can drop as lowas 17.5 kV, causing a reduction in overallsystem performance as well as spurioustripping of the network protection andcontrol systems.

Voltage dropThe cause of the voltage drop is the inherent design of the isolation transformers (used to isolate between High Speed 1’s AC traction power supply and the adjacent Network Rail DCtraction power supply), located insubstations along the line. This is becausethey require large magnetising currents and therefore demand substantial inductive reactive power, which results in adrop in the voltage supply as seen by thetrain’s catenary.

A number of studies commissioned byHigh Speed 1, including a detailedinvestigation by ABB’s power quality expertteam based in Sweden, confirmed that areduction in the reactive power demandfrom the isolation transformers will improvesystem performance. ABB was thenawarded a major contract to design,

develop, manufacture and install a turnkeycapacitive compensation solution that willeffectively cancel out the inductive powerdemand of the transformer, and hencereduce the voltage drop.

Harmonic filtersThe ABB solution for High Speed 1 is basedon harmonic band pass filters with a ratedoutput of 1512 kVAr, each comprising a 6.4 MVAr capacitor bank and a 303 mHinductor. This equipment installation alsoincludes associated protection and controlequipment and a switch-disconnector thatenables it to be isolated from the network formaintenance and repair.

A total of 17 capacitive compensationfilters have been installed at nine AC/DCcompounds at strategic positions along the line.

“The strength of ABB’s technical solutionis of course vital to the success of the High Speed 1 project. However, our overalldetailed, consistent and consultativeapproach to the stakeholder managementof all the parties involved during theconstruction and installation phases whileworking alongside a live operating railway

network is just as important,” said SeamusO’Neill, ABB Power Systems OperationsManager for Rail. “For example, we workedvery closely with the High Speed 1 andChannel Tunnel Rail Link (CTRL) SystemReview Panel, who are responsible for theintroduction of all new assets, to ensure thatour project met their stringent technical andoperational needs.”

“Furthermore, during the equipmentdelivery and construction phase the ABBteam worked very closely with High Speed1’s own stakeholder management team tosupport their efforts in liaising with localauthorities and residents to minimize anypotential disruption.”

Live testsThe ABB capacitive compensation filtershave already passed comprehensive factory acceptance tests (FATs) and pre-commissioning testing with flyingcolours. Now, in the live test phase, trainsare being run between two selected pointson the High Speed 1 route to validate thedesign and prove their capability, ready forall nine sites to be put into full operation later in 2012.

ABB is well known for its superb long termtrack record in delivering major multi-millionpound turnkey substation projects, such asConnah’s Quay – one of Europe’s largestsubstations – which you can read about inthe other pages of this newsletter. What isperhaps not so well appreciated is that weare equally adept at working on smaller value projects such as the delivery ofindividual packages.

ListeningThat is why over the past year or so we havespent a lot of time talking to our customersand importantly listening to exactly whatthey need in terms of delivery models andprocesses when we work with them onlower level contracts. A clear pictureemerged that a ‘one size fits all’ servicesimply isn’t appropriate. What is needed is atotally flexible, tailored service that candeliver the ideal response for each project.

An important change is reflected in theadoption of multi-functional roles. Thismeans that the project manager might alsobe the design engineer and then follow onto be the site manager. While making thesechanges, the over-riding concern is ofcourse to maintain the outstanding levels ofhealth and safety performance, on timedelivery and quality demonstrated on ourlarger projects. In essence, the aim is todeliver ‘big project’ performance for oursmall project customers in a model thatmeets their needs.

Encouraging resultsWe rolled out this new approach in 2011and the results have been extremelyencouraging, both in terms of winning ordersand in the feedback from customers on ourtender submissions. The approach to smallprojects is continuing to evolve as we createa new team with the specific skill sets

aligned to the needs of this market,especially in terms of flexibility, adaptabilityand speed of response.

Upgrades and extensionsTypical utility substation projects that theteam is focusing on include upgrades and extensions, such as circuit breakerreplacements, as well as system integration or installation of equipment. In fact, we anticipate that the need formodification and extension of substations is set to increase significantly as they have to adapt to the increasing demands of renewable energy sources inthe UK grid.

Overall, the message is that ABB nowhas the flexibility to support any size ofsubstation project from £100k to £100million. And for what some may describe asa small project we still aim to deliver bigproject performance and quality.

Flexibility is the key for smallersubstation projects Jon Downs, General Manager Utility Substations, explains how ABB has replacedthe old ‘one size fits all’ approach with a new philosophy tailored to meet the needsof smaller substation projects.

High Speed 1 power qualityproject enters test phase The start of on-line testing is a critical milestone in ABB’s project todesign, manufacture and install state-of-the-art capacitive compensationsystems for High Speed 1.

Power Products and Power Systems FFWD 1|12 13

HVDC

12 FFWD 1|12 Power Products and Power Systems

HVDC

Hybrid DC Breaker

Main DC Breaker

Residual DC Current

Breaker

Current Limiting Reactor

Fast Disconnector Auxiliary DC Breaker

As you can see from the other stories in thisnewsletter, High-Voltage Direct Current(HVDC) technology is well established inapplications such as bringing offshore windpower to shore, supplying oil and gasoffshore platforms, interconnecting powergrids in different countries and reinforcingexisting AC grids. However, as the numberof these point-to-point HVDC connectionsincreases, it is becoming apparent that itwould be beneficial to connect them directly, rather than through the broader AC grid, as they are currently. This is creating interest in plans for HVDC supergrids.

The creation of an HVDC supergrid is aconsiderable technical advance on singleroute and multi-terminal HVDC schemes.Multi-terminal HVDC installations have tapsalong the DC line, however a true DC grid ismeshed and provides multiple power flowpaths between two points, and might havesingle or multiple DC voltage levels. Theadvantages of DC networks are in flexibilityand security, in addition to numerous capital

and operating cost incentives. Indeed, manyof the reasons for developing meshed ACgrids at the beginning of 20th century applynow for enhancing HVDC into DCtransmission grids.

Hybrid HVDC breakerFor smaller regional grids, multi-terminalHVDC technology is available and ready togo now. However, in developing large inter-regional DC grids we need to achieve thesame levels of reliability and performance asAC grids. This has not been possible untilnow, due to the lack of a suitable DCbreaker for isolation of a faulted line or unit.In fact, the relatively low impedance in theDC grid means that, should a short-circuitfault occur, the fault penetration is muchfaster and deeper than in an AC grid. Fastand reliable HVDC breakers, capable ofclearing a fault within a few milliseconds, aretherefore required to avoid a collapse of thecommon DC voltage.

