Data Center Cooling Modules www.ASTmodular.com

Welcome message from author

This document is posted to help you gain knowledge. Please leave a comment to let me know what you think about it! Share it to your friends and learn new things together.

Transcript

Data CenterCoolingModules

www.ASTmodular.com

1

TABLEOF CONTENTS

Executive SummaryWorldwide PUEs Comparison Operational Expenditure & ROI Selection Guide & Features Real Projects

To help reduce energy consumption in datacenters AST Modular has developed 4 ultra energy efficient and modular cooling solutions that can be implemented in both traditional and containerized datacenters. AST Modular Data Center Cooling Modules have been engineered with the aim of drastically reducing OPEX whilst allowing for future growth and density increase thanks to a scalable approach. Energy Efficiency and Modularity are indeed the cornerstone concepts of our newest addition.

In the attempt to meet the different scenarios that data center operators face, we have designed both air based and water based cooling modules. The four available models represent the fruit of our R&D work over the last 3 years and provide great levels of energy efficiency and security whilst still showcasing specific features. A selection guide at the end of this catalogue highlights common features and peculiari-ties attached to each of them to help you select the right technology.

EXECUTIVE SUMARY

Natural Free Cooling ModulesNFC

NFC Modules, a worldwide patented AST Modular’s technology, are an indirect air to air and evaporative cooling solution that leverage temperature differences between outside cold air and hot IT exhaust air to cool the data center. NFC Modules provide multiple types of econo-mization and are capable to select between air-to-air, adiabatic and mechanical cooling to run your mission critical applications in the most efficient way.

Chilled Water Block ModulesCWB

CWB Modules are a water based datacenter cooling technology composed of a chiller, variable-speed fans and a water coil whose surface is bigger than the one of a traditional Computer Room Air Conditioning (CRAC). The extended cooling surface of the coil allows the chiller to supply water to the coil at higher tempera-tures, thus resulting in improved energy efficiency.

Direct Free Cooling ModulesDFC

DFC Modules use external air to cool the datacenter by driving the air from the outside to the inside of the datacenter. The mechanical cooling support system is activated only when the external dry bulb tempera-ture exceeds 27° C and therefore does not meet ASHRAE requirements

Hot Corridor Exchanger ModulesHCX

HCX Modules are a water based overhead cooling technology composed of a chiller, variable-speed fans and a water coil, whose surface is bigger than the one of In Row Cooling Units. The extended cooling surface of the coil allows the chiller to supply water at higher tempe-ratures, thus resulting in improved energy efficiency.

2

Data Center Cooling Modules

3

Energy consumption is a critical issue for IT organizations today, whether the goal is to reduce cost, protect the environment or to keep the datacenter up and running. According to Gartner, energy-related costs account for approximately 12% of overall data center expenditure and are the fastest-rising cost in the data center. Power cost problems are likely to worsen during the next few years as organizations grow their technology infrastructure , emerging from a recessionary period. Data Center inefficiencies threaten the profitability of business.

SCALABILITY ENABLING FUTURE GROWTH AND DENSITY INCREASENFC and DFC Modules feature 50 KW cooling capacity for each module whereas CWB are available in 100KW and 150KW models. Finally HCX can be purchased in the 7,5KW and 20KW version. Regardless of the different cooling capacity, all the cooling modules have been designed to easily scale along with your business needs, allowing for additional cooling capacity to be deployed quickly in a live environment and without disruption to the service. This results in minimizing capital expenditure and maximizing efficiency.

RIGHT SIZINGWhen the IT load is uncertain data center cooling systems are often oversized and operate inefficiently. Therefore, it makes sense to plan for modular growth of the cooling systems. AST Modular Cooling Modules allow you to avoid overbuilding in advance of actual needs and give your cooling infrastructure the flexibility needed in today’s economic climate.

SERVICEABILITY & LOW LEVEL OF MAINTENANCE NEEDED The specific design of AST Modular Cooling Modules makes them easy to maintain. Most of the modules feature an independent maintenance area, separeted from the IT space and maintainable without load interruption.

ADAPTABLE TO IT LOAD VARIATIONAST Modular’s Cooling Modules feature an accurate air management system that allows variable speed fans to match different server flow requirements. By constantly monitoring pressure and temperature the system ensures consistent and efficient cooling across various IT loads.

Advantages at a Glance

EXECUTIVE SUMARY

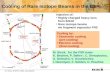

Compare among several PUEs available at some of the datacenter locations world wide. If your location is not shown in the sample chart below, please contact us at [email protected] to find your own PUE. With data from more than 5000 weather stations we are able estimate the savings and the ROI that you are going to generate by implementing our energy efficient cooling technologies.

4

WORLDWIDEPUEsCOMPARISON

CITY

MadridZurichParis

MoscowLondon

AmsterdamCopenhagen

OsloReykjavikBruxelles

PrahaFrankfurt

MilanStockholmIstanbul

MiamiSeattlePhoenixDenver

Mexico CityChicagoDallas

Los AngelesNew York

San FranciscoWashington

Sao PauloBuenos Aires

Santiago de ChileLima

MedellinBogotá

TokyoSydney

SingaporeCasablanca

ShangaiCape TownMelbourne

Beijing

All PUE calculations include IT, cooling infrastructure, UPS at Eco Efficient mode, auto transformer and electrical distribution at nominal load on a Tier 1 configuration

