-

8/12/2019 Col 407840

1/20

VOLCLAY BENTONITE GEOTEXTILEWATERPROOFING

PRODUCT MANUAL

Certificate No 86/1650

-

8/12/2019 Col 407840

2/20

2

CONTENTSWHAT IS VOLCLAY ?

HOW VOLTEX WORKS

ACCESSORIES

LIMITATIONSINSTALLATION GUIDELINESSECTION 1: UNDERSLAB INSTALLATION

1.1 Substrate Preparation1.2 Installation1.3 Pile Caps & Ground Beams1.4 Slab Penetrations1.5 Lift Pits1.6 Edge of Slab, Backfilled Walls

SECTION 2: PROPERTY LINE CONSTRUCTION

2.1 Property Line Installation Guidelines2.2 Metal Sheet Piling2.3 Earth Formed Shotcrete Retention Wall2.4 Auger Cast Caisson Walls2.5 Contiguous and Secant Piling

SECTION 3: BACKFILLED WALLS3.1 Surface Preparation3.2 Installation3.3 Wall Penetrations3.4 Terminations3.5 Masonry Block Walls

SECTION 4: TUNNELS/ EARTH COVERED ROOFS4.1 Installation

SECTION 5: SPECIAL CONDITIONS5.1 Pre-cast Concrete Plank Installation5.2 Contaminated Conditions5.3 Tie-in with Envirosheet Self-Adhering

Waterproofing Membrane

WHAT IS VOLCLAY ?Volclay sodium bentonite is a non-toxic mineral ofvolcanic origin found exclusively in the Black Hills regionof the United States. Volclay is specially processed by

CETCO to achieve the highest possible performance forall of our waterproofing products. CETCO alsomanufacturers Volclay CR, a contaminant resistantbentonite to assure optimum performance in saline orcontaminated water.

Volclay prevents water intrusion by forming a densemonolithic membrane upon contact with water. Thespecially processed Volclay expands under confinement,forming an impervious membrane that will be maintainedfor the life of the structure.

HOW VOLTEX WORKS

Voltex

is a highly effective waterproofing compositecomprised of two polypropylene geotextiles and aminimum 4.88 kg of Volclay sodium bentonite per squaremetre. The two geotextiles are interlocked by a patentedneedle-punching process which encapsulates andconfines the bentonite. Voltex DS integrates an HDPEliner bonded to the outside surface of the thick non-wovengeotextile. The HDPE liner provides extremely lowpermeabilities for water vapour and gas transmission.

Voltex is excellent for waterproofing belowgroundhorizontal and vertical surfaces. Typical installations areunderslab and property line applications including metal

sheet piling and concrete caisson construction. There isno concern about deterioration before or after the concreteis poured.

Installation of Voltex is fast and easy. Simply position theproduct into place and fasten. Voltex can be installed ongreen concrete, in virtually any weather, without the needfor primers or adhesives. Voltex can be easily cut on siteto form around corners and penetrations. The result isalways a consistent self-healing membrane.

Concrete

NeedlepunchedGeotextile Fibres

Woven Geotextile

Granular VolclaySodium Bentonite

Nonwoven Geotextile

Voltex forms acontinuousmechanical bond toconcrete. This bondis created whenVoltexs stronggeotextile fibres areencapsulated bypoured concrete asshown in theillustration.

-

8/12/2019 Col 407840

3/20

3

DURABILITYThe Volclay sodium bentonite in Voltex is uniformlyencapsulated between two high-strength woven and non-woven geotextiles. CETCOs state-of-the-art needle-punching process interlocks the geotextiles, preventing

the displacement of bentonite prior to, during, and afterinstallation. The geotextiles provide superior protectionfrom inclement weather and construction related damage,without requiring the use of a protection course.

SUPERIOR ADHESIONWhen concrete is poured against Voltex, a tenaciousmechanical bond is created with Voltexs high strengthgeotextile. Independent laboratory testing conducted inaccordance with ASTM D-903 (Peel Adhesion toConcrete), yields an average adhesion value of 66.7 N/M.The mechanical bond will hold Voltex in intimate contactwith the concrete should any ground settlement occur,

thereby preventing water migration between thewaterproofing and the concrete.

COST EFFECTIVE AND TIME EFFICIENTVoltex is designed to be installed on a properly preparedsubground, without the need to pour a working slab. Theproducts inherent flexibility allows for easy installation onirregular surfaces and rough property line forming. Voltexseams are easily overlapped without the need to roll outevery small wrinkle or air pocket. Voltex can be installedas soon as the forms are stripped; there is no waiting forthe concrete to cure.

NSF STANDARD 61 CERTIFIEDVoltex and Voltex DS are certified by NSF International toconform with the requirements of NSF Standard 61 Drinking Water System Components Health Effects.Both Voltex and Voltex DS are certified as an externalprotective barrier material for portable water concretetanks with a 1,000 gallon capacity or larger.

