Dr. R. T. Patil Dr. R. T. Patil Former Director, CIPHET, Ludhiana Former Director, CIPHET, Ludhiana Chairman & ED, Benevole for PHT, Bhopal Chairman & ED, Benevole for PHT, Bhopal POST HARVEST MACHINERY AND POST HARVEST MACHINERY AND STORAGE OF AGRICULTURAL PRODUCE STORAGE OF AGRICULTURAL PRODUCE

Cfmtti 2014

Jul 15, 2015

Welcome message from author

This document is posted to help you gain knowledge. Please leave a comment to let me know what you think about it! Share it to your friends and learn new things together.

Transcript

Dr. R. T. PatilDr. R. T. PatilFormer Director, CIPHET, LudhianaFormer Director, CIPHET, Ludhiana

Chairman & ED, Benevole for PHT, BhopalChairman & ED, Benevole for PHT, Bhopal

POST HARVEST MACHINERY AND POST HARVEST MACHINERY AND STORAGE OF AGRICULTURAL PRODUCESTORAGE OF AGRICULTURAL PRODUCE

Primary Processing of Horticultural Primary Processing of Horticultural Produce: Current Technologies Produce: Current Technologies

and Future Potentialand Future Potential

Dr. R.T. PatilDr. R.T. Patil

Production & Post Harvest ScenarioProduction & Post Harvest Scenario

•Agriculture contributes about 17.5% of GDP, employees 57% workforce and sustains approx over 70% of the population •India produces about 255 million tons of food grains and 268 million tons of fruits and vegetables and ranks second in world however losses are 3-18%•Low level of processing of fruits and vegetables at only 3.5% .•Food processing is employment intensive, creates 1.8 jobs directly and 6.4 indirectly for every Rs. 10 lakh investment

Agro Processing Agro Processing

1. Can provide processed food of highest quality at affordable cost to consumers

2. Help environment by processing food in production catchment with least food miles

3. Ensure traceability of raw materials used for processed product hence great for export and elite urban market.

4. Help effective backward linkage with farmers for processing their raw produce

5. Shorten the supply chain, increase the profitability of farmers and ultimately increase in GDP from agriculture and reduce poverty

6. Reduce post harvest losses and increased availability of by products for animal feed.

Price Difference Price Difference Wheat - Rs 12/kg Wheat Flour Rs. 16-18/kg

Fortified Flour Rs. 20-25/kgOil seed – Rs 35/kg Oil Rs. 70/kgPaddy – Rs 12/kg Rice – Rs. 25/kgMung- Rs. 20/kg Mung dal – Rs. 60/kgMaize-Rs.13/kg Maize flour-Rs. 16/kgTomato-Rs. 5/kg Tomato ketchup-Rs 50-80/kgFruit- Rs. 15-20/kg Fruits Bar-Rs. 200/kg

Fruit Juice- Rs. 35/litreCoriander -Rs. 80/kg Coriander Powder-Rs. 200/kgTurmeric-Rs.65/kg Turmeric Powder –Rs. 200/kgChili- Rs. 200/kg Chili Powder-Rs. 300/kgBlack pepper-Rs. 100/kg B Pepper Powder- Rs.300/kgChana Dal- Rs. 28/kg Chana Dal-Rs. 35/kg

Besan- Rs. 40/kg

Modern Rice MillingModern Rice MillingThe major operations performed by modern rice mills are: storage, cleaning, husking, separation, whitening and grading. De-husking is done in rubber roll shellers while polishing is done in cone polishers or horizontal abrasive polishers. The rice mills can be of following capacity.(i) Composite rice milling machine-a single unit (capacity 250 kg/hr).(ii) Mini rice mills: Capacity of 250 kg/hr. However, husking and polishing is done by separate machines.(iii) Modern rice mills of capacity 2-4 t/hr.

Oil MillingOil MillingCommon capacity of baby oil expeller is 60 kg / hr of oil seed. Improved expellers are equipped with a special cooling system consisting essentially of hollow worm shafts or hollow barrel frame through which cooling water or oil is pumped. A filtration system is coupled with baby oil expeller becomes an integral part of a model agro industrial complex.

Dal MillingDal Milling

Capacity 100-125 kg/h,

Power required 3 hp

Approx. Cost: Rs 60000

Efficiency-82-85%

Versatility of PKV dhal mill has been enhanced

(i) for polishing mold-affected sorghum and also

(ii) for cleaning wheat.