JapanAustralia

SingaporeMorocco

ChinaSouth Africa

AustraliaChina

1,131,111,281,121,151,101,121,17

1,251,261,281,261,251,251,261,24

1,331,311,301,311,331,311,301,27

BrazilArgentina

ChilePeru

ColombiaColombia

1,141,131,101,131,091,09

1,131,111,281,121,151,101,101,13

1,181,141,101,181,081,07

1,261,261,251,261,251,25

1,301,311,331,301,301,28

USAUSAUSAUSAUSA

MexicoUSAUSAUSAUSAUSA

1,231,091,131,101,101,121,161,101,121,091,13

1,281,121,261,201,101,181,241,111,181,081,16

1,281,241,271,231,271,231,281,271,231,251,25

1,301,341,311,351,311,261,321,311,271,291,28

SpainSwitzerland

FranceRussia

UKNetherlands

DenmarkNorwayIcelandBelgium

Czech RepublicGermany

ItalySwedenTurkey

1,101,091,101,101,091,091,091,091,091,091,091,121,121,091,12

1,161,151,131,161,131,121,131,151,151,151,171,151,141,141,13

1,251,231,241,221,241,241,231,221,221,221,211,221,241,201,25

1,341,351,341,351,351,351,361,361,381,261,251,251,281,231,29

COUNTRY

EUROPE

NORTH AMERICA

SOUTH AMERICA

OTHERS

ASHRAE 2008 CONDITIONS: TEMPERATURE(18ºC<T COLD<27ºC/ 64.4 F<80.6F) HUMIDITY (35%

NFC DFC CWB HCX

1,441,451,511,451,441,441,431,41

1,471,451,431,461,441,41

1,501,411,481,381,441,391,461,441,401,421,42

1,421,381,411,351,401,391,381,361,351,391,381,391,421,361,43

CRAC

1,151,091,341,081,171,071,081,16

1,091,091,081,081,071,07

1,221,091,201,181,081,141,181,081,141,071,14

1,121,121,091,151,091,091,101,141,131,101,131,111,111,121,09

TEMPERATUREASHRAE & HUMIDITY (20% <RH%<80%)

DFC

5

The BELOW OPEX Comparison is based on a 10 years period at 0,12 € / 0,12 $/Kwh and includes:

2. Maintenance Costs

3. UPS losses Transformers and Gesets on a TIER 3 configuration

1. Cooling Electrical Consumption

OPERATIONALEXPENDITURE& ROI

Equatorial LatitudesMid LatitudesHigh Latitudes

Equatorial LatitudesMid LatitudesHigh Latitudes

Equatorial LatitudesMid LatitudesHigh Latitudes

Equatorial LatitudesMid LatitudesHigh Latitudes

Equatorial LatitudesMid LatitudesHigh Latitudes

2.701.183 €2.460.166 €2.219.149 €

5.352.365 €4.870.332 €4.388.299 €

10.654.730 €9.690.664 €8.726.598 €

21.259.461 €19.331.328 €17.403.195 €

31.864.191 €28.971.992 €26.079.793 €

CracData Center Colocation

6.005.298 €5.737.390 €5.469.482 €

12.010.595 €11.474.779 €10.938.963 €

24.021.191 €22.949.559 €21.877.927 €

48.042.381 €45.899.118 €43.755.854 €

72.063.572 €68.848.676 €65.633.781 €

100 KW/T Load

200 KW/T Load

400 KW/T Load

800 KW/T Load

1200 KW/T Load

ROICWBHCX

2.572.622.78

1.892.022.33

1.461.411.75

1.411.361.70

1.361.311.65

ROINFCDFC

2.532.582.70

1.902.002.27

1.321.581.65

1.271.531.60

1.221.481.55

1.435.845 €1.363.540 €1.315.337 €

2.821.691 €2.677.081 €2.580.674 €

5.593.382 €5.304.162 €5.111.349 €

11.136.764 €10.558.324 €10.172.697 €

16.680.145 €15.812.486 €15.234.046 €

CWB-HCX

1.737.116 €1.616.608 €1.556.354 €

3.424.232 €3.183.216 €3.062.707 €

6.798.465 €6.316.432 €6.075.415 €

13.546.930 €12.582.863 €12.100.830 €

20.295.394 €18.849.295 €18.126.245 €

NFC-DFCEURO

Equatorial LatitudesMid LatitudesHigh Latitudes

Equatorial LatitudesMid LatitudesHigh Latitudes

Equatorial LatitudesMid LatitudesHigh Latitudes

Equatorial LatitudesMid LatitudesHigh Latitudes

Equatorial LatitudesMid LatitudesHigh Latitudes

3,522,880 $3,208,546 $2,894,212 $

6,980,550 $6,351,883 $5,723,216 $

13,895,890 $12,638,556 $11,381,222 $

27,726,573 $25,211,903 $22,697,234 $

41,557,254 $37,785,250 $34,013,246 $

CracData Center Colocation

7,832,105 $7,482,699 $7,133,294 $

15,664,209 $14,095,398 $14,266,587 $

31,328,419 $29,930,797 $28,533,176 $

62,656,837 $59,861,595 $57,066,352 $

93,985,257 $89,792,392 $85,599,528 $

100 KW/T Load

200 KW/T Load

400 KW/T Load

800 KW/T Load

1200 KW/T Load

ROICWBHCX

ROINFCDFC

2,265,545 $2,108,378 $2,029,795 $

4,465,880 $4,151,547 $3,994,380 $

8,866,553 $8,237,885 $7,923,551 $

17,667,896 $16,410,560 $15,781,893 $

26,469,237 $24,583,236 $23,640,235 $

CWB-HCX

7,294,884 $6,917,684 $6,666,217 $

1,872,627 $1,778,327 $1,715,461 $

3,680,047 $3,491,447 $3,365,713 $

14,524,559 $13,770,158 $13,267,223 $

21,754,232 $20,622,632 $19,868,231 $

NFC-DFCUS DOLLAR

2.572.622.78

1.892.022.33

1.461.411.75

1.411.361.70

1.361.311.65

2.532.582.70

1.902.002.27

1.321.581.65

1.271.531.60

1.221.481.55

6

When evaluating the different cooling technologies introduced in this catalogue it is important to take into account the upfront capital investment required as opposed to operational expenditure. While Capex are fixed costs, Opex are deter-mined by climate conditions and the level of redundancy required (Tier 1-2-3-4). By leveraging meteorological data of about 5000 weather stations world wide, AST Modular can quantify the savings you will generate since the first day of operations and predict the time it will take to recover from the initial investment. This ROI analysis report comes at no cost and on a non commitment basis. Find out what savings can be generated by sending us an email today at [email protected]

SELECTION GUIDE& FEATURES

What Cooling technology should you choose?