ACCESSORIESBENTOSEAL - patented trowel grade sodium bentonitecompound used to detail around penetrations, cornetransitions and terminations.

HYDROBAR TUBES- water soluble plastic tubing filled

with bentonite, used at the footing/wall intersection.

VOLTEX GRANULES - granular Volclay bentonite usedat detail areas that may require additional Volclayprotection.

ASSOCIATED SYSTEM PRODUCTSWATERSTOP-RX- expanding bentonite-based concrete

joint waterstop used around penetrations and applicableconcrete joints.

AQUADRAIN - prefabricated drainage composite

constructed of a molded polystyrene core and a filtefabric.

LIMITATIONS FOR VOLTEX /VOLTEX DSVoltex/Voltex DS is not designed for above ground ounconfined waterproofing applications.

Voltex and accessories should not be installed in standingwater. If ground water contains strong acids, alkalis, or isof a conductivity of 2,500 mhos/cm or greater, watesamples should be submitted to the manufacturer fo

compatibility testing. Voltex CR is recommended icontaminated ground water or saltwater conditions exist.

Voltex is engineered for use under reinforced concreteslabs 100 mm thick or greater on a compactedearth/gravel substrate. Voltex requires a minimum 150mm thick reinforced concrete slab if installed over a mudslab. Voltex is not designed for split-slab deckconstruction. Voltex is not designed to waterprooexpansion joints. Expansion joints are theresponsibility of others.

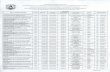

Voltex Physical Properties

Property Test Method ValuePeel Adhesion to Concrete ASTM D 903 66.7n/mHydrostatic Pressure Resistance ASTM D 5385 70.2 mPermeability ASTM D 5084 1 x 10

-9 cm/sec

Tensile Strength ASTM D 4595 329 NPuncture Resistance ASTM D 4833 61.3 kgLow Temperature Flexibility ASTM D 1970 Unaffected at -25 F (32C)

Voltex Product SpecificationBentonite Content .4.88 kg/sq.mDry Thickness.. 6.4 mmRoll Dimensions.. 1.10 m x 5.0 m (5.5 m

2)

Roll Weight.. 35 - 40 kg

-

8/12/2019 Col 407840

4/20

4

INSTALLATION GUIDELINES

Before installing Voltex/Voltex DS read this installation

manual to gain familiarity with specific procedures andapplications. For applications not covered in this manual,contact CETCO for specific installation guidelines.

SECTION 1UNDERSLAB INSTALLATION

Voltex/Voltex DS is engineered for use under reinforcedconcrete slabs 150 mm thick or greater on a compactedearth/gravel substrate. Voltex requires a minimum 150

mm thick reinforced concrete slab if installed over a mudslab. Voltex CR bentonite is used in contaminatedconditions as determined by a Volclay water sampletest.

Prior to installing Voltex the substrate must be properlyprepared. Complete all required lift pit, sump pit, groundbeam and piling work prior to installing Voltex undermain slab area. These areas must be correctly tied intothe underslab waterproofing to form a monolithic seal.

1.1 Substrate Preparation

Substrate may be concrete, earth, sand, pea gravel orcrushed stone. Earth and sand substrates should becompacted to a minimum 85% Modified Proctor density.Crushed stone should not be larger than 18 mm in size.Substrate should be smooth and without sharpdeflections or pockets.

1.2 Installation

Install Voltex or Voltex DS over the properly preparedsubstrate with the dark grey (woven) geotextile sideup. Overlap all adjoining edges a minimum of 100 mm

and stagger sheet ends a minimum of 300 mm (Figure1.1). Nail or staple edges together as required toprevent any displacement before and during concreteplacement.

When the slab is poured in sections, Voltex shouldextend a minimum 300 mm beyond the slab edge(Figure1.2). This enables Voltex to be properlyoverlapped for subsequent slab section pours. VolclayWaterstop-RX should be installed in all slabconstruction joints where applicable (Figure 1.2).?@@?h@@6

Figure1.1 Overlap Voltex 100mm with seams staggered300mm

V o l t e x

V ol t e xV o l t e x

V o l t e xV o l t e x

3 0 0 m m S T A G G E R E N DL A P S 3 0 0 m m .

O V E R L A P S m i n .1 0 0 m m .

1 0 0 m m m i n .L A P

Figure 1.2 Extend Voltex a minimum 300 mm beyond slab

edge. Install Watersop-RX in joint.

300

100

RX101 Waterstop Securedwith Revofix Mesh Nailedat 300mm Centres. With aMinimum 75mm ConcreteCover.

Voltex Over

Concrete Blinding

Slab FirstPour

Slab SecondPour

.

