-

7/30/2019 Composites in Industrial Plants Pt1

1/23

An Introductory Guide

in Industrial PlantsComposites

-

7/30/2019 Composites in Industrial Plants Pt1

2/23

Preace

The Queensland Governments Fibre Composites Action Plan New TechnologyTaking Shape launched in April 2006 sets out over 50 initiatives under six theme

areas, ranging rom innovation to skills and training.

The Fibre Composites Action Plan identied the potential or signicant benets

rom increased use o composites in target sectors such as mining, minerals

processing and associated inrastructure.

Deborah Wilson Consulting Services (DWCS) and GHD were engaged to undertake

a study to assess this opportunity and develop approaches that make the choice

o composites in mining applications easier, and more relevant to delivering cost

savings and other benets to industry.

The Queensland Government, through the Department o Employment, Economic

Development and Innovation (DEEDI), unded this study as part o a larger initiativeto help one o the States most promising new industries grow and compete on a

global level.

The aim o the study was to deliver:

case studies on successul use o composites in the mining industry and the

benets composites deliver

business case inormation on the use o composites in dierent applications in

mining, minerals processing and associated inrastructure

inormation covering availability, technical guides and benets o using

composites in common applications in the mining industry

improved links between composites suppliers, manuacturers and the mining

industry to better respond to mining industry needs

inormation kits, presentations and technical seminars on the ndings and

applications where composites deliver value to the mining industry

a model or the composites industry to use in proling valuable applications or

composites in other industries.

This introductory guide addresses a number o these aims. It has been prepared

ollowing a review o relevant technical literature and discussions with the

composites industry.

Disclaimer

This publication was unded by the

Queensland Government (through the

Department o Employment, Economic

Development and Innovation). It is

distributed by the Queensland Government

as an inormation source only. The State

o Queensland makes no statements,

representations, or warranties about

the accuracy or completeness o, and

you should not rely on, any inormation

contained in this publication.

Readers should not act or rely upon anyinormation contained in this publication

without taking appropriate proessional

advice relating to their particular

circumstances.

The Queensland Government disclaims all

responsibility and all liability (including

without limitation, liability in negligence)

or all expenses, losses, damages and

costs you might incur as a result o the

inormation being inaccurate or incomplete

in any way, and or any reason.

-

7/30/2019 Composites in Industrial Plants Pt1

3/23

in Industrial Plants

Composites

An Introductory Guide

-

7/30/2019 Composites in Industrial Plants Pt1

4/23

Table o contents

1. Introduction ___________________________________ 3

2. Overv iew o materials and products _______________ 4

2.1 Qualitative comparison o materials___________ 4

2.2 Benets o composites ______________________ 5

2.3 Product applications________________________ 6

2.3.1 Current applications _____________________ 6

2.3.2 Future applications ______________________ 7

2.3.3 Pipes and ducts _________________________ 7

2.3.4 Tanks and process vessels ________________ 8

2.3.5 Launders _______________________________ 9

2.3.6 Joints and ttings________________________ 9

2.3.7 Coatings and linings ____________________ 10

3. Composite product manuacturing_______________ 11

3.1 Components______________________________ 11

3.2 Fibre reinorcement ________________________ 11

3.3 Resins ___________________________________ 13

3.4 Additives ________________________________ 14

3.5 Cores____________________________________ 14

3.6 Example o a composite laminate ____________ 15

3.7 Manuacturing processes___________________ 15

3.8 Manuacturers ____________________________ 15

4. Australian case stories _________________________ 16

5. Technical perormance _________________________ 18

5.1 Design___________________________________ 18

5.2 Standards________________________________ 18

5.3 Guides __________________________________ 19

5.4 Relative perormance o materials ___________ 19

5.5 Service lie _______________________________ 20

5.6 Mechanical properties _____________________ 20

5.6.1 General _______________________________ 20

5.6.2 Strength ______________________________ 20

5.6.3 Fatigue________________________________ 21

5.6.4 Creep _________________________________ 22

5.6.5 Abrasion resistance_____________________ 22

5.7 Thermal properties ________________________ 22

5.8 Chemical properties _______________________ 23

5.9 Electrical properties _______________________ 265.10 Perormance o composites in re____________ 26

5.11 UV resistance_____________________________ 27

5.12 Working with composites on site_____________ 28

5.13 Inspection and testing _____________________ 28

6. Economic comparison__________________________ 30

7. Environmental comparison _____________________ 31

8. Reerences ___________________________________ 32

9. Australian manuacturers o composite

industrial products ____________________________ 34

10. Australian composites design and

engineering service providers ___________________ 41

11. Acknowledgements____________________________ 43

List o abbreviations

ACI American Concrete Institute

AS Australian Standard

BS British Standard

CFRP Carbon Fibre Reinorced Plastic

CTE Coecient o Thermal Expansion

F RP F ibre Reinorced Plastic

GRP Glass Reinorced Plastic

HDT Heat Distortion Temperature

ISO International Standards Organisation

PTFE Polytetrafuorethylene

PVC Polyvinyl Chloride

PVDF Polyvinylidene Fluoride

UV Ultraviolet (sunlight)

-

7/30/2019 Composites in Industrial Plants Pt1

5/23

3

1 Introduction

A composite is a material made up o two or more components so the benecialproperties o each component are utilised. In this guide, composite reers to a

material composed o a thermosetting resin and bre reinorcement. Composites

are also reerred to as breglass, glass reinorced plastic (GRP), bre reinorced

plastic (FRP) and carbon bre reinorced plastic (CFRP). As there are many dierent

resins, reinorcements and methods o putting the two together, there are a

multitude o materials which can be described as composites.

Composites oer unique products in many o Queenslands most important

industry sectors, including advanced manuacturing, aerospace, building and

construction, deence, inrastructure, marine, mining and transport. As composites

are light-weight and corrosion-resistant, the materials have the potential to reduce

costs, save time and provide a saer work environment. At a time o fuctuating

steel prices and long delivery times, composites oer a real alternative to reducecapital and operational costs, and downtime. Composites light-weight nature

provides operational savings or trucks and mobile equipment, and their

corrosion-resistance prevents the hazards o rusting steel structures.

Composites have been used in many Australian industries since the 1940s. For

example, in the minerals processing and chemical industries, the materials are

used in a variety o applications including tanks, pipes, process vessels and foor

grating. In the mining industry, the materials are used in applications including

ducts, truck bodies and rock bolts. It seems the Bronze Age and Iron Age have

passed, and the composites age is now upon us.

The Queensland Government is capitalising on Queenslands strengths as a world

leader in the research, development and commercialisation o bre composites

technologies through the implementation o its Fibre Composites Action Plan, andsignicant investment under the Smart Futures Fund.