***

****

*****

*****

*****

****

***

***

*****

**

*****

*****

*****

*****

*****

*****

DENSITY COMPACT SOLUTION

NFC

DFC

CWB

HCX

SECURITYOPEXCAPEXMODULES

***

***

***

*****

Variable Speed Fans to mach the airflow demand

Positive pressure on cold corridor

Hot Cold Corridor Insulation

Suitable for High Densities

Adaptable to load variations

Modular Design No water next to IT area*

Humidity control system located outside of the cooling module

Intelligent Sensor Technology Capacity to grow in the futureDrainage on cooling block and no drainage needed on IT Space*

Easy to Maintain

Cooling Maintenance area independent from IT Space*

Maintainable without load interruption nor disruption to the service (n+1 redundancy)

*Features not available for HCX Modules

ENERGY EFFICIENCY MODULARITY SECURITY SERVICEABILITY

Plug & Play

REAL PROJECTS

AST Modular promised our Tier 3 Data Center would run under an average yearly PUE of 1,09. We have been able to lower it down to 1,07. The energy efficiency, reliability and robustness of NFC is just amazing".

Arni Jonsson, CTO - THOR Data Center

NFC on a containerized installation in Sydney, Australia.

NFC Modules in a modular datacenter park in Brøndby, Denmark.

NATURAL FREE COOLING NFC

TECHNOLOGYNatural Free Cooling Modules, a worldwide patented AST Modular’s technology are an indirect air to air and evaporative cooling solution that leverage temperature differences between outside cold air and hot air coming out of the servers. Thanks to its heat pipe exchanger technology and the intelligent control system NFC Modules provide multiple types of economiza-tion. They are capable to select between air-to-air, adiabatic and mechanical cooling to run your mission critical applications in the most efficient way.

MULTI ECONOMIZATION EXPLAINEDNFC Modules capitalize free cooling at 100% with dry bulb temperatures below 20° C/68 F. They operate with adiabatic cooling with average wet bulb temperatures below 20 ° C/68 F and are supported by a chiller when ASHRAE’s temperature and humidity ranges cannot be met, specifically with wet bulb temperatures above 20° C/68 F. Unlike direct free cooling systems, NFC Modules are the first solution in the market able to prevent cross contamination and humidity within the datacenter. The exhaust air coming from the servers is cooled inside segregated chambers and no outdoor air is introduced into the IT space. As a result the datacenter remains as a sealed enclosure, unaffected by external conditions such as humidi-ty, pollution, corrosive gases, and particles. This approach drastically reduces filter, maintenance, and fan power costs, thus resulting in added security, resiliency and much better energy efficiency than direct free cooling technologies.

MODULESNFC Modules have been designed and are available in 50kw individual modules. This scalable approach enables the custo-mer to purchase only the cooling capacity needed to meet current requirements. Additional NFC units can be added as the data center load grows.

9

NFC

NATURAL FREE COOLING

WHY WOULD YOU USE NFC MODULES?• Modular design that allows for future densities growth.• Great PUEs. Reduce up to 70% energy savings over other cooling designs.• Applicable in traditional and modular datacenters as well as for retrofitting purposes.• Indirect Free Cooling. No concerns over humidity and datacenter contaminants.• Totally Secure.• Low level of maintenance.• Minimum use of filters.• Passive and static heat exchanger.• No single points of failure. • Accurate Air Flow Management.

Hot air coming from the Data Center is ducted into the Hot Chamber.

Cold air is blown into the external chamber without cross contamination between air flows.

Air economizer exchanges heat.

Cold air is recirculated into the cold corridor.

Hot air is exhausted outside of the NFC Module and reusable for different purposes.

1

2

3

4

5

1 2 3

4 5

10

OPERATION

ParisPUE 1.10

MoscowPUE 1.10

New YorkPUE 1.12

MiamiPUE 1.23

ChicagoPUE 1.12

Sao PauloPUE 1.14

Bueno AiresPUE 1.13

SydneyPUE 1.11

ShanghaiPUE 1.15

LondonPUE 1.09

1 2 3

MODELS

NFC Modules are available in the 3 following configurations:

11

NFC Module with Chilled Water Cooling Support

NFC Module with Direct Expansion Cooling Support

NFC Module without any Cooling Support

1

2

3

AST Modular NFC Modules are applicable to both traditional and modular datacenters with the same level of security energy efficiency and scalability. Here are some views of the different applications.

_APPLICATION

Brick & Mortar Data Center Integration

12

APPLICATION

Modular Data center Integration

Two different options of Air Flow management are available:

_APPLICATION AIR FLOW

13

Side Flow

Down Flow

Module Maximum Cooling Power [kW] *

Number of internal Fans

OPTION 1: External Axial Fans

Internal Radial FanMaximum Airflow [m3/h] **

External Axial FanMaximum Airflow [m3/h] **

External Axial FanNominal Airflow [m3/h] **

Internal Radial FanNominal Airflow [m3/h] **

50

1

1

10.500 m3/h with 400 Pa available pressure

13.500 m3/h with 280 Pa total static pressure

11.000 m3/h with 200 Pa total static pressure

8.500 m3/h (@100CFM/kW) with 400 Pa available pressure

50

1

1

10.500 m3/h with 400 Pa available pressure

13.500 m3/h with 280 Pa total static pressure

11.000 m3/h with 200 Pa total static pressure

8.500 m3/h (@100CFM/kW) with 400 Pa available pressure

50

1

1

OPTION 2: External Radial Fans

1 1 1

Sound Pressure Level/ Nominal Airflow Lp [dBA]

72 dBA @ 3mts 72 dBA @ 3mts 72 dBA @ 3mts

Sound Pressure Level/ Nominal Airflow Lp [dBA]

63 dBA @ 3mts 63 dBA @ 3mts 63 dBA @ 3mts

Sound Pressure Level/ Nominal Airflow Lp [dBA]

70 dBA @ 3mts 70 dBA @ 3mts 70 dBA @ 3mts

Inlet Evaporating or CW coil temperatures

from 7ºC to 19ºC(if supplied by AST)

from 7ºC to 14ºC -

Number of Compressors Chiller to be supplied apart 1 -

Condeners Chiller to be supplied apart 2 with 2 fans -

Electrical Consumption at Nominal Cooling Power

3,6 kW NFC unit1,1 kW adiabatic system

3,6 kW NFC unit18 kW DX system 1,1 kW adiabatic system

3,6 kW NFC unit1,1 kW adiabatic system

Electrical Consumption at Maximum RPMs

4,6 kW NFC unit1,1 kW adiabatic system

4,6 kW NFC unit18 kW DX system1,1 kW adiabatic system

4,6 kW NFC unit1,1 kW adiabatic system

Dimensions (mm) 1.350 (W) X 2.300 (L) X 2.650 (H)

1.350 (W) X 2.300 (L) X 2.650 (H)