-

8/12/2019 Col 407840

5/20

5

DARK GREY (WOVEN) GEOTEXTILE SIDE UP WITH VOLTEX OR VOLTEX DS Figure 1.3Voltex installed directly over compacted earth/gravel substrate requires a minimum 150 mm thick

reinforced slab.

WELL COMPACTED SUBSTRATE

Geotextile Side UpDark Grey (Woven)

Minimum 150mm ThickReinforced Concrete Slab

100m

m

With Min. 75mmWaterstop RX101

Fixed With RevofixConcrete Cover.

300mmMIN.

VOLTEX

ROLLED HARDCOREOR GRANULAR FILL.

Figure 1.4 Slab on Footing Detail

VOLTEX

40X40mm FILLETOF VOLCLAYPASTE (GRANULES&WATER)

VOLTEX

RX101WATERSTOP

CONCRETEUNDERBLIND

Figure 1.7 Kicker level detail.

FORMWORK

VOLTEX

CONCRETEUNDERBLINDING

RC WALL

VOLTEX

WATERSTOPRX101

.

-

8/12/2019 Col 407840

6/20

-

8/12/2019 Col 407840

7/20

7

1.3 Pile Caps and Ground Beams

Voltex should not be installed over pile caps. Cut Voltexto fit tightly around pile caps. Then apply a minimum 40

mm thick fillet of Volclay Paste/Bentoseal at intersectionof Voltex and the piling (Figure 1.10). VolclayPaste/Bentoseal should extend onto Voltex and piling aminimum of 40x40mm thickness.

Detail ground beams the same as pile caps with a non-hydrostatic condition. If a hydrostatic condition exists,

Voltex should be installed under the entire groundbeam (Figure 1.11). Line the concrete formwork withVoltex prior to placement of reinforcing steel. Leave aminimum 300 mm of Voltex at the top of the form to tieinto below slab waterproofing.

FOR PROJECT SPECIFIC DETAILS CONSULT CETCOSTECHNICAL DEPARTMENT

Figure 1.10 Pile Cap Detail

UNDERBLIND

CONCRETE

CONCRETE

PILE.

LAP100

(GRANULES & WATER)BENTONITE PASTE

40X40mm FILLET OF

PILECAP

RC. SLAB

VOLTEX

Figure 1.11 Ground Beam (Hydrostatic condition)

100

RC. SLAB

BEAMGROUND

CONCRETEUNDERBLIND

LAP

VOLTEX

-

8/12/2019 Col 407840

8/20

8

1.4 Slab Penetrations

Cut Voltex to closely fit around penetrations (Figure1.12). Trowel a minimum 40 mm thick fillet of VolclayPaste (granules & water). around the penetration to

completely fill any void area between Voltex and thepenetration (Figure 1.13). The Volclay Paste shouldextend up the penetration about 40mm and extend ontoVoltex. In areas where multiple penetrations are closetogether, it may be impractical to cut Voltex to fit aroundeach penetration. Pour Voltex Granules, granularbentonite, minimum 12 mm thick around thepenetrations covering the entire substrate area. Thenapply a thick layer of Bentoseal around each penetrationas detailed (Figure 1.15).

FOR PROJECT SPECIFIC DETAILS CONSULT CETCOSTECHNICAL DEPARTMENT

Figure 1.12 Cut Voltex to closely contourpenetrations

VOLT

EX

CUT VOLTEX TO

CLOSELY CONTOURPENETRATIONS.

Figure 1.13 Bentoseal Troweled around penetration

VOLT

EX

RX101 WATERSTOP

AS A PUDDLEFLANGE.

40X40mm FILLET OF

BENTONITE PASTE

(GRANULES & WATER)

PIPE

Figure 1.14 Slab penetration cross section detail

40X40mm FILLET OFBENTONITE PASTE(GRANULES & WATER)

AS A PUDDLEFLANGE.RX101 WATERSTOP

VOLTEX

PIPE

Figure 1.15 Multiple pipe penetrations. Trowel Bentoseal around pipes and covering area between pipes

VOLTEX

RX101 WATERSTOP

AS A PUDDLEFLANGE.

40mm FILLET OF

BENTOSEAL

PIPES

DRY BENTONITE

GRANULES.

-

8/12/2019 Col 407840

9/20

9

1.5 Lift PitsVoltex should be placed on vertical surfaces and on thesubstrate below the slab to form a continuous envelopearound the lift pit (Figure 1.16). If the vertical soil cut

remains stable, Voltex may be installed directly againstthe soil. Contain unstable soils with a retaining wall.Install Voltex directly against the retaining wall.

Figure 1.16 Voltex under lift pit slab and on vertical surfaces

VOLTEX

LAP100

RX101WATERSTOP

TEMPORARY/PERMANENT

SELF SUPPORTING SOIL

PIT

LIFT

OR

UNDERBLINDCONCRETE

100 LAP

VOLTEX

100LAP

WORKS

1.6 Edge of Slab, Backfilled WallsWhen the installation reaches the outer edge of the slab,continue Voltex up and out of the form a minimum of 300mm (Figure 1.17). At the corner, Voltex should remain incontact with the substrate and the inside surface of the

concrete form. No void area should exist.