For more inormation on Queenslands Fibre Composites industry please visit:

www.composites.industry.qld.gov.au

Lucy Cranitch, GHD, produced this guide. It aims to provide an introduction to

composites in the mining, mineral processing and chemical industries, and to

assist in the decision to purchase a composite component. It does not provide

design details o composite components.

For more inormation on GHD please visit www.ghd.com.au

A composite is a material

made up o two or more

components so the benecial

properties o eachcomponent are utilised.

Carbon bre-epoxy drill rod prototype

with embedded strain gauges and carbon

nanotube-epoxy threads

Image courtesy of Teakle Composites

-

7/30/2019 Composites in Industrial Plants Pt1

6/23

4

2 Overview o materials and products

2.1 Qualitativecomparisonofmaterials

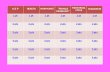

The table below provides a quick comparison o materials.

Table 1 Qualitative comparison o materials

Material Advantages Disadvantages

Mild steel High strength

High stiness

High ductility

Susceptibility to corrosion

Susceptibility to atigue

High weight

High energy required or production

Stainless steel Corrosion resistance High cost

Aluminium Low weight

High ductility

Ease o recycling

Susceptibility to corrosion in strong acids and alkalis

High energy required or production

Plastic (polyethylene,

polypropylene, polyvinyl

chloride (PVC), etc)

Corrosion resistance

Low cost

Low coecient o riction

Ease o recycling

Susceptibility to creep

Low stiness

Non-conductive properties can be a disadvantage

Limited temperature resistance above 200C

Composite Corrosion resistance

Low weight

High strengthConductivity or non-conductivity

Low coecient o riction

Limited temperature resistance above 250C

Sensitivity to impact damage

Wagners Composite Fibre 100 x 100 mm

pultruded sections

Image courtesy of

Wagners CFT Manufacturing Pty Ltd

-

7/30/2019 Composites in Industrial Plants Pt1

7/23

5

2.2 Benetsofcomposites

Corrosion resistant

With the selection o correct materials, composites will not deteriorate in acids,alkalis, solvents and salt water, and can be used rom pH 0 to 14. Composites are

thereore used widely in tanks, pipes and process vessels in chemical extraction

o base and precious metals. Plant operating time can thereore be maximised.

Both minerals processing and chemical plants use this durable material or plant

inrastructure, such as gratings and hand rails, where rusting o steel structures

can place the saety o plant personnel at risk. Since composites do not require

painting, there are also reduced maintenance costs.

Durable

Composite materials are durable due to their high strength and high resistance

to atigue, abrasion and creep. Agitated tanks made rom composites have been

ound to operate successully or many years despite the cyclic loads experienced.

In pipelines, resistance to abrasion combined with a low coecient o riction aidsprocess fow and reduces downtime. This overall durability o composites reduces

the need or maintenance and repair, which maximises plant running time.

Light in weight

Composites are relatively light in weight compared to steel, iron and concrete.

For example, typical composite pipes are approximately 25 per cent o the weight

o ductile iron and 2 per cent o concrete equivalent pipe mass per metre. The

reduced weight o composite pipes, tanks and process vessels has led to lower

transportation and installation costs or the mining industry, and reduced plant

downtime through enabling installation at sites where access is restricted. Where

electrical guarding and hatches need to be lited by plant operators, the composite

option at less than 10 kg per sheet is certainly preerable to the steel option at

more than 20 kg. This also applies to hatches and all components that must belited to ensure the saety o all personnel.

Electrically insulating or conductive

For saety reasons, the electrical insulation o process equipment is critical

where high electric currents or voltages are used. Composites that are electrically

insulating are used in high electric currents or voltage environments, such as pot

rooms in aluminium processing and in electrowinning. The radio and magnetic

transparency o composites is useul in a number o applications. In applications

where static charge can build-up, static dissipation and grounding o equipment

is critical to keep plants operating and to prevent res where fammable solvents

are used. Conductive properties can also be built into the composite equipment or

applications such as solvent extraction.

Thermally insulating

Where high temperature fuids are stored in vessels or pipes, thermal insulation

is critical or saety. The use o composites in these applications can reduce or

eliminate the need or insulation with external temperatures typically being less

than 60C or fuids and liquors up to 100C. Furthermore, being an insulator, the

transer o heat rom composite materials to any body part is very much less than

that rom a conductive material such as stainless steel.

Flexible in design and manufacture

Composite materials oer solutions to many manuacturing problems due to the

vast array o resins, reinorcements and unique manuacturing methods used

to produce them. Such fexibility in design and manuacture can result in cost

and time savings. For example, it is relatively simple or composite materials to

create compound curves in metallic materials. Also, while large covers usually

require large support structures, the light weight nature o composites means it is

possible to design covers that are supported on the edge o a vessel without the

requirement or intermediate supports. Composites manuacturing processes,

such as hand lay up, also enable unique designs to be manuactured at relatively

All FRP (handrails, stair treads, landing

and support structure) stair platorm

Image courtesy of Exel Composites

-

7/30/2019 Composites in Industrial Plants Pt1

8/23

6

low cost. The ability o composites to conorm to any shape and bond with steel

and concrete enables rehabilitation and retrot. For example, composite materials

are well used in the lining o process vessels. Composite materials fexibility in

design and manuacture also means on-site manuacture o very large vessels,

such as lament winding o large tanks, is possible

2.3 Productapplications

2.3.1 Current applicat ions

Composites can be used in many applications in the mining and process

industries, including:

Mining

ducts or ventilation, chilling and cooling in underground operations

cuttable rock bolts (used in reinorcement), rib bolts and brackets

mobile and stationery containers or water, diesel and other liquid

storage on site

bore casings and insulation in underground structures

theodolites and legs or survey equipment.

Mineral and chemical processing

tanks or storage o corrosive and non-corrosive materials

process vessels including gas cooler condensers, electrostatic mist

precipitators, leach tanks, reactor tanks, thickeners, electrolytic cells, cell

bearers, mixer settlers, spent tanks, cr ystallisers, solvent ext raction and

electrowinning cells, and pulse columns

mineral sands separation equipment including spirals, cone concentrators

and hydrocyclones

cooling towers

linings or concrete and steel tanks and equipment

claustra walls and panels

ans, blades, bafes, agitators, bottom scrapers and mixing tools

pipes, ttings and launders including products or abrasive (e.g. slurry)

and non-abrasive materials

nozzles, fanges, elbows, reducers, branches, tees and joints

ducts or transporting process gases and ume extraction

scrubbers and waste gas towers, quench towers and demisters

dampeners/valves

gratings, ladders, walkways, handrails, steps and platorms

inspection hatches, hoods and covers

structural applications such as support beams, channels and angles

roth crowders or fotation tanks

protective guards on machines

consoles

telescopic handles or sampling and testing

stacks, fues and other large structures

use o composites to repair ailed plant components.

