CHAPTER 1 PROJECT CONCEPTION – LITERATURE SURVEY 1.0 Introduction As an introduction, a few concepts and definitions concerning the project, “Refined Glycerine from RBD Palm Oil” will bw given in this part. Before the plant is designed, some literature study on the feasibility of this project has been performed. The feasibility study will be covered in this chapter too. 1.1 Process Background

Welcome message from author

This document is posted to help you gain knowledge. Please leave a comment to let me know what you think about it! Share it to your friends and learn new things together.

Transcript

CHAPTER 1

PROJECT CONCEPTION – LITERATURE SURVEY

1.0 Introduction

As an introduction, a few concepts and definitions concerning the project,

“Refined Glycerine from RBD Palm Oil” will bw given in this part. Before the plant

is designed, some literature study on the feasibility of this project has been

performed. The feasibility study will be covered in this chapter too.

1.1 Process Background

1.1.1 Introduction to Glycerine

Glycerine, Glycerin or Glycerol is a 1,2,3-propanetriol, a trihydric alcohol.

The term “glycerol” applies only to the pure chemical compound 1,2,3-propanetriol.

“Glycerine” or “glycerin”, is a purified commercial product whose principal

component is glycerol and normally containing about 95% or more glycerol.

Several grades of glycerine are available commercially. They differ somewhat n

Chapter I– Project Conception - Literature Survey I- 2

their glycerol content and in other characteristics such as colour, odour and trace

impurities.

The name comes from the Greek word glykys meaning sweet. Glycerol was

first discovered in 1779 by Scheele, who had heated a mixture of litharge and olive

oil and then extracted it with water. Upon evaporating the water, he obtained a

viscous sweet tasting solution later identified by Chevreul, Plouze, Berthelot and

others as a concentrated solution of trihyric alcohol, glycerol.

H H H CH2-OH

| | | |

H---C---C---C---H or CH-OH

| | | |

OH OH OH CH2-OH

Glycerol occurs in combined form in all animal and vegetable fats and oils.

It is rarely found in the free state in these fats but is usually present as a triglyceride

combined with such fatty acids as stearic, oleic, palmitic and lauric and these are

generally mixtures or combinations of glycerides of several fatty acids. Such oils as

coconut, palm kernel, cottonseed, soybean and olive yield larger amounts of

glycerine than do such animal fats as tallow and lard. Beginning in the 1980s, two

important sources of raw materials for the glycerine production come from the palm

oil industry. The fruit from oil palm produce two distinctive oils, the palm oil which

is mainly a C16 and C18 oil, and the palm kernel oil, which is a C12 and C14 oil. These

two oils have overtaken tallow and coconut oil as the raw materials for

oleochemicals at this present moment and with their continued dominance in

production, will continue to be the primary feed stocks.

Traditionally, glycerol has been recovered as a by-product from animal or

vegetable oils that have been saponified in the process of manufacturing soaps.

More recently it has been commercially produced by chemical synthesis from

propylene and from sugar. Until 1949 all glycerine was obtained from glycerides in

fats and oils from two sources:

(1) From soap manufacture

Gly World (M) Sdn. Bhd

Chapter I– Project Conception - Literature Survey I- 3

Fat is boiled with caustic soda slution and salt. The fatty acid

constituents of the fat combine with the caustic soda to form soap,

which is obtained as an upper layer. The lower aqueos layer, referred

to as spent lye contain glycerine, water, salt and unchanged caustic

(2) From oil splitting or hydrolysis without added alkali, of fats and oils

This is a method for preparing fatty acids which are the reduced to

the corresponding fatty alcohols. The glycerine is the obtained in the

sweet water. Crude glycerine recovered from this is referred to as

saponification crude. The spent lyes resulting from current

soapmaking processes generally contain from 10-15% glycerol while

sweet water from hydrolysis of fats contain up to 20% glycerol

In its common liquid form, glycerol is non-poisonous, colourless, odourless

and sweet tasting and has a high viscosity. It is miscible in water and forms a

solution in any proportion. It is also soluble alcohol but only partially soluble in

common organic solvents such as ether and ethyl acetate. It resists freezing. It is

hygroscopic, which favors as a humectant to retain moisture in cosmetics. Because

it is soluble in water and alcohol, its versatility is a major benefactor in its purported

growth and popularity within the manufacturing sector. It is invaluable as a natural

source ingredient with emollient like properties which can soften and soothe the skin

and it assist the outer epidermis is retaining moisture. This helps to explain why it is

one of the most popular cosmetic additives used today. Glycerine also has a wide

range of application areas on cosmetic and food products, tobacco and paints.

1.1.2 Grades

The crude glycerine can be refined by redistillation to obtain refined

glycerine which is more than 99% pure. When the crude glycerine is refined, the

value added is about 80%.

Gly World (M) Sdn. Bhd

Chapter I– Project Conception - Literature Survey I- 4

Several grades of refined glycerine, such as high-gravity, dynamite, and USP

are marketed; specifications vary depending on the consumer and the intended use:

(1) USP-grade glycerine is water white, meeting the requirements of the

USP. It is classified as GRAS (Generally Recognized As Safe for

human use) by the US Department of Agriculture and is suitable for

use in foods, pharmaceuticals, and cosmetic, or when the highest

quality is demanded or the end product is designed for human

consumption.

(2) The BP grade is similar to the USP

(3) The CP grade designates a grade of glycerine that is about the same

as USP but with the specifications varying slightly as agreed by

buyer and seller

(4) The high gravity grade is a pale-yellow glycerin for industrial use

(5) The dynamite grade is more yellow

1.1.3 Palm Oil: An Overview

1.1.3.1 History of Palm Oil

Palm oil is produced from the fruit of the oil palm or also known as Elaeis

Guinnesis tree, which originated in West Guinea. The palm bears its fruit in

bunches varying in weight from 10 to 40 kg. The individual fruit, ranging from 6 to

20 gm, are made up of an outer skin (the exocarp), a pulp (mesocarp) containing the

palm oil in a fibrous matrix; a central nut consisting of a shell (endocarp); and the

kernel, which itself contains an oil, quite different to palm oil, resembling coconut

oil. Palm oil is obtained from flesh surrounding the seed through cooking, mashing

and pressing. The flesh is oily, and oil can be recovered by very simple means, so

that it is probable that palm oil has been recovered and used for human food for tens

of thousands of years.

Gly World (M) Sdn. Bhd

Chapter I– Project Conception - Literature Survey I- 5

Because of its economic importance as an high-yielding source of edible and

technical oils, the oil palm is now grown as a plantation crop in most countries with

high rainfall (minimum 1 600 mm/yr) in tropical climates within 10° of the equator.

The tree was introduced into other parts of Africa, South East Asia and Latin

America during the 15th century while in Asia, it was first introduced at 1848 into

the botanical gardens at Bogor in Java as an ornamental plant. Its commercial

exploitation started in Sumatra after 1910 and in Malaya in the 1920s.

Palm oil is available in a variety of forms; crude palm oil, palm olein, palm

stearin, RBD palm oil, double-fractionated palm olein and palm mid-fraction.

1.1.3.2 Malaysia Palm Oil

Today palm oil is a well known commodity throughout the world’s food and

oleo-chemical industries. Oil palm growth in Malaysia started in 1950s when

Malaysia has decided to diversify significantly away from rubber, the principal

export crop. Commercial cultivation of palm oil did not begin until 1960’s. This was

due to government was opening up huge jungle track for the FELDA scheme for

landless farmers. By 1975, more than 640,000 hectares were planted with palm oil

and the hectarage continue to surge so much until recently Malaysia had more than

2.8 million hectares under palm oil. Consistent with the rapid expansion in palm oil

cultivation, production of palm oil also rose dramatically from the 1960’s. Apart

from the expansion in hectarage, yields have also risen steadily over the years, as

plantations introduce better yielding and better quality fruits as extraction method.

A principal agent of this development was the government Federal Land

Development Agency (FELDA) which undertook jungle clearance and the settling

of smallholders. Until today, FELDA continues to be a major successful participant

in the palm oil industry. For the user of Malaysian palm oil products there is a

technical backup service provided by the Palm Oil Research Institute of Malaysia Gly World (M) Sdn. Bhd

Chapter I– Project Conception - Literature Survey I- 6

(PORIM), which has a well equipped and staffed Research Centre near Kuala

Lumpur, and Technical Advisory Officers stationed in Europe, America, Asia and

Africa.

In 1966, Malaysia had surpassed Africa’s total palm oil production.

According to Oil Palm Review, published by the Tropical Development and

Research Institute in the United Kingdom, over 3 million tonnes of palm oil was

produced by Malaysia alone in 1983, compared with a total of about 1.3 million

tonnes of African production. Malaysia currently accounts for 51 % of world palm

oil production and 62% of world exports, and therefore also for 8% and 22% of the

world’s total production and exports of oils and fats. As the biggest producer and

exporter of palm oil and palm oil products, Malaysia has an important role to play in

fulfilling the growing global need for oils and fats in general.

1.1.3.3 Palm Oil Composition

Palm oil contains an equal proportion of saturated fatty acids and unsaturated

fatty acids. Fatty acids are the major oleochemicals derived from animal and

vegetable oils and fats. Fatty acids consist of the elements carbon (C), hydrogen

(H), and oxygen (O) arranged as a carbon chain skeleton with a carboxyl (--COOH)

group at one end. Fatty acids appear in chain lengths between C6 and C22, with the

vast majority in C18.