Spice MillingSpice Milling

It comprises of two functions: grinding and grading such as in hammer mills or in pin mill which gives cool grinding in one direct operation. No dressing is needed to get fine grinding. The degree of fineness required can be achieved by changing screen. The hammer and hammer pins are hard heat-treated steel, interchangeable and reversible giving four times the life of ordinary hammer

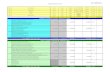

Shrink Packaging of Fruits and VegetablesShrink Packaging of Fruits and Vegetables

Storage life Ambient Cold store

Commodity

Shrink wrapped Unwrapped Shrink wrapped Unwrapped Kinnow 27 13 70 41 Tomato 19 10 39 23

Capsicum 25 4 46 21

Garlic Processing MachinesGarlic Processing Machines

Garlic Flaking MachineGarlic PeelerGarlic Bulb Breaker

Capacity-800 kg/hCost-US$300

Capacity-400 kg/hCost-US$300

Capacity-40-50 kg/hCost-US$1400

Equipment for Cassava ProcessingEquipment for Cassava Processing

In India cassava is mainly grown in Kerela, Tamilnadu, Karnataka, Andhra Pradesh The CTCRI developed post harvest management and value addition technologies

•Tool for harvesting•Method to prolong shelf life of fresh cassava•Production of Cassava rava•Production of Cassava Porridge•Starch based biodegradable plastic•Mobile Starch extraction unit

Harvesting tool

Chipping machine

Chips dryer

Mobile starch extraction unit

Mango Processing Machinery-IIHRMango Processing Machinery-IIHR

Slices mango 4,6&8 piecesCapacity – 1 tonne/hCost - US$4000

Cubes the mango slices Capacity – 500 kg / hCost – US$ 4000

Peels raw mangoCapacity – 200 kg /hCost – US$4000

Raw mango peeler

Raw mango slicer Raw mango cube cutter

Improved Farm Level Turmeric Boiling Improved Farm Level Turmeric Boiling Unit-TNAUUnit-TNAU

• Capacity : About 200 kg per batch /40 quintals per day

• Fuel requirement : 25–30 kg per batch of 200 kg.

• Three persons are required

• No skilled labour is required

• The unit can be fabricated to any capacity

• Cost of the unit: Appox. Rs.15,000

RecommendationsRecommendations• Need to develop proper process protocols for primary

processing and also develop crop specific machines • Processing of fruits and vegetables to the stage of

dehy, puree or pulp is a primary processing industry and need to be established in production catchment.

• There should be flexibility in operations – a combination of manual and mechanical systems but following proper sanitary and hygienic standards.

• Need to develop standards for primary processed products which in turn will increase value addition and secondary agriculture activities

Grain Quality in StorageGrain Quality in Storage•Optimum storage conditions-moisture less than 12% and temperature less than 30°C will not deteriorate quality during storage over a season. Problems due to Higher temperatures: 1)Development of hot-spots, 2)Moisture migration from warmer to cooler grain causing caking, 3)Mould development in over-moist grain 4)Decrease in seed germination 5)Decrease in malting quality of barley, 6)Decrease in baking and milling quality of wheat, 7)Colour deterioration of pulses and 8)Rancidity in oilseeds

Conditions in Storage Conditions in Storage

•Grain entering a temporary storage structure should be cool and dry. •Temperatures of grain loads placed into storage should be within 5 to 10°C of each other to prevent moisture movement due to temperature gradients. •The grain should be placed in the storage at less than 14% (w.b.) and preferably 13% for greater safety. •The average moisture content of the pile should be 0.5 to 1% less than the safe storage moisture content. •Grain of poor quality should be dried 1% more than required for good quality grain.

Grain Storage in India Grain Storage in India

•FCI and state agencies stored 23.08 lakh tonnes and 144.97 lakh tonnes, respectively in 2010 and the damaged grain in CAP was 716 metric tonne in 2010 •Storage gap (deficit) to the tune of 12-14 MMT. •The efficient alternative to CAP is necessary to meet the growing demand for storage and reduction of storage losses

Grain AerationGrain Aeration•Aeration is necessary, if more than 50 MT grain is stored for longer than 2 months. •Aeration rates of at least 0.04 m3 per minute per MT should be provided. •Provide two or three smaller fans and ducts to obtain proper air distribution in flat storage structures. •Aeration ducts of 30 cm or larger dia. corrugated drain pipes are used in temporary structures. •The drainpipe is covered with cloth to prevent grain from plugging the openings. •The number of fans and aeration ducts depends on the grain type and dimensions of the grain pile.

