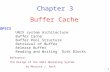

5 C40 100 TO 2000 LITRES Range from 100 Lt up to 2.000 Lt inertia tanks for primary circuits, manufactured in F18 Stainless Steel. Only to be used in heating circuits Exterior finish in white polyester reinforced with fiberglass, which allows easy cleaning and ensures its durability. Coballes accumulators and tanks are manufactured according ecodesign Directive ErP, (Energy related Products), using a quality injected polyurethane foam CFC free. Buffer Tank for heatin/HVAC systems BUFFER TANK FOR HEATING CIRCUIT/ HVAC C40 Solar Firewood, pellets Gasoil/Gas

Welcome message from author

This document is posted to help you gain knowledge. Please leave a comment to let me know what you think about it! Share it to your friends and learn new things together.

Transcript

5 C40 100 TO 2000 LITRES

Range from 100 Lt up to 2.000 Lt inertia tanks for primary circuits, manufactured

in F18 Stainless Steel.

Only to be used in heating circuits

Exterior finish in white polyester reinforced with fiberglass, which allows easy

cleaning and ensures its durability.

Coballes accumulators and tanks are manufactured according ecodesign Directive

ErP, (Energy related Products), using a quality injected polyurethane foam CFC

free.

Buffer Tank for heatin/HVAC systems

BUFFER TANK FOR HEATING CIRCUIT/ HVAC C40

Solar Firewood, pellets Gasoil/Gas

6

MODEL REF. LT INSTALL WALL

MOUNT

S.STEEL

LEG

FLOOR

STAND

ELECTRICAL

KIT

C40

1050060 100 Vertical yes - yes

1050061 150 Vertical yes - yes

1050062 200 Vertical yes - yes

1050063 300 Vertical - - yes

1050064 500 Vertical - - yes

1050065 750 Vertical - yes -

1050066 1000 Vertical - yes -

1050067 1500 Vertical - yes -

1050068 2000 Vertical - yes -

BUFFER TANK FOR HEATING CIRCUIT/ HVAC C40

To be used ONLY in heating circuits.

Maximum working pressure 4 bar.

Up to 200Lt the same model is valid wall mount and floor stand.

Coballes resistance Ref: 800237/800238

OPTIONAL ACCESORIES

7

Buffer tank for heating circuits C40

Suitable to storage hot water produced with multiple enrgy sources (heat pumps, Pellet, gas boilers...)

through an external heat exchanger.

Operating pressure 4 bar both primary and secondary circuit T: 90ºC both primary and

secundary circuit.

Manufacturing and materials 100% European

Manufactured according to Directive 2014/68/UE and Standard EN13445

Manufactured according to Directives ErP 2009/125 CE and ELD 2010/30/UE

BUFFER TANK FOR HEATING CIRCUIT/ HVAC C40

PICKLING

P i c k l i n g a n d

p a s s i v a t i o n b y

immersion which

allows a perfect

treatment of the

welds on the tank in

the face both internal

and external.

F18 STAINLESS STEEL

Manufactured in F18

Stainless Steel.

TIG WELDING

The highest accuracy in

welding, to avoid the

presence of pores.

KEY FEATURES

MAINTENANCE FREE

The high quality of

material we use does not

require any maintenance.

It does not need any type

of cathode protection.

ISOLATION

Thermal insulation in

polyurethane foam injected

C F C - f r e e , e n s u r i n g

compliance with the new

ERP Directive.

8

MODEL REFERENCE Energy class LT Dimensions (mm)

A ØB C D E

C40

1050060 C 100 430 740 1160 I

1050061 C 150 530 740 1245 I

1050062 C 200 600 740 1300 I

1050063 C 300 600 1830 II

1050064 C 500 750 1880 II

1050065 750 1740 980 110 1850 III

1050066 1000 2190 980 110 2300 III

1050067 1500 2490 1110 110 2600 III

1050068 2000 2290 1360 110 2400 III

Energetic class A avaliable. Request info

I

Dimensions

II III

9

MOD REF LT Connections

1 2 3 4 5 6 7 8 9 10 11 12

C40

1050060 100 1/2" 1 1/4" 1 1/4" 1 1/4" 1 1/4" 1/2"

1050061 150 1/2" 1 1/4" 1 1/4" 1 1/4" 1 1/4" 1/2"

1050062 200 1/2" 1 1/4" 1 1/4" 1 1/4" 1 1/4" 1/2"

1050063 300 1/2" 1 1/4" 1 1/4" 1" 1" 1 1/4" 1 1/4" 1/2" 2"

1050064 500 1/2" 1 1/2" 1 1/2" 1" 1" 1 1/2" 1 1/2" 1 1/2" 1 1/2" 1/2" 2" 3/4"

1050065 750 1/2" 1 1/2" 1 1/2" 1" 1" 1 1/2" 1 1/2" 1 1/2" 1 1/2" 1/2" 2" 1"

1050066 1000 1/2" 1 1/2" 1 1/2" 1" 1" 1 1/2" 1 1/2" 1 1/2" 1 1/2" 1/2" 2" 1"

1050067 1500 1/2" 2" 2" 1" 1" 2" 2" 2" 2" 1/2" 2" 1"

1050068 2000 1/2" 2" 2" 1" 1" 2" 2" 2" 2" 1/2" 2" 1"

Connections

1.-Purger

2.-Outlet (energy source) I

3.-Ida (energy source) I

4. Inlet solar panel (external heat exchanger) II

5.-Outlet solar panel(external heat exchanger) II

6.-Inlet (heating circuit) I

7.-Outlet (heating circuit) I

8.-Inlet (heating circuit) II

9.-Outlet (heating circuit) II

10.-Temp connection

11.-Resistance connection

12.-Drain

10

WARM-UP TIME

Tank1

Supplied energy (KW)

C40-100L C40-150L C40-200L C40-300L C40-500L C40-750L C40-1000L C40-1500L C40-2000L

5 min 70 105

10 min 35 52 70 105

15 min 23 35 46 70 116

25 min 21 28 42 70 105

35 min 20 30 50 75 100

50 min 21 35 52 70 105

75 min 23 35 46 70 93

100 min 26 35 52 70

150 min 23 35 46

200 min 26 35

1-Initial temperature 10ºC ; Final Temperatura 60ºC

Thermal characteristics

1kW=860kcal/hour

Tank Total

volume

Heating coil

surface

Maximum

pressure

(tank)

Maximum

operating

temperature

Net weight Energy

class

L m2 bar ºC Kg

C40-100L 100 − 4 90 23 C

C40-150L 150 − 4 90 34 C

C40-200L 200 − 4 90 43 C

C40-300L 300 − 4 90 57 C

C40-500L 500 − 4 90 90 C

C40-750L 750 − 4 90 120

C40-1000L 1000 − 4 90 147

C40-1500L 1500 − 4 90 187

C40-2000L 2000 4 90 413

11

MODEL D20 para INSTALL horizontal con panel solar

Installation examples

Model C40 may be installed with different energy sources

Gasoil/Gas Solar Electricity Heat Pump Firewood, pellets Others

To be used ONLY in heating circuits

Related Documents