Chemical resistant FRP piping system

with coupling or use in highly

corrosive environments

Image courtesy of A.C.Whalan Composites

The ability o composites

to conorm to any shape

and bond with steel

and concrete enablesrehabilitation and retrot.

-

7/30/2019 Composites in Industrial Plants Pt1

9/23

7

Mine site inrastructure

guards, grating, walkways, platorms, kick rails, stairs and ladders

rebar and stay-in-place ormwork or concrete

polymer concrete

concrete foor and bund coatings and lining

cable supports, trays and ladders

pumps

power poles including cross-arms

wall and roo sheeting as well as purlins in site buildings

window and door rames

water treatment and supply

bridges

trusses

manhole covers

railway sleepers

drains and sumps

poles to remove high voltage lines.

Port inrastructure

guards and inspection hatches

gratings, ladders, walkways, handrails, steps and platorms

structural panelling, sheet piling and other applications in marine environments.

2.3.2 Future applications

The advantages o composites described above have led to investigations intonew applications or composites, including:

truck bodies, cabs, panels and engine casings (ully breglass cabs have been

used by Leader trucks and Mack trucks since the 1970s)

access ladders, hand rails and steps attached to major mining and

earth moving equipment

wear blocks

long and short conveyors including supports, covers and hoods, guards

and rollers

wash plant pipes and air receivers

port loading inrastructure

gag ducts or re suppression in underground mines.

2.3.3 Pipes and ducts

From pipes carrying sulphuric acid in leaching o copper bearing ore, to waste

water, composite pipes have widespread use in the chemical and minerals

processing industries in Australia. Key benets include resistance to corrosion

in chemical environments, increased hydraulic fow and reduced operating costs

through comparatively low riction compared to steel. Conductive composite

pipes are much saer than plastic pipes in solvent extraction plants, and have

been ound to be more cost eective and durable than the alternative SAF2507

stainless steel.

21 mm solid FRP rods supplied to customer

as concrete rebar to eliminate any

electrostatic intererence with its equipment

Image courtesy of Exel Composites

-

7/30/2019 Composites in Industrial Plants Pt1

10/23

8

In underground mining, composite ducts are used or ventilation as its light weight

nature enables much easier installation and lighter supports than other products.

In the chemical and minerals processing industries, composite ducts are used or

applications like transporting sulphur dioxide in plants manuacturing sulphuric

acid, and in minerals processing plants to extract umes.

There are a range o standards and guidelines available or the design and

manuacture o composite ducts and pipes. Those most widely used in

Australia include:

Composite pipes can be used at low and high pressures. For example, the API 15

HR specication or high pressure breglass line pipe covers pipes rated or

3.45 MPa to 34.5 MPa.

For above ground pipes and ducts, BS 6464 contains inormation on installation

including supports, guides and anchors. Pipe support spacing is important and the

ratio o the vertical defection o a pipe to the horizontal span between supports

is oten limited to 1:300. For pipe supports, a minimum contact arc o 120 under

the pipe is typical and rubber packers between the support and the pipe can help

reduce point loads.

For buried pipes, AWWA C950 contains inormation on design whilst AS 2566

and BS 6464 can be used or installation. Inormation on trench preparation,

backlling material and installation procedures are given in these standards.

It is possible to make continuous radius bends, including elbows and long radius

bends, as a single unit with no longitudinal joints in composites.

2.3.4 Tanks and process vessels

In the chemical and minerals processing industries, composite tanks and process

vessels have a long history o successul use in chemical environments which

readily corrode steel and attack concrete.

Sulphuric and hydrochloric acids are widely used in processing copper, lead, nickel

and zinc. In these manuacturing plants, composites are used to construct leach

tanks, thickeners, electrolytic cells mixer settlers, spent tanks and pulse columns.In sulphuric acid manuacturing plants, composites are widely used in radial fow

scrubbers, gas cooler condensers and electrostatic mist precipitators.

AS 3571 Plastics piping systemsGlass-reinorced thermoplastics (GRP) systems based on unsaturated

polyester (UP) resinpressure and non-pressure drainage and sewerage; and pressure and non-

pressure water supply

AS 2634 (obsolescent) Chemical plant equipment made rom glass-bre reinorced plastic (GRP), based on thermosetting

resins

AS/NZS 2566 Buried fexible pipelines

BS 7159 Code o practice or design and construction o glass-reinorced plastics (GRP) piping systems or

individual plants or sites

BS 6464 Specication or reinorced plastic pipes, ttings and joints or process plants

BS EN ISO 14692 Petroleum and natural gas industriesglass-reinorced plastics (GRP) piping

ISO 10467 Plastics piping systems or pressure and non-pressure drainage and sewerageglass-reinorced

thermosetting plastics (GRP) systems based on unsaturated polyester (UP) resin

ISO 10639 Plastics piping systems or pressure and non-pressure water supplyglass-reinorced

thermosetting plastics (GRP) systems based on unsaturated polyester (UP) resin

ANSI/AWWA C950 Standard or berglass pressure pipe

ISO 10639 Plastics piping systems or pressure and non-pressure water supply using GRP systems based on

unsaturated polyester (UP) resin.

FRP Fuel tanks

-

7/30/2019 Composites in Industrial Plants Pt1

11/23

9

While the corrosion resistance o composites is a key benet, the relatively low

cost o composites compared to alternative materials such as stainless steel,

duplex and other alloys has also accelerated their acceptance.

The ollowing standards and guides are applicable to composite tanks and vessels:

As well as storage tanks and process vessels, composites can also make internal

components such as bafes and weirs. For example, composite fanges, manways

and other xtures can be built into the composite tank or vessel.

It is important to reinorce areas o composite tanks and vessels subject to higher

loads. Shells should be reinorced with external circumerential reinorcing ribs

to provide rigidity, particularly where agitators are not independently supported.

Floors should be reinorced where intermediate supports are needed or tank

roos. Roos should be reinorced where personnel and/or other equipment need to

be supported.

Inormation on supports or tanks and process vessels is given in the standards.

It is standard practice to use concrete slabs as supports, however, concrete ring

beams lled with compacted sand nished with a layer o sand and oil mixture can

also be used.

2.3.5 Launders

There is no design standard specically or composite launders, although BS 6464

contains some applicable inormation. The stiness o the launder should be

sucient to prevent sag, twist, camber or spreading without ull length supports or

restraints while the launder is operating. It is advisable to reinorce o-take areas

o launders.

2.3.6 Joints and fttings

The type o joints aects the durability and cost o pipelines. Common methods

o joining composite pipes are butt and strap; rubber ring type and fanged joins.Restrained joints eliminate the need or and thus cost o thrust blocks etc. Butt

and strap joints used with composite pipes are restrained, have similar chemical

resistance to the parent pipe material and are less susceptible to leaks. However,

in terms o installation butt and strap joints are slow and costly and do not tolerate

misalignment or movement well. Whilst rubber ring type joints are not restrained,

they are quick to install and tolerate some degree o misalignment and movement.