When the form is removed, the extra portion of Voltexoutside the form should be positioned and secured ontothe footing or vertical wall. Overlap this Voltex aminimum 150 mm with the succeeding verticalwaterproofing.

If Voltex is damaged during form removal along thlower edge of the slab, form a trough and fill it wiVoltex Granules. Seat the vertical Voltex, on the edge the slab, into the Voltex Granules.

Volclay Waterstop-RX should be installed in thperimeter wall/slab intersection joint.

The Voltex may be continued up to kicker level within thformwork. When the formwork is removed the Voltex wbe mechanically attached (peel-adhered) to the face the concrete. (Figure 1.18)

FOR PROJECT SPECIFIC DETAILS CONSULT CETCOSTECHNICAL DEPARTMENT

Figure 1.17 Voltex turned up and extended out ofconcrete form to tie into vertical waterproofing

VOLTEX

SLAB EGEFORMWORK

"FLAP" OF VOLTEXTO BE USED TO FORMA 100mm LAP

R.C SLAB

Figure 1.18

VOLTEX

SLAB EDGEFORMWORK

RC. SLAB

KICKERFORMWORK

VOLTEX TERMINATEDAT KICKER LEVEL.

-

8/12/2019 Col 407840

10/20

10

FOR PROJECT SPECIFIC DETAILS CONSULT CETCOSTECHNICAL DEPARTMENT

SECTION 2PROPERTY LINE CONSTRUCTION

The use of construction techniques described in thissection allow the exterior building dimensions to coincide

with the property line, thereby maximizing use ofavailable land for building. Voltex has been proven to beone of the most effective and widely used means forwaterproofing property line construction.

For all property line construction methods, installVoltex or Voltex DS with the dark grey (woven)geotextile out, away from the retaining wall facingthe installer. Refer to each applicable constructionmethod in Section 2 for specific substratepreparation and detailing installation guidelines.

After installing the Voltex system, the structural concrete

wall should be poured directly against the Voltex.Shotcrete structural walls also may be applied againstVoltex. Apply shotcrete in the direction of Voltex seamsso that the shotcrete does not get behind or separate therolls.

2.1 Property Line Installation Guidelines

Install Voltex oriented horizontally at the base of theproperty line wall. Fasten the Voltex into position withwasher-headed fasteners at 600 mm centres around theedge. Install succeeding Voltex roll overlapping theprevious roll edge 100 mm (Figure 2.1).

The vertical wall Voltex should overlap theunderslab Voltex which projects from under the

slab a minimum of 250 mm. If hydrostatic pressureexceeds 15m, consult CETCO for installationrecommendations and guidelines.

Cut Voltex to closely fit around penetrations andtie-back plates. After installing the Voltex, trowel an40mm thick fillet of Bentoseal to completely fill thevoid area between the detail and the cut Voltexedge. When multiple penetrations are closetogether it may be impractical to closely cut theVoltex. Therefore, trowel Bentoseal 18 mm thickover the entire surface area between thepenetrations and extend the Bentoseal onto each

penetration. (Figure 2.3)Bentoseal should extend outward from eachpenetration a minimum 50 mm.Cut and position a section of Voltex over tie-backplates (Figure 2.2). The Voltex section shouldextend a minimum of 150 mm onto the main Voltexlayer. (Note: Cut an X into the Voltex section sothat it can be slipped over the tie-back rod.)

Figure 2.1 Start Voltex at base of property line wall

RC WALL

250100

CONCRETE

RX101WATERSTOP

VOLTEX

DRESS THE VOLTEX UP

THE PROPERTY LINE

TO A POINT 250mm

ABOVE THE KICKER

JOINT TO FORM A

100mm LAP.

VOLTEX

BLINDING

PROPERTYLINE/EXISTINGBUILDING

Figure 2.2 Installation at Tie-Back Box-out

RC WALL

RX101WATERSTOP

VOLTEX FIXED TO

18mm BENTOSEALTROWELED OVERTIE BACK

VOLTEX PATCH FIXEDOVER BENTOSEAL

DIAPHRAGMWALL DIAPHRAGM WALL

GROUNDANCHOR

-

8/12/2019 Col 407840

11/20

11

FOR PROJECT SPECIFIC DETAILS CONSULT CETCOSTECHNICAL DEPARTMENT

Install succeeding Voltex course overlapping theprevious course a minimum 100 mm, staggering thevertical overlap seams a minimum 300 mm (Figure 2.3).(Note: Lap seams so that the upper roll is over the lower

rolls top edge.)

Figure 2.3

RC WALL

PIPE

SECURED WITH WIRE

FILLET OF BENTOSEAL.