The difference between fatty acid types is mainly due to their degree of

saturation and their chain length. Saturated fatty acids, for examples, palmitic and

stearic acids have all the hydrogen that the carbon atoms can hold.

Monounsaturated fatty acids have only one double bond, e.g. oleic acids.

Polyunsaturated fatty acids have more than one double bond, such as linoleic acids

Gly World (M) Sdn. Bhd

Chapter I– Project Conception - Literature Survey I- 7

(two double bonds) and linolenic acids (three double bonds). Fatty acids are

generally found combined with glycerol in lipids such as triglycerides.

Table 1.1: Fatty Acids Found in Palm Oil and Palm Kernel Oil in Weight

Percentage

Group Fatty Acids Carbon Chain

Identification

Palm Oil (%wt)

Saturated Fatty

Acids

Caproic C6 -

Caprylic C8 -

Capric C10 -

Lauric C12 0.2

Myristic C14 1.101

Palmitic C16 44.044

Stearic C18 4.505

Arachidic C20 0.4

Unsaturated Fatty

Acids

Oleic C18:1 39.34

Linoleic C18:2 10.01

Linolenic C18:3 0.4

Molecular formula is a notation that indicates the type and number of atoms

in a molecule. Below is the table that shows the molecular formula for all the fatty

acids contained in the palm oil.

Gly World (M) Sdn. Bhd

Chapter I– Project Conception - Literature Survey I- 8

Table 1.2: Molecular Formula of Fatty Acids

Trivial Name IUPAC Name Notation Molecular Formula

Caproic Acid Hexanoic Acid C6:0 C6H12O2

Caprylic Acid Octanoic Acid C8:0 C8H16O2

Capric Acid Decanoic Acid C10:0 C10H20O2

Lauric Acid Dodecanoic Acid C12:0 C12H24O2

Myristic Acid Tetradecanoic Acid C14:0 C14H28O2

Palmitic Acid Hexadecanoic Acid C16:0 C16H32O2

Stearic Acid Octadecanoic Acid C18:0 C18H36O2

Oleic Acid 9-octadecanoic Acid C18:1 C18H34O2

Linoleic Acid 9, 12-octadecadienoic Acid C18:2 C18H32O2

Linolenic

Acid

9, 12, 15-octadecatrienoic

Acid

C19:3 C18H30O2

Arachidic

Acid

Eicosanoic Acid C20:0 C20H40O2

1.1.3.4 Structural Formula

Structural formula is a diagram that shows how the atoms in a molecule are

bonded together. Atoms are represented by their element symbols and covalent

bonds are represented by lines. Most structural formulas do not show the actual

shape of the molecule (they’re like floor plans that show the layout but not the 3D

shape of a house).

Table 1.3: Structural Formula of Fatty Acids

Name Structural Formula

Caproic

Acid

CH3(CH2)4COOH

Gly World (M) Sdn. Bhd

Chapter I– Project Conception - Literature Survey I- 9

Caprylic

Acid

CH3(CH2)6COOH

Capric Acid

CH3(CH2)8COOH

Lauric Acid

CH3(CH2)10COOH

Myristic

Acid

CH3(CH2)12COOH

Palmitic

Acid

CH3(CH2)14COOH

Stearic Acid

CH3(CH2)16COOH

Oleic Acid

CH3(CH2)7CH=CH(CH2)7COOH

Linoleic

Acid

Gly World (M) Sdn. Bhd

Chapter I– Project Conception - Literature Survey I- 10

CH3(CH2)4CH=CHCH2CH=CH (CH2)7COOH

Linolenic

Acid

CH3CH2CH=CHCH2CH=CHCH2CH=CH(CH2)7COOH

Arachidic

Acid

CH3(CH2)18COOH

1.2 Product market survey

1.2.1 Introduction

One of the main considerations for planning a plant is the economics of the

industry. Before proceeding with the plans, economic survey is the first and most

important criteria to be observed. Glycerine or glycerol is one of the common basic

oleochemical products. Refined glycerine is used in the manufacture of many

pharmaceutical, food, and oral care products. The markets are renowned for their

complexity and unpredictability. It is because glycerine is produced primarily as co-

product, so the demand for the primary product influences the amount of glycerine

produced. At the same time, there are hundreds of end uses for glycerine. Thus, the

large number of uses and the complexity of supply markets make the future

glycerine pricing very difficult to predict.

1.2.2 Global Market

Gly World (M) Sdn. Bhd

Chapter I– Project Conception - Literature Survey I- 11

The production of glycerine as co-product comes from several process in

oleochemicals, soap and biodesel industries and also synthetically process. As the

co-product, sometime the demand of glycerine is really depend to the main

oleochemical product prices.

Figure 1.1: Total World Production of Glycerine

The demand for glycerine in the world has been increases since 1992. In 1992,

the world estimate consumption of glycerine was 638,000 MT. It has been increase

to 730,000 MT in 1995. In 1998 it has been rise to 800,000 MT. This represents a

growth rate of 4 ½ % between 1992 and 1995, and 3% between 1995 and 1998. The

demand is made up 30% for Europe, 30% North America and the rest of the world,

40%.

Figure 1.2: Geographic Demand for Glycerine

Gly World (M) Sdn. Bhd

Chapter I– Project Conception - Literature Survey I- 12

Before 90’s, the world consumption for glycerine is just below 600 k MT per

year. Most of the glycerine was produced by natural raw material. Countries in

Western Europe have a high demand for glycerine. This maybe caused by the

developing of their industries.

Table 1.4: World Glycerine Production, Consumption and Capacity, 1988(1,000 MT)

Production Consumption Refining Capacity

Natural Synthetic

North America 153 166 170 60

Western Europe 200 160 177 50

Asia/Pacific 150 137 189 40

Other 85 125 107 20

The high demand for glycerine comes from the developing country as the

increasing of its application in producing a basic oleochemical product. In addition,

nowadays most of the consumer want something that is seemed more environmental

friendly and come from the nature product. This brings to the increasing of glycerine

market in the world.

The demand for natural glycerine has also been increased since 1988. In

1988, the demand for natural glycerine is only 240 k MT, but it has been increased

to 300 k MT in 1995 and 341 k MT in year 2000. The increasing of natural glycerine

demand has increased the production of this oleochemical product from fats and

oils.

The increasing of its application in many industries also caused the increase

of glycerine demand. At this moment, there are more than 1500 known end uses for

glycerine. An approximate breakdown by major application area for Western Europe

is detailed below.

Gly World (M) Sdn. Bhd

Chapter I– Project Conception - Literature Survey I- 13

Table 1.5: The Application of Glycerine in Western Europe

Percentage (%)

1978 1985 1993 1997

Pharmaceuticals

Cosmetic Toiletries

Esters

Polyols

Resins

Food and Drinks

Cellulose Film

Other Chemical Uses

Tobacco

Nitration

Paper

Resale

Others

-

-

-

8.0

17.0

-

8.0

-

-

9.0

-

-

-

11.5

9.7

15.4

12.2

9.9

5.9

4.8

4.5

3.5

3.4

1.8

14.6

2.8

9.4

14.5

13.1

10.6

7.1

7.0

5.8

3.5

3.3

0.7

1.1

18.5

5.4

9.8

16.1

10.7

11.7

5.7

8.5

3.1

8.2

3.6

0.2

0.9

17.3

4.2

(I) Supplier

Table 1.6: Global Market Supplier of Glycerine

PRODUCER CAPACITY*

Cognis, Cincinnati, Ohio 65

Colgate-Palmolive, Jeffersonville,

Ind.

20

Crompton, Mapleton, Ill. 20

Crompton, Memphis, Tenn. 30

Dial, Montgomery, Ill. 30

Gly World (M) Sdn. Bhd

Chapter I– Project Conception - Literature Survey I- 14

Dow, Freeport, Tex. 140

Lever, Hammond, Ind. 25

Lonza, Painesville, Ohio 20

Marietta American, Olive Branch,

Miss.

2

Procter & Gamble, Ivorydale, Ohio 150

Starchem, Fostoria, Tex. 20

Uniqema, Chicago, Ill. 35

Total 557

*Millions of pounds per year of refined glycerine.

Dow Chemical is the only producer of synthetic glycerine. Others obtain

glycerine as a byproduct in soap and oleochemicals production using natural fats and

oils as raw materials. Colgate refines glycerine at Jeffersonville using purchased

crude.

Algroup lonza, formerly known as Lonza Inc. expanded glycerin capacity at

Painesville, Ohio, in 1997 to 15 million pounds, and again in 1999 to 20 million

pounds.Archer Daniels Midland Company had planned to build a 50-million-pound-

per-year glycerine plant at Cedar Rapids, Iowa, based on a proprietary fermentation

process. The project was due online in 2000, but in 1999 the project was been put on

hold because of glycerine market conditions.

And last year another ethanol from corn producer, High Plains Corp.,

announced plants to install a 10-million-pound-per-year glycerin recovery unit at its

Gly World (M) Sdn. Bhd

Chapter I– Project Conception - Literature Survey I- 15

ethanol plant in Colwich, Kan. But earlier this year, this project too was put on

indefinite hold.