The existing mechanical HVDC breakers,capable of interrupting DC currents within

several tens of milliseconds, are too slow tofulfill the requirement of a reliable DC grid.Furthermore, they are complex deviceswhich include additional passivecomponents to create the resonance circuitrequired to generate current zero crossingfor successful breaking of the current oncethe contacts open.

Semiconductor-based DC breakers caneasily overcome the limitations in operationspeed but generate large transfer losses.ABB has now taken the advantages ofmechanical and semiconductor designs andcombined them in a prototype hybridbreaker that offers both fast operation andreduced transfer losses.

ABB is also addressing a number ofother technical issues relating to multi-terminal grids including:

• Power flow control• Automatic network restoration• DC/DC converters for connecting

different regional systems.

Hybrid HVDC breakers – a vitalbreakthrough for Europe’s DC gridPeter Jones, Engineering Manager Grid Systems for ABB UK, explains why therecent announcement of ABB’s Hybrid HVDC breaker concept is a crucialdevelopment in plans to create large DC grids.

Hybrid HVDC breaker

Fenno-Skan 2 commissionedABB has successfully commissioned theFenno-Skan 2 HVDC power link betweenFinland and Sweden, a cable-based power transmission system that enables the exchange of an additional 800 MW of power between the twocountries, mitigating transmission bottle-necks in the region. The Fenno-Skan link isowned and operated by Fingrid andSvenska Kraftnät.

The installation includes two converterstations, one situated in Rauma, on theFinnish side, and the other in Finnböle, inSweden. The control system of the originallink will also be upgraded. The newlycommissioned link will run in parallel withFenno-Skan 1, delivered by ABB in 1989providing a bipolar link to enhance thecapacity for power trading and improve thesecurity of supply in the region.

Valhall offshore platform power link completedABB has successfully commissioned anHVDC Light link that enables onshore powerfrom Norway’s mainland grid to supply BP’sValhall multi-platform complex in the NorthSea. The new link allows BP to substitutethe use of offshore gas turbines to generateelectric power thereby eliminating up to300,000 tons of carbon dioxide (CO2)emissions a year - equivalent to the annualemissions of around 125,000 modernEuropean cars.

The installation includes one converterstation onshore connected by an HVDCsubmarine cable to a second converter onthe platform, about 294 km offshore. Itallows 78 MW of power to be supplied fromthe mainland to run the field facilities,including a new production and living quarter platform.

Fenno-Skan 2 Swedish HVDC station

Power Products and Power Systems FFWD 1|12 15

Design engineering

14 FFWD 1|12 Power Products and Power Systems

Design engineering

As well as being ABB engineering manager,I am also the detailed design manager forNational Grid’s Electricity Alliance Central(EAC), a consortium of ABB, Morgan Sindalland Atkins, working on high profilesubstation projects such as Carrington,Cleve Hill and Connah’s Quay.

In the nearly two years I have been in thisrole I have focused on introducing methodsthat can help improve our engineeringperformance, including reducing projectdelivery times, lowering costs and improvingquality through increased standardisationand repeatability.

Working across the diverse organizationsin the Alliance has presented a majorlogistical challenge. However, we have allpulled together to create a single deliveryteam, learning from each other and buildingon our individual strengths. Aboveeverything else, our success is based oneffective communication. One example ofthis is the creation of a design standardshandbook that has been made available onNational Grid’s Livelink system to shareideas and best practice relating to thedesign of primary and secondary plant andcivil engineering.

I believe it is vital to keep building anddeveloping our engineering team to ensurethat we have the resource in place as oursubstation business continues to develop.

We are committed to developing peoplethrough training, for example we haverecently helped one of our layout engineersto make the step up to become anapplication engineer. Thinking ahead, wehave a very active graduate trainingprogramme while we have just boosted ourintake of apprentices and they will add realvalue to the business in four years time.

To supplement our resources we are also working very closely with the ABB team in Chennai who are now providingexcellent electrical engineering support forprimary layouts and protection and controlsystem design.

Design for safety ‘Design for safety’ is a theme that runsthrough all our engineering activities. Onearea where some simple thinking ahead hasmade a tangible impact is in improvingaccess to gas insulated switchgear (GIS)buildings with access ramps that make iteasier to move test equipment in and out,as well as reducing manual handling.Lighting has also been brought down to alower level to eliminate hazardous darkareas, and we are also using reliable lowmaintenance lighting.

Attention to design has enabled us to reduce the size of diesel generators

Design engineering drives Alliance success Leigh Turley, ABB engineering manager, explains how design engineering is makinga significant impact on the delivery of high profile substation projects by NationalGrid’s Electricity Alliance Central (EAC).

required to supply backup power forsubstations by 40%. This saves fuel,reduces CO2 emissions and provides asmaller installation footprint. We have also been able to eliminate the need for a 48 V DC battery system completely,reducing infrastructure and equipment costs as well as commissioning andmaintenance costs.

Lean build approach for CarringtonCarrington Substation is a very high profileproject in which the EAC has built a new 7bay 400 kV GIS substation that will enablethe connection to the transmission systemof the new CCGT power station that is beingbuilt by Carrington Power Limited in GreaterManchester. This project was used topioneer a lean building approach that hasenabled us to reduce the amount of ‘wettrades’ required on site, such as concreting,brick laying and plastering.

An important innovation was the use of prefabricated relay rooms (PRRs). This enabled all the protection and control equipment to be assembled and tested into a series of containers in thecontrolled environment of our Stone facility. The containers were then transported to site and lowered onto basic concrete foundations, making the installation and commissioning process very fast and simple. Not only does reducing the time we have people

working on site save on project costs, it alsoreduces risk.

All that was then needed for the buildingitself was a basic weathershield to protectthe site equipment.

Cleve Hill to connect the world’s largestoffshore wind farm The lessons learned at Carrington wereapplied in the construction of a new 400 kVsubstation at Cleve Hill, near Faversham,Kent. This will form a key element of the upto 1,000 MW London Array – which will bethe world’s largest offshore wind farm whenit starts operation in 2012.