1.350 (W) X 2.300 (L) X 2.650 (H)

Weight [Kg]* Upon Data Center Conditions (see Cooling Power section)** Fan Data such as Consumption, RPM, etc. to be checked on Fans Technical Specs Sheet

1.150 1.485 1.065

Cooling Support Power [kW] 50 50 0

10.500 m3/h with 400 Pa available pressure

13.500 m3/h with 280 Pa total static pressure

Internal Radial FanMaximum Airflow [m3/h] **

10.500 m3/h with 400 Pa total static pressure

10.500 m3/h with 400 Pa total static pressure

10.500 m3/h with 400 Pa total static pressure

Internal Radial FanNominal Airflow [m3/h] **

8.500 m3/h with 400 Pa total static pressure

8.500 m3/h with 400 Pa total static pressure

8.500 m3/h with 400 Pa total static pressure

11.000 m3/h with 200 Pa total static pressure

8.500 m3/h (@100CFM/kW) with 400 Pa available pressure

NFC DX Cooling Support No Cooling SupportChilled Water Cooling Support

14

_APPLICATIONTECHNICALSPECIFICATIONS

NFC Modules are capable to match the cooling capacity to the appropriate levels of airflow needed. The next chart illustrates different server needs (100 CFM and 120 CFM per kW of airlow) at different IT loads (40%, 70% and 100%).

Coolin

g c

apaci

ty/h

eat

pip

e (k

W)

Temperature difference (°C)

50.0

45.0

40.0

35.0

30.0

25.0

20.0

15.0

10.0

5.0

0.0

9.0 10.0 11.0 12.0 13.0 14.0 15.0 16.0 17.0 18.0

Cooling available @ 120 CFM / kW at different IT Load Capacity:

Cooling available @ 100 CFM / kW at different IT Load Capacity:

Cooling capacity vs temperature difference(Hot Corridor vs Cold Corridor) considering 100CFM/kW

70% AirFlow

40% AirFlow

100% AirFlow

Coolin

g c

apaci

ty/h

eat

pip

e (k

W)

Temperature difference (°C)

60.0

50.0

40.0

30.0

20.0

10.0

0.0

8.0 9.0 10.0 11.0 12.0 13.0 14.0 15.0 16.0 17.0 18.0

Cooling capacity vs temperature difference(Hot Corridor vs Cold Corridor) considering 120CFM/kW

70% AirFlow

40% AirFlow

100% AirFlow

15

8.0

NFC ATDIFFERENTIT LOADS

Appro

ach

Tem

per

atu

re (

T co

ld -

Tex

t)

Total DC Power Load (%)

08

07

06

05

04

03

02

01

00

100%

NFC Operational Range: Approach Temperatire vs DC Power Load

100 CFM/kW, Delta T= 12ºC

0%

The external temperature limit to which NFC Modules can work is related to the cold corridor desired temperature which each data center operator may choose. The following graph illustrates the temperature limit up to which NFC modules are able to work without any cooling support at different server loads (40%, 70% or 100% IT Load). As an example, if we have a data center load of around 70% overall and would like to keep the cold corridor temperature at 25ºC, as per ASHRAE recommended levels, NFC modules will operate without the need of any chiller below 20ºC/71.6F external temperature.

120 CFM/kW, Delta T= 14ºC

16

OPERATIONALRANGE

NFC

Ex

tern

al T

emper

atu

te W

ork

ing

Lim

it (

ºC)

Cold Corridor Temp (°C)

35.0

30.0

25.0

20.0

15.0

10.0

17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33

NFC Operational Range: Exteranal Temperatures vc Cold Corridor Desired Temperature @ 100CFM/kW (Delta T=12ºC)

70% AirFlow

40% AirFlow

100% AirFlow

NFC effectiveness varies upon total load of data center nominal power. If the IT load is low the effectiveness of NFC improves and it drops at high loads. The next chart illustrates different approach temperatures (Difference between T cold – T external) obtained with different Data Center loads.

Total kW

Water: Tinlet

Water: Toutlet

Waterflow

Water: pressure drop

Airflow

Air: T/RH inlet

Air: T/RH outlet

Air: pressure drop

kW

ºC/F

ºC/F

lt/h

kPa

m3/h

ºC/%

ºC/%

Pa

58,5

12/53.6

17/62.6

10.065

16

9.680

39/22

21/60

91

55,1

14/57.2

19/66.2

9.477

14

9.680

39/22

22/57

90

52,4

17/62.6

22/71.6

9.004

12

9.680

39/22

24/50

93

43,2

19/66.2

24/75.2

7.429

8

9.680

39/22

26/44

93

NFC CW

Etylene glycol percent by weight (%)

Cooling capacity corr. factor

Power input corr. Factor

Mixture flow corr. Factor

Pressure drop corr. Factor

NFC DX available in Q2 2012

10%

0,986

1

1,023

1,061

20%

0,98

0,995

1,054

1,114

30%

0,973

0,99

1,092

1,19

40%

0,966

0,985

1,14

1,244

50%

0,96

0,975

1,2

1,31

Correction factors

NFC Modules feature a traditional data center support cooling system, when ASHRAE levels of temperature and humidity cannot be met. We offer both a chilled water and a direct expansion system as per the next chart:

17

SUPPORTCOOLING

18

GeneralNumber of racks: 1 rackAtomization nozzles: 5 Rated atomization capacity: 4kg/h/nozzleTotal atomization capacity: 20 kg/h/block

Distribution systemPipe material: stainless steelConnection Stainless steel pipe external Ø 10 mm/ 0.4 inch

Pump assemblyPower supply: .EU: 230 Vac single-phase, 50 Hz / 400 Vac three-phase, 50 Hz .USA: 230 Vac single-phase, 60 Hz

Electrical consumption 1,15 kWWater inlet connections: Ø 1/4”G female / Ø 1/2”G emale depending on the model Water outlet connection: Ø 1/4”G female Water outlet pressure limits (bar) 20 to 80

Water supply conditionsTotal hardness (ppm CaCO3) 0 to 25 Conductivity limits (µS/cm) 30 to 50 µS/cmWater inlet pressure limits (bar) 3 to 8

Min 2% Slope in horizontal sections

BLOCK 2 BLOCK N

INOX Pipe 10-12 mmCabinet with

Thermic isolation

Vaporizer pumpThermic Resistance

with thermostat

Water Supply from water treatment system (reverse osmosis) not

suppliedBLOCK 1

Drainage

5 holesper line5 nozzles

NO

NO

Drainage Drainage

Drainage

5 holesper line5 nozzles

NO

NO

NO

NO

NONC

Filters

1um 5um

1um 5um

Data per Module

It is recommended to use a water treatment system such as a reverse osmosis unit with demineralizer (not included in AST Modular’s offer).Alternative Adiabatic system can be supplied without previous notice.