PUDDLE FLANGE

40X40mm TRIANGULAR

WATERSTOP RX101

VOLTEX FIXED TO

PIPE

TROWEL BENTOSEALAROUND MULTIPLEPENETRATIONS.

DIAPHRAGM WALL

Figure 2.4 Termination at Ground Level

VOLTEX

GROUND LEVEL

300mmWIDE UV RESISTANT

MEMBRANE (OPTIONAL)

TERMINATE VOLTEX WITH A

METAL TERMINATION STRIP

COVERED WITH A 12X50mm

BEAD OF BENTOSEAL

2.2 Metal Sheet Piling

Complete the following substrate preparationinstructions. Then install Voltex following the propertyline installation guidelines. Special knurled powderactuated (Hilti type) fasteners are recommended tosecure Voltex to the sheet piling.

Preparation: If excessive water is penetrating the sheetpiling knuckles, Trowel an 18 mm thick layer ofBentoseal along all sheet piling knuckles and over tie-back plates. Volclay Bentogrout may be injected to theoutside of the knuckle to stop water flow (Figure 2.5).Consult CETCO for Bentogrout applications andinstallation guidelines.

Alternate Plywood MethodAlternatively, 12 mm plywood may be fastened to thesheet piling to create a flat surface upon which Voltex isfastened. All void spaces between the plywood andsheet piling must be filled with compacted earth orconcrete. Apply Voltex to plywood following BackfilledWall Guidelines.

Figure 2.5 Sheet pile interlock detail

VOLTEX

BENTOGROUT INJECTED TOEXTERIOR SIDE OF THESTEEL SHEET PILING

BENTOSEAL

RETAINED

EARTH

SHEET PILEINTERLOCK

Continue installing Voltex up to ground level. After thewall has been poured, terminate Voltex at ground levelwith a rigid termination bar fastened at 300 mm centres.

A 300 mm wide strip of UV resistant flashing is

recommended to be installed with the termination bar.Embed the top edge of Voltex and termination bar in a50 mm wide by 12 mm thick bead of Bentoseal. (Figure2.4)

-

8/12/2019 Col 407840

12/20

12FOR PROJECT SPECIFIC DETAILS CONSULT CETCOS

TECHNICAL DEPARTMENT

Figure 2.6 Voltex Installation over metal sheet piling

RETAINEDEARTH

STEEL SHEETPILING

VOL

TEX

VOL

RCWALL

RX101WATERSTOP

VOLTEX OVERPLYBOARD

PLYBOARD

COMPACTED SOILOR CONCRETE

BEHIND PLYBOARD

FIX VOLTEX TO FACE

OF STEEL SHEET PILING

OR PLYBOARD WITH THE

DARK GREY SIDE FACING

THE INSTALLER.

NOTE!

VOLTEX FIXED

TO STEEL SHEET

2.3 Earth Formed Shotcrete Retention Wall

Complete the following substrate preparationinstructions. Then install Voltex following the property

line installation guidelines.Preparation: The surface of the earth formed diaphragmwall must be sufficiently planar to provide an adequatelysmooth surface to apply Voltex.

Voltex can be applied over large, relatively shallowindentations. The surface should not contain voids or

sharp protrusions in excess of 25 mm. Fill all voids withcementitious grout and remove protrusions prior tomounting Voltex (Figure 2.9).

Figure 2.7 Grout void areas and remove protrusions toprovide lush mounting surface

RC WALL

CONCRETE

RX101WATERSTOP

VOLTEX

VOLTEX

BLINDING

SHOTCRETE RETAININGWALL WITH DEPRESSIONSGROUTED

Figure 2.8 Earth formed concrete retention wall withConcrete caisson supports (Plan view)

SHOTCRETE RETAINING WALL

CONCRETECAISSON

RETAINEDEARTH

VOLTEX FIXEDTO SHOTCRETE

RC. WALL

RX101 WATERSTOPIN CONSTRUCTIONJOINTS.

-

8/12/2019 Col 407840

13/20

13FOR PROJECT SPECIFIC DETAILS CONSULT CETCOS

TECHNICAL DEPARTMENT

Figure 2.9 Voltex Panel installation over an earth formed shotcrete retention wall.

VOLTEX

VOLTEX

VOLTEX

SHOTCRETE

RETAINING WALL

RETAINED

EARTH

IRREGULAR SURFACE

GROUTED SMOOTH

DARK GREY (WOVEN) GEOTEXTILEFACING THE INSTALLER

100mm VOLTEX

LAPS.

Figure 2.10 Rock formation shotcrete wall detail

SHOTCRETE WALL

VOLTEX FIXEDTO SHOTCRETE

RC. WALL

RX101 WATERSTOPIN CONSTRUCTIONJOINTS.