The Cleve Hill scheme required theconstruction of a five-bay 400 kV GIS indoorsubstation and associated infrastructure ona greenfield site. The location of thesubstation, which is cut into the side ofCleve Hill, means that it is subject to strictplanning constraints with regard to its designand size, and the project required carefuldesign and planning in order to gainapproval from the local authority.

Deeside – ABB’s largest ever substationproject The jewel in the crown for the EAC is theconstruction of a replacement for NationalGrid’s 400 kV Deeside substation – thelargest ever UK substation project that ABBhas been involved in. The new substation,scheduled for completion in 2018, will play a

vital role in the reinforcement of the high-voltage transmission infrastructure innorthwest England, and pave the way for the connection of new high-voltage direct current (HVDC) power links underconstruction.

The project scope includes theconstruction of a new 24-bay GIS substationand the supply of key products likeswitchgear and high voltage cabling, as wellas the integration of three 400/132 kV 240 MVA grid transformers and therefurbishment of an existing unit. Not only is the project technically challenging, it also requires effective liaison with multiple stakeholders such as National Grid, International Power, SP Manweb and EON.

One team, one goalWithin the EAC we have worked extremelyhard to integrate all the various differenttypes of engineers into a single deliveryteam. The hard work clearly paid off, asfeedback from the tutors at the IET PowerAcademy following a recent training exercisewas that they couldn’t tell which peoplebelonged to the individual Alliance partners,since they all presented as one team withone clear goal. And this teamwork hasbrought its own reward with the recentannouncement that National Grid hasextended the EAC contract for a further five years.

Connecting Carrington Power Station

GIS installation at Carrington Cleve Hill Substation site (Copyright London Array Limited)

Power Products and Power Systems FFWD 1|12 17

Power generation software

16 FFWD 1|12 Power Products and Power Systems

Power generation software

Commenting on the launch, Franz-JosefMengede, head of ABB’s power generationbusiness, said, “With the launch ofSymphony Plus, we are taking theSymphony success story to the next level,ushering in a new era of total plantautomation that is simple, scalable,seamless and secure.

“With Symphony Plus, we help balanceperformance objectives like asset availability,operational reliability and productionefficiency with business goals like asset lifeextension, carbon reduction and regulatorycompliance – providing plant owners with anessential tool for achieving sustainable andprofitable growth.”

Total plant automationSymphony Plus meets a broad spectrum ofplant configurations and applications,especially in the power and water industries.It is flexible and scalable; designed to servethe needs of everything from small,serverless applications to large multi-system, multi-server architectures.

Symphony Plus supports the seamlessintegration of field devices, process and turbine automation systems, electrical and Supervisory Control and Data Acquisition (SCADA) solutions, as well as business and maintenance systems. It provides users with a secure,reliable control environment and built-in

security features that prevent unauthorized system access.

Since its introduction over 30 years ago,the Symphony family has gone throughseveral evolutionary changes. ThroughABB’s ‘evolution without obsolescence’lifecycle policy, each generation of the familybuilds on and enhances its predecessors,while protecting the customer’s previouscontrol system investments. There are nowmore than 6,000 Symphony systemsinstalled worldwide, making it one of thewidest deployed process automationsystems in the world.

Symphony Plus provides users with acomprehensive view of the plant by

Symphony Plus in tune withcurrent and future powergeneration needsThe launch of Symphony Plus, the latest generation of our Symphony family ofdistributed control systems, continues ABB’s tradition of delivering power generationsoftware that helps drive plant productivity and energy-efficiency, as well asenhanced operational security, plant safety and lower total cost of ownership.

integrating data from all plant areas andsystems, including turbine control, electrical balance of plant and remoteSCADA systems. Through its openarchitecture, Symphony Plus seamlesslyconsolidates and rationalizes plant data toimprove operator response to changingconditions, so improving plant safety and uptime.

Transforms data into actionablebusiness decisionsInformation is the key to successful business performance. In Symphony Plus Operations, historical, process andbusiness data is collected from across the plant and stored securely. Transformingdata into meaningful information, Symphony Plus Operations presentspertinent, easy-to-understand information in intuitive desktop displays to all levels ofthe organization.

Unified engineering workbenchShort time to production is the measure ofengineering efficiency, Symphony PlusEngineering provides a world-classintegrated engineering environment, with the functionality required to engineer, configure, administrate, secure,commission and maintain any SymphonyPlus component.

Single control and I/O platformSymphony Plus provides total plantautomation from a single control and I/Oplatform that encompasses dedicated

interface modules and devices for all turbine types, OEMs and sizes, as well as an unparalleled selection of combustion instruments.

Electrical and device integrationSymphony Plus provides process andelectrical control from a single platform.Using open standard protocols like IEC61850 and Modbus TCP, Symphony Plusintegrates electrical devices with processcontrol and plant operations. It provides full integration of just about every type ofdevice, and enables the monitoring andmanagement of all plant assets at all levelsof the plant.

System securityABB understands the need to maintain asecure, reliable control environment whileexpending minimal time and effort. Inaddition to the many security features ofSymphony Plus, ABB actively participates in several major control system securitystandards committees. The guidanceprovided by these committees is designed to increase the integrity andconfidentiality of all system functions and help prevent unauthorized controlsystem access.

System 800xAABB will continue to deliver and support800xA, our mainstream offering for theprocess industries (and its specific add-onsfor power generation) when and where it is required.

Power Products and Power Systems FFWD 1|12 19

EBoP

18 FFWD 1|12 Power Products and Power Systems

EBoP

ensure the best performance and quality ofengineering workmanship and deliveries.

Through innovative electrical powerapplications, we help utilities to build andmaintain reliable power systems installationssafely and efficiently, providing cost-effectivesolutions that guarantee results.

ABB has supplied turnkey EBoPsolutions to a wide variety of projectsworldwide, resulting in these benefits:

• Integrated solution• Reduced project risk• Optimization of the complete system• Improved plant efficiency• Pre-tested plant configurations• Reduced overall project cost• Reduced number of interfaces• Consistent technology approach

and spares strategy• Improved project delivery • Reduced commissioning time and cost • Complete system approach to meet

compliance and local regulations• Common platform that minimizes the

required investment in hardware spares,reduces training needs and eliminatesthe need for serial interfaces.