ADIABATICCOOLING

Evaporative cooling comes built into each module in order to leverage wet bulb temperatures. At certain locations where humidity levels are high, the adiabatic cooling systems can be optionally not included.

The system is composed of the following parts:

Rack with water atomization nozzles and electronic valves

High pressure connection pipes

Pump assembly with continuous modulation (inverter)

19

AST Modular NFC Modules present the following operational ranges:

Feeding conditions towards Cold Corridor: Between 21°C/69.8F 27°C/80.6F, 35-55% R.H. according to ASHRAE recom-mended values. Higher limits can be applied upon request.

OUTDOOR AMBIENT CONDITIONS:

VOLTAGE:

STORAGE CONDITIONS:

Humidity System (OPTIONAL)

Humidity system can be optionally installed in each model with the following specifications: Maximum Humidifier Capacity (liters/h) -> 2 l/h Nominal Power -> 180 W Water supply conditions -> Demineralizer/Reverse osmosis unit (AST Modular does not supply the demineralizer).

OPERATIONALLIMITS & HUMIDITYSYSTEM

. Lower limit: -25°C / -77F (optional winter kit needed)

. Upper limit: +40°C / +104F

. Voltage tolerance: +/- 10%

. Frequency: 50Hz - 60Hz +/- 1%

. 400V - 480V / 3ph / 50Hz - 60Hz; N; PE

. Humidity: 10% – 90%

. Atmosphere pressure: 70 kPa – 110 kPa

. Temperature: 0/+40ºC +104F

DIRECT FREE COOLING DFC

TECHNOLOGYDirect Free Cooling Modules are a cooling solutions able to leverage outdoor fresh air by driving it from the outside to the inside of the data center. Direct Free Cooling generates significant savings since in certain locations data centers operators can take full advantage of free cooling for several hours of the day without the need of expensive mechanical cooling. Indeed the back-up cooling support embedded into DFC Modules is activated only when ASHRAE recommended temperature levels cannot be met and specifically beyond 27°C/80.6F external dry bulb temperature.

MAIN COMPONENTSFilters: to protect the equipment from dust and air pollution.Motorized Dampers: Each module is composed by 3 sets of dampers. Supply air dampers, Exhaust air dampers, By-pass dampers.Fans: variable speed fans guarantee accurate air flow management and adaptability to variable loads.Mechanical Cooling Support System: available both as Chilled water (CW) or as Direct expansion (DX).

MODULES & MODULARITYDFC Modules are available in 50kw individual modules. This scalable approach enables the customer to purchase only the cooling capacity needed to meet current requirements. Additional DFC units can be added as the data center load grows and installed in a “live environment” without disruption to the service.

21

DFC

DIRECT FREE COOLING

WHY WOULD YOU USE DFC MODULES?

• Lower capital investment than with Indirect Natural Free Cooling Modules.

• Ideal where cross contamination and external contaminants (pollution, corrosive gases, humidity) are not a matter of concern.

• Scalability. Add modular cooling capacity “as needed”.

• Suitable to both traditional and modular datacenters.

• Reduce up to 70% energy consumption over other cooling designs.

Phase 1 External Temperature < 18ºC/64.4F (Limits upon customer’s preferences)

The dampers of DFC Modules mix the outside fresh air with the hot air coming from the datacenter to achieve the correct supply conditions. The outside air is filtered before entering the IT area. Filtering is performed according to site conditions and the level of security required and part of the air coming from the datacenter is exhausted towards the outside with intake air pressure given by the fan. Variable speed fans together with dampers match the airflow needed to cool the datacenter to the temperature required.The Mechanical Cooling Support System is not in use.

Phase 2 18ºC/64.4F < External Temperature < 27ºC/80.6F (Limits upon customer’s preferences)

22

OPERATION

The outdoor air is blown into the cold corridor and no outside air is mixed with the hot air coming from the datacenter. The whole of the hot air coming from the servers is exhausted towards the outside with intake air pressure given by the fan. Variable speed fans match the airflow needed to cool the datacenter to the temperatu-re required. The maximum external temperature allowed inside the cold corridor varies upon design conditions and compliance with ASHRAE limits.The Mechanical Cooling Support System is not in use.

23

Phase 3 External Temperature > 27ºC/80.6F (Limits upon customer’s preferences)

No free cooling is available, hence the mechanical support cooling system is in use. The system recirculates the air from the hot to the cold corridor and cools down the servers to the desired temperature and upon design conditions.Two cooling systems are available: Chilled water (CW) or Direct expansion (DX). Variable speed fans match the airflow needed to cool the datacenter to the temperature required.The Mechanical Cooling Support System is in use.

OPERATION

ParisPUE 1.13

MoscowPUE 1.16

New YorkPUE 1.18

MiamiPUE 1.28

ChicagoPUE 1.18

Sao PauloPUE 1.18

Bueno AiresPUE 1.14

SydneyPUE 1.15

ShanghaiPUE 1.22

LondonPUE 1.13

1 2 3

MODELS

DFC Modules are made available in the 3 following configurations

24

DFC Module with Chilled Water Cooling Support

DFC Module with Direct Expansion Cooling Support

DFC Module without any cooling support

1

2

3

AST Modular DFC Modules are applicable to both traditional and modular datacenters with the same level of security energy efficiency and scalability. Here are some views of the different applications.