Unichema International acquired by ICI in May 1997 as part of its

acquisition of Unilever's specialty chemicals businesses. Its name was changed to

Uniqema, on January 1, 1999, and became part of a new ICI business, The Uniqema

Group. Uniqema also includes ICI surfactants and synthetic lubricants, Mona

Industries and Solaveil.The Unilever glycerine and surfactants plant at Hammond,

Ind., operates as part of its Lever Brothers Company subsidiary.

In 1999, Crompton & Knowles and Witco merged to form CK Witco. The

company was renamed Crompton Corp. in 2000. Witco brought on a new still at

Mapleton, Ill., in January, 1999. The still upgrades crude glycerine to refined

material. Crompton Corp. is known to be looking to divest its refined products

operation, which is considered a non-core business.

In October 2001 Procter & Gamble Chemicals announced plans for and

additional 50,000 metric tons of glycerine capacity through a new grassroots

refinery. Although the lead option for the site is Kuantan, Malaysia, additional sites

in North America and Europe are also under consideration. P&G had earlier

increased its glycerine refining capacity by 10,000 metric tons as a result of

debottlenecking in West Thurrock, England and Cincinnati, Ohio.

(2) Strength

The market sector for personal care products is growing at 3.5% annually, as

the increasing of the generation consumes more skin care creams. The strong growth

of sunscreen lotions in this sector also reflects the greater public concern these days

about exposure to sun rays. Good solubility and taste give glycerine an edge on

sorbitol in toothpastes and mouthwashes, and the oral care sector is growing at

approximately 1.5% annually. The best performing sector, is food. In year 2000,

food product consumed about 49.4 million-kilogram glycerine and its derivatives.

Glycerine in the food sector is growing better than 4% annually as a result of the

Gly World (M) Sdn. Bhd

Chapter I– Project Conception - Literature Survey I- 16

continuing trend towards lowering the fat content in foods, particularly baked goods.

These three sectors together represent 64% of glycerine application.

(3) Weakness

However, the glycerine market experienced major swings in market

conditions from the mid-1990s to the present time. In 1995, the industry was supply-

limited, but by 1998 glycerine was abundant and production was declining. By the

end of 1999 and into 2000, the glycerine market was again tight. It is not so much as

a declining demand in 2001, but more of an increase in supply that has put

additional pressure into the marketplace. This is because there is a significant

increase of crude glycerine in biodiesel-related generation in Europe, where crude

glycerine is one of its by products. Some demand has moderated though. Glycerine’s

use in polyether polyols and alkyd resins is shrinking at 1 percent and 1.5 percent

annually. These application areas have both been hurt by the decrease in GDP

growth. Moreover, alkyd resins have been facing increased competition by water-

based acrylic and vinyl formulations.

(4) Prices

The prices for glycerine also increase in these recent years. As new uses are

found and the economies of developing countries are grow, the demand for

glycerine is rising at this time. However the increases in supply have been unable to

match increases in demand. Thus, prices for refined glycerine are now very high.

Currently, refined glycerine sells for US $2.32/kg although in the recent past,

refined glycerine prices have been as low as US $1.25/kg. It may also caused by the

increasing of the raw material prices especially palm oil.

Gly World (M) Sdn. Bhd

Chapter I– Project Conception - Literature Survey I- 17

Figure 1.3: World Market Demand for Glycerine

Glycerine is effective 10% or more of fat or oil molecule, so the price of

glycerine is almost depends to the oil or fat itself in the economic of oleochemicals.

Increasing supply will cause price to fall, whilst high prices will cause substitution

by other polyoils and price will fall. In the year 199 and 2000, the world price for

glycerine has varied by as much as $ 1000/ton.

Gly World (M) Sdn. Bhd

Chapter I– Project Conception - Literature Survey I- 18

Figure 1.4: U.S. Refined Glycerine Pricing History - 99.5% U.S.P.

1.2.3 Asian Market

The world production of basic oleochemical is expected to increase from 5.0

million tonnes in 1995 to 7.8 million tonnes in 2010. The Asean countries are

expected to contribute 3.5 million tonnes or equal 50% from the world demand.

Malaysia gives the highest percentage, 70% or 1.2 million tonnes from the Asean

output.

In this century, the well development of oleochemical industry in Asian will

also brings to the very high demand for glycerine. It is an advantage if the glycerine

was produced from the vegetables because of the changing in customer demand in

more nature product.

Excluded Malaysia, Indonesia and Philippines are just starting to put

themselves in the world market as glycerine supplier. It may look as competitors to

Malaysia but it will bring a more stable market price for glycerine in the world. It is

because it can cover the demand for the product in industry.

In Philippines, the oleochemicals industry is a strategic sector owing to its

linkage with the Coconut and Palm Oil Industries. These sectors are highly

complementary in their socio-economic and business setting, particularly the high

value-adding impact of downstream processing (oleofoods/oleochemicals) to these

upstream industries (CNO / PO processing). Development of oleochemical ventures

could easily transform the coconut exports and fledgling palm oil industries into at

least $4-5 billion export industries.

As a foreign exchange earner, the industry generated substantial export

earnings of $299.5 million from 1996-2001. The specific leading products stearyl

alcohols, industrial fatty alcohols and refined glycerine. The major destinations

Gly World (M) Sdn. Bhd

Chapter I– Project Conception - Literature Survey I- 19

included Japan, USA, Korea, the Netherlands, Taiwan, China, India, Thailand,

Belgium and France.

As oleochemical manufacturers are either local large enterprises or joint

ventures with foreign companies operating overseas plants, they maintain well-

established distribution channels through which, marketing activities are made for

both export and domestic markets.

Some of the factory in Philippines that involves in producing glycerine are

listed in table 1.7 below:

Table 1.7: Asian Companies Producing Glycerine

COMPANY PRODUCT

United Coconut Chemicals, Inc. - Fatty Acid

- Fatty Alcohol

- Glycerine

Pilipinas Kao, Incorporated - Elem. Resinoid

- Fatty Alcohol Beads

- Hydrogenated Fatty Alcohols

- Methyl Ester

- Refined Glycerine

- Fractionated Alcohol

- Sodium Lauryl Sulfate

- Mono Alkyl Phosphate

- Alkanolamide and Surfactants

- Coco-Tertiary Amines

Gly World (M) Sdn. Bhd

Chapter I– Project Conception - Literature Survey I- 20

- Fractionated Methyl Ester

and/or Fractionated Fatty Alcohol, flaked

Primo Oleochemicals, Inc. - Fatty Alcohol

- Low MW Fatty Acid

- Glycerine

Sakamoto Orient Chemical

Corporation

- Crude Glycerine

- Refined Glycerine

Senbel Fine Chemicals - Fatty Alcohols

- Methyl Esters

- Glycerine

- Alkanolamides

- Others

In Indonesia, there are five producers of basic oleochemicals with an annual

capacity to produce 374,000 tons of fatty acid, 55,900 tons of glycerin, 90,000 tons

of fatty alcohol and 10,000 tons of methyl ester. Three largest producers are located

in Medan namely PT Sinar Oleochemical International (SOCI) of the Sinar Mas

Group, PT Flora Sawita Chemindo and PT Ecogreen Oleochemicals formerly PT

Prima Inti Perkasa of the Salim Oleochemical Group Ecogreen Oleochemicals also

has a factory in Batam formerly named PT Batamas Megah.

Two other producers are PT Cisadane Raya Chemicals (CRC) in Tangerang

and PT Sumi Asih Oleochemicals in Bekasi. SOCI, which started operation in 1994,

is a subsidiary of PT Smart Corp. of the Sinar Mas Group (SMG) with co-owners

including Nippon Oil & Fat (NOF) Corp., Shiseido Company Ltd, Hitachi Zosen

Corp. and Marubeni Corp. from Japan. PT Ecogreen Oleochemicals was formerly

owned by the Salim Group, but in late 2000, it was acquired by the Wings Group in

a tender through the Carhart Investment Pte Ltd consortium, which is the investment

vehicle of Bhakti Investama.

Ecogreen Oleochemicals from its two factories has an annual capacity to

produce 90,000 tons of fatty alcohol and 12,500 tons of glycerin. Sumi Asih, which

Gly World (M) Sdn. Bhd

Chapter I– Project Conception - Literature Survey I- 21

started operation in 1984, has an annual capacity to produce 90,000 tons of fatty acid

and 15,000 tons of glycerin and 32,000 tons of stearic acid (stabilizer) and metallic

soap.

Sumi Asih has established cooperation with Goldschmidt AG from Germany

to produce oleochemical derivatives namely betain - a shampoo additive - with an

annual capacity of 20,000 tons. Sumi Asih has also divested its 25% stake in

Goldschmidt Sumi Asih (GSA) to Goldschmidt. Previously GSA was a joint venture

between Sumi Asih and Goldschmidt AG each with a 50% stake.

Sumi Asih also established PT Biolina Trio Sintesa to produce 100% stearin

with an investment of US$ 8 million. It has an annual capacity to produce 75 million

sticks of candle a year.

PT Cisadane Raya Chemical (CRC), a pioneer in oleochemical industry

started operation in 1979. IT has an annual capacity to produce 120,000 tons of

products including 70,000 tons of fatty acid, 15,000 tons of glycerin, 10,00 tons of

distilled fatty acid and 25,000 tons of bar soap. CRC in Tangerang also produce

edible oil with an annual capacity of 180,000 tons. In June 2000, the company

secured the ISO-9002 certificate from the Dutch Council for Accreditation.