HV electrical contract for BlackburnMeadows biomass energy project At the end of 2011, ABB made an importantbreakthrough within the UK’s biomasssector by securing a major contract withE.ON to supply the HV installation for abiomass-fired renewable energy plant underconstruction at Blackburn Meadows, near Sheffield.

The £120 million renewable energy plantwill be set near the site of the old TinsleyTowers, adjacent to Meadowhall, and whenoperational (in mid-2014) will generate up to 30 MW, enough to power 40,000 homes,by converting recycled waste wood into electricity.

As part of the turnkey EBoP solution for the Blackburn Meadows power plant, ABB will be responsible for the design, manufacture, supply, installation and commissioning of a fully complete HV installation associated with the safe and reliable delivery of electrical powergenerated by the steam into the local grid. Key products to be supplied include an 11/33 kV 40 MVA Generator Step Up (GSU) transformer and StationAuxiliary transformers, 33 kV GISswitchboard and the associated protectionand control equipment including the site SCADA system that will interface withDCS systems.

Turnkey EBoP solution for Didcot OCGTABB’s momentum in UK EBoP projectscontinued in early 2012 with the award of amajor contract by RWE npower to supply aturnkey electrical balance of plant (EBoP)solution for the repowering of the OpenCycle Gas Turbine (OCGT) plant at DidcotPower Station in Oxfordshire.

The Didcot OCGT plant, comprising fourdiesel fired turbines with a total capacity of 100 MW, is designed specifically forpeaking operation. During periods of high demand, it offers a flexible, reliable and fast-responding source ofadditional capacity to provide support for theNational Grid. In the repowering project theOCGT plant’s electrical control andprotection systems are being upgraded tothe very latest operational standards.

ABB’s turnkey EBoP solution for theDidcot OCGT power plant includes thedesign, engineering, supply, installation andcommissioning of all the equipment and civilengineering required to control the electricalpower generated by the gas turbines and to deliver it safely and reliability into the local grid. Key systems to be suppliedinclude an 11 kV substation based on ABB’s UniGear ZS1 switchgear fitted withVD4-G Generator Circuit Breakers, auxiliarytransformers, and the protection and controlequipment including the control system that will interface with the DCS at Didcot BCCGT station.

ABB has the capability, experience and in-house technologies to deliver turnkey EBoPsystems and plant packages tailored to awide variety of applications (new build andretrofit), especially gas-fired combined-cyclepower plants, coal-fired boiler power plantsand hydro-electric plants, while ourcomprehensive portfolio extends toembrace renewable applications particularly

energy from waste and biomass, as well as industrial-sized turbine and boiler power schemes."

Our EBoP service covers every electricalcontrol and instrumentation system andcomponent in the power plant, apart fromthe generator and turbine. This includes abroad portfolio of products and solutionsthat provide a single source of supply for

both new build and refurbishments projects, from high voltage down to the lowvoltage level.

ABB takes responsibility for the completeengineering, supply, manufacture, delivery tosite, installation, commissioning, testing andquality of the EBoP package. Direct controlover all engineering and projectmanagement functions enables ABB to

EBoP – delivering thebalance of powerTony Rooney, Head of ABB’s UK Power Generation business, outlines ourcomprehensive service for electrical balance of plant (EBoP) projects.

Blackburn Meadows biomass energy project

UniGear ZS1 switchgear

Transport for London (TfL) has a number ofexisting 132 kV BSPs that supply power forLU. This additional BSP is now needed toincrease the available power to support the full operation of new air-conditionedrolling stock that, since 2010, is beingphased in on the sub-surface (SSL) lines –the Circle, District, Hammersmith & City and Metropolitan.

The BSP’s desired 120 MW capacitydictated that it should be located relativelyclose to a grid supply point. It also had to be located close to the LU infrastructurein order for the necessary cable connections to be made between it and the existing distribution system. Themost appropriate site for the new BSPsubstation was identified adjacent to anunderground station.

Restricted siteThe new BSP is designed to take electricityfrom a nearby National Grid 400/132 kVsubstation (constructed by ABB in 2004)and step it down through transformation(132/22/11kV) to feed into the LU powersupply system. In the past there werehouses and shops on the site, but they havebeen long since demolished and mostrecently, the site was used as a car park.The major challenge for ABB has been inworking within this restricted site, hemmedin on all sides with an operating railway close by, to create a large, modernsubstation building.

The project commenced in 2009, andABB has focused on the excavation and civilworks to create a new cable and switchgearbasements and multi-level reinforcedconcrete building. The scale of this exerciseis illustrated by the need to remove 11,000cubic metres of spoil materials – some 2,300lorry loads. Extensive deep piling has alsobeen carried out to create the foundations.This level of civils work in a busy area ofLondon has called for a very detailedapproach to logistics and communications,not only with contractors and travelauthorities but also in ensuring minimaldisruption for the local community.

Electrical equipmentFollowing completion of the civil works, ABB moved on to install the electrical equipment. This includes: three22/11 kV 25 MVA coupling transformers;two 132/22 kV 120 MVA grid transformers;a 35 panel 22 kV switchboard featuring ZX2 GIS (gas insulated switchgear); a 27 panel 11 kV switchboard featuringUniGear AIS (air insulated switchgear); LV switchgear; two 11 kV earthing / auxiliarytransformers; ventilation system andassociated mechanical systems; 110 Vbatteries and charger.

A major project milestone was thesuccessful delivery and installation of the twogrid transformers, each weighing 97 tonnes,completed over two weekends at the end of2011. Transporting the transformers into the

centre of London and manoeuvring theminto position was a highly complex logisticalexercise requiring months of planning withABB’s transportation partner ALE (AbnormalLoad Engineering) to develop the optimuminstallation methodology.

Stakeholder managementEqually important was detailed attention tostakeholder management. This involvedworking in close liaison with the localcouncil, police and residents to identify thebest route, arrange the necessary roadclosures, traffic diversions, suspension ofparking spaces, removal of traffic lights andsigns to enable the two massive loads toreach the site with minimum disruption.

The substation is also being providedwith new SCADA RTU (remote terminalunits) for the 11 kV and 22 kV switchgear.Extensive fibre optic cabling will be installedto provide the communication path betweenthe BSP, other substations and the LUcontrol centres.