Thus rubber ring type joints are particularly useul or buried pipelines.

There are a number o requirements or durable butt and strap joints. The strength

o the joint must be at least equivalent to that o the parent material. The required

widths o pipe joints are given in the standards, and where accessible, the internal

surace o the joint should be laminated. Since joints are hand laid, their thickness

must be that o a hand laid pipe, even or joints in a lament wound pipe. To

prevent ingress o fuids into the laminate, all cut ends must be sealed with resin.

Tees, branches and other similar joints can be prepared using similar techniques

to those employed or standard composite butt and strap joints.

AS 2634 (obsolescent) Chemical plant equipment made rom glass-bre reinorced plastic (GRP), based on

thermosetting resins

BS 4994 (superseded) Specication or design and construction o vessels and tanks in reinorced plastics

BS EN 13121 GRP tanks and vessels or use above ground. Design and workmanship

BS EN 13923 Filament-wound FRP pressure vessels. Materials, design, manuacturing and testing

ASME RTP-1 Reinorced thermoset plastic corrosion resistant equipment

ASTM D3299 Standard specication or lament-wound glass-ber-reinorced thermoset resin

corrosion-resistant tanks.

FRP fange installed at a ertilizer (phosphates)

manuacturing acility in Australia

Image courtesy of Lucy Cranitch, GHD

-

7/30/2019 Composites in Industrial Plants Pt1

12/23

10

Flanged joints are also widely used and fanges can be made rom composite

materials. The thicknesses o composite fanges depend on the design, but are

generally greater than that o metal fanges. ANSI dimensions are commonly used

or bolt patterns, and composite fanges can be manuactured to be compatible

with most existing fanges made o PVC, steel and ductile iron. It is important

to ensure composite fanges are fat to provide a good seal, so ull fat-aced

fanges with steel backing rings are oten used. It is important to never mix ull

ace composite fanges and raised ace fanges as this readily results in leaks and

ailures. To avoid point loads caused by nuts directly in contact with the composite

fange ace, washers should be used under nuts, relies can be cut into the ace o

the fange and care must be taken with bolt torque. All cut outs or bolt holes must

be sealed with resin to enhance durability. A number o standards are applicable

to fanges.

2.3.7 Coatings and linings

Composites can be used in conjunction with concrete or steel to provide a

corrosion-resistant lining or coating. This may be in the orm o an internal

corrosion protection to steel or concrete tanks, or as a protective layer on concrete

foors or bunds. The ollowing standards and guides are applicable to composite

coatings and linings:

The ollowing steps are typical in applying a bonded composite layer to concrete:

1. The concrete should be let 28 days to cure prior to application o any coating

or lining.

2. Surace preparation o the substrate is important. Abrasive grit blasting (high

pressure water or grit blasting) o the surace is required to improve bonding

o the coating or lining.

3. Remove dust or grit by vacuuming and/or sweeping.

4. Wash the surace to remove oils, greases and other contaminants.

5. Dry the substrate.

6. Test or suitability o the coating or lining. Various tests are required

depending on the substrate, or example pH, moisture and surace pull-o

tests are required or concrete.

7. Fill voids with a resin-based ller.

8. Prime.

9. Apply the basecoat, consisting o resin reinorced with bre mats or

with llers.

10. Apply the top coat, and i required spread silica aggregate to provide

slip resistance.

Quality control during the coating or lining process is important. This should

include wet lm thickness tests, adhesion tests, coating sensitivity tests and resin

gel time tests. I an additional conductive primer coat is applied, spark testing can

be conducted once the basecoat is applied.

BS 6374-4 Lining o equipment with polymeric materials or the process industries. Part 4: Specication or lining

with cold curing thermosetting resins

ACI 515.1R Guide to the use o waterproong, damp-proong, protection and decorative barrier systems or concrete.

AS 4087 Metallic fanges or waterworks purposes

AS 2129 Flanges or pipes, valves and ttings

AS 4331.1 (ISO 7005) Metallic fanges (steel fanges)

-

7/30/2019 Composites in Industrial Plants Pt1

13/23

11

3 Composite product manuacturing

3.1 Components

Each component contributes to the overall properties, perormance and

appearance o the composite product. The precise type o materials and

manuacturing process used are determined by the specic properties required

or the nal product. The ollowing principles are essential or the production

o good-quality composite products:

quality o materialsresins, glass bres, additives and cores

quality o designquantity, orientation and suitability o bres, suitability and

volume o resins, suitability and volume o additives, and suitability o cores

quality o manuacturingconsistency and control o the manuacturing and

curing processes. Full curing o the product is essential to attain optimum

mechanical properties, prevent heat sotening, limit creep and reduce fuiddiusion

quality o transport and installation practices.

As the composite material itsel is made at the same time as the part, quality

assurance and inspection throughout these processes are essential.

3.2 Fibrereinforcement

The role o the reinorcement in a composite part is to carry the applied load.

The actors which aect the contribution o the reinorcement to the composite

properties are:

the type o reinorcement

the orm o reinorcement

the quantity o reinorcement (resin-to-reinorcement ratio)

the orientation o the reinorcement.

Type: Many dierent types o reinorcement are available, including E glass,

ECR glass, C glass, carbon, aramid (Kevlar) and many other less common bres.

Carbon bre is used in the mining industry primarily to provide conductivity.

The bulk o the reinorcements are made o glass. E glass is the most widely

used bre type due to its high strength and relatively low cost. C glass is used

where excellent chemical resistance is required, usually in the orm o a tissue

as described in the table below. ECR glass is sometimes used to provide better

resistance to chemicals.

The ollowing table, taken rom the Eurocomp Design Code, compares typical glassbre properties. Compared to steel, glass bres have approximately 2.5 times the

strength with only one third o the density, and higher dimensional stability.

Table 2 Comparison o properties o glass fbre types and steel

Composite products consist

o a combination o bres,

resins, additives, and in

some cases, cores.

Fibreglass borehole liner

Image courtesy of Teakle Composites

Property Eglass Cglass Steel

Specic gravity 2.54 2.50 7.8

Tensile strength (MPa) 3400 3000 1350

Tensile modulus (GPa) 72 69 200

Elongation (%) 4.8 4.8 1032

Coecient o thermal expansion (106/C) 5.0 7.2 11.5

-

7/30/2019 Composites in Industrial Plants Pt1

14/23

12

Form: Fibres are available in many orms, as described in the ollowing table.

