Pioneering Innovation in Optical Fiber Sensing Pioneering Optical Fibre Sensing Case Study: Subsea pump Pump Condition Monitoring 2007-2010

Welcome message from author

This document is posted to help you gain knowledge. Please leave a comment to let me know what you think about it! Share it to your friends and learn new things together.

Transcript

Pioneering Innovation in Optical Fiber Sensing Pioneering Optical Fibre Sensing

Case Study: Subsea pump Pump Condition

Monitoring 2007-2010

© Smart Fibres Ltd

1

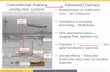

Partners: Smart Fibres, Flowserve, SKF, Teledyne ODI Project Sponsor: Shell Upstream Americas – Deepwater Platform: Subsea twin-screw pump and motor Objective: Develop fibre optic condition monitoring Why fibre: Harsh environment, no subsea electronics

© Smart Fibres Ltd

2

18 motor temperature sensors

© Smart Fibres Ltd

3

Pump lube oil pressure & temperature

© Smart Fibres Ltd

4

Bearing housing tri-axis acceleration

© Smart Fibres Ltd

5

Bearing condition monitoring (with SKF)

© Smart Fibres Ltd

6

Bearing loads match FE model within 5%

© Smart Fibres Ltd

7

10 kHz raw data. Odd signal on one roller

Enveloping shows defect. Time period = cage speed

© Smart Fibres Ltd

8

Enveloping of FFT

Healthy bearing

Damage bearing

© Smart Fibres Ltd

9

Data analysis predicted: 3.0 mm scratch length, minimal scratch depth

© Smart Fibres Ltd

10

Inspection found… 3mm scratch length, and 2 micron scratch depth

© Smart Fibres Ltd

11

Image c/o Shell

on a bearing inside here

visible on an instrument here

A 2 micron scratch here

+44 1344 484111 [email protected] smartfibres.com Smart Fibres Ltd, Spectrum House, Brants Bridge, Bracknell, RG12 9BG, United Kingdom

Pioneering Optical Fibre Sensing

Thank You

Related Documents