Click here to load reader

Welcome message from author

This document is posted to help you gain knowledge. Please leave a comment to let me know what you think about it! Share it to your friends and learn new things together.

Transcript

R

Bp

GD

C

a

ARAA

KNMMSSF

0d

Coordination Chemistry Reviews 256 (2012) 28– 45

Contents lists available at SciVerse ScienceDirect

Coordination Chemistry Reviews

journa l h o me page: www.elsev ier .com/ locate /ccr

eview

eyond the synthesis of novel solid phases: Review on modelling of sorptionhenomena

iancarla Alberti, Valeria Amendola, Maria Pesavento, Raffaela Biesuz ∗

ipartimento di Chimica, Università di Pavia, via Taramelli 12, 27100 Pavia, Italy

ontents

1. Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 282. Survey on novel sorbent solid-phases . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

2.1. From traditional hydrophobic PS-DVB to mixed-mode ion-exchange resins . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 292.2. Carbon-based sorbents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 292.3. New silica-based materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 302.4. Imprinted polymers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

2.4.1. Molecular imprinted polymers (MIPs) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 312.4.2. Ion-imprinted polymers (IIPs) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

3. Modelling the sorption phenomena . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 313.1. Sorption isotherms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

3.1.1. Classification and modelling of sorption isotherms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 323.1.2. Advantages and disadvantages of the different models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

3.2. Kinetic sorption modelling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 383.2.1. Sorption kinetic model based on reaction mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 383.2.2. Sorption kinetic model based on reaction order . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

3.3. Dynamic process: Modelling the breakthrough curve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 413.3.1. Breakthrough curves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 413.3.2. Breakthrough capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 413.3.3. Bohart–Adams model . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 423.3.4. BDST (bed depth service time) model . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 423.3.5. Yoon and Nelson model . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 423.3.6. Dose–Response model . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

3.4. Statistical analysis: Goodness of fitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 434. Conclusion. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

References . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

r t i c l e i n f o

rticle history:eceived 13 April 2011ccepted 29 August 2011vailable online 22 September 2011

a b s t r a c t

A large number of new solid phases have been proposed in the literature during the past decade with alarge variety of purposes: separation and preconcentration for the solid phase extraction, specific chro-matographic applications, assemblies of devices for recognition of a family of substances, sensors for asingle species identification.

In spite of this variety of materials, their properties are mostly depicted by physical descriptors and

eywords:ovel solid sorbentsodelling of sorption equilibriaacroscopic and mechanistic models,orption isothermsorption kineticsixed bed columns

operational exchange properties, instead of quantities independent of the experimental conditions. Inthe present review the methods proposed for the description of the sorption phenomena, from the ther-modynamic, kinetic and dynamic point of view, will be critically reviewed, focusing on general methodsto describe the sorption that could be used in alternative to descriptive and operational approaches.

© 2011 Elsevier B.V. All rights reserved.

∗ Corresponding author. Tel.: +39 382 987348; fax: +39 382 528544.E-mail address: [email protected] (R. Biesuz).

010-8545/$ – see front matter © 2011 Elsevier B.V. All rights reserved.oi:10.1016/j.ccr.2011.08.022

1. Introduction

In the last decades solid-phase extraction has played a crucialrole in sample preparation and in chemical analysis, replacing the

hemis

ci

csbse[

oivdakac

oottu

2

fialstttboataEtih

2i

dadOioibptDl

au

G. Alberti et al. / Coordination C

lassic liquid–liquid extraction, in environmental, food and biolog-cal analyses [1–3].

Many papers dealing with novel sorbent solid phases specifi-ally developed for these applications have been published; also thecope of sorption phenomena under investigation has significantlyeen extended. Methods for the detailed analysis of sorbents’ andolutes’ state have gained ground, so a few methods for the math-matical simulation of sorption processes have become available4].

Focusing on literature appearing from 2000 to the present, anverview of the large variety of materials is presented and sortedn the next chapter. The second part of this review provides a sur-ey on the empirical and mechanistic models most often used toescribe sorption phenomena, to deepen the chemical–physicalspects of the sorption process, both from the thermodynamic andinetic point of view. Comments on the common statistical toolspplied for the analysis of sorption data are reported in the finalhapter.