Table 3 Forms o reinorcement

Quantity: The manuacturing process has a large eect on the quantity o

reinorcement in composites. Fabrics with closely packed bres will give a higher

volume raction o reinorcement than those abrics with large gaps between bre

bundles. The weight per unit area o reinorcement varies greatly rom as low as

20 g/m2 or tissues, to 300 or 450 g/m2 or chopped strand mat, to 800 g/m2

or woven rovings, and to well over 1600 g/m2 or lament wound rovings. As a

general rule, the strength and stiness o a composite are proportionate to the

quantity o reinorcement present. However, the laminate strength peaks at an

optimum bre volume o about 70 per cent, above which the strength declines due

to a lack o resin to hold the bres together.

Orientation: The tensile strength o bres is greatest in longitudinal directionrather than width. Fibres must thereore be oriented in the direction o the load,

and orientation can be designed to suit the particular loading requirements o the

Reinforcementform Description

F ilament Individual bres as initially drawn rom the raw materials. F ilaments are processed ur ther

beore use.

Continuous strand Filaments gathered in continuous bundle. Continuous strands are processed urther

beore use.

Milled bre Continuous strands hammer-milled into lengths o 0.8 to 3 mm. Milled bres are used as

llers and additives to control heat distortion and improve surace quality in compounding

and casting.

Chopped strand Strands chopped to 5 to 60 mm leng ths.

Roving Strands bundled together without twist. Rovings are used in various manuacturing processes

including lament winding and pultrusion to give high strength in the direction o the bres.

Yarn Twisted strands. Yarns are processed urther beore use such as in the manuacture o cloths.

Chopped strand mat Non-woven mat o chopped strands in random orientations. This reinorcement is widely used

to give strength in all directions and good inter-laminar adhesion.

Continuous strand mat Non-woven mat o continuous strands in random orientations.

Tissue/veil Fine non-woven mat o continuous laments that are uniormly distr ibuted over the surace

in random orientations. Tissues have relatively low strength. Their purpose is to support a

resin-rich layer which protects the composite rom moisture and chemicals, through preventing

these fuids entering the laminate along the bres.

Unidirectional abric Rovings in one direction held together by a small amount o bres woven or stitched at 90.

Unidirectional abrics give strength in one direction.

Woven roving Rovings woven into a abric in a particular pattern, usually a plain weave. Woven rovings give

strength in two directions.

Cloth Fabric made rom yarns woven in a par ticular pat tern. Cloths give streng th predominantly in

two directions.

Stitched abric Layers o bres held together by stitching. Stitched abrics give strength predominantly in two

directions and have higher interlaminar strength than cloths.

Multi axial abrics Fabric made rom yarns or rovings in more than two directions. Multi axial abrics give strength

in three or more directions.

Needle punched and

combi-mats

Fibreglass cloth composed

in a swirl pattern

-

7/30/2019 Composites in Industrial Plants Pt1

15/23

13

part. Unidirectional bres run in one direction only, whereas abrics have bres in

predominantly two directions, and chopped strands are oriented in all directions.

The combination o reinorcements results in an anisotropic material, where its

properties vary with direction.

3.3 Resins

While the bres are the principal load-carrying members, the surrounding matrix

o resin maintains them in the desired orientation and location. It also allows

the applied load to be transerred between the reinorcing bres. Another very

important unction o the resin is to provide a barrier to the environment, which

protects the composite rom the elements, such as water and chemicals.

Resins are also reerred to as polymers as they are made up o many (poly)

long-chain molecules (mers). It is helpul to distinguish between two broad groups

o polymersthermoplastic and thermosetting. Thermoplastic polymers melt

when heat is applied. This is because their long chains are not chemically bound

together (i.e. they are not cross-linked). Thermosetting polymers, on the other

hand, do not melt when heated because their long chains are chemically bound

together (i.e. they are cross-linked). The resins used in composites (and those

described here) are all thermosetting polymers.

There are a great variety o resins. The most common groups are polyester, vinyl

ester and epoxy. Whilst re retardant versions o these resins are available,

phenolic resins are also used in situations where re retardant properties are

required. Resins are supplied to composite manuacturers in a liquid state, and

during the manuacture o the composite part the resin is cured to orm a solid.

This process o curing the resin is a chemical reaction in which the cross-links are

ormed between the polymer chains. Beore curing, the resin is in a liquid state as

the polymer chains can fow easily. Once the polymer chains are linked together,

the polymer chains can no longer fow and the resin becomes a hard solid.

Polyester and vinyl ester resins supplied to the composite industry are dissolved

in styrene monomer. This reduces the viscosity, so that the resin fows more readily

to allow ease o spreading and ensures ull bre-wetting, complete impregnation

and minimal voids. The styrene monomer is also a key component in the curing

process o polyester and vinyl ester resins, orming the cross-links between the

polymer chains.

Polyesterresins provide good strength at a relatively low cost and are used widely

in the marine industry, and in pools, spas, transport, casting, inrastructure and

automotive applications. Various types o polyester resins provide a wide variety

o properties relating to water and chemical resistance, weathering and shrinkage

during curing.

Vinylesterresins are used primarily where improved water and chemical

resistance, heat resistance or improved fexibility is required. Standard and

high perormance vinyl ester resins are widely used in the mining and chemical

industries due to their high resistance to acids, alkalis and solvents.

Epoxyresins have a dierent structure to polyester and vinyl ester resins. They are

usually sold as a two-pack systemPart A and Part B and these two parts must be

mixed strictly in the ratios given by the supplier. The part A is the resin and the part

B is the hardener and there are a number o dierent types o each. Epoxy resins

are not dissolved in styrene monomer and do not shrink as much as polyester or

vinyl ester resins when they cure.

Epoxy Resins provide particularly good mechanical strength and adhesion and

have good stiness, toughness, heat resistance and water resistance. Epoxy resins

tend to be more expensive than polyester resins. Epoxy resins are widely used in

piping and inrastructure.

It is helpul to distinguish

between two broad groups

o polymersthermoplastic

and thermosetting.

Spent Electrolyte Tank installed at

Cause Nickel, Kalgoorlie

Image courtesy of Marky Industries Pty Ltd

-

7/30/2019 Composites in Industrial Plants Pt1

16/23

14

3.4 Additives

The ollowing additives can be incorporated into the resin:

Fillers are powders used to add bulk to the resin, which reduces costs and

enhances the compressive strength o the composite material. Fillers can also

reduce the exotherm (heat build-up) and shrinkage during curing. Fillers may be

added to the resin at up to 50 per cent by weight (or dense llers) or 35 per cent by

volume. Addition o ller over these amounts should be avoided as it reduces the

fexural and tensile strengths, as well as the chemical resistance o the composite.

Thixotropes are powders added to the resin to allow it to hold up onto a vertical

surace. The addition o thixotropes is required when the resin must not run or

sag when it is applied to steep moulds or to vertical walls (such a lining o a tank).

Thixotropes allow the resin to fow when a shear orce is applied (i.e. when resin

is orced through a spray gun), and prevent the resin rom fowing when the orce

is removed.