Brick & Mortar Data Center Integration

25

APPLICATION

Modular Data center Integration

Two different options of Air Flow management are available:

_APPLICATION AIR FLOW

26

Side Flow

Down Flow

Module Maximum Cooling Power [kW] *

Number of internal Fans

Internal Radial FanMaximum Airflow [m3/h] **

Number of Compressors

Condensers

Dimensions (mm)

Weight (kg)

Fan Power Absortion (kW)

Fan Maximum PowerAbsortion (kW)

Internal Radial FanNominal Airflow [m3/h] **

Inlet Evaporing or CW coil temperatures

Cooling Support Power (kW)

50

1

10.500 m3/h with 400 Pa available pressure

50

from 7ºC to 19ºC (if supplied by AST Modular)

Chiller to be supplied apart

Chiller to be supplied apart

8.500 m3/h (@100CFM/kW) with 400 Pa available pressure

50

1

10.500 m3/h with 400 Pa available pressure

50

from 7ºC to 14º

1

2 with 2 fans

8.500 m3/h (@100CFM/kW) with 400 Pa available pressure

50

1

10.500 m3/h with 400 Pa available pressure

-

-

-

-

1,7 kW @8.500 m3/h (@100CFM/kW) with 400 Pa

1,7 kW @8.500 m3/h (@100CFM/kW) with 400 Pa

1,7 kW @8.500 m3/h (@100CFM/kW) with 400 Pa

2,4 kW @10.500 m3/h with 400 Pa

2,4 kW @10.500 m3/h with 400 Pa

2,4 kW @10.500 m3/h with 400 Pa

Sound Pressure Level / Nominal Airflow Lp [dBA] ***

* Upon Data Center Conditions (see Cooling Power section)** Fan Data such as Consumption, RPM, Sound Pressure, etc. to be checked on Fans Technical Specs Sheet *** Sound pressure level directly measured in fan suction/discharge (data given by manufacturer).

63 dBA @ 3 mts 63 dBA @ 3 mts 63 dBA @ 3 mts

1.350 (W) X 2.300 (L) X 2.650 (H)

1.350 (W) X 2.300 (L) X 2.650 (H)

1.350 (W) X 2.300 (L) X 2.650 (H)

875 1.210 790

8.500 m3/h (@100CFM/kW) with 400 Pa available pressure

DFC DX Cooling Support No Cooling SupportChilled Water Cooling Support

27

_APPLICATIONTECHNICALSPECIFICATIONS

Total kW

Water: Tinlet

Water: Toutlet

Waterflow

Water: pressure drop

Airflow

Air: T/RH inlet

Air: T/RH outlet

Air: pressure drop

kW

ºC/F

ºC/F

lt/h

kPa

m3/h

ºC/%

ºC/%

Pa

58,5

12/53.6

17/62.6

10.065

16

9.680

39/22

21/60

91

55,1

14/57.2

19/66.2

9.477

14

9.680

39/22

22/57

90

52,4

17/62.6

22/71.6

9.004

12

9.680

39/22

24/50

93

43,2

19/66.2

24/75.2

7.429

8

9.680

39/22

26/44

93

DFC CW

Etylene glycol percent by weight (%)

Cooling capacity corr. factor

Power input corr. Factor

Mixture flow corr. Factor

Pressure drop corr. Factor

DFC DX available in Q2 2012

10%

0,986

1

1,023

1,061

20%

0,98

0,995

1,054

1,114

30%

0,973

0,99

1,092

1,19

40%

0,966

0,985

1,14

1,244

50%

0,96

0,975

1,2

1,31

Correction factors

DFC Modules feature a traditional data center support cooling system, when ASHRAE levels of temperature cannot be met. We offer both a chilled water and a direct expansion system as per the next chart.

16

SUPPORTCOOLING

28

29

GeneralNumber of racks: 1 rackAtomization nozzles: 5 Rated atomization capacity: 4kg/h/nozzleTotal atomization capacity: 20 kg/h/block

Distribution systemPipe material: stainless steelConnection Stainless steel pipe external Ø 10 mm/ 0.4 inch

Pump assemblyPower supply: .EU: 230 Vac single-phase, 50 Hz / 400 Vac three-phase, 50 Hz .USA: 230 Vac single-phase, 60 Hz

Electrical consumption 1,15 kWWater inlet connections: Ø 1/4”G female / Ø 1/2”G emale depending on the model Water outlet connection: Ø 1/4”G female Water outlet pressure limits (bar) 20 to 80

Water supply conditionsTotal hardness (ppm CaCO3) 0 to 25 Conductivity limits (µS/cm) 30 to 50 µS/cmWater inlet pressure limits (bar) 3 to 8

Min 2% Slope in horizontal sections

BLOCK 2 BLOCK N

INOX Pipe 10-12 mmCabinet with

Thermic isolation

Vaporizer pumpThermic Resistance

with thermostat

Water Supply from water treatment system (reverse osmosis) not

suppliedBLOCK 1

Drainage

5 holesper line5 nozzles

NO

NO

Drainage Drainage

Drainage

5 holesper line5 nozzles

NO

NO

NO

NO

NONC

Filters

1um 5um

1um 5um

Data per Module

It is recommended to use a water treatment system such as a reverse osmosis unit with demineralizer (not included in AST Modular offer).

ADIABATICCOOLING

Evaporative cooling can be integrated into DFC Modules in order to leverage wet bulb temperatures. At certain locations where humidity levels allow implementation the adiabatic cooling systems can be optionally installed.

The system is composed of the following parts:

Rack with water atomization nozzles and electronic valves

High pressure connection pipes

Pump assembly with continuous modulation (inverter)

30

AST Modular DFC Modules present the following operational ranges:

Feeding conditions towards Cold Corridor: Between 21°C/69.8F 27°C/80.6F, 35-55% R.H. according to ASHRAE recom-mended values. Higher limits can be applied upon request.

OUTDOOR AMBIENT CONDITIONS:

VOLTAGE:

STORAGE CONDITIONS:

Humidity System (OPTIONAL)

Humidity system can be optionally installed in each model with the following specifications: Maximum Humidifier Capacity (liters/h) -> 2 l/h Nominal Power -> 180 W Water supply conditions -> Demineralizer/Reverse osmosis unit (AST Modular does not supply the demineralizer).