In the present review, the term ‘sorption’ indicates the transferf analytes (ions or molecules) onto the surface or into the bulkf a solid phase from liquids and it will be commonly preferredo ‘adsorption’ for a more broad meaning, while the term ‘absorp-ion’ will be avoid since it refers to phenomena which are largelynrelated (e.g.: sponge absorbs water when it is dry).

. Survey on novel sorbent solid-phases

The survey is limited to synthetic sorbents developed from arti-cial solid matrices and the overview is far from comprehensive ofll the materials proposed in the literature in last decade. We fol-owed a general line along which the research on novel syntheticolid-phases has been mainly developed: in order to increase selec-ivity and other performances of the extraction process, or to offerailored materials. Usually this is done by introducing suitable func-ional groups into traditional synthetic matrices, the main matriceseing DVB, methacrylate, carbon-based sorbent and silica; on thether hand, modifying pre-existing resins through their function-lization or copolymerization of functional monomers. Followinghis line, molecularly imprinted polymers MIPs have been includedmong the materials examined for their overwhelming importance.ven though a huge number of sorbents have been obtained fromhe chemical modification of both inorganic (i.e. clays) and biolog-cal (i.e. biomasses) materials, these materials are not examinedere.

.1. From traditional hydrophobic PS-DVB to mixed-modeon-exchange resins

A traditional polymeric sorbent is poly(styrene-ivinylbenzene); PS-DVB displays a hydrophobic structurend its interactions with analytes are mainly due to �–� and vaner Waals forces, involving the aromatic rings of the polymer [1].ne way to improve the retention of solutes by PS-DVB consists in

ncreasing the specific surface area, by incrementing the numberf sites available to �–� interactions with the analyte. This goals achieved with highly crosslinked polymeric materials, obtainedy using high levels of crosslinker (DVB) in the polymerizationrocess [5]. The specific surface area can be also enhanced withhe family of the hypercrosslinked resins, originally obtained byavankov and Tsyurupa [6], through extensive post-crosslinking of

inear polystyrene chains by means of the Friedel-Crafts reaction.Nevertheless, in spite of their extremely high specific surface

rea, their strong hydrophobicity makes most of these materialsnsuitable for the extraction of polar compounds. One solution to

try Reviews 256 (2012) 28– 45 29

this problem is to introduce polar functional groups in the poly-meric structure, obtaining more hydrophilic materials.

Hydrophilic resins may be prepared either by copolymeris-ing monomers containing polar groups or by introducing polargroups in existing hydrophobic polymers [5,7]. To date, manycommercial hydrophilic copolymers are available, made froma balanced ratio of hydrophilic monomer (methacrylate, MA;amide, AM; vinylpyrrolidone, VP) and crosslinked agent (generallyDVB). Metacrylate-divinylbenzene (MA-DVB) resins are appliedto the clean up of complex matrices, such as body fluids [8–11]and animal tissues [12,13]. Macroporous poly(N-vinylpyrrolidone-divinylbenzene (PVP-DVB) copolymer is used to extract and cleanup several analytes from biological matrices [14,15] and to extractpollutants from aqueous samples [16–18]. Also resins based onacrylonitrile (AN) and methacrylonitrile (MAN) have been devel-oped [19–21]. In the last decade, Marcé and coworkers synthesisedhydrophilic resins, from the copolymerization of pyridine, imi-dazole or pyrrole containing monomers with DVB [22,23]. Thepresence of nitrogen atoms in the sorbent’s structure improvespolarity and the retention of polar compounds. Bagheri et al. syn-thesised hydrophilic conducting polymers, by polymerization ofnitrogen containing organic molecules (polyaniline, PANI; poly-N-methylaniline, PNMA; polypyrrole, PDPA, etc.) [24–27], withoutcrosslinking agents [28,29]. With respect to DVB based polar sor-bents, these materials suffer from a small specific surface area, dueto their linearity, and their retention capacity is often lower. Theseresults indicate that both polarity and surface area contribute tothe retention of polar molecules.

