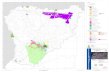

W P D 2-d Section X-X SPRING-LOADED WORK LOCATORS CP710 CP710-A ( Standard ) CP710-B ( Accurate ) CP710-A ( Standard ) CP710-B ( Accurate ) X X G 0.8 G 0 . 8 G 0 . 8 G 0.8 G 0 . 8 0.8 G G 0 . 8 H 4 D3 0.03 A A D4 30° Air Outlet D2 D1 S H H H 3 H 1 H 2 Body Quenched and tempered Black oxide finish Steel (S45C) Steel (SK95) Quenched and tempered Locating Pin

Welcome message from author

This document is posted to help you gain knowledge. Please leave a comment to let me know what you think about it! Share it to your friends and learn new things together.

Transcript

-

WP

D

d

Section XX

SPRING-LOADED WORK LOCATORSCP710

CP710-A(Standard)

CP710-B(Accurate)

CP710-A(Standard)

CP710-B(Accurate)

XX

G

G

G

G

G

G

G

H4

D30.03

A

A

D4

30

Air Outlet

D2

D1

SH

H1

H3H

1H

2

Body

Quenched and temperedBlack oxide finish

Steel (SC) Steel (SK95)Quenched and tempered

Locating Pin

-

*) The through hole can be chamfered up to 1x1mm.

5.8 8.2

CP710-06020B

7.6

CP710-08020B

7.810.2

CP710-08020B

Part Number

CP710-04015BCP710-05015B

Part Number

CP710-05015BCP710-06020B

CP710-04015B 4.8 6.2 3.8 5.2

5.6

H4 g

15

15

20

20

H1

D1

7.515

20 10

D2 H2

Continuing on Next Page

5.520.5 100

6.419.3

Support CapacityN

50

Weightg

7.4

6

8

9.9

H3

S

25

35

40

30

D

P

7.1 11

16

22 4.5

W d

5.14.1

97

3.1

D4

6

D3

CP710-04015A

Accurate

CP710-04015ACP710-05015ACP710-06020ACP710-08020A

Part Number

CP710-06020ACP710-08020A

CP710-05015A 3.8 5.2 4.8 6.2 5.8 8.2 7.810.2

9.9

7.4

Proper Through-HoleDia. *)

Proper Through-HoleDia. *)

20

18

H4

13

15

1020

15 7.5

Part Number

Standard

gH1

D1

D2 H2

63.1

gN

5.520.5

6.419.3

95

45

9.6

8

Support Capacity

6

7.6

30

40

Weight

35

25

22

16

4.5

117.1

4.15.1

79

H3

S D

PW d

D4 D3

13.58.611.6 16.5

26

45

3510

12.4 25 12.523

25

CP710-12025ACP710-10025A

160170

8.519.8

11.6

27.6

20.6

H

34.612.315.7 9.312.7

25

CP710-10025BCP710-12025B

9.6

27.6

20.6

H

34.6

CP710-10025ACP710-12025A

CP710-10025BCP710-12025B

25

12.52512.4

10 35

45

26

16.511.68.6 13.5

1708.519.8

9.312.712 16

-

When the workpiece is set the tapered pin is pressed down to locate it.The accurate style allows vertically as well as horizontally positioning the workpiece with accuracy.

Use of tapered pin allows secure locating with no clearance between the locating hole and the tapered pin.

Round Pin

Clearance

Present Method

Before Setting Workpiece

No Clearance

Imao Method

After Setting Workpiece

How To Use

Locating Pin IsPressed Down

H7-effective depth : 13CP710-12025CP710-10025 25 26

Series MH5

21 M40.7

16

H

15

20

d1

CP710-06020CP710-08020

CP710-05015CP710-04015

H7-effective depth : 8

H7-effective depth : 10

M Hex Socket Head

Mounting Hole Dimensions

MH

5d1

Accurate

-

NoteIn clamping hold down the workpiece by hand to avoid lift that can be generated by spring force.

Swing ClampQLSW

Related Documents