NATURAL ROCK FORMATION

10 0LA P

2.4 Auger Cast Caisson Walls

Complete the following substrate preparationinstructions. Then install Voltex following theproperty line installation guidelines in Section 2.1 onpage 10 and 11.

Preparation: The surface of auger cast caisson wallsmust be sufficiently planar to provide an adequatelysmooth surface to apply Voltex. Voltex can beapplied over large, relatively shallow indentations.The surface should not contain voids or sharpprotrusions in excess of 25 mm. Fill all large recessesbetween caissons with cementitious grout (Figure2.11).

Figure 2.11 Fill in recesses between cast caissonswith grout.

CONCRETECAISSON

RETAINEDEARTH

VOLTEXRC. WALL

RX101 WATERSTOPIN CONSTRUCTIONJOINTS.

GROUT THERECESSES

-

8/12/2019 Col 407840

14/20

-

8/12/2019 Col 407840

15/20

15

FOR PROJECT SPECIFIC DETAILS CONSULT CETCOSTECHNICAL DEPARTMENT

Figure 3.1 Concrete form tie details

SECURED WITH REVOFIXWATERSTOP RX 101

VOLTEX PATCH

MAIN VOLTEX LINER

NAILED AT THE TOP

(200X200) SECONDARY

APPROX. 75 -- 100mm OFCETCO TIEBOLT FILLER(TBF)

BENTOSEAL SEALANT

100 LAPTYPICAL

TIEBOLT HOLE PLUGDETAIL

Figure 3.2 Start Voltex at the cornerhorizontally. Place Panel section at corner& Bentoseal

VOLT

EXVOLTEX

VOLTE

X

VOLTEX

40X40mm FILLET

OF VOLCLAY PASTE(GRANULES & WATER)

BENTOSEALSEALANT

Figure 3.3 Apply fillet of Bentoseal to internalcorner beneath the Voltex.

VOLTEX

40X40mm FILLET OF

VOLCLAY PASTE INALL INTERNAL CORNERS

VOLTEX

ALL INTERNAL CORNERSVOLCLAY PASTE IN40x40mm FILLET OF

PRIOR TO FIXING VOLTEX

Figure 3.4 Voltex installed on a backfilled wall, overlapped 100 mm with vertical joints staggered.INSTALL VOLTEX OR VOLTEX DS WITH DARK GREY (WOVEN) GEOTEXTILE SIDE AGAINST THECONCRETE

VOLTEX

STAGGER THE ENDLAPS BY MIN. 300mm

TYPICAL VOLTEXLAP 100mm

RX101 WATERSTOP

40X40mm TRIANGULARFILLET OF VOLCLAYPASTE (GRANULES&WATER)UNDER THE VOLTEX.

VOLTEX NAILED AT300 CENTRES THROUGH

VOLTEX

VOLTEX

VOLTEX

THE LAPS.

-

8/12/2019 Col 407840

16/20

16

The excavated area should be backfilledimmediately after Voltex is installed and used as aplatform in applying succeeding Voltex courses.However, several courses may be installed beforebackfilling. The backfill must be compacted to aminimum 85% Modified Proctor density.

Figure 3.5 Minimum Voltex overlap detail

100mm LAP

VOLTEX

RC. WALL

FOR PROJECT SPECIFIC DETAILS CONSULT CETCOS

TECHNICAL DEPARTMENT

3.3 Wall Penetrations

Cut Voltex to closely fit around penetrations. Afterinstalling Voltex, trowel a minimum 40 mm thick fillet ofBentoseal around the penetration to completely fill any

space between the penetration and the Voltex edge.The Bentoseal should extend onto the penetration 40mm and cover Voltexs edge (Figure 3.6). In areaswhere multiple penetrations are close together, it maybe impractical to cut Voltex to fit around eachpenetration. Trowel Bentoseal 20 mm thick covering theentire surface around the penetrations (Figure 3.7).Then apply a 40 mm thick fillet of Bentoseal aroundeach penetration, extending 40 mm onto thepenetration.

Figure 3.6 Single poured-in-place penetration detail.

R C W A L L

PIPE

SECURED WITH WIRE

OF BENTOSEAL.

PUDDLE FLANGE

40X40mm TRIANGULAR F ILLET

WATERSTOP RX101

COMPACTEDBACKFILL

VOLTEX

Figure3.7 Cut Voltex to fit around multiple Penetrations

RC WALL

PIPE

SECURED WITH WIRE

FILLET OF BENTOSEAL.

PUDDLE FLANGE

40X40mm TRIANGULAR

WATERSTOP RX101

COMPACTEDBACKFILL

VOLTEX

PIPETROWEL BENTOSEAL

AROUND MULTIPLEPENETRATIONS.