Table 1.8: Producers of Oleochemicals and Capacity in Indonesia, 2002

Companies Location Production capacity

(ton/year)

Cisadane Raya Chemicals, PT Tangerang Fatty acid - 120,000

Glycerine - 15,000

Stearic acid - 30,000

Ecogreen Oleochemicals, PT (d/h Salim

Oleochemical)

Medan Fatty alcohol - 30,000

Fatty acid - 5,000

Glycerine - 12,500

Methyl ester - 10,000

Batam Fatty alcohol - 60,000

Sumi Asih Oleochemicals, PT Bekasi Fatty acid - 90,000Gly World (M) Sdn. Bhd

Chapter I– Project Conception - Literature Survey I- 22

Glycerine - 15,000

Sinar Oleochemical International (SOCI),

PT

Medan Fatty acid - 80,000

Glycerine - 8,000

Flora Sawita Chemindo, PT Deli Serdang Fatty acid - 52,000

Glycerine - 5,400

Total

Fatty acid - 347,000

Glycerin - 55,900

Stearic Acid - 75,600

Fatty alcohol - 90,000

Methyl ester - 10,000

1.2.4 Local Market

The oleochemical industries are growing in Malaysia. Starting in 1979, the

first fatty acid plant was built in Malaysia and producing over 30 thousand metric

tons annually. Two other plants were open after that in 1981 with combined capacity

of about 62 thousand metric tons. In 1990, there have been six oleochemical plants

in Malaysia with total annual capacity of 250 thousand metric tons.

An industrial development program in Malaysia, the Industrial Master Plan

(IMP), calls for n increase to 750 thousand metric tons by 1995. in 1993, the US

Department of Agriculture (USDA) estimated Malaysia’s oleochemical capacity at

600 thousand metric tons. This has been accomplished by several joint venture

projects between Malaysian companies and foreign companies.

As example, Procter and Gamble joined with Felda Mills Corporation, a

subsidiary of the Malaysian Federal Land Development Authority (Felda) to build a

$50 million natural fatty alcohol and glycerine plant production, that which began in

1992 and the capacity is 60 thousand metreic tons annually.

Gly World (M) Sdn. Bhd

Chapter I– Project Conception - Literature Survey I- 23

Now days, in Malaysia, glycerine is one of the component exports of major

oleochemical products. In 2002, 12.59% of oleochemical product that has been

export is glycerine, this equal to 160 kMT or RM 344.86 million. The total income

from oleochemical export at that moment is RM 2,739.2 million or 1, 267, 942

tonnes. This brings the bright future for the investment in glycerine production.

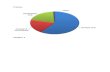

Figure 1.5: Export of Major Oleochemical Products in 2002

Figure 1.6: Major Glycerine Supplier Country

Gly World (M) Sdn. Bhd

Chapter I– Project Conception - Literature Survey I- 24

Malaysia is one of the major countries that supply the glycerol in the world

market. In year 2000, Malaysia supplies 43% of the world export. It is followed by

Netherlands (22%) and other countries are France, USA, Czech Republic and the

others. The main factor for the Malaysia to become the main country that supplies

glycerine is the developing of palm oil industry in this country.

The reason of this phenomenon is the development of oil palm industry in

Malaysia. The increasing of production of palm oil has increase the oleo chemical

industry including the production of glycerine.

Malaysia also becomes the main country that supplies the glycerine for

United States of America. In March 2003, 87.65% of United States imports for

glycerine come from Malaysia. The value of the American import is RM5.21

million. It is prove that the production of glycerine can give a very high profit to the

investor.

Figure 1.7: U.S. Imports for Consumption of Glycerine in March 2003

Glycerine was used in lot of industries in our country. Most of the glycerine

is using as the basic oleo chemical product in producing surfactants, emulsifiers,

lubricants and cosmetic products. The highly demand for the glycerine in the

industrial uses make it as a very potential investment.

Gly World (M) Sdn. Bhd

Chapter I– Project Conception - Literature Survey I- 25

Figure 1.8: Usage Of Glycerine In Malaysia

Currently in Malaysia, large multi-national companies dominate the

glycerine market. Five companies that produce glycerine in Malaysia are:

a. Lam Soon (M) Sdn. Bhd.

b. Fatty Chemical (M) Sdn. Bhd.

c. Natural Oleochemical Sdn. Bhd.

d. Pan-Century Oleochemical Sdn. Bhd.

e. Palmco Holdings Berhad.

Besides glycerine, the factories also produce other basic oleochemical

product like fatty acid, fatty alcohol. Most of the glycerine was used in the country

and some of them are exported to the other country. The demand for glycerine in our

country also high and there is not enough suppliers to cover it. This brings to the

bright future in investing in this field.

Gly World (M) Sdn. Bhd

Esterification with Fatty Acid

Transesterification with Fatty Monoester

Transesterification with Monoglycerides

Glycerol

Surfactants

Emulsifiers

Lubricants

Cosmetic Products

Shampoo, Foam, Shower Bath, Gels

Food Industry

Engine, Hydraulic, Gearbox oil

Molding, Chain Saw Oil

Acidic

Basic

Basic

Chapter I– Project Conception - Literature Survey I- 26

1.2.5 The Raw Material

Good quality glycerine can be derived either naturally from vegetable or

animal origin, or synthetically from epichloohydrin but for marketing reason, it is

most suitable to use the vegetable based raw material as the requirement from many

customer. It is because of the religious sensibilities and the purity.

Over 20% of the worldwide production of fats and oils were used in non-

edible products in 1990. The major raw material that is use is tallow, coconut oil,

palm oil and palm kernel oil. The prices for the four major raw materials for the oleo

chemical market as given in the Chemical Marketing Report (November 1993) are

shown below:

Table 1.9: Prices of Major Raw Materials of Oleochemicals in

November 1993

Raw Material Price US$/ MT

Palm Kernel 418

Palm Oil 407

Coconut Oil 522

Tallow (inedible) 319

If we compare, the price for palm oil is the lowest. This will reduce the raw

material cost in producing the oleochemical product.

Some other reasons of the choice are:

a) The market price for CPO is low in Malaysia. So we can reduce the raw

material cost.

b) CPO is one of the major palm oil products in Malaysia. It can be getting

easily in a large quantity.

c) It is a biological substance. Easier to process the waste and reduce the

pollution.

Gly World (M) Sdn. Bhd

Chapter I– Project Conception - Literature Survey I- 27

Malaysia, as the main manufacture of palm oil product in the world, has

produce million tonnes of crude palm oil, crude palm kernel oil and it derivatives

every year. In year 2002, Malaysia has produce 1,473 k MT crude palm kernel oil.

Indonesia has produced 1,050 k MT and Thailand and Philippines, each 90 and 8 k

MT. This will give an enough raw material for the production of glycerine.

The average price of CPO in 2004 for local delivered is RM 1,416 per tonne

(The Star, 6 December 2004). The refined glycerine was sold at RM 8.81/kg. The

refined glycerine market may be more complex to penetrate than the crude glycerine

market. This is because, for crude glycerine, a small number of refineries represent

the entire potential customer base. In contrast, refined glycerine can be sold to

hundreds of different companies.

1.3 Several Strategic Plant Locations

The manufacture of refined glycerine can be classified as oleochemical

project. This industries must be therefore be sited in a special zone provided by government.

In Malaysia, the locations of the oleochemical plants are majority located at

Petaling Jaya Selangor, Prai Pulau Pinang and Pasir Gudang Johor. The location

of any purpose plant plays a very important role as it can affect on the success of

the plant and its operation. The choice of the final site should be based on a

complete survey of the advantages and disadvantages of all available location.

For the production of 100 KMT per year of refined glycerine, there is five main

location industrial estates have been shortlist for our new plant. They are:

1. Teluk Panglima Garang Industrial Estate, Selangor

2. Prai Industrial Complex, Prai, Penang.

3. Pasir Gudang Industrial Estate, Johor.

4. Gebeng (Phase IV) Industrial Area in Pahang.

5. Teluk Kalong Industrial Area Terengganu.

Gly World (M) Sdn. Bhd

Chapter I– Project Conception - Literature Survey I- 28

1.3.1 Criteria of Plant Site Selection

The assessment of site location for sitting a plant would depend mainly on several factors such as:

(1) Production and Distribution Factors

a) Freight rates

Competitive points

Differentials

Favorable territory

b) Markets

Local area

Favorable area

Competitive area

National area

c) Competitive, feeder and consumer industries

d) Municipal restriction

Nuisance laws relating to fumes

Waste disposal

e) Corporation fees and taxes

f) Fuel

Types of fuel

Thermal efficiency

Reserve and alternate sources

Gly World (M) Sdn. Bhd

Chapter I– Project Conception - Literature Survey I- 29

(2) Specific Factors

a) Transportation facilities

Highways – regularly used for short distance and generally small

quantities.

Availability of various services and project rates.

Water – cheaper but may be slow and irregular.

Railroads – dependable for light and heavy shipping aver all distance.

Pipelines – for gases and liquids, particularly for petroleum product.