Pigments can be incorporated into the resin to produce a specic colour and to

provide UV resistance.

UVinhibitorsandabsorbers can be added to the resin to improve its UV resistance.

Flameretardants can be added to the resin to improve its resistance to re.

Inhibitors are chemicals added to the resin to slow down the curing reaction, so

more time is available to work with the resin during manuacture beore it cures.

As resins can cure in storage, inhibitors help to extend the resins storage lie.

Promotersandaccelerators are chemicals added to the resin to speed up the

curing reaction to enable manuacture in a reasonable timerame.

While additives improve many properties o composites, they can also impair other

properties at the same time. For example, some re retardants can reduce thecomposites resistance to weathering and chemicals. Additives should thereore

be careully selected.

3.5 Cores

Some composite parts incorporate core materials, primarily to impart stiness

without increasing weight. Cores may also be used to increase the impact strength,

atigue resistance, thermal insulation and sound deadening eect. For a panel, the

fexural stiness is proportional to its thickness cubed, which means as thickness

increases, stiness increases dramatically. Cores can be used in specic areas o

a structure where extra stiness is required (e.g. stiening ribs) or throughout the

area o a laminate as a sandwich panel.

A sandwich panel consists o a core with reinorcement and resin on either side(skin). In a sandwich panel, the adhesive layers between the skins and the core

must be able to transer the loads and thereore be at least as strong as the core

material. Without a good bond, the three components work as separate beams

and the stiness is lost.

Figure 1 shows a sandwich panel under a bending load. As a result o the bending,

the upper section is placed under compression, the lower section in tension and

the core in shear. Shear strength and stiness o a core material are important.

Fibreglass drill rod joint assembly

in Instron testing machine

Image courtesy of Teakle Composites

Figure 1. Bending a sandwich panel

Compression

Shear

Tension

Skin

Core

Skin

-

7/30/2019 Composites in Industrial Plants Pt1

17/23

15

3.6 Exampleofacompositelaminate

Figure 2 shows the wall o a composite tank or pipe to illustrate the

layers that make up the composite material.

The reinorcement sequence is oten given on drawings in the

ormat below, in order rom the internal surace to the outer surace:

C/2M/4(MW)/M/C*

Reinorcements:

C = 40 g/m2 C glass or synthetic tissue such as Nexus tissue.

M = 450 g/m2 E glass powder bound chopped strand mat.

W = 800 g/m2 E glass woven roving.

C* = 40 g/m2 C glass or synthetic tissue such as Nexus tissue with

resin containing wax and UV inhibitors or pigment.

3.7 Manufacturingprocesses

Formation o a composite product involves combining layers o reinorcement withresin. A chemical reaction o the resin then converts it rom a liquid to a solid to

bind everything together as a whole. This chemical reaction is called curing, and is

activated by catalysts or polyester and vinyl ester resin and a hardener or epoxy

resins. The catalyst or hardener must be added to the resin prior to combining the

resin with the reinorcement. It is important to achieve good cure o resins in a

timely manner. This can be achieved through adjusting the chemicals involved in

curing, including the inhibitors, accelerators and catalyst or hardener, and through

taking account o the temperature during manuacture. There are a number o

dierent manuacturing processes.

Handlayupinvolves the manuacture o a part in a mould. Resin is rst applied to

the mould surace, then layers o glass which are wet by the resin and consolidated

with rollers.

VacuumInfusionProcessing(VIP) involves the lay up o dry glass on a mould. A

fexible lm (bag) is then laid over the glass and sealed to airtight and then the

resin is pulled through the glass under the orce o a vacuum.

ResinTransferMoulding(RTM) uses two matched moulds a bottom mould and a

top mould. This process thereore produces parts with two nished suraces.

Filamentwindingis perormed on a machine that winds glass bres onto a

cylindrical mandrel in a prescribed pattern to orm the desired nished shape (e.g.

a pipe). Fibres in the orm o continuous rovings are routed through a bath o resin

beore reaching the mandrel. Ater curing, the tube is removed rom the mandrel.

Pultrusion is used or the manuacture o products o a constant cross-section.

The glass bres are pulled through a die (as compared to extrusion where thematerial is orced through a die) in a continuous process, injected with resin,

shaped by the die and then cured.

3.8 Manufacturers

Australias composites industry is represented by Composites Australia Inc.

Composites Australia is a membership-based, not-or-proft association dedicated to

increasing the awareness and general usage o composites in Australia. Composites

Australia has access to an extensive database o organisations in the Australian

composites industry including raw material suppliers, manuacturers, designers

and engineers, research and development agencies and training and education

providers. See section 9 o this guide or contact details or a number o Australian

composite product manuacturers, or contact Composites Australia at:

Level 15, 10 Queens Road, Melbourne Victoria 3004

Telephone: + 61 3 9866 5586 or 1300 654 254

Facsimile + 61 3 9866 6434

www.compositesaustralia.com.au

Figure 2. An example o the makeup o a composite wall

C = Tissue

M = Chopped Strand Mat

W = Woven Roving

Alternating chopped mat& woven roving to desired

thickness

Vinyl Ester Resin resin/waxtopcoat

C M M W M M M M M C

Primarycorrosion

barrier

-

7/30/2019 Composites in Industrial Plants Pt1

18/23

16

4 Australian case stories

The ollowing tables provide examples o where composites have been usedin Australia.

Table 4 Current composite components in Australian mining and minerals

processing plants

Enduser Industry Location Components

Rio Tinto Aluminium Gladstone, QLD Hoods or ume tanks, pipes, claustra walls in pot rooms

Adelaide Chemical

Company

Copper Burra, WA Acid leach tanks (agitated), tank, slurr y pipe, grating, gas

cooling tower

Xstrata Copper

Reneries

Copper Townsville, QLD Electrolyte pipework, polymer concrete Electrolytic cells,

galvanizing tank, acid storage tank, grating, wall cladding,

roong

BHP Billiton,

Olympic Dam

Copper,

uranium,

gold, silver

Roxby Downs, SA Mixer settlers, Jameson cells, pipes in solvent extraction and

electrowinning, bund linings, ducts, electrolytic cells, stack,

tanks, electrostatic mist precipitators

Kanowna Belle Gold Gold WA Roaster stack, an to stack ducting

Posgold Ltd Gold WA Tanks

Nystar Lead Port Pirie, SA Roo and wall sheeting, cable ladder to support cabling

Heraeus Ltd Metals VIC Fume extraction ducting or precious metals recovery plant

Rennison Mine Mining Burraga, NSW Pump

Centaur Mining

Minproc/Davy

JV Cawse Nickel

Nickel WA Settler tank and lids

Kombalda Nickel Smelter Nickel WA Process equipment in the sulphuric acid plant

Kalgoorlie Nickel Smelter Nickel Kalgoorlie, WA Electrostatic mist precipitators, scrubber

BHP Billiton, QNI Nickel Yabulu, QLD Leach tanks, linings in the stage 2 organic running tank and

the cobalt sulphate discharge storage tank, lining o gas

cooler condensers

Sunmetals Zinc Townsville, QLD Cooling towers, grating

Xstrata Zinc and lead Mt Isa, QLD Froth crowders or fotation tanks

Nyrstar Zinc Hobart, TAS Leach reactor tanks and wash down tanks, electrolytic

cells, spent tanks, launders, cooling towers, tank covers,

cell bearer, bafes or tank, copper sulphate reactor tanks,

mercury removal towers, oreshore stacks, pipework,

precipitators, concrete tank linings, tanks, agitator blades,

segmented clarier covers, tank, dampeners, butterfy valve,

gas cooling towers and internals.