Another approach to synthesise hydrophilic sorbents consists inthe chemical modification of pre-existing hydrophobic polymers,through the introduction of polar functional groups. Fritz et al.developed the first modified resins, with the introduction of acetyl,hydroxylmethyl or sulfonic groups [7,30]. Other researchers modi-fied hypercrosslinked resins with benzoyl and polycarboxybenzoylgroups [31,32]. To the class of chemically modified polymers belongthe so-called mixed-mode ion-exchange sorbents, which com-bine a polymeric skeleton with ion-exchange groups. Mixed-modepolymers are classified as cationic or anionic, and as strong orweak ion-exchange, depending on the ionic group appended tothe resin [33]. These materials are usually prepared by chemi-cally modifying pre-existing polymers, e.g. PS-DVB, with sulfonicand carboxylic groups (to obtain strong and weak cation exchangeresins, respectively) or with quaternary amines and diamines(for strong and weak anion exchange, respectively). Mixed-modepolymeric sorbents overcome the problems displayed by tradi-tional ion-exchange resins, in terms of low stability at extremepH and lack of retention for polar species. As a matter of fact,these new materials are chemically more stable than conventionalsilica-based resins; moreover, they mix two types of interactionmechanism, reversed-phase and ionic-exchange. In consequence,according to the experimental conditions, they can be tuned toselectively extract charged or neutral species. The matrix compo-nents, the interferences and the analytes can be separately elutedby changing the solvent and/or by using a suitable pH combination,in the different steps of the extraction process. Generally, thesesorbents are used to separate and/or extract neutral or chargedanalytes from complex matrices such as wastewaters, biological orfood samples [5,33,34]. The sorption properties of these materialshas been modelled according to the methods described below.

2.2. Carbon-based sorbents

Carbon sorbents have been known since the ancienttimes. Recently carbon materials have attracted growinginterest due to their excellent adsorption properties [35].Adsorption capacities strictly depend on their micro-porous

3 hemis

ssctpbGcmfOpDtomtaho(mdp

teicbrrc(TtppatdtauacbtptoLratbstpas

2

h

0 G. Alberti et al. / Coordination C

tructure and on the presence of functional groups on theurface, which can be seen as ion exchanging groups or metalhelating agents. Synthetic carbon sorbents are prepared from syn-hetic materials (e.g. polymers); compared to active carbons, pre-ared from natural materials, synthetic carbons are characterisedy lower ash content and higher mechanical resistance. Recently,ierak et al. prepared new sorbents by carbonization of polyvinylhloride (PVC) resin at 873 K in a nitrogen stream [36–38]. Theaterial obtained was applied to the preparation of the SPME fibres,

or the analysis of volatile organic compounds in aqueous solution.ther carbon sorbents have been prepared by carbonisation oforous copolymers (e.g. 4,4-dimethyl sulfone dimethacrylate, DPSM). After carbonisation, the materials obtained can be subjected

o additional modification (heating under hydrogen atmospherer oxidation by concentrated nitric acid). Synthetic carbon poly-ers have been used in adsorption processes from gaseous (low

emperature nitrogen adsorption) and liquid matrices (phenolnd naphthalene adsorption); moreover, activated carbon fibresave been investigated for SPME applications [39–41], insteadf the conventional coated fused-silica fibres for several analytespesticides, chlorohydrocarbons, etc.) [42,43]. Carbon fibres are

ore effective than the conventional granular activated carbon,ue to the special surface structure and excellent adsorptionroperties.

Carbonaceous sorbents, including activated charcoal, graphi-ized carbon black and carbon molecular sieves have proven to beffective adsorbents for the removal of a wide variety of organic andnorganic pollutants dissolved in aqueous media [44,45]. Amongarbon-based sorbents, special attention must be devoted to car-on nanotubes (CNTs). Advances in this field have been recentlyeviewed by Valcarcél et al. [46,47]. CNTs are cylindrical nanomate-ials, composed entirely of sp2 bonds similar to graphite. The hollowylinders may consist of one or multiple layers of graphene sheetssingle-walled, SWNTs, and multi-walled nanotubes, respectively).he ability of CNTs to establish �–� electrostatic interactions, andheir large surface areas, can facilitate the sorption of analytes. Inarticular, the distortion of planar graphene into a cylinder com-licates the orbital overlapping, resulting in carbon atoms woundround in a helical fashion. As a result, nanotubes experience fluc-uating and induced dipole moments, which result in excellent vane Waals adhesion to other molecules, especially to those con-aining aromatic rings. Multi-walled nanotubes (MWNTs) possess