Air – for business transportation for personnel.

b) Regulatory Laws

Zoning ordinances.

Highway ordinances.

Building codes.

Waste-disposal codes.

c) Site characteristics

Soil structure.

Costs of site.

Control of site.

Room of expansion.

Access to railroads, highways and water.

Site and facilities available by expansion on present company –

owned property.

d) Flood and fire control

Flood history.

Flood control.

Fire hazards in surrounding area.

e) Community factors

Rural or urban.

Gly World (M) Sdn. Bhd

Chapter I– Project Conception - Literature Survey I- 30

Medical facilities – hospitals, doctors, etc.

Housing costs.

Recreation facilities.

Cultural and religion aspects – mosque, surau, libraries, theatres, etc.

School system.

f) Waste disposal

Regulation laws.

Steam carry – off possibilities.

Air – pollution possibilities.

g) Vulnerability to wartime attack

General industry concentration.

Distance from important facilities.

h) Taxes

States and local taxes.

i. Income

ii. Property

iii. Use

iv. Franchise

v. Unemployment insurance

Low assessment or limited term exemption to attract industry.

(3) Major Factors

a) Reasonable land price

The land will influence the working capital. In terms of reasonable, it

means that with the good incentive from local government and low land

price. If the land chosen is not classified as industrial area, the condition

should be change first. State and local tax rates on property income,

unemployment insurance and similar items vary one location to another.

Gly World (M) Sdn. Bhd

Chapter I– Project Conception - Literature Survey I- 31

b) Labors

The types and supply of labor available in the vicinity of proposed

plant site must be examined. Some of the factors that should be considered

on labor are supply, kinds, nationality, diversity, intelligence, wage scales,

efficiency and costs. Consideration also should be given to prevailing pay

scales, restrictions on number of hours worked per week, competing

industries that can cause dissatisfaction or high turnover rates among the

workers and variations in the skill and productivity of the workers there for

industrial housing, safety-first movement, welfare institutions, better

sanitation and lunchroom have all contributed to the solution of labor welfare

and problems as well as the radio and automobile, also have helped towards

building up and maintaining a supply satisfied and contented laborers. This

factor can contribute to the saving of the operation cost.

c) Distance From Market

Demand versus distance, inventory storage requirements, growth or

decline, competition-present and future. The location of market or

intermediate distribution centers affects the cost of product distribution and

the time required for shipping. The buyer usually finds that it is more

advantage to purchase from nearby sources. Market of major final product

and by-product should be considered.

d) Waste disposal

Another serious consideration that should be made before choosing a

site is the disposal of waste liquors and waste products from the chemical

plant. If there is a sewer in the street adjoining to the property, the quantity

of waste liquors to be disposed off should be estimated and the size of the

street sewer should be checked to determine whether it could take care of the

liquors. If the waste liquors such as acids or alkaline, contain solids, or has

other objectionable features, it is advisable to learn from the local authorities

whether the disposal of such liquor in the sewerage system is permissible.

Any waste from atomic energy plants cannot just be disposed of by dumping

it into sewers or rivers.

Gly World (M) Sdn. Bhd

Chapter I– Project Conception - Literature Survey I- 32

Usually most chemical plants often simply dispose of their waste by

locating on a stream, rivers or at the tidewater. However, this is no longer

satisfactory, for there is a growing list of state, which has instituted

legislation against such pollution by industrial wastes. Seepage through the

ground is also can be used as another method of waste disposal. Before that,

soil tests should be made to determine whether the soil is porous enough to

permit the disposal of considerable quantities of liquor with out

accumulation. It is also advisable to check the topographic factor of the area

to determine where the liquor will sleep in order to avoid trouble from

neighboring plants or the local authorities. Towns lower down the valley mat

draw their water supply from the drainage shed upon which the plant is

situated.

Nevertheless, a systematic toxic and industrial waste will be more

effective as disposal waste will be treated accordingly. This method is

getting popular and encourages using as will product non-polluting, clean

and environmental friendly.

e) Climate

Seasonal range

Precipitation

Humidity and temperature conditions.

Wind

Hurricane, tornado and earthquake history.

Investment required for construction.

f) Raw materials or semi-finished products

These particularly important if large volumes of raw material are

consumed because these permit considerable reduction in transportation and

storage charge. Any way attention should be given to the purchased price of

the raw materials, distance from the source of supply, purity of the raw

materials, reserve stock and storage requirements. In order to save the

Gly World (M) Sdn. Bhd

Chapter I– Project Conception - Literature Survey I- 33

transportation costs, the plant should be located near to the raw material

supply and sources.

g) Transportation Facilities

The relation of railways, ports or road facilities to market is so close

in making a prudent investigation of transportation rates before definitely

deciding upon a plant location. Water, railroads and highways are the

common means of transportation used by major industrial concern. There is

usually need for convenient air and rail transportation facilities. A location

which has several competing railroads, ports and road networks as well as

waterways in order that the competition will help to maintain low rates and

give better service should be chosen.

h) Government Incentives

In order to attract new investors, the government will offer an

incentive to them, the better the incentive offered the feasibility to build the

plant there would be better.

i) Water supply

Sources

Mineral analysis

Bacterial content

Turbidity

Quantity

Temperatures

Costs

The process industries use a lot of water for cooling, washing steam

generation and as raw material. So the plant must be located where supply

water is available. The temperature, mineral content, silt or sand content and

cost for supply must also be considered when choosing a water supply.

Gly World (M) Sdn. Bhd

Chapter I– Project Conception - Literature Survey I- 34

j) Energy Supply

Hydroelectric

Public service

Alternate source

Power and steam requirement is high in most industrial plants and

fuel is ordinarily to supply this utilities. Location should near to the

hydroelectric installation if the plant using electrolytic process. If the plant

requires large quantities of oil or coal, location near a source of supply may

be essential for economic operation. The local cost of power can help

determine whether power should be purchased or self-generated. Local

authorities or whoever provided power supply to locations should have a

contingency plan if power failure occurs during plant operations beside

contingency plan from the plant it self.

(4) Port Facilities

i) Prai Industrial port:

Blue Orient Shipping:

- Warehouses provided

- 20 minutes to Penang airport

- 10 minutes distribution to three other locations

- Located in the Free Commercial Zone

ii) Pasir Gudang Port:

Haulers:

- Kontena Nasional Sdn. Bhd.

- MISC Haulage Sdn.Bhd

- Shapadu kontena Berhad

- Multimodal Freight Transportation Sdn. Bhd.

- Konsortium Perkapalan Berhad

Gly World (M) Sdn. Bhd

Chapter I– Project Conception - Literature Survey I- 35

iii) Kuantan Port

Facilities:

- Berth

Berth Container:

- Length = 200m

- Draft = 11.2m

Two units with length of 450m have been completed in 1999.

Multipurpose Berth

- Three units

- Length = 525m each

- Draft = 11.2m each

- Storage:

- Seven godowns

- Total area = 31.75m2

- Open yard = 41.25 m2

- Container freight

- Stations - 9.6m2

- Yard – 72.0 m2

- Port Equipments:

Container crane

- 40 tons capacity

- Able to handle 20’, 40’ and 45’ container.

- Multipurpose crane

- 30.5 tons-container capacity

- 40 tons-sling capacity

- 16 tons-grab capacity

Presently, the port has total area of 605.3 hectares with the following comprises:

- 48.4 hectares used for operation purposes.

Gly World (M) Sdn. Bhd

Chapter I– Project Conception - Literature Survey I- 36

- 69.2 hectares accommodate a water basin.

- 205.7 hectares for industrial purposes.

- 11.4 hectares for commercial purposes.

- 151.7 hectares reserved for future expansion.

- 12.5 hectares accommodates recreation and staff quarters.

- 106.4 hectares consist of road, hill and drainage.

- The port is in the midst of RM300 million-expansion program.

iv) Kemaman Port

Dedicated liquid bulking terminal under construction:

- Length of 240 meters.

- Ship capacity up to 40,000 DW.

- Handling capacity 15,000 tons per day.

- Pipeside 8” – 12” (50 in number)

It is an all weather port facing South China Sea. The draft at East Wharf has

17 meters draft (upgraded from initially 13 meters in October 1996). It can handle

ships up to 100,000 DWT. Upgrading exercises would cater 120,000 DWT vessels.

Currently dry general and liquid cargo on average two to three million tons per year.

Current capacity estimated at 6.84 millions tons per year (Tango crane).

It consists of three selections:

- East wharf (684 m)

- Supply base (650 m)

- Petroleum Export Terminal

Gly World (M) Sdn. Bhd

Chapter I– Project Conception - Literature Survey I- 37

Table 1.10: Comparison of short-listed of the potential site location

Selection

Criteria

Teluk Panglima Garang

Industrial Estate,

Selangor

Prai Industrial Complex, Prai, Penang

Pasir Gudang

Industrial Estate,

Johor

Phase IV, Gebeng

Kuantan Pahang

Teluk Kalong,

Terengganu

Developer Perbadanan Kemajuan

Negeri Selangor

(PKNS)

Pulau Pinang

Economic

Development

Corporation

Johor State

Economic

Development

Corporation

(JCORP)

Perbadanan

Tempatan Pasir

Gudang (PBTG)

Land

Price

(RM per

sq ft)

7.00 – 20.00 12.20 – 21.00 8.00 – 22.00 2.00 – 12.00

Total area of 4000

acres

0.46 – 4.18

Total area of 516.18

hectares

Raw

Material

Supplier

Southern Edible Oil

Industries (M) Sdn.

