Visual Dictionary Spring ‘09 Cope & Casting Part II

Casting (Part II)

Sep 12, 2014

Visual Dictionary Part II

Welcome message from author

This document is posted to help you gain knowledge. Please leave a comment to let me know what you think about it! Share it to your friends and learn new things together.

Transcript

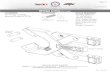

Visual Dictionary Spring ‘09

Cope & Casting

Part II

Insulation

The purpose of insulation is to keep warm air out and cool air in during warm weather, and cool air out and warm air in during cold weather. It plays an role in keeping your home energy-efficient .

Insulation (loose fill)

Insulation (foam)

Insulation (batt/blanket)

Insulation (rigid board)

Lintel

A beam that carries the load of a wall across a door or window opening

Mortar (joint 1)

Tooled joint, 3/8”, Church, Type N

Mortar (joint 2)

Neither tooled or troweled, 3/8”, Office Building, Type N

Oriented Strand Board

Non-veneer panel composed of very small wood particles that are randomly oriented in layers.

It is manufactured in wide mats from cross-oriented layers of thin, rectangular wooden strips compressed and bonded together with wax and resin adhesives (95% wood, 5% wax and resin). The layers are created by shredding the wood into strips, which are sifted and then oriented on a belt or wire cauls. The mat is made in a forming line, the layers are built up with the external layers aligned in the panel's strength axis with internal layers cross-oriented. The number of layers placed is determined partly by the thickness of the panel but is limited by the equipment installed at the manufacturing site. However individual layers can also vary in thickness to give different finished panel thicknesses. The mat is placed in a thermal press to compress the flakes and bond them by heat activation and curing of the resin that has been coated on the flakes. Individual panels are then cut from the mats into finished

sizes.

Oriented Strand Board

Plumbing (lavatory)

A plumbing fixture and disposal system primarily intended for the disposal of the bodily wastes: urine and fecal matter. Additionally, vomit and menstrual waste is sometimes disposed in toilets in western societies.

Generally 1-1/2” piping

Plumbing (water closet)

3” drain

Plumbing ( shower and tub)

Plumbing (vent)

Vents provide for relief of sewer gases, admission of oxygen for aerobic sewage digestion, and maintenance of the trap water seals which prevent sewer gases from entering the

building

Plumbing (kitchen sink)

Drop in stainless steel sink

Plywood

A type of engineered board made from thin sheets of wood, called plies or wood veneers. The layers are glued together, each with its grain at right angles to adjacent layers for greater strength. There are usually an odd number of plies, as the symmetry makes the board less prone to warping, and the grain on the outside surfaces runs in the same direction. The plies are bonded under heat and pressure with strong adhesives, usually phenol formaldehyde resin, making plywood a type of composite material.

Veneer- To overlay (a surface) with a thin layer of a fine or decorative material.

Plywood

Radiant Barrier

A reflective barrier that inhibits heat transfer by thermal radiation. Thermal energy may also be transferred via conduction or convection, however, radiant barriers do not necessarily protect against heat transfer via conduction or convection.

Rebar

The cross hatchings, called "deformations," help transfer the load between concrete and steel.

#6 or ¾’

Steep Roof Drainage (gutter)

A narrow channel, or trough, forming the component of a roof system which collects and diverts rainwater shed by the roof. The main purpose of a rain gutter is to protect a building's foundation by channeling water away from its base.

Steep Roof Drainage (downspout)

A vertical pipe for conducting water from a roof to a lower level

Steep Roof Drainage (splash block)

A small precast block of concrete or plastic used to divert water at the bottom of a downspout

Steep Roof Materials (tar paper/underlayment)

A glass fiber or polyester fleece impregnated with bituminous material, used for waterproofing roofs to prevent ingress of moisture.

Steep Roof Material (clay tile)

Steep Roof Material (shingle)

A small unit of water-resistant material nailed in overlapping fashion with many other such units to render a wall or sloping roof watertight

This example is slate or a rubber slate imitation

Steep Roof Material (metal roof)

A roofing system made from metal pieces or tiles. Preformed metal roof are panels that are manufactured to fit together. (aluminum)

Steep Roof Shapes (gable)

Steep Roof Shapes (gambrel)

Steep Roof Shapes (hip)

Steep Roof Shapes (Mansard)

Steep Roof Terms (ridge)

The level intersection of two roof planes in a gable roof

Steep Roof Terms (valley)

A trough formed by the intersection of two roof slopes

Steep Roof Terms (eave)

The horizontal edge at the low side of a sloping roof. Eaves usually project beyond the side of the building generally to provide weather protection.

Steep Roof Terms (rake)

The sloping edge of a steep roof

Steep Roof Terms (soffit)

The undersurface of a horizontal element of a building, especially the underside of a stair or roof overhang

Steep Roof Terms (fascia)

The exposed vertical face of an eaveWithout a fascia With a fascia

Stone (random rubble)

Stone (coursed rubble)

Stone (random ashlar)

Stone (coursed ashlar)

Vapor Retarder

A layer of material intended to obstruct the passage of water vapor through a building assembly

The International Residential Code (IRC Section R322) specifies that a vapor retarder must be installed on the warm-

in-winter side of the insulation

Waterproofing

•An impervious membrane applied to the outside of a foundation,

•Purpose to keep ground water from entering the building

Weep hole

A small opening whose purpose is to permit drainage of water that accumulates inside a building component or assembly

Welded Wire Fabric

4” x 4”

Windows (awning)

Opens outward

Windows (hopper)

Opens inward

Windows (sliding)

it slides

Related Documents