In its first large scale cabling exercise forLU, ABB is also carrying out cabling worksassociated with the BSP including around55 km of 22 k and 11 kV XLPE cableinstalled in tunnels and ducts.

Power Products and Power Systems FFWD 1|12 21

Project delivery

20 FFWD 1|12 Power Products and Power Systems

Project delivery

New BSP substationwill provide essentialpower boost forLondon UndergroundThe current major project to create a new Bulk Supply Point (BSP) for LondonUnderground (LU) provides a perfect example of ABB’s capability to deliver acomplete design, project management and construction service for rail substationprojects. This capability that not only includes all the electrical equipment, but alsocabling and the very substantial civil works required to create a new substationbuilding within an extremely restricted footprint.

Two grid transformers have now been installed at the BSP

The new BSP project isscheduled for completionin the summer of 2012.

Power Products and Power Systems FFWD 1|12 23

Medium voltage

22 FFWD 1|12 Power Products and Power Systems

Medium voltage

The GridShield recloser enhances gridreliability and efficiency by providing anautomatic response to system disturbances.

Reclosers combine a circuit-breakingfunction with the ability to restore the powerautomatically and quickly, so that temporaryfaults are less likely to result in prolongedpower outages for utility customers.

The GridShield recloser is intended for use on distribution feeders or in substations,and incorporates a number of designfeatures aimed at maximising long-termreliability and minimising routinemaintenance needs.

The GridShield recloser has also beendesigned to meet the challenges of

enhanced grid automation. It offers thecapability to perform as recloser, breaker,automated switch or sectionalizer, or evento connect distributed generation to the grid or to communicate GOOSE(Generic Object Oriented Substation Event) messaging utilizing the IEC 61850data model.

New generation recloser is ready forcurrent and future grid challenges

RER620 relay – part of ABB’s newRelion® family of IEDsThe GridShield recloser is controlled by the RER620 relay, which is part of ABB’snew generation Relion® family of intelligentelectronic devices (IEDs). The RER620provides extensive protection andautomation capabilities based on full native implementation of the core values ofthe IEC 61850 standard. In addition to IEC61850, the relay also supports the industrystandard DNP3.0, IEC 60870-5-101, IEC60870-5-104 and Modbus® protocolsensuring easy incorporation within existingsystems with the flexibility to migrate easilyto IEC 61850.

When integrated with ABB’s COM600station automation device, the RER620 canbe used to perform network-level controland system management functions. Inapplications using smart peer-to-peerGOOSE communications, the RER620delivers enhanced fault detection, isolationand restoration schemes, re-routing loadswhile maintaining protection coordination toprovide power for the healthy portion of thefeeder swiftly and effectively.

High impedance fault detection – sensinga downed conductor – is one of theadvanced integral protection features of the GridShield recloser and RER620combination. The GridShield recloser also

provides advanced time synchronizationcapabilities that eliminate the inaccuracyissues related to the time stamping ofdisturbances and other events.

New generation insulation material andother important featuresThe use of hydrophobic cycloaliphatic epoxy (HCEP) as insulation material reduces the likelihood of flashovers andinsulator erosion.

The creepage performance of theseHCEP insulators is the best in the industry,and far exceeds the requirements of ANSIstandards. In addition, it exceeds IEC LevelIV requirements for equipment operating inpolluted environments.

The magnetic actuators and vacuuminterrupters are rated at 10,000 full-loadoperations. The actuators require no routinelubrication, maintenance or adjustments;and the bi-stable technology means nopower is required to maintain an open orclosed position.

No electronics are housed in theinterruption compartment, reducing unitdown time and eliminating the costs of lineswitching when servicing the unit controls.

Single or triple-phase applicationsBecause there are three independentactuators fitted in the cabinet, the GridShieldrecloser can be used in single or triple-phasetripping applications. The single phasetripping capability reduces the number ofmomentary interruptions caused by onephase to ground temporary faults.

Why use reclosers?

ABB’s new GridShield® outdoor vacuum recloser for 15 kV and 27 kV feeder andsubstation applications has been developed to meet the growing need for increasedautomation in electricity distribution networks, higher service reliability and lowernetwork maintenance and management costs.

A recloser is a protection device forelectrical distribution networks. Itcombines a circuit breaker that trips if an overcurrent is detected (indicating a short circuit somewhere in a section ofthe network), with an electronically-controlled reclosing function thatautomatically restores power to theaffected line if the fault clears itself quickly – which usually happens around80 percent of the time.

There is a double incentive forelectricity distribution companies todeploy reclosers in their networks. Thefirst is that reclosers prevent transientshort circuits from triggering prolonged

power outages. This results in bettersupply continuity to customers. Thesecond benefit is that reclosers restorepower automatically, without requiring anengineering site visit.

A transient short circuit is the type of event that can be caused, forexample, when a branch of a treemomentarily touches overhead cablesas it falls to the ground. Reclosershandle this type of event much betterthan circuit breakers. Typically, powerwould be restored to customers in amatter of a few seconds or less. Only ifthe cause of the short circuit has notcleared itself would the recloser keep

the breaker open until the cause ismanually cleared.

Reclosers like the new ABBGridshield also have electronic controlequipment with multiple networkinterfaces, so the reclosers can beintegrated into a wider networkautomation strategy. However, even witha fast-acting recloser installed in a feeder network, a transient short circuit will still cause a momentaryinterruption to customer supplies. Butthis is much preferable to a poweroutage that lasts until a maintenanceteam can get to the breaker site torestore power.

Power Products and Power Systems FFWD 1|12 25

Grid connection

24 FFWD 1|12 Power Products and Power Systems

Circuit breaker replacement

The project, featuring ABB’s state-of-the-artUniGear primary MV switchgear, includesthe modification of the site’s single existing33 kV circuit breaker and the installation ofan additional second circuit breaker toensure fail-safe operation.

Construction of Cwm Dyli commenced in1906 to supply power for Wales’ thenprosperous slate industry. It also producedelectricity for the first ever transatlantictransmission station set up by Marconi in1912, near the village of Waenfawr,Caernarfon. Water for the site comespredominantly from the Llydaw lake some320 metres above the site high on theslopes of Mount Snowdon and travels to thepowerhouse through a two kilometre longpipeline. The site was rebuilt in 1989 , whenthe original Pelton wheel turbines werereplaced by a single Francis turbine capableof producing 9.8 MW of green energy.