Bhd.

United Plantation Oil

Mill

Sime Darby Edible

Sime Darby Edible

Product

Limited(SDEPL)

Cargill Palm

Products Sdn. Bhd.

Felda Vegetable Oil

Gly World (M) Sdn. Bhd

1 1 331

2

1 1 2

Chapter I– Project Conception - Literature Survey I- 38

Socktek Sdn. Bhd

UNITATA Berhad

Anson Oil Mill Sdn

Bhd.

Lee Oil Mill Sdn. Bhd

Sime Darby Edible

Product

IOI Edible Oils Sdn

Bhd.

Felda Marketing

Services Sdn. Bhd.

KL-Kepong Edible Oil

Sdn. Bhd.

Welli Edible Oil Sdn.

Bhd.

Ngo Chew Hong Oils

& Fats (M) Sdn Bhd

Kempas Edible

Oil. Sdn. Bhd.

Product

Wilma Edible Oil

Sdn. Bhd.

Palmco Oil Mill

KeckSeng(M) Bhd.

Marakot Industries

Public Company

Limited.

Johore Tenggara

Oil Palm Sdn. Bhd.

Mewaholeo

Industries Sdn. Bhd.

Products Sdn. Bhd.

Incentive given

State Government

itself.

Waste

Disposal

Kualiti Alam Sdn.

Bhd.

Kualiti Alam Sdn.

Bhd.

Kualiti Alam Sdn.

Bhd

Kualiti Alam Sdn.

Bhd

Kualiti Alam Sdn.

Bhd

Gly World (M) Sdn. Bhd

32 2

Chapter I– Project Conception - Literature Survey I- 39

Distance

from

Nearest

Town

15 km from Sepang

25 km from Shah

Alam

25 km from Klang

50 km from KL

35 km from Petaling

Jaya

118 km from Alor

Setar

25 km from Kulim

37 km from Sungai

Petani

40 km from

Butterworth

48 km from Johor

Bharu

5 km from Johor

Port

45 km from

Kuantan Town

4 km from Kuantan

Port

9.6 km from

Kemaman District

Types of

Industries

Small, medium and

heavy industry

Oleochemical industry

Chemical

Petro-chemical

Sea related industry

oleochemical

industry

Light, medium and

heavy industry

Sea related industry

Chemical and

plastic

Petrochemical

Medium and heavy

industry

Chemical

Petrochemical

Medium and heavy

industry

Road

Facilities

North-South Highway

(Bukit Kayu Hitam to

Singapore)

Persekutuan Highway

PLUS Highway

North-South

Highway (Bukit

Kayu Hitam to

Singapore)

Pulau Pinang Bridge

Pasir Gudang to

Kim Kim River

Bridge over Kim

Kim River

Bridge to Johor

Main road to KL,

JB, Singapore

340km East-Coast

Highway, linking

Karak and

Coastal highway

Terengganu – KL

and Singapore

Gly World (M) Sdn. Bhd

2 2 2

2 2 32 3

12 2 3 3

2 2

Chapter I– Project Conception - Literature Survey I- 40

ELITE Highway

Sepang International

Airport

South Klang Valley

Expressway

Dedicated Highway

Lebuhraya B15

River

North-South

Highway (Bukit

Kayu Hitam to

Singapore)

Highway from Pasir

Gudang-Tanjung

Kupang-Tuas,

Singapore

Terengganu via

Kuantan

Kuala Lumpur-

Kuantan travel

reduced to at least

two hours.

Airport

Facilities

KLIA Bayan Lepas

International Airport

Sultan Ismail

Airport, Senai

Changi

International

Airport, Singapore

Kuantan Airport Airport – Kuala

Terengganu

Seaport Klang Port Pulau Pinang Port Johor Port (Pasir

Gudang)

Kuantan Port

Transportation

Kemaman Port

Kuantan port

Gly World (M) Sdn. Bhd

23 3

1 1 2 2 1

23

Chapter I– Project Conception - Literature Survey I- 41

Tanjung Pelepas

Port

under Kuantan Port

Consortium (KPC)

Railway PUTRA LRT

Butterworth-Pasir

Gudang-

Singapore(KTM)

(787 km)

Express Rail Link

Butterworth-Pasir

Gudang-

Singapore(KTM)

(787 km)

Butterworth-Pasir

Gudang-Singapore

(KTM)

Kuantan Port-

Gebeng-

KemamanPort-

Kerteh to Tuk Arun

in Terengganu

Electricity IPP Kuala Langat

Banting(Genting

Sanyen Power Sdn.

Bhd)

Sultan Salahudin Abd.

Aziz ( Stesen

Janakuasa Kapar :

2420MW)

IPP Petaling Jaya (Projass

Engineering Sdn. Bhd. ;

IPP Perai

(Voltage:1500MW)

Tariff :

Tariff D (low voltage,

less than 6.6kV supply)

All units : 25.8 cent

Sultan Iskandar

Power Station

(Voltage: 220-240

V; max 132 KVA

taped from 275

KVA line)

IPP YTL Power

Generation Sdn.

Bhd.

Tg. Gelang,

Kuantan

Tenaga Nasional

Berhad (800 MW)

Paka Power Plant

(800 MW)

Tasik Kenyir

Hydroelectric Dam

(600 MW)

IPP YTL Power

Generation Sdn.

Bhd. (808MW)

Gly World (M) Sdn. Bhd

2 2 3 3 3

2 2 32

Chapter I– Project Conception - Literature Survey I- 42

17 MW)

Water

Supply

Sungai Selangor water

supply

Sungai Semenyih

water supply

Tariff :

0 – 35m3 : RM1.80

More than 35m3 : RM 1.92

Penang Water Supply

Corporation

Empangan Bersia

Tariff:

0 -20m3 : RM0.52

21 - 40m3 : RM0.70

41 – 200m3 : RM0.90

More than 200m3 :

RM1.00

Syarikat Air Johor

Loji Air Sungai

Layang

Sungai Buloh

(Capacity: 24

mg/day; Flowrate:

0.04-30.0 liter per

second)

Tariff:

0 - 20m3 : RM1.68

More than 20m3 :

RM2.24

Loji Air Semambu

Tarif :

1st 700 m3 : RM 0.95

More than 700 m3 :

RM 1.15

Surrounding

district especially

from Dungun

Kenyir Dam

Tarif :

0 – 227 m3 : RM 0.92

More than 227 m3 :

RM 0.84

Resident

Area

Petaling Jaya

Shah Alam

Kuala Lumpur

Seberang Perai

Georgtown

Butterworth

Pasir Gudang

Kempas

Johor Bahru

Gly World (M) Sdn. Bhd

3 2 32 3

3 331

1

Chapter I– Project Conception - Literature Survey I- 43

Klang

Sepang

Bukit Mertajam

Human

Resources

Training facilities such as:

Politeknik Shah Alam

Universiti Teknologi

MARA

Malaysia Agriculture

Research and

Development Institute

(MARDI)

Universiti Kebangsaan

Malaysia

Universiti Putra

Malaysia

Universiti Islam

Antarabangsa

Training facilities such

as:

Universiti Teknologi

MARA

Universiti Sains

Malaysia

Universiti Utara

Malaysia

Training facilities such

as:

Universiti

Teknologi

Malaysia, Skudai

Universiti

Teknologi MARA,

Segamat

Politeknik Pasir

Gudang

Institut Latihan

Perindustrian Pasir

Gudang

Johor Skills

Development

Center (JSDEC)

Johor

Technovation Park

Polytech

nic Kuantan

Institut

Kemajuan Ikhtisas

Pahang (IKIP)

Gly World (M) Sdn. Bhd

2 2 2

2 2

Chapter I– Project Conception - Literature Survey I- 44

Total Site

value

Gly World (M) Sdn. Bhd

27

25

28

32

23

2 2

Chapter I– Project Conception - Literature Survey I- 45

1.3.2 Selected Site

After considering the available site locations that depend upon several

factors including primary and specific factors, Gebeng (Phase IV), Kuantan Pahang

is chosen as the site for this proposed refined glycerine plant selected as a totally

satisfactory solution for future benefits. Generally the main reasons why Gebeng

(Phase IV), Kuantan Pahang have been chosen as the glycerine refinary industrial

area are:

i) Gebeng Industrial Estate had been specialized for heavy and medium

industries where waste treatment is easy to carry out.

ii) Close to raw material sources. We can get our raw materials (RBDPO)

from Cargill Palm Products Sdn. Bhd and Felda Vegetable oil Products

Sdn. Bhd. In Gebeng Industrial Estate. So, the price of raw materials is

cheaper.

iii) Reasonable land price (RM 2.00 – RM 12.00 per square feet) compared

to the other sites. Since our plant is quite small, the land price won’t

affect the economic analysis much.

iv) Since the industrial is new, so there is much space for us to construct our

plan and for our future expansion. The available area is 4000 acres

(1,618.76 hectares).

v) Common pipe rack link Gebeng and Kuantan Port.

vi) This location is quite near to Kuantab Port (4 km), so that any trade

involving import and export product to the other countries can be

accomplished easily.

vii) Far enough from residents. This site is located 45 km from Kuantan.

viii) Good transportation in terms of road facilities, railway, airport and

seaport to get raw materials and market our product.

ix) Attractive incentives from Pahang State Government. The state

government is giving Pioneer Status, Investment Tax Allowance (ITA),

Gly World (M) Sdn. Bhd

Chapter I– Project Conception - Literature Survey I- 46

Infrastructure Allowance, Incentives for Strategic Projects, Exemption on

Import Duties, and Discount on Electricity Bills etc.

x) Adequate supply of electricity and water. There are Paka Power Plant,

IPPYTL Power Generation Sdn. Bhd. And Tasik Kenyir Hydroelectric to

supply electricity. On the other hand, Semambu Water Treatment can

supply water.

xi) Training facilities are given by Universiti Teknologi Malaysia, Indera

Mahkota, Politeknik Sultan Ahmad Shah (POLISAS), Universiti

Teknologi MARA, Bandar Jengka, Universiti Islam Antarabangsa,

Kuantan and Institut Kemajuan Ikhtisas Pahang (IKIP).

xii) Suitable climate (Annual rainfall: 2500 mm, average temperature: 25-27 0C)

xiii) Other facilities: Eastern Corridor Incentives, establishment of Multi

National Company (MNC’s) etc.