3.4 Terminations

Voltex should be brought up to the ground level onvertical wall installations. Terminate Voltex at groundlevel with a rigid metal or plastic termination bar fastenedat 300 mm centers. A 300 mm wide strip of UV resistantflashing is recommended to be installed with thetermination bar at ground level (Figure 3.8). Embed thetop edge of the Voltex and termination bar in 50 mmwide, 12 mm thick bead of Bentoseal. Alternate groundterminations are illustrated in Figures 3.9, 3.10, 3.11 and

3.12.

Figure 3.8 Termination at finished ground

VOLTEX

GROUND LEVEL

300mm WIDE UV RESISTANTMEMBRANE (OPTIONAL)

TERMINATE VOLTEX WITH A

METAL TERMINATION STRIP

COVERED WITH A 12X50mm

BEAD OF BENTOSEAL

-

8/12/2019 Col 407840

17/20

17FOR PROJECT SPECIFIC DETAILS CONSULT CETCOS

TECHNICAL DEPARTMENT

Figure 3.10 Termination at ground with Volseal10F

VOLTEX

GROUND LEVEL

15 0

RC WALL

VOLSEAL 10F

VOLTEX TERMINATION

35mm dia BEAD OFBENTOSEAL

STRIPVOLSEAL10F300mmWIDE

Figure 3.11 Termination above ground using a300mm wide UV resistant membrane and a metaltermination strip.

GROUND LEVEL

RC WALLVOLTEX

5X50 BEAD OF

BENTOSEAL

300mm WIDE UV RESISTANTMEMBRANE

URETHANE CAULKING

METAL TERMINATION STRIP

Figure 3.12 Termination at ground with cut reglet

GROUND LEVEL

RC WALLVOLTEX

METAL FLASHINGDRESSEDDOWN OVER VOLTEX WITH5X50mmBEAD OF BENTOSEAL

5X50 BEAD OF

BENTOSEAL

Figure 3.9 Termination at ground level.

VOLTEX

GROUND LEVEL

150

RC WALL

VOLTEX OVERLAPPED 150mm BY

A LOAD BEARING DPM WITH A

5X50 BEAD OF BENTOSEAL IN THE

LAP. FOR CONTINUITY OFWATERPROOFING THE DPM

SHOULD PASS THROUGH THE

WALL TO BOND ON TO THE DPC.

5X50mm BEAD OFBENTOSEAL.

3.5 Masonry Block Walls

Voltex or Voltex DS is not recommended forwaterproofing masonry block walls. Consult withCETCO regarding recommended Volclayproducts and installation guidelines for masonryblock walls.

-

8/12/2019 Col 407840

18/20

18FOR PROJECT SPECIFIC DETAILS CONSULT CETCOS

TECHNICAL DEPARTMENT

SECTION 4TUNNEL/EARTH COVERED ROOFS

Before installing Voltex on the horizontal roof surface ofa tunnel, install Voltex under slab and on vertical wallsfollowing the applicable installation section(s) in thismanual. Install Voltex with the dark grey (woven)geotextile down, against the concrete roof surface.

In this application Voltex requires a minimum 200 mmthick reinforced concrete topping (wear) slab or 600 mmof compacted earth.

4.1 Installation

Prior to installing Voltex, distribute 3 mm of granular

bentonite, Voltex Granules, onto the concrete roof deck.Install Voltex from the low point to the high point acrossthe fall line to create a shingle type installation. OverlapVoltex edges a minimum 100 mm and stagger thetransverse roll ends a minimum 300 mm (Figure 4.1).

Staple Voltex edges together with a standard box stapleto keep the Voltex from moving during the backfiloperation.

Treat all penetrations with 40 mm thick fillet oBentoseal. Bentoseal should extend onto Voltex andcompletely fill any area around the penetration (Figure4.2).

At tunnel surface edges, turn Voltex down onto thevertical wall surface covering the top edge of the verticawall waterproofing a minimum of 300 mm (Figure 4.3).

When backfilling, earth should be placed in front of theequipment so that the heavy wheels or tracks will traveon the fill and not directly on Voltex. Backfill shouldcontain ground material 25 mm or less. A minimum 600mm of backfill compacted to a minimum 85% ModifiedProctor density is required over Voltex to provide

containment ballast and protection from traffic (Figure4.2).

When a concrete slab less than 200 mm will beplaced onto the tunnel roof, Volclay Swelltite isrecommended. Consult CETCO for specificinstallation guidelines.

Figure 4.1 Voltex cut and cover tunnel installation

VOLTEX LAID

OVER 3mm LAYER

OF DRY BENTONITE

VOLT

EX

VOLT

EX

VOLT

EX

GRANULES

100 LAP

TYPICAL

RX101WATERSTOPTUNNEL

CONCRETE

40X40mm FILLET OFBENTONITE PASTEUNDER VOLTEX

WATERSTOPRX101

300lap

-

8/12/2019 Col 407840

19/20

19FOR PROJECT SPECIFIC DETAILS CONSULT CETCOS

TECHNICAL DEPARTMENT

Figure 4.2 Earth covered deck/roof penetration detail

WATERSTOP RX101

PIPE VOLTEX OVER

40X40mm FILLET

OF BENTONITE

PASTE.