Reliability, safety and securityThe substation equipment from the 1989rebuild is now nearing the end of its servicelife. ABB is therefore upgrading thesubstation with the latest switchgear andcircuit breaker technology to ensure theoptimum reliability, safety and security ofsupply. The existing site circuit breaker willbe modified to meet the latest standardswhile a new second circuit breaker willinstalled in the form of ABB’s well provenVD4 vacuum circuit breaker fitted in aUniGear air insulated switchgear (AIS) panel.Other work will include the installation ofearthing transformers and the modificationof the protection and control circuits withnew current and voltage transformers withmetering capability.

Listed buildingThe Cwm Dyli project represents twospecific challenges relating to its age andlocation. First, the Listed building (which isknown locally as the ‘Chapel in the Valley’due to its design) has required significant

attention to detail to obtain the requisiteplanning permission for the work to becarried out. Second, the valley locationmakes access difficult. When it was built,three traction engines were needed to help mule and horse teams haul heavymachinery and other supplies the eight miles over the Llanberis pass from the

railway station. This time ABB is relying on four-wheel-drive vehicles.

In order to avoid working through thewinter, the ABB site team carried out thepreparatory civil works in Autumn 2011.They will return in Spring 2012 to carry outthe installation and commissioning of theelectrical equipment.

Substation upgrade for the‘Chapel in the Valley’ABB has been awarded a contract by RWE npower renewables to upgrade thesubstation serving Cym Dyli, within the Snowdonia National Park, one of Britain’soldest hydroelectric power stations which started generation in 1906.

The new connection, comprising a 66 kVsite substation together with a 1.5 kmunderground cable, will enable SITA UK tofeed an additional 21 MW of power into thelocal grid via Northern Powergrid’s TeesNorth substation.

SITA UK specialises in the controlledincineration of residual waste, which cannotbe recycled or composted, to recoverrenewable energy in the form of electricity.The site at Haverton Hill Road, Billinghamcurrently has three Energy from Waste lines that process around 390,000 tons of household and commercialwaste a year to generate just over 29 MW. The site is now being extended with the construction of the North East

Energy Recovery Centre (NEERC), which will add two further processing lines capable of handling an additional 256,000 tons of waste a year to generate afurther 21 MW.

ABB is providing a complete gridconnection solution for SITA UK’s two newprocessing lines covering the design,manufacture, installation and commissioningof a new 66 kV substation, includingswitchgear and protection and controlsystems, and the underground cable link to the local Northern Powergridsubstation. The project is being carried out on a fast-track basis to ensure that thegrid connection is in place ready for theplant’s planned start-up in 2013.

“This latest contract for SITA follows the success of the similar grid connection project we carried out for thesite’s third processing line that came on-line in 2009”, said Richard Holliday, ABB UK General Manager – T&DInfrastructure & Grid Integrated Solutions. “It is a perfect example of ABB’s proven capability as an IndependentConnection Provider (ICP), as an everincreasing number of developers are nowcoming to us to help solve their utilityconnection issues by providing a project-focused single interface to drivedown costs, improve cash flow, speed upthe programme and reduce the overallproject risk.”

Fast-track grid connection forextension to SITA UK’s TeessideEnergy from Waste plantABB has been awarded a major contract by SITA UK, part of the SUEZENVIRONNEMENT group, to provide a fast-track grid connection for the extensionof its Energy from Waste plant currently under construction at Billingham, Teesside.

Co

urte

sy o

f N

orm

an C

hild

s P

hoto

gra

phy

SITA UK is the latest in ABB’s global series of waste to energy projects shown here

Acids form as a result of oil degradation dueto oxidation, indicating that the transformeroil is ageing. Corrosive sulphur is also wellknown as a significant cause of prematuretransformer failure as it reacts with coppercomponents to form highly conductivecopper sulphide that deposits on windingsand the paper insulation, causing abreakdown of insulating properties andresulting in shorting, arcing and even fires.

Deeside Power Station, which opened in1994, is a 515 MW CCGT (combined cyclegas turbine) power station owned byInternational Power GDF Suez and sited bythe river Dee in Flintshire, North Wales. It hasthree GSU transformers (two for each of thegas turbines and one for the steam turbine)that step-up the voltage produced by thegenerator units to the 400 kV required by theUK transmission system.

Oil tests carried out as part of a generalmaintenance programme had indicatedincreasing levels of acidity and the presenceof corrosive sulphur. The oil in each of thethree transformers had previously beenpassivated using 7 litres (100 ppm) ofIrgamet 39. Subsequent tests showed anunexpectedly high consumption of the

passivator so Deeside Power asked ABB’sspecialist UK transformer repair andmaintenance team to take further samplesand recommend remedial measures. Thesenew tests confirmed that the oil was in acondition where it needed reconditioning orreplacement. The main aim was to removethe acidity and sulphur that were reducingthe DP (Degree of Polymerization) value ofthe paper insulation, which is an importantindicator of its remaining service life.

It was decided to use ABB’s unique on-line oil reclamation service to reclaim the oilrather than replacing it with new. Thisprocess enabled the acidity and sulphur tobe removed over a period of time with thetransformers remaining energized, so thepower station could continue to operate atfull capacity without the need for an outage.

Mobile oil reclamation rigThe reclamation process, in which the oil iscirculated continuously through ABB’smobile oil reclamation rig, housed in a 40 foot trailer, took around 10 weeks foreach transformer due to the large volume ofoil to be processed – a 190 MVA GSUtransformer, such as the units at Deeside

Power, holds 70,000 litres. The progress ofthe reclamation process was monitored bychecking the colour of the oil as it changedfrom a dark brown to a light straw colour. Atthis point the oil was sampled for laboratorytesting to confirm the successful removal ofacids and corrosive sulphur.

Reclamation is superior to an oil changeInitially, it might appear that carrying out acomplete change of the transformer oilwould be a faster and more efficient method of eliminating the by-products of oil degradation. However, extensivelaboratory and field tests carried out by ABB have shown this offers only a shortterm benefit as the new oil soon becomescontaminated by the residual oil in the tank and the insulation. So, while thereclamation process is longer and slower, it provides a permanent long-term solutionthat restores the properties of the oil to very near those of new oil by removingacids, sludge and other degrading products like corrosive sulphur. This also hasa beneficial effect on the ageing of the paper insulation.