Gly World (M) Sdn. Bhd

Chapter I– Project Conception - Literature Survey I- 47

1.3.3 Proposed Plant Layout

1.4 Physical and Chemical Property Data

Tabulated below are the physical and chemical properties of the components involved in this design (Perry, 1984).

Gly World (M) Sdn. Bhd

Par

kin

g L

ot

Par

king

L

ot Par

kin

g L

ot

Par

kin

g L

ot

Secu

rity

Office &

A

dministration

Departm

ent

Sec

uri

ty

Pla

nt A

rea

Pla

nt

Uti

lity

Ch

emic

al

War

eho

use

Fire Station

Future

ExpansionTank Farm

Canteen

Toil

et

Sur

au

Chapter I– Project Conception - Literature Survey I- 48

1.4.1 Glycerine

Chemical Name: Glycerine (Glycerol)

Physical Properties ValueFormula C3H8O3

Physical State LiquidColor ClearOdor Faint odorSolubility in Water Miscible in water; insoluble in

CloroformMolecular Weight 92.095Critical Temperature (F) 1070.33Critical Pressure (psia) 1087.788Critical Volume (ft3/lbmol) 4.228874Melting Point (F) 64.72398Normal Boiling Point (F) 550.13IG Heat of formation (Btu/lbmol) -248452.3Specific gravity 60 F 1.265331 Heat of vaporization (Btu/lbmol)Min value at T (K) = 291.33Max value at T (K) = 850Coefficients:ABCDE

9.035704E+070

1.1067E+084.8319E-01

000

2 Liquid Density (kmol/m3)Min value at T (K) = 291.33Max value at T (K) = 850Coefficients:ABCDE

13.708433.788321

9.2382E-012.4386E-018.5000E+022.2114E-01

3 Vapor Pressure (Pascal)Min value at T (K) = 291.33Max value at T (K) = 850Coefficients:C1C2C3C4C5

0.0095222277497165

9.9986E+01-1.3808E+04-1.0088E+013.5712E-196.0000E+00

4 Ideal gas Heat Capacity (J/kmol-K)Min value at T (K) = 298.15Max value at T (K) = 1200.15

115314.2249812.9

Gly World (M) Sdn. Bhd

Chapter I– Project Conception - Literature Survey I- 49

Coefficients:ABCDE

9.6490E+041.5187E+058.2120E+021.8280E+053.2720E+03

5 Liquid Heat Capacity (J/kmol-K)Min value at T (K) = 187.4Max value at T (K) = 561Coefficients:ABCDE

168553348146.3

7.8468E+044.8071E+02

000

1.4.2 Lauric Acid

Chemical Name: Lauric Acid (Dodecanoic Acid)

Physical Properties ValueFormula C12H24O2

Physical State LiquidColor WhiteOdor Slight odor of bay oilSolubility in Water InsolubleMolecular Weight 200.32Critical Temperature (F) 877.73Critical Pressure (psia) 281.3731Critical Volume (ft3/lbmol) 11.29302Melting Point (F) 110.894Normal Boiling Point (F) 569.66IG Heat of formation (Btu/lbmol) -275149.4Specific gravity 60 F 0.89273631 Heat of vaporization (Btu/lbmol)Min value at T (K) = 291.33Max value at T (K) = 850Coefficients:ABCDE

9.807806E+070

1.3164E+085.2913E+01

000

2 Liquid Density (kmol/m3)Min value at T (K) = 291.33Max value at T (K) = 850Coefficients:A

4.3510921.418513

3.7897E-01Gly World (M) Sdn. Bhd

Chapter I– Project Conception - Literature Survey I- 50

BCDE

2.6716E-017.4300E+022.9396E-01

3 Vapor Pressure (Pascal)Min value at T (K) = 291.33Max value at T (K) = 850Coefficients:C1C2C3C4C5

0.041180881946081

2.0156E+02-2.0484E+04-2.4334E+018.0558E-186.0000E+00

4 Ideal gas Heat Capacity (J/kmol-K)Min value at T (K) = 298.15Max value at T (K) = 1200.15Coefficients:ABCDE

300015.2739509.3

2.1052E+056.3439E+05-1.4923E+034.0290E+05-6.8190E+02

5 Liquid Heat Capacity (J/kmol-K)Min value at T (K) = 187.4Max value at T (K) = 561Coefficients:ABCDE

300015.2739509.3

2.1685E+056.7377E+02

000

1.4.3 Myristic Acid

Chemical Name: Myristic Acid (Tetradecanoic Acid)

Physical Properties ValueFormula C14H28O2

Physical State SolidColor WhiteOdor None reportedSolubility in Water Insoluble Molecular Weight 228.38Critical Temperature (F) 917.33Critical Pressure (psia) 246.5641Critical Volume (ft3/lbmol) 12.99097Melting Point (F) 129.596Normal Boiling Point (F) 619.16

Gly World (M) Sdn. Bhd

Chapter I– Project Conception - Literature Survey I- 51

IG Heat of formation (Btu/lbmol) -293636Specific gravity 60 F 0.88954641 Heat of vaporization (Btu/lbmol)Min value at T (K) = 327.37Max value at T (K) = 765Coefficients:ABCDE

1.063899E+080

1.4572E+085.6325E-01

000

2 Liquid Density (kmol/m3)Min value at T (K) = 327.37Max value at T (K) = 765Coefficients:ABCDE

3.7763351.233171

3.2938E-012.6710E-017.6500E+022.9570E-01

3 Vapor Pressure (Pascal)Min value at T (K) = 327.37Max value at T (K) = 765Coefficients:C1C2C3C4C5

0.025596441687843

2.0948E+02-2.177E+04

-2.53218E+017.2474E-186.0000E+00

4 Ideal gas Heat Capacity (J/kmol-K)Min value at T (K) = 300Max value at T (K) = 1500Coefficients:ABCDE

335012.3864542.7

2.4692E+057.5533E+05-1.6468E+035.2798E+05-7.5355E+02

5 Liquid Heat Capacity (J/kmol-K)Min value at T (K) = 327.37Max value at T (K) = 599.32Coefficients:ABCDE

505872682873.4

2.9280E+056.5086E+02

000

Gly World (M) Sdn. Bhd

Chapter I– Project Conception - Literature Survey I- 52

1.4.4 Palmitic Acid

Chemical Name: Palmitic Acid (Hexadecanoic Acid)

Physical Properties ValueFormula C16H32O2

Physical State ChipsColor WhiteOdor n/aSolubility in Water Insoluble Molecular Weight 256.43Critical Temperature (F) 937.13Critical Pressure (psia) 219.0136Critical Volume (ft3/lbmol) 14.68893Melting Point (F) 145.04Normal Boiling Point (F) 663.8IG Heat of formation (Btu/lbmol) -311692.7Specific gravity 60 F 0.88385921 Heat of vaporization (Btu/lbmol)Min value at T (K) = 327.37Max value at T (K) = 765Coefficients:ABCDE

9.982221E+07115266.7

1.2647E+084.1760E-01

000

2 Liquid Density (kmol/m3)Min value at T (K) = 327.37Max value at T (K) = 765Coefficients:ABCDE

3.3237651.1012

2.9241E-012.6805E-017.7600E+022.9470E-01

3 Vapor Pressure (Pascal)Min value at T (K) = 327.37Max value at T (K) = 765Coefficients:C1C2C3C4C5

0.0012604151507850

6.3503E+02-4.5621E+04-8.7646E+013.5199E-052.0000E+00

4 Ideal gas Heat Capacity (J/kmol-K)Min value at T (K) = 300Max value at T (K) = 1500Coefficients:

381011.7985759.6

Gly World (M) Sdn. Bhd

Chapter I– Project Conception - Literature Survey I- 53

ABCDE

2.8475E+058.6494E+051.6878E+036.1107E+057.6735E+02

5 Liquid Heat Capacity (J/kmol-K)Min value at T (K) = 327.37Max value at T (K) = 599.32Coefficients:ABCDE

577842.6816698.4

-4.8415E+05-3.4568E+00

000

1.4.5 Stearic Acid

Chemical Name: Stearic Acid (Octadecanoic Acid)

