Annual Presentation for PLC Section

Welcome message from author

This document is posted to help you gain knowledge. Please leave a comment to let me know what you think about it! Share it to your friends and learn new things together.

Transcript

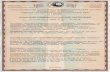

RC1 1740620, 42%

RC2 756595, 18% RC3

402815, 10%

RC4

430244, 10%

RC5 638637

RC6 155020

Unit wise expense

RC6

0

100000

200000

300000

400000

500000

600000

700000

800000

900000

1000000

Ramco tuning; 678640

UPS card repair 23951

RM plc upgradation 866812

Shell scanner, wifi modem 41222

Cables 78428

Other expense 51567

RC1 ExpenseRs17,40,620

0

50000

100000

150000

200000

250000

300000

350000

Rockwell License Upgradation;

318298

UPS card repair 204000

RM plc upgradation 108917

Shell scanner, wifi modem 54859

Cables 42078

Other expense 28246

RC2 ExpenseRs 756586

0

50000

100000

150000

200000

250000

Box Panel; 225000

PLC Card; 61000

CCR Lab; 37000

Cable 33000

Video kit 31000

Other (Jyotsna Ent)

15655

RC3 ExpenseRs 4,02,815

0

50000

100000

150000

200000

250000Box Panel; 225000

PLC Card; 91500

U6 Sec Crusher; 44000

OBCS 70180

MATERIAL EXPENSE

MATERIAL EXPENSE

RC4 ExpenseRs 4,30,244

0

50000

100000

150000

200000

250000

Controlnet cable; 195500

PLC Card; 180236

Others; 135700

N/W H/W 75700

UPS Shifting;42200

Antivirus 35600

RC5 ExpenseRs 6,38,635

0

10000

20000

30000

40000

50000

60000

70000

PLC Spare; 59000

KVM 42000

Beltsway; 33650

Biometric Lock;20550

RC6 ExpenseRs 1,55,020

Breakdowns & Problems(May-14)

SECTION REASON DURATION FREQ. TOTAL

CM3 DROP FAILURE PROBLEM 0.50Hrs 1 0.50Hrs

Breakdowns & Problems(Jun-14)SECTIO

N Stoppage ReasonDURATIO

N FREQ.TOTAL(Hrs

)

CM3 PLC DATA COMMUNICATION FAILURE 0.75Hrs 1 0.75

CM3 R.P. PLC (ROLCOX PANEL) HANGED 1Hrs 1.00 1

CM4 CNBR Hang Due to over heat 1Hrs 1.00 1.00

Breakdowns & Problems(July-14)

SECTION REASON DURATION FREQ. TOTAL

CM3 WATER PUMP TRIPPED DUE TO PACKING PLANT UPS SUPPLY FAILURE 1.08Hrs 1 1.08Hrs

Breakdowns & Problems(Aug-14)

SECTION REASON DURATION FREQ. TOTAL

CM3 ROLLER PRESS ROLCOX PANEL UNHEALTHY 4Hrs 1 4Hrs

Breakdowns & Problems(Feb-15)

SECTION REASON DURATION FREQ. TOTAL

CM3 Controlnet cable damage due to excavation work 4.67Hrs 1 4Hrs

Breakdowns & Problems(Mar-15)SECTION DATE REASON DURATIO

N FREQ. TOTAL

MARCH

CM3 08-Mar-15 COMPRESSOR TRIPPED DUE TO I/O SUPPLY FAILURE 0.42 1 1.08

KILN3

29-Mar-15 PLC RIOR REPLACEMENT WORK 1.58 1.00

2.00

29-Mar-15COOLER FAN 10 & 11 AND

GRATE 1&2 TRIPPED DUE TO L&T PLC DROP FAILURE

0.17 1.00

30-Mar-15KILN MAIN DRIVE COOLING BLOWER TRIPPED DUE TO L&T

PLC FAILURE0.25 1.00

• INSTALLATION OF BLADE SERVERS TO UPGRADE OLD SERVERS FOR FAST

SCANNING & TRENDING AND BETTER STORAGE OF DATA

• GPP DATA TRANSFER BETWEEN CEMENT PLANT AND POWER PLANT OVER OPC TO AVOID ANY

MISMATCHING IN PARAMETERS

• NEW ANDROID APPLICATION FOR PLANT INDICATION TO GET INSTANT ACCESS TO MONITOR THE PLANT RUNNING STATUS

ONLINE

• INSTALLATION OF ALL IN ONE PC FOR CCR OPERATION FOR VIEWING

• PREPARED LOGIC IN ALL THE UNITS TO CONTROL FLUSHING FROM KILN FEED

FLOWMETER TO AVOID PLANT STOPPAGES DUE TO AIR SLIDE JAMMING

• NEW WEB SERVER FOR PLC SECTION REPORTING

• WIRELESS SYSTEM FOR PACKING PLANT FOR ONLINE CORRECTION

AND REPORTING PURPOSE

• XRF AND RAMCO COMMUNICATION OVER ETHERNET FOR FASTER AND TROUBLE FREE OPERATION OF XRF MACHINES AND RAMCO

SYSTEM

• AUTOMATION OF NEW PHYSICAL LAB

Related Documents