Power Products and Power Systems FFWD 1|12 27

Service

26 FFWD 1|12 Power Products and Power Systems

Service

Oil reclamation serviceprolongs active life for transformersABB’s state-of-the-art on-line oil reclamation service has helped DeesidePower Station to ensure the reliability and long service life of its three vitalGSU (generator step-up) transformers by removing high levels of acidityand harmful corrosive sulphur from their insulating oil.

Taking an oil sample from a transformer

The oil is circulated through the mobile rig Laboratory testing

Spalding – detuned PFC equipmentaddresses harmonic current issuesThe project commenced when CV Electrical,the contractor responsible for maintainingParagon’s electrical infrastructure, called inABB to investigate an issue with frequentnuisance tripping of the main incomingsupply protective device at the Spalding site.Paragon had already taken an importantstep in maintaining the site’s power qualityby installing a series of capacitor banks toensure that the power factor on the 415 Vnetwork was held at the acceptable industrystandard level of 0.95 lag. However, it wasfound that the harmonic currents present onthe network were causing the five capacitorbanks (5 x 50 kVAr) to degrade prematurely.Not only was this reducing the operatingefficiency of the capacitors, during peak loadperiods it was causing the main incomingbreaker to trip – a major concern for a sitewhere the reliability and availability of theproduction lines are core to its business.

It was actually Paragon’s investment inthe state-of-the-art printing technologyrequired to maintain its position as the UK’slargest manufacturer of self-adhesive foodlabels that was contributing to the problem.This is because advanced printingequipment utilises variable speed drives(VSDs) that are a notorious source ofnetwork harmonics.

ABB’s detailed investigation establishedthat the total harmonic distortion (THD) onthe network was above the recommendedlevels stipulated in Energy NetworksAssociation Engineering RecommendationG5/4-1 – Stage 2 Table 12 ‘Planning levelsfor harmonic current distortion andconnection of non-linear equipment totransmission systems and distributionnetworks in the UK’. If this issue, togetherwith possible system resonance, was notaddressed then the output of the existingcapacitors would continue to degrade overa period of time, reducing the power factorand allowing the site’s peak demand toincrease, with the possibility of further mainincomer tripping occurring.

The recommendation was to remove theexisting capacitors completely and replacethem with a 250 kVAr Advance automaticcapacitor assembly fitted with detuningreactors to mitigate the damaging effects ofthe harmonics. A year on from theinstallation, the Spalding site is operatingefficiently with no reported tripping incidents.

Boston – harmonic filtration solutionFollowing the success of the Spaldingproject, ABB was asked to investigateParagon’s Boston site. It was found thatagain the harmonic distortion on the networkwas outside the G5/4-1 recommendation.

ABB was able to offer the ideal solution inthe form of its new generation PQF (powerquality filter) family of active filters. Theyoperate by continuously monitoring thecurrent in real time to determine whatharmonics are present and then injectingharmonic currents into the network withexactly the opposite phase to thecomponents that are to be filtered. The twoharmonics effectively cancel each other outso that the feeding transformer sees a cleansine wave.

A 450 A PQFI unit designed specificallyfor heavy industrial loads was installed andharmonic distortion assessments carried outfollowing its commissioning confirmed thatthe harmonics are now limited to well belowthe G5/4-1 requirement.

Wisbech – PFC solutionAt Wisbech, ABB was asked to helpimprove the site’s power factor (PF). PF is essentially a measure of how effectively electrical power is being used.Ideally it would be 1 (unity), and the closer to this figure it actually is then themore effectively electrical power is beingused and vice versa. The investigationsfound that the PF of 0.845 lag was well below acceptable industry standardlevels, which usually call for a PF of 0.95 or better. In fact, a site PF lower than0.95 can now result in penalty charges being imposed by the local electricity supply company.

To rectify the situation, ABB installedsophisticated power factor correction (PFC) equipment in the form of its Advance 400 automatic capacitorequipment comprising a total bank of 300 kVAr, complete with a detuning reactor to eliminate any issues with network harmonics.

Power Products and Power Systems FFWD 1|12 29

Power quality

28 FFWD 1|12 Power Products and Power Systems

Power quality

Power quality issues put to bedfor Paragon Print & PackagingABB’s specialist power quality service has enabled Paragon Print & Packaging, theUK market leaders in food packaging for the fresh and chilled food sector, to solvepotential plant reliability and efficiency issues at three of its key printing facilities inthe east of England. ABB’s Advance power factor correction (PFC) systems havebeen installed at the Paragon sites in Spalding and Wisbech, while a PQFI activeharmonic filter has been installed at Boston.

PQFI filters

Power Products and Power Systems FFWD 1|12 31

Data centres

30 FFWD 1|12 Power Products and Power Systems

Data centres

Rather than dealing with separate suppliersfor individual project elements, a data centre developer can work with ABB tomeet all its power requirements from a singlesource. This saves both time and money. Italso has the advantage that all ABBequipment is guaranteed to work togetherseamlessly, ensuring fast-track installationand commissioning.

ABB’s scope of supply goes well beyondgrid connection, medium-voltage (MV) andlow-voltage (LV) switchboards, powerdistribution units, protection relays andtransformers. It also offers variable speeddrives (VSDs), motors and power qualityequipment. This all comes with theinstallation, maintenance and 24/7 servicesupport of a major global organization.

Grid Connection: As an Independent Connection Provider(ICP) registered under the Lloyds NERSscheme, ABB can offer a turnkey solution forcontestable utility connections at all voltagesto include the integration of Air InsulatedSwitchgear (AIS), Gas Insulated Switchgear(GIS) and Hybrid solutions. ABB offers acomplete one-stop shop package for theelectrical distribution in data centres. ABBcan also provide ‘Rapid Build Substations’that enable customers to have a gridconnection in the minimum time.

Medium voltage switchgear ABB offers the full spectrum of both AIS andGIS switchgear. With the growth in size ofdata centres the full load current and faultlevels can increase dramatically. ABB hasthe product range to cater for these and alldata centre applications.

An important element in ABB’s range isthe UniGear 500 R Fixed Circuit Breakerpanel, which is currently the most compactair-insulated MV switchboard on the market.A further advantage of the UniGear 500 R is that it coordinates perfectly with the well-proven UniGear ZS1 portfolio. So, forexample, it is possible to specify on thesame busbar: a UniGear with withdrawableincomer; fixed circuit breaker outgoing; andadditional starter switchgear.