Physical Properties ValueFormula C18H36O2

Physical State SolidColor WhiteOdor Slight tallow-like odorSolubility in Water Slightly soluble in water Molecular Weight 284.48Critical Temperature (F) 987.53Critical Pressure (psia) 197.2513Critical Volume (ft3/lbmol) 16.33883Melting Point (F) 157.28Normal Boiling Point (F) 707.36IG Heat of formation (Btu/lbmol) -328459.6Specific gravity 60 F 0.8471 Heat of vaporization (Btu/lbmol)Min value at T (K) = 342.75Max value at T (K) = 804Coefficients:ABCDE

1.223813E+083169.206

1.7410E+086.3436E-01

000

2 Liquid Density (kmol/m3)Min value at T (K) = 342.75Max value at T (K) = 804Coefficients:AB

2.9717310.9867467

2.6257E-012.6778E-01

Gly World (M) Sdn. Bhd

Chapter I– Project Conception - Literature Survey I- 54

CDE

8.0400E+023.1050E-01

3 Vapor Pressure (Pascal)Min value at T (K) = 342.75Max value at T (K) = 804Coefficients:C1C2C3C4C5

0.0058632971339989

2.3303E+02-2.4932E+04-2.8343E+016.2621E-186.0000E+00

4 Ideal gas Heat Capacity (J/kmol-K)Min value at T (K) = 300Max value at T (K) = 1500Coefficients:ABCDE

437912.11100061

3.2620E+059.4730E+051.6260E+036.4154E+057.4310E+02

5 Liquid Heat Capacity (J/kmol-K)Min value at T (K) = 342.75Max value at T (K) = 648.3499Coefficients:ABCDE

653938.8852080.7

4.3171E+056.4837E+02

000

1.4.6 Oleic Acid

Chemical Name: Oleic Acid (9-Octadecanoic Acid)

Physical Properties ValueFormula C18H34O2

Physical State LiquidColor Colorless to pale redOdor LardlikeSolubility in Water Insoluble Molecular Weight 282.46Critical Temperature (F) 946.13Critical Pressure (psia) 201.5842Critical Volume (ft3/lbmol) 16.01846Melting Point (F) 56.08403Normal Boiling Point (F) 679.73IG Heat of formation (Btu/lbmol) -288820.9

Gly World (M) Sdn. Bhd

Chapter I– Project Conception - Literature Survey I- 55

Specific gravity 60 F 0.89341 Heat of vaporization (Btu/lbmol)Min value at T (K) = 286.53Max value at T (K) = 781Coefficients:ABCDE

1.12485E+08180974.2

1.3470E+083.9430E-01

000

2 Liquid Density (kmol/m3)Min value at T (K) = 286.53Max value at T (K) = 633.15Coefficients:ABCDE

3.1676452.253934

2.6810E-012.6812E-017.8100E+022.8970E-01

3 Vapor Pressure (Pascal)Min value at T (K) = 286.53Max value at T (K) = 633.15Coefficients:C1C2C3C4C5

1.074907E-0599453.47

1.8610E+02-2.0.15E+04-2.2472E+016.1199E-182.0000E+00

4 Ideal gas Heat Capacity (J/kmol-K)Min value at T (K) = 298.15Max value at T (K) = 1500.1Coefficients:ABCDE

417795.11069776

3.2000E+059.3620E+05-1.7431E+036.7540E+057.8250E+02

5 Liquid Heat Capacity (J/kmol-K)Min value at T (K) = 286.53Max value at T (K) = 550Coefficients:ABCDE

517916.91114050

4.5900E+05-8.6600E+023.7400E+00

00

Gly World (M) Sdn. Bhd

Chapter I– Project Conception - Literature Survey I- 56

1.4.7 Linoleic Acid

Chemical Name: Linoleic Acid (9,2 Octadecadienoic Acid)

Physical Properties ValueFormula C18H32O2

Physical State LiquidColor Clear, very slight yellowOdor n/aSolubility in Water Insoluble Molecular Weight 280.45Critical Temperature (F) 935.33Critical Pressure (psia) 204.494Critical Volume (ft3/lbmol) 15.85828Melting Point (F) 23.00001Normal Boiling Point (F) 670.73IG Heat of formation (Btu/lbmol) -23215.3Specific gravity 60 F 0.908781 Heat of vaporization (Btu/lbmol)Min value at T (K) = 268.15Max value at T (K) = 775Coefficients:ABCDE

1.130197E+080

1.3387E+083.9870E-01

000

2 Liquid Density (kmol/m3)Min value at T (K) = 268.15Max value at T (K) = 628Coefficients:ABCDE

3.2893612.250581

2.1880E-012.3756E-017.7500E+022.8600E-01

3 Vapor Pressure (Pascal)Min value at T (K) = 268.15Max value at T (K) = 628Coefficients:C1C2C3C4C5

6.448264E-07100576.3

1.4363E+02-1.8347E+04-1.6000E+013.0041E-186.0000E+00

4 Ideal gas Heat Capacity (J/kmol-K)Min value at T (K) = 298.15Max value at T (K) = 1500Coefficients:

394299.81049282

Gly World (M) Sdn. Bhd

Chapter I– Project Conception - Literature Survey I- 57

ABCDE

3.3200E+051.0420E+062.2884E+037.9840E+059.2350E+02

5 Liquid Heat Capacity (J/kmol-K)Min value at T (K) = 268.15Max value at T (K) = 628Coefficients:ABCDE

527508.3844896

2.9100E+058.8200E+02

000

1.4.8 Linolenic Acid

Chemical Name: Linolenic Acid (9,12,15-Octadecatrienoic Acid)

Physical Properties ValueFormula C18H30O2

Physical State LiquidColor n/aOdor n/aSolubility in Water Insoluble Molecular Weight 278.435Critical Temperature (F) 944.33Critical Pressure (psia) 208.8543Critical Volume (ft3/lbmol) 17.13976Melting Point (F) 12.02Normal Boiling Point (F) 677.93IG Heat of formation (Btu/lbmol) -174118Specific gravity 60 F 0.92120871 Heat of vaporization (Btu/lbmol)Min value at T (K) = 262.05Max value at T (K) = 780Coefficients:ABCDE

1.158786E+080

1.3680E+084.0540E-01

000

2 Liquid Density (kmol/m3)Min value at T (K) = 262.05Max value at T (K) = 780Coefficients:AB

3.3638880.9356537

2.2204E-012.3731E-01

Gly World (M) Sdn. Bhd

Chapter I– Project Conception - Literature Survey I- 58

CDE

7.8000E+022.8570E-01

3 Vapor Pressure (Pascal)Min value at T (K) = 262.05Max value at T (K) = 780Coefficients:C1C2C3C4C5

1.014866E-071444430

1.4949E+02-1.8892E+04-1.6791E+013.2413E-186.0000E+00

4 Ideal gas Heat Capacity (J/kmol-K)Min value at T (K) = 300Max value at T (K) = 1200Coefficients:ABCDE

378008925310.7

2.6915E+058.7906E+051.6363E+036.2440E+057.4228E+02

5 Liquid Heat Capacity (J/kmol-K)Min value at T (K) = 390Max value at T (K) = 585Coefficients:ABCDE

586543795914.5

1.6780E+051.0737E+03

000

1.4.9 Arachidic Acid

Chemical Name: Eicosanoic (Arachidic Acid)

Physical Properties ValueFormula C20H40O2

Physical State CrystalsColor WhiteOdor None reportedSolubility in Water Practically insoluble in water Molecular Weight 312.536Critical Temperature (F) 1018.13Critical Pressure (psia) 179.8467Critical Volume (ft3/lbmol) 18.10086Melting Point (F) 167.54Normal Boiling Point (F) 746.6IG Heat of formation (Btu/lbmol) -349267.8

Gly World (M) Sdn. Bhd

Chapter I– Project Conception - Literature Survey I- 59

Specific gravity 60 F 0.88415841 Heat of vaporization (Btu/lbmol)Min value at T (K) = 348.23Max value at T (K) = 821Coefficients:ABCDE

1.078658E+08118190.2

1.3593E+084.1900E-01

000

2 Liquid Density (kmol/m3)Min value at T (K) = 348.23Max value at T (K) = 821Coefficients:ABCDE

2.6923750.8883711

2.2977E-012.5964E-018.2100E+023.4829E-01

3 Vapor Pressure (Pascal)Min value at T (K) = 348.23Max value at T (K) = 821Coefficients:C1C2C3C4C5

0.0025786241211789

2.4459E+02-2.6449E+04-2.9833E+015.9700E-186.0000E+00

4 Ideal gas Heat Capacity (J/kmol-K)Min value at T (K) = 300Max value at T (K) = 1500Coefficients:ABCDE

484021.91176239

3.5814E+056.7278E+057.2784E+024.4834E+051.9194E+03

5 Liquid Heat Capacity (J/kmol-K)Min value at T (K) = 348.23Max value at T (K) = 610.5Coefficients:ABCDE

715714.4967964.7

8.3000E+05-1.0640E+032.1130E+00

00

Gly World (M) Sdn. Bhd

Chapter I– Project Conception - Literature Survey I- 60

1.4.10 Water

Chemical Name: Water