-

7/30/2019 Composites in Industrial Plants Pt1

19/23

17

Table 5 Current composite components in Australian chemical processing plants

EndUser Industry Component

Ferro Corporation Ammonium and

sulphur products

Sieve tray scrubbing tower

Nuarm Chloralkali Plant Chloralkali plants Sodium hypochlorite storage tanks, chlorine headers, chlorine

scrubber, anolyte tank

Incitec Pivot Sulphuric acid and

ertilizer

Settlers, pipes, radial fow scrubber, 2 gas cooling towers, ducts,

drying tower inlet maniold, 8 electrostatic mist precipitators

Alcoa General chemical Tank

Australian Chemical

Company

General chemical Mist eliminator vessel or copper roaster

NSW Brickworks General chemical Freestanding insulated ume stack

Chemplex efuent

treatment plant

General chemical Pipework

Feld Proctor Gamble General chemical Tank

ICI Operations General chemical Tank

Koka Chrome Ind. Co Ltd General chemical Fume extraction ducting or plating plant

Metalok (S) Pte Ltd General chemical Plating line ume exhaust ducting

Pritcorp Sdn Bhd atty

alcohol plant

General chemical HCl vapour scrubber, glycerine reactor/settler, acidulated soap

storage surge tank, tank

SCM Milenium Chemicals General chemical Titanium dioxide stack, chlorine scrubber

Tiwest General chemical Titanium dioxide stack, plant pipework

Toxide Group Services General chemical Ducting (ume extraction), stack (steel supported)

Unizon Singapore General chemical 3600 cm vertical scrubber

Delta (BHP) EMD Plant Manganese dioxide Electrolytic cells, storage tanks or resh and spent electrolyte

Cold Rolling Sdn Bhd Steel Pipe (or pickle line), lining o steel prefux tank, lining o steel acid

pickling tank

Tubemakers Steel Acid pickling tank

BHP Pellet Plant Steel Waste gas tower, ne scrubber, quench tower, ne scrubber demister,

pre-quench scrubber

Minnehasa Sulphuric acid Mercury removal tower.

50 m Composite Fibre Conveyor.

Modulus design or easy transport,

assembly and dismantling.

Capacity: 400 tone per hour

Belt speed: 2 m/sConveyor span: 24 m

Number o spans: 2

Incline angle: 20 degrees

Image courtesy of

Wagners CFT Manufacturing Pty Ltd

-

7/30/2019 Composites in Industrial Plants Pt1

20/23

18

5 Technical perormance

This section is particularly aimed at people who are relatively unamiliar withcomposites, and or those who would not normally have considered them or

applications. This section aims to raise awareness o the properties o composites

and the actors to be considered in their use.

Properties o composites and their raw materials given in this document are typical

or average gures. It is important to use the actual product data rom the suppliers

when designing products with composites.

5.1 Design

Composites are less successul when they are used to replace another material

without considering its specic design. For example, composite pipes are less sti

than metallic pipes, and thereore the supports need to the placed more closely

together when installing composite pipes. Such actors have been considered in

the various design standards or composites.

It is important to engage composite designers and also have 3rd party verication

where appropriate. Specialist designers can be contacted directly or through the

composite manuacturer. Consideration o the various loads must be perormed

diligently and by those who have the background and knowledge o the materials

and structures.

Section 10 o this guide contains details or a number o Australian composites

design and engineering service providers.

5.2 Standards

Standards can be accessed at www.sai-global.com and other online stores.

AS 3571 Plastics piping systemsglass-reinorced thermoplastics (GRP) systems based on unsaturated

polyester (UP) resinpressure and non-pressure drainage and sewerage; and pressure and

non-pressure water supply

AS 2634 (obsolescent) Chemical plant equipment made rom glass-bre reinorced plastic (GRP), based on thermosetting

resins

AS/NZS 2566 Buried fexible pipelines

AS 2376.2 (superseded) Plastics building sheetsglass bre reinorced polyester (GRP)

AS 2424 (superseded) Plastics building sheetsgeneral installation requirements and design o roong systems

AS/NZS 4256.3 Plastic roo and wall cladding materialsglass bre reinorced polyester (GRP)

AS/NZ 2924 High-pressure decorative laminatessheets made rom thermoset ting resinsclassication and

specications

AS/NZS 3572 Plasticsglass lament reinorced plastics (GRP)Methods o Test

BS 4994 (superseded) Specication or design and construction o vessels and tanks in reinorced plastics

BS 6464 Specication or reinorced plastic pipes, ttings and joints or process plants

BS 6374-4 Lining o equipment with polymeric materials or the process industries, Part 4: specication or

lining with cold curing thermosetting resins

BS EN 13121 GRP tanks and vessels or use above ground. Design and workmanship

BS EN ISO 14692 Petroleum and natural gas industriesglass-reinorced plastics (GRP) piping.

Finite element buckling analysis o a large

breglass nozzle under external pressure

Image courtesy of Teakle Composites

-

7/30/2019 Composites in Industrial Plants Pt1

21/23

19

5.3 Guides

5.4 Relativeperformanceofmaterials

Table 6 Composite properties* compared to other materials

* The properties in this table are indicative only

ACI 440.1R-01 Guide or the design and construction o concrete reinorced with FRP bars, Committee 440,

American Concrete Institute, Farmington Hills, MI. (May 2001), www.aci-int.org

ACI 515.1R A guide to the use o waterproong, damp-proong, protection and decorative barrier systems

or concrete.