higher sorption capacity than SWNTs. Thus, MWNTs have beensed as sorbents in packed minicolumns for metal ions, organomet-ls, and a wide variety of aromatic compounds (phenols, dioxins,hlorobenzenes, etc.) [48,49]. In addition to external surfaces, car-on nanotubes can encapsulate protein molecules in their internalube cavities. Valcarcél et al. have also explored the analyticalotential of C60 fullerene [50], a carbon nanotube-related struc-ure, as a solid-phase sorbent for chelates or ion pairs of metal ions,rganic or organometallic compounds from aqueous solutions.eading on from this, the potential of MWNT to preconcentrateare earth [51] and trace amounts of metal ions, such as Cd, Mnnd Ni [52] has been pointed out in the literature. NT appear ableo sorb substances both via weak, but multiple, interactions and/ory forming coordinative bonds particularly with metal ions. Theorption on this kind of materials has been modelled accordingo the methods described below, sometimes considering a sim-le distribution of the sorbate between two immiscible phasesnd sometimes also a combination with active groups at carbonurface.

.3. New silica-based materials

Silica gel functionalized with various organic groups (e.g.ydrophobic alkyl chains, C8 and C18, [53,54] and metal chelating

try Reviews 256 (2012) 28– 45

agents) has received great attention. Modified silica gel can be pre-pared from the chemical reaction of the envisaged organosilanewith silanol groups of silica. Because of the large number of reac-tive sites in silica gel, the modified materials so obtained exhibithigher sorption capacities, with respect to organic polymers. Thereare several recent reports on the use of functionalized silica gel formetal enrichment and extraction from aqueous samples [55,56].

An alternative matrix is silica obtained by sol–gel process-ing [57]. Particularly noteworthy are the silica-based mesoporousmaterials, displaying a periodic and regular arrangement ofwell-defined mesopores and amorphous inorganic frameworkstructures. They are usually highly porous, exhibit high specific sur-face areas and share characteristics of both silica gels and molecularsieve zeolites. In particular, the mesoporous silica molecular sieveshave been examined with considerable attention due to their highsurface area, large pore volume, and good performance as effectivesorbents [58].

Ordered mesoporous silicas are usually prepared by the sol-gel process, involving the hydrolysis and condensation of atetraalkoxysilane (Si(OR)4), in the presence of a supramoleculartemplate (surfactant or water-soluble polymer). The template isthen removed by calcination or solvent extraction to give theresulting mesoporous open structure. The materials obtained havea controlled porosity, which can provide controlled capacities.Complexing agents can be immobilized in these solids both byencapsulation in the pore structure and by covalent bonding[59,60].

Organically-modified mesoporous silica materials have beenproposed as novel organic-inorganic hybrid sorbents for seques-tering pollutants from water samples. Due to the exceptionallylarge specific surface area and regular porous framework, thesesorbents ensure easy and fast access to a high number of organo-functional groups per mass unit of the material. Moreover, the richsurface chemistry of silica enable the design of materials bear-ing a wide range of tailormade functionalities. Pioneering studiesdealt with accumulation of heavy metals; nowadays the inter-est is extended to the extraction of other contaminants like toxicanions, radionuclides, dyes, aromatic hydrocarbons and relatedcompounds, pesticides and pharmaceuticals. However, the fieldof functionalized mesoporous silica materials is still underdevel-oped in real-world applications. As a matter of fact, mesoporousmaterials present several drawbacks: (a) the short term stabil-ity; (b) the low particle size, not suitable for efficient columnpacking (too high resistance to liquid percolation due to mm-sized particles). Also the recovery (i.e., by filtration) after batchadsorption experiments is not easy; (c) the restricted commercialavailability of organosilane reagents limits the design of selec-tive materials [61,62]. The sorbing properties of such materialshave been modelled by one or more of the approaches describedbelow.

2.4. Imprinted polymers

Many of the previously described sorbents retain analytes bynon-selective hydrophobic or polar interactions, leading to a par-tial co-extraction of interfering substances. To improve selectivity,the so-called “Restricted Access Materials” (RAMs) have beendeveloped [63–65]. Because of their biporous structure, RAMsinteract with the analyte by ion-exchange or RP (reversed phase)interactions, and exclude high molecular weight compounds bysize-exclusion. RAMs are used mainly for the recovery of lowmolecular mass molecules from complex matrices (e.g. for the