Relion range of relaysABB has developed its Relion family of IEDs (intelligent electronic devices) tounleash the full potential of the IEC 61850standard for communication, Powermonitoring and interoperability of substationautomation equipment. This new familyincludes the Relion 615 relay that providesabsolutely selective protection, making itideally suited to data centre protection andcontrol applications.

DC power leads the way for data centreenergy efficiency Data centres consume around 1.5% of theentire world’s electric power. Given thetremendous growth that the industrycontinues to experience, energy efficiencyhas become a top priority.

DC (direct current) powered data centresare now being adopted across the industrylargely due to their cost advantage in termsof both initial investment (less equipment)and operating costs (greater efficiency). Butsignificant energy efficiency gains can alsobe made in a variety of areas such as:

• HVAC efficiency – variable speed drivesand high efficiency motors can cutHVAC costs by as much as 50%

• Facility efficiency – Electrical powerdistribution design can reduce energywasted in the facility by up to 30%compared to conventional designs • Personnel efficiencies – instrumentationcan be configured from a central controlarea, eliminating the need for engineersto physically adjust the device • Utility rates and billing – with the rightmonitoring and control capability, datacentre operators can take advantage oftime-of-use rates and demand responseprograms to lower electricity costs.

– Low voltage switchboards MNS system– iPDUs (Power Distribution Units)– Active filters– Power factor correction– Network communication– Air-insulated medium voltage switchboards– Dry-type transformers

– iPDUs (Power Distribution Units)– Rack power panel– Power measurement– Network communication

– EFF1 high efficiency motors– Inverter– Network communication

i-bis EIB/KNXNetwork communication

ABB’s data centre portfolio:• Grid connection solutions at all

utility voltage levels

• AC and DC power solutions

• HV, MV and LV switchgear

• Transformers

• Motor control centres (includingvariable speed drives)

• Power distribution units (PDUs)

• Rack power panels

• Protection relays

• Power quality solutions

• SCADA systems

• Electrical power monitoring andremote supervision

• UPS systems

• Data centre informationmanagement (DCIM)

• 24/7 service support

Delivering energy efficient data centrepower from incomer to serverThe developers and operators of today’s new-generation data centres make majordemands on their power network infrastructure. Downtime due to loss of powersimply cannot be contemplated, so operators insist on total reliability and availability.ABB has responded by developing a unique comprehensive approach that coversevery need from the incoming supply through to the server racks. This includes allthe AC and DC systems, automation and services required to deliver reliable andefficient solutions for a diverse range of data centre installations.

The ABB strategy for Data Centres is to provide the technology and servicesrequired to build reliable and efficient solutions that meet the client’s requirements.

Power Products and Power Systems FFWD 1|12 33

Corporate Social Responsibility

32 FFWD 1|12 Power Products and Power Systems

Switchgear

PASS M00 is a combination of well provenstandard components including: circuitbreaker, a spring operating mechanism,current transformer and an innovative newconcept for the combined disconnectingand earthing function. This five-positiondisconnector, which is integrated in the mainchamber, enables the following functions:

• Line disconnection• Busbar disconnection• Earthing of the line through the

circuit breaker• Earthing of the busbar through

the chamber

The multifunctional PASS M00 modulecan also integrate current and voltagetransformers, surge arresters and protectionand control systems. It is available for single and double busbar configurations,has a single and triple pole operatingmechanism option and is ideally suited

for use as a standard product in the design of new modular substations or forretrofit applications.

Wind farm applicationsPASS M00 is ideally suited to high-voltage(HV) wind farm collection grid applicationswhere it offers these advantages:

• Compactness due to full gas insulation• Fast installation time (no HV test is

required on site)• High reliability obtained through lean

design;• Fast repair in case of faults due to

modular assembly• Remote control provided by motor

operability;• Easy combination with oil insulated, gas

insulated and dry power transformers.

A case study of new generation offshorewind farms equipped with 5 MW turbines

revealed that the use of PASS M00 modulesin 72 kV collection grids made it possible tofit a complete HV substation within a towerwith the following advantages:

PASS M00 is perfect for wind farmHV internal collection grids ABB’s PASS series of hybrid switchgear modules combines the advantages oftraditional air-insulated switchgear (AIS) and advanced SF6 gas-insulated switchgear(GIS) technologies. The newest addition to the family is the PASS M00 range ofmultifunctional modules that cover voltages between 72.5 kV and 100 kV andbreaking currents up to 40 kA.

Cancer is the toughest fight most of us willever have to face. But there is a team ofpeople who are there to support every stepof the way and that’s the Macmillan team.They simply couldn't provide their vitalservices without the people who supportthem – people like you.

There are many ways that ABB staff hasgot involved in the past year – some moreenergetic than others! Among the moreenergetic activities were two separateclimbing expeditions to conquer Kilimanjaro,the highest mountain in Africa; a teamparticipated in the Great North Swim, the

UK’s biggest outdoor swimming event; andothers pounded 13 miles of Newcastle’sstreets to complete the Great North Run, theworld’s largest half marathon. Other moregentle fund-raising activities included the whole company participating inMacmillan’s annual ‘Wear your Macmillan t-shirt to work’ day.

Sharon Cottam from Macmillan CancerSupport said of ABB’s fund-raising efforts:“This is testament to the support from ABBstaff, raising yet another superb total in 2011of over £28,000. I cannot thank ABBenough. One in three of us will get cancer

and it’s the toughest fight most of us will ever face. By joining Team Macmillan in a fundraising event you're helping support people and their families living with cancer.”

Trevor Gregory, Managing Director ofABB in the UK, said: “Our staff arepassionate about supporting such aworthwhile cause as Macmillan CancerSupport. Thanks to the efforts of our staff,we are helping Macmillan to support cancersufferers, their friends and families. It’s bothhumbling and rewarding but something ABBis proud to be involved in.”

Supporting Macmillan Cancer Support ABB recently celebrated its 12th year as a supporter of Macmillan Cancer Support,during which time our UK employees have raised over £700,000 to help change thelives of people affected by cancer.

• Reduction in the number of arraysnecessary to export the energy produced

• Reduction in the number of cables inparallel for each feeder;

• Increase in the power capacity/currentampacity of a single feeder;