A guide or Flowtite GRP pressure and non-pressure pipe, engineering design guidelines, Iplex

Pipelines Australia, www.iplex.com.au

Material

Randomglass

composite

Bi-

directionalglass

composite

Uni-

directionalglass

compositeAramid

compositeCarbon

composite Aluminium MildsteelStainless

steel

Fibre content by

weight (%)

2550 4570 5090 4055 4059 0 0 0

Density (g/cm3) 1.41.9 1.51.9 1.62.2 1.4 1.5 2.62.8 7.8 7.92

Tensile strength

(MPa )

48170 190440 4101730 3452067 4102700 80480 200800 190552

Tensile modulus

(GPa )

618 1225 2162 1980 30180 70 190210 193200

Compressive

strength (MPa)

115170 98280 210480 102172 360 84338 410480 220552

Compressive

modulus (GPa)

69 817 - 1619 - - - -

Flexural

strength (MPa)

90340 200450 6901860 301 378 310 413 551

Flexural

modulus (GPa)

517 923 2748 15 28 69 207 193

In-plane shear

strength (MPa)

6296 5583 110140 - - 276 - -

In-plane shear

modulus (GPa)

2.83.0 3.04.0 4.15.2 - - 2630 7580 -

Tensile

elongation (%)

1.62.1 34.5 2.4 22.6 11.5 2.523 2237 40

Thermal

conductivity

(W/mC)

0.150.52 0.190.35 0.3 (in bre

direction)

1.7 (in bre

direction)

1.4 (90 to

bres)

34 (in bre

direction)

0.8 (90 to

bres)

140200 4350 110

Coecient o

linear thermal

expansion

(106/mm/C)

1833 916 9 (in bre

direction)

14 (90 to

bres)

4 (in bre

direction)

57 (90 to

bres)

0.5 (in bre

direction)

25 (90 to

bres)

23 1114 1618

-

7/30/2019 Composites in Industrial Plants Pt1

22/23

20

Figure 3. Stress strain curves o various materials

5.5 Servicelife

It is typical to speciy a minimum design lie o 20 years o continuous operation or

composite process equipments in the mining industry. In other industries, such as

underground water pipelines, a design lie o 100 years is more typical.

5.6 Mechanicalproperties

5.6.1 General

The mechanical properties o composites depend on a number o actors:

resin-to-glass ratio

orientation o bres

method o abrication.

Composites are anisotropic, which means their properties vary with direction. For

the mechanical properties discussed below, it is important to remember the values

will be dierent in the direction o the bres to that normal to the bres. In terms

o strength, composites have the greatest strength in the direction o the bres. In

the direction normal to the bres, the resin and the bre-resin interace determine

the strength, which may be one or two orders o magnitude lower than in the

direction o the bres. Designers must thereore avoid stress systems that result

in signicant loads normal to the bres.

Detailed design literature and programs are available to estimate the eect

o combinations o bres in dierent directions on the overall capacity o the

composite. Calculations o the anisotropic properties o composites require the

application o the theory o anisotropic elasticity or use o simpler means to obtain

reasonable estimates. For this type o work, the reader is reerred to the various

standards, guides and sotware programs available.

5.6.2 StrengthThe rule o mixtures is used to calculate the strength o composites. This rule takes

into account the relative ractions o the strength o both the bres and resin.

Tensile strength

The bres in composites are the principal contributor to the tensile strength o the

component. The resin has signicantly lower strength and acts to bind the bres

together and transmit the loads between them.

Compressive strength

The strength o the resin has a much greater infuence on the compressive strength

o composites than it does on the tensile strength. This is because the resin must

have sucient compressive strength to prevent the bres rom undergoing local

buckling or kinking under compression. The resin also helps to prevent ailurethrough longitudinal splitting. The resistance to buckling under compression can

be improved at the design stage by incorporating edge fanges, double curvature

and troughs.

Anti-static cable tray supplied for the

Blacktip Offshore Gas Production PlatformImage courtesy of Exel Composites

Stress

Yeild and ultimate

strength can be

considered the

same. Design is

to ultimate using

saety actor.

Stress

Strain

A. Composites

Yeild strength

lower than

ultimate. Design

is to yeild using

saety actor.Strain

B. Common metals

Non-linear

curves

depending on

polymer.

Stress

Strain

C. Non-reinforced plastics

-

7/30/2019 Composites in Industrial Plants Pt1

23/23

Shear strength

When subject to shear stress, the load-bearing abilities o the bres and

matrix, and the extent to which stresses are transerred between them, aects

the stiness and strength o composites. Most composites contain planes o

weakness between the layers which can result in interlaminar ailure in shear.

The property o interlaminar shear strength describes this behaviour.

Composites made rom abrics which have some bres in the z direction

(through-wall thickness), such as stitched cloths or chopped strand mat, are

more resistant to interlaminar ailure than composites made rom abrics

without bres in the z direction.

Flexural strength

Flexure/bending involves a combination o tensile, compressive and shear orces.

At a simple level, the tensile, compressive and shear properties o the materials

can be used in the design or fexure. However, fexural strength is seldom the

limiting criterion in composites, as stiness more oten dominates the design.

Stiffness

The stiness o composites is low compared to steel, although carbon bre-

reinorced composites are an exception. Since the tensile strength-to-weight ratio

o composites is high and stiness low compared to steel, stiness tends to be the

key determinant in structural design with composites.

The stiness o composite parts can be increased by:

selecting bres with a higher elastic modulus (e.g. carbon bres)

sandwich construction. Since stiness is a unction o thickness, cores can be

incorporated into a composite to provide rigidity, while keeping the weight low

localised increase in thickness, or example, progressive thickening along a

local edge or fanging along the edge o a panel

ribs can be incorporated into the reverse side o the part

compound curves or local corrugations. A olded plate construction can be used

to achieve the required stiness rom the overall geometry o the structure.

For most composites with more than about 50 per cent volume o bres, the

stiness in tension is dominated by the bres, and the resin contribution is

insignicant.

5.6.3 Fatigue

Fatigue is the progressive damage that occurs when a material is subject to cyclic

loading and when the stress values o each cycle are less than the ultimate stress

limit. For example, in the mining and chemical industries, tanks and process

vessels with internal agitators can be subject to constantly imposed stress cycles

and are thereore susceptible to atigue.

The atigue behavior o steel tends to involve intermittent propagation o a single

crack, while the material close to the crack is virtually unchanged. In contrast to

this, cyclic loading o composites results in the ormation o many micro-sized

cracks. Since the small cracks in composites are spread uniormly in the material

rather than concentrated in a single area, a greater area o material is involved in

resisting atigue ailure. Furthermore, as the ormation o each small crack absorbs

energy, composites tend to have good atigue resistance compared to most metals.

However, as damage accumulates, a critical point is eventually reached at which

the material can no longer sustain the applied load and ailure occurs.

To improve the atigue resistance o composites, resins which are tougher and have

greater resistance to micro-cracking should be used, and the amount o voids and

other deects in the laminate should be minimised. It is also important to ensure

the load normal to the direction o the bres is minimised.

Flowtite GRP Pipe (Continuous

Filament Wound) installed in South-East

Queenslands western corridor recycled

water pipeline

Image courtesy of Iplex Pipelines Pty Ltd

and Fibrelogic Pipe Systems