For long duration storage a LDPE sandwitched PUSA bin has been found to be most suitable. he performance of the bin is similar to any other metal or concrete structures. In fact because of good insulation properties of mud brick, the problem of moisture migration is also negligible. About 9.5 million tonnes of food grains are stored in such bins in India. The capacity of such bins ranges from 0.5 to 4 t.

PUSA Bin PUSA Bin

The structure is circular in shape having 2 m diameter and 1 m depth. Upper part of 600 mm is kept above the ground level to make it rat proof and prevent entry of surface water. The entire structure is made of RCC except the floor. The floor construction consists of two layers of cement concrete. A thick layer of bitumen is also provided in between these layers. It is suitably air tight and as a result one fumigation serves the purpose for 33 months storage of wheat.

Underground Air Tight RCC StructuresUnderground Air Tight RCC Structures

These are primarily meant for providing warehousing facilities to the farmers. The godowns, 100 t to 5000 t capacity, are owned by Govt. agencies. Twin span warehouse with structural trusses design was adopted in early sixties and constructed with brick or stone masonary. Asbestos or corrugated GI sheets supported by steel trusses are used for roofing. Due to provision of valley gutters, there is perennial problem of leakage resulting in damage of stored grain.

Godowns (Bag Storage Structures) Godowns (Bag Storage Structures)

Metal silos are cheaper than concrete silos by 15-20% depending on their size. Generally Silo system is equipped with other preparatory units like cleaning and drying equipment. Initially silos are 50% more expensive but this additional cost is recovered within 2-4 years. The loss of grain in such system is only 0.2% compared to 1% in godown and warehousing systems. The loss caused by rodents, insects, fungi and handling is about 0.2% compared to 8% in godown system.

SilosSilos

Storage Structures used WorldwideStorage Structures used Worldwide

•The CAP storage•Grain Storage Rings•Flexible silos•Prefabricated relocatable warehouses•Cocoons•Large Plastic Membrane Bags

•In CAP 50 kg capacity jute bags are used •The most commonly constructed size is for 1500 tonnes with 3000 bags of 50 kg •CAP storage are with the length and breadth of 8.55 and 6.30 m, respectively. •The sides and ridge heights are 4.50 and 6.00 m, respectively. •Regular opening of covers is necessary to allow some aeration. •The advantage of CAP is its low establishment cost, which is only 25% the cost of godown storage

Cover and Plinth StorageCover and Plinth Storage

• Thermal model has been developed based on solar energy for predicting the wheat grain temperature while stored in CAP.

• The model showed around 10 to 12°C rise in grain temperature from the mean monthly ambient temperature during the year with black cover.

• A white colour plastic cover simulated result showed reduction in the grain temperature by 6-8oC compared to black sheet.

Effect of Color of Cover on QualityEffect of Color of Cover on Quality

Grain Storage RingsGrain Storage Rings•Corrugated galvanised panels are rolled and crimped on a line•This deep corrugation are made in 22 SWG.•The industrial gasket is also provided on the top edge of the ring for the entire diameter protecting the tarp from the sharp edges of the steel panels.

Flexible silosFlexible silos•Early types employed butyl rubber sheeting as the membrane and had capacities of up to 1,000 tonnes.• Currently available silos use PVC-coated polyester fabric & have 500 tonne capacity. •The silos require little site preparation, are easy to erect and are relocatable. •The silos require no mechanical equipment

Prefabricated Relocatable Prefabricated Relocatable WarehousesWarehouses

•It has tubular steel frame covered by PVC-coated polyester fabric tensioned over the frame.•The capacity of structures varies from 50 to 3000 tonnes. •Stores require minimal foundations, and the integral base frame can be effectively anchored to the ground

CocoonsCocoons•These are tough but flexible UV-resistant PVC enclosures sealed with zip fasteners. •Light in weight when empty and can be delivered easily to site. •Capacity ranges from 5–50 tonnes.•They prevent insect, water and water vapour penetration into the contents. •The cocoons are modular, fabricated in 5, 10, 20 and 50 tonnes capacity.

Large Plastic Membrane BagsLarge Plastic Membrane Bags

•The system is very cost competitive in comparison to other storage options. •This system of storage offers a low investment storage system that can be quite effective on farm in several scenarios.• The polymer bag is described as a hermetic type of storage system.

Major RecommendationsMajor Recommendations•The color of the polyethylene used in traditional CAP storage should be changed to white.•The prefabricated relocatable warehouses may be installed on the railway platforms where the grain need to kept for transit•In grain mandies the harvest bags and rings may be explored to avoid the damage to the grain due to sudden rain during harvest season.•Investigations may be undertaken to test the suitability of structures for Indian conditions

Related Documents