MINIMUM SOIL

COVER 600mm

RC. ROOF

STRUCTURE

BUILDING

INTERIOR

3mm LAYER OF

DRY BENTONITEGRANULES

Figure 4.3 Tunnel roof installation detail. Apply a 3 mmlayer of granular bentonite prior to Voltex

WATERSTOP RX101

MINIMUM SOILCOVER 600mm

RC. ROOFSTRUCTURE

VOLTEX

VOLTEX

300

LAP.

3mm LAYER OFDRY BENTONITEGRANULES

SECTION 5SPECIAL CONDITIONS

5.1 Pre-cast Concrete Plank Installation

CETCO recommends Volclay Swelltite membranesfor waterproofing pre-cast concrete plank decks androofs. Consult CETCO regarding recommendedproducts and installation guidelines.

5.2 Contaminated Conditions

Use Voltex CR (Contaminant Resistant) in conditionswhere the groundwater contains high concentrations of

chemicals or salts. These conditions are typicallyencountered at industrial sites and coastal regions.

If groundwater contains strong acids, alkalis, or has aconductivity of 2,500 mhos/cm or greater (high saltconcentration), water samples should be submitted toCETCO for compatibility testing.

For compatibility testing, provide one litre of sitegroundwater in a clean, unbreakable container. Shipwater sample to: CETCO Technical Department, CWG,Birch House, Scotts Quays, Birkenhead, UnitedKingdom, CH41 1FB. Upon analysis, CETCO willprovide a written report evaluating the waterscompatibility with Voltex and recommend any specialinstallation requirements.

5.3 Tie-in with Envirosheet Self-AdheringWaterproofing Membrane.

Occasionally, a project design will require Voltex to tie-inwith Envirosheet self-adhering waterproofing membrane.The following installation guidelines refer to this detail.

First, apply Envirosheet waterproofing membrane tostructural substrate following Envirosheet installation

instructions. Trowel M-2000 Liquid Flashing orEnvirosheet Mastic over the termination edge of theEnvirosheet.

Install Voltex, with dark grey side against the concrete,overlapping the Envirosheet a minimum of 30 cm.mechanically fasten Voltex at 300-600 mm centres withwasherhead fasteners. (Fastener will penetrate throughEnvirosheet into concrete.) Trowel Bentoseal 9 mm thickover each fastener, extending onto Voltex in a 25 mmcircle around each fastener.

Finally, install a 300 mm wide strip of Envirosheetcentred on the edge of the Voltex. Firmly press theEnvirosheet strip against the Voltex and Envirosheetmembrane.

FOR APPLICATIONS NOT COVERED IN THISMANUAL, CONTACT CETCO FOR TECHNICALASSISTANCE AND INSTALLATION GUIDELINES.

-

8/12/2019 Col 407840

20/20

CONSTRUCTION WATERPROOFING GROUP

Birch House

Scotts Quays

Birkenhead

United Kingdom

CH41 1FB

Tel: +44 (0) 151 606 5900

Fax: +44 (0) 151 606 5932

LIMITED WARRANTY

The information and data contained herein are believed to be accurateand reliable. Specifications and other information contained hereinsupersede all previously printed material and are subject to changewithout notice.Manufacturers warranty of installed system is available. Contact sellerfor terms and sample documents including all limitations.All goods sold by seller are warranted to be free from defects inmaterial and workmanship.The foregoing warranty is in lieu of and excludes all other warrantiesnot expressly set forth herein, whether express or implied by operationof law or otherwise including but not limited to any implied warranties ofmerchantability or fitness.Seller shall not be liable for incidental or consequential losses,damages or expenses, directly or indirectly arising from the sale,handling or use of the goods, or from any other cause relating thereto,and sellers liability hereunder in any case is expressly limited to the

replacement (in the form originally shipped) of goods not complying with thisagreement or at sellers election, to the repayment of, or crediting buyer with,an amount equal to the purchase price of such goods, whether such claimsare for breach of warranty or negligence. Any claim by buyer with reference tothe goods sold hereunder for any cause shall be deemed waived by buyerunless submitted to seller in writing within thirty (30) days from the date buyerdiscovered or should of discovered, any claimed breach.Materials should be inspected and tested by purchaser prior to their use ifproduct quality is subject to verification after shipment. Performanceguarantees are normally supplied by the applicator.

Note: Volclay Voltex is not an expansion joint material. Expansion joints shallbe the responsibility of OTHERS.

U.S. Patents #4, 048, 373; #4, 139, 586; #4, 084, 362Foreign Patents and Other Patents Pending

AUGUST 2001 (Supersedes all previous versions)