OPERATIONALLIMITS & HUMIDITYSYSTEM

. Lower limit: -25°C / -77F (optional winter kit needed)

. Upper limit: +40°C / +104F

. Voltage tolerance: +/- 10%

. Frequency: 50Hz - 60Hz +/- 1%

. 400V - 480V / 3ph / 50Hz - 60Hz; N; PE

. Humidity: 10% – 90%

. Atmosphere pressure: 70 kPa – 110 kPa

. Temperature: 0/+40ºC +104F

CHILLED WATER BLOCK CWB

TECHNOLOGYChilled Water Block Modules are a water based datacenter cooling technology composed of a chiller, variable-speed fans and a water coil, whose surface is bigger than the one of a traditional Computer Room Air Conditioning (CRAC). The exten-ded cooling surface of the coil allows the chiller to supply water to the coil at higher temperatures thus resulting in improved energy efficiency.Dependent upon design conditions and desired cold corridor temperatures water can be supplied to temperatures up to 19°C/66.2F. External chiller is available as a free cooling chiller or as evaporative Cooling Tower.

MAIN COMPONENTSVariable Speed FansWater CoilFree cooling chiller or evaporative Cooling Tower (optional)Humidifier (optional)

MODULESCWB Modules are available in 100 KW and 150 KW models. This scalable approach enables the customer to purchase only the cooling capacity needed to meet current requirements. Additional CWB modules can be added as the data center load grows and installed in a ‘live environment’ without disruption to the service.

32

CWB

CHILLED WATER BLOCK

WHY WOULD YOU USE CW BLOCKS?

• Lower capital investment than with Indirect and Direct Free Cooling modules

• Scalability. Add modular cooling capacity “as needed”.

• Reduce up to 60% energy consumption over other cooling designs.

• Suitable to both traditional and modular datacenters.

Hot Air coming from the servers is ducted into the Hot Chamber.

Hot Air is ducted through the coil.

Hot air is cooled down by the coil.

Cooled air comes out of the coil.

Cooled air is blown into the cold corridor.

1

2

3

4

5

1 2 3

4 5

33

OPERATION

ParisPUE 1.23

MoscowPUE 1.20

New YorkPUE 1.23

MiamiPUE 1.32

ChicagoPUE 1.23

Sao PauloPUE 1.29

Bueno AiresPUE 1.28

SydneyPUE 1.27

ShanghaiPUE 1.26

LondonPUE 1.23

1 2

MODELS

Chilled Water Block Modules are available in the two following 100 Kw and 150 Kw models accor-ding to the cooling capacity required:

34

CWB100 ModuleCWB150 Module

1

2

AST Modular CWB Modules are applicable to both traditional and modular datacenters with the same level of security energy efficiency and scalability. Here are some views of the different applications:

_APPLICATION

Brick & Mortar Data Center Integration

35

APPLICATION

Modular Data Center Integration

Two different options of Air Flow management are available:

_APPLICATION AIR FLOW

36

Side Flow

Down Flow

Chilled Water Block Modules main specifications are as follows:

Total kW

Water: Tinlet

Water: Toutlet

Waterflow

Water: pressure drop

Airflow

Air: T/RH inlet

Air: T/RH outlet

Air: pressure drop

kW

ºC/F

ºC/F

lt/h

kPa

m3/h

ºC/%

ºC/%

Pa

65,9

12/53.6

17/62.6

11.335

29

10.000

39/22

19/68

167

56,9

15/59

20/68

9.790

22

10.000

39/22

22/57

169

53,5

17/62.6

22/71.6

9.205

16

10.000

39/22

23/53

169

42,8

19/66.2

24/75.2

7.360

12

10.000

39/22

25/45

179

CWB100

Etylene glycol percent by weight (%)

Cooling capacity corr. factor

Power input corr. Factor

Mixture flow corr. Factor

Pressure drop corr. Factor

10%

0,986

1

1,023

1,061

20%

0,98

0,995

1,054

1,114

30%

0,973

0,99

1,092

1,19

40%

0,966

0,985

1,14

1,244

50%

0,96

0,975

1,2

1,31

Correction factors

Includes two coils with the following specifications

CWB150Includes three coils with the following specifications

Total kW

Water: Tinlet

Water: Toutlet

Waterflow

Water: pressure drop

Airflow

Air: T/RH inlet

Air: T/RH outlet

Air: pressure drop

kW

ºC

ºC

lt/h

kPa

m3/h

ºC/%

ºC/%

Pa

97,3

12/53.6

17/62.6

16.730

32

14.750

39/22

22/57

192

84,0

15/59

20/68

14.441

27

14.750

39/22

22/57

193

78,9

17/62.6

22/71.6

13.578

24

14.750

39/22

23/53

193

74,7

19/66.2

24/75.2

12.847

22

14.750

39/22

25/45

205

Etylene glycol percent by weight (%)

Cooling capacity corr. factor

Power input corr. Factor

Mixture flow corr. Factor

Pressure drop corr. Factor

10%

0,986

1

1,023

1,061

20%

0,98

0,995

1,054

1,114

30%

0,973

0,99

1,092

1,19

40%

0,966

0,985

1,14

1,244

50%

0,96

0,975

1,2

1,31

Correction factors

37

_APPLICATIONTECHNICALSPECIFICATIONS

38

AST Modular CWB Modules present the following operational ranges:

Feeding conditions towards Cold Corridor: Between 21°C/69.8F 27°C/80.6F, 35-55% R.H. according to ASHRAE recom-mended values. Higher limits can be applied upon request.

OUTDOOR AMBIENT CONDITIONS:

VOLTAGE:

STORAGE CONDITIONS:

Humidity System (OPTIONAL)

Humidity system can be optionally installed in each model with the following specifications: Maximum Humidifier Capacity (liters/h) -> 2 l/h Nominal Power -> 180 W Water supply conditions -> Demineralizer/Reverse osmosis unit (AST Modular does not supply the demineralizer).

OPERATIONALLIMITS & HUMIDITYSYSTEM

. Lower limit: 0 (winter kit optionally available)

. Upper limit: +40°C / +104F

. Voltage tolerance: +/- 10%

. Frequency: 50Hz - 60Hz +/- 1%

. 400V - 480V / 3ph / 50Hz - 60Hz; N; PE

. Humidity: 10% – 90%

. Atmosphere pressure: 70 kPa – 110 kPa

. Temperature: 0/+40ºC +104F

HOT CORRIDOR EXCHANGER HCX

TECHNOLOGYHCX Modules are a water based overhead cooling technology composed of variable-speed fans and a water coil whosesurface is bigger than the one of In Row Cooling units. The extended surface of the coil allows the chiller to supply water at higher temperatures, thus resulting in improved energy efficiency. Dependent upon design conditions the water can be supplied up to 17°C/62.6F. Originally engineered for containerized datacenters HCX Modules are a compact solution specifically suitable for all data center environments where valuable IT space is a critical business requirement and specifica-lly modular datacenters.

MAIN COMPONENTSVariable Speed FansWater CoilMist EliminatorDrainage system that prevents the water from leaking into the IT space.

MODULESHCX Modules are available in the following 7,5 Kw/Rack and 20 Kw/Rack modules. This scalable and approach enables the customer to purchase only the cooling capacity needed to meet current requirements. Additional HCX Modules can be added as the data center load grows and installed in a “live environment” without disruption to the service.

40

HCX

HOT CORRIDOR EXCHANGER

WHY WOULD YOU USE HCX MODULES?• Compact Solution that saves valuable IT space

• Lower capital investment than with Indirect and Direct Free Cooling modules.

• Reduce up to 60% energy savings over other cooling designs.

• Scalability. Add modular cooling capacity “as needed”.

• Particularly suitable to modular datacenters.

• Accurate air flow management system.

Hot Air comes from the servers

Hot air is ducted through the coil

Hot Air is cooled down by the coil

Cold Air is blown back into the servers

1

2

3

4

1 2

4 5

41

OPERATION

ParisPUE 1.27

MoscowPUE 1.23

New YorkPUE 1.27

MiamiPUE 1.36

ChicagoPUE 1.26

Sao PauloPUE 1.34

Bueno AiresPUE 1.32

SydneyPUE 1.31

ShanghaiPUE 1.30

LondonPUE 1.27

2

MODELS

1

Hot Corridor Exchanger Modules are available in the two following 7,5 kW/Rack and 20 kW/Rack configurations according to the cooling capacity required:

42

HCX 7,5 kW/Rack1

HCX 20 kW/Rack2

AST Modular HCX Modules are applicable to both traditional and modular datacenters with the same level of security energy efficiency and scalability. Here are some views of the different applications:

_APPLICATION

Brick & Mortar Data Center Integration

43

APPLICATION

Modular Data Center Integration

kW/rack

Total kW

Water: Tinlet

Water: Toutlet

Waterflow

Water: pressure drop

Airflow

Total available pressure per fan

Number of fans every 2 racks or 1 coil

Air: T/RH inlet

Air: T/RH outlet

Air: pressure drop

Noise

Weight

kW

kW

ºC/F

ºC/F

lt/h

kPa

m3/h

Pa

units

ºC/%

ºC/%

Pa

dB(A)

kg

7,5

14,9

7/44.6

12/53.6

2.568

18,0

2.600

300

1 unit

35,5/25

18/66

59

7,3

14,7

10/50

15/59

2.520

18,0

2.600

300

1 unit

35/25

20/55

64

7,5

15,4

12/53.6

17/62.6

2.654

18.0

2.600

300

1 unit

40/20

22/55

58

7,0

14,1

14/57.2

19/66.2

2.422

15,6

2.600

300

1 unit

40/20

24/50

59

HCX 7,5 Kw (CW)

Etylene glycol percent by weight (%)

Cooling capacity corr. factor

Power input corr. Factor

Mixture flow corr. Factor

Pressure drop corr. Factor

HCX DX available in Q2 2012

10%

0,986

1

1,023

1,061

20%

0,98

0,995

1,054

1,114

30%

0,973

0,99

1,092

1,19

40%

0,966

0,985

1,14

1,244

50%

0,96

0,975

1,2

1,31

Correction factors

kW/rack

Total kW

Water: Tinlet

Water: Toutlet

Waterflow

Water: pressure drop

Airflow

Total available pressure per fan

Number of fans every 2 racks or 1 coil

Air: T/RH inlet

Air: T/RH outlet

Air: pressure drop

Noise

Weight

kW

kW

ºC/F

ºC/F

lt/h

kPa

m3/h

Pa

units

ºC/%

ºC/%

Pa

dB(A)

kg

20

39,0

7/44.6

12/53.6

6.715

14,4

6.800

300

1 unit

35/25

18/66

234

19

38,3

10/50

15/59

6.591

12,9

6.800

300

1 unit

35/25

20/55

252

20

40,4

12/53.6

17/62.6

6.944

14,4

6.800

300

1 unit

40/20

22/55

232

18

36,7

14/57.2

19/66.2

6.316

12,9

6.800

300

1 unit

40/20

24/50

236

HCX 20 Kw (CW)

HCX Modules main specifications are as follows:

44

_APPLICATIONTECHNICALSPECIFICATIONS

45

AST Modular HCX Modules present the following operational ranges:

Feeding conditions towards Cold Corridor: Between 21°C/69.8F 27°C/80.6F, 35-55% R.H. according to ASHRAE recom-mended values. Higher limits can be applied upon request.

OUTDOOR AMBIENT CONDITIONS:

VOLTAGE:

STORAGE CONDITIONS:

Humidity System (OPTIONAL)

Humidity system can be optionally installed in each model with the following specifications: Maximum Humidifier Capacity (liters/h) -> 2 l/h Nominal Power -> 180 W Water supply conditions -> Demineralizer/Reverse osmosis unit (AST Modular does not supply the demineralizer).

OPERATIONALLIMITS & HUMIDITYSYSTEM

. Lower limit: 0 (winter kit optionally available)

. Upper limit: +40°C / +104F

. Voltage tolerance: +/- 10%

. Frequency: 50Hz - 60Hz +/- 1%

. 400V - 480V / 3ph / 50Hz - 60Hz; N; PE

. Humidity: 10% – 90%

. Atmosphere pressure: 70 kPa – 110 kPa

. Temperature: 0/+40ºC +104F

www.ASTmodular.com

Emea AST Modular Emea, 43 Albert Eisntein E-08940 Cornellà de Llobregat Barcelona, Spain, Tel.: +34 93 475 14 81,[email protected] America AST Modular North America, 15281 Northwest 33rd Place Opa-locka, FL 33054, US, Tel.: +1 954 753-4081, Mobile: +1 330 472 2800, [email protected], Souht America AST Modular Souht America, Rua Maestro João Gomes de Araújo, 106 Água Fria, 02332-020 - São Paulo - SP, Tel.: +55 11 2976 5701, Mobile: +55 11 9635 9051, [email protected]

AST Modular Cooling Modules’ Technical Specifications may suffer changes without previous notice.

Related Documents