determination of drugs or other biologically-active substances inbody fluids) [66–72]. However, RAMs do not always act selectivelyand, when they do, their selectivity is low. More recently, antibod-ies immobilised on solid supports have been applied to selectivehemis

sbddnndm

2

cmmafasdiraat

stbavodccfbticctt

daimTasactpaobf[pctmsro

G. Alberti et al. / Coordination C

olid-phase extractions. The materials obtained, called immunosor-ents (ISs) [73,74], have been used in the analyses of pesticides [75],rugs and polyaromatic hydrocarbons [76], displaying an excellentegree of cleanup attributable to antibodies’ selectivity. Unfortu-ately, ISs are expensive and time-consuming to prepare; they areot very stable and their use is restricted to aqueous solution. Theserawbacks have been solved by the technology of imprinted poly-ers.

.4.1. Molecular imprinted polymers (MIPs)MIPs are synthetic polymeric materials, possessing tailor-made

avities, obtained by free radical copolymerization of functionalonomers and cross-linkers, in the presence of a templateolecule and a porogenic solvent. Most of the MIP described are

crylate-based materials prepared by bulk polymerization. Theunctional monomer, containing a polymerisable group (i.e. vinyl orllyl), is first mixed with the template molecule, in order to form atable complex. Then, the crosslinker (for example ethylene glycolimethacrylate, EDMA) is added to the mixture and polymerization

s started by means of a radical initiator (f.e. AIBN, azobisisobuty-onitrile). After polymerization, the template is removed, makingvailable cavities, complementary to the template molecule in sizend shape [32,77–86], which are ready for the specific recombina-ion with the template.

Molecular imprinting introduces molecular memory into theolid matrix, which becomes capable of selectively recognize aarget molecule with affinities comparable to those of immunosor-ents. With respect to immunosorbents, MIPs present severaldvantages in terms of mechanical robustness, of resistance to ele-ated temperatures and pressures, of inertness to extreme pHs,f easier and cheaper preparations. Many approaches have beeneveloped for the synthesis of MIPs, based on covalent, non-ovalent and semicovalent imprinting. Wulff’s group pioneered theovalent imprinting approach [87], in which functional monomersorm complexes with template molecules via reversible covalentonds (e.g. boronate ester, ketal and acetal, or Schiff base) prioro polymerization. The subsequent rebinding of the analytes tomprinted polymers takes place through the formation of non-ovalent bonds. The principal drawbacks of this approach are theomplexity in the preparation of the reagents for the polymeriza-ion and the potentially difficult removal of the chemically bondedemplate from the highly cross-linked polymer matrix.

These drawbacks are solved by the non-covalent approach,eveloped by Mosbach and co-workers, which uses weak inter-ctions (such as hydrogen bonds, ionic interactions, hydrophobicnteractions, and metal-ion chelating interactions) for both the

olecular imprinting process and the subsequent rebinding [88].his approach is flexible in terms of preparation because of thebsence of complicated synthetic chemistry, as well as the broadelection of functional monomers and possible target moleculesvailable. In addition, imprinted polymers prepared by the non-ovalent imprinting approach show much faster rebinding kineticshan those prepared by the covalent approach, making themarticularly suitable as stationary phases in HPLC system ands sensors. MIPs have been widely used in applications basedn specific molecular recognition, as substitutes of antibodies ininding immunoassays [85,86], for chemical sensors [89–104],or drug delivery [92,105,106] and in separation techniques32,78,80,95,104,107–116]. A possible drawback of some of theseolyacrylate MIPs is the presence of non-specific binding, whichauses loss of selectivity. Organically modified silicas preparedhrough sol–gel procedures can be alternative molecular imprinted

edia with reduced non-specific activity. A serious shortcoming ofol–gel molecularly imprinted (MI) silicas results from the limitedange of possible functional monomers, which restricts the classesf templates that could be successfully imprinted [117,118].

try Reviews 256 (2012) 28– 45 31

2.4.2. Ion-imprinted polymers (IIPs)Ion imprinting is a versatile technique for preparing polymeric

materials, capable of high ionic recognition [119,120]. The prin-ciple of ion imprinting is based on complex formation between atemplate metal ion and a suitable ligand in solution prior to thepolymerization process. The polymerization is performed in thepresence of cross-linking monomers and is carried out thermallyor photochemically, in the presence of a free radical initiator. Inthe course of polymerization, the ligand can be trapped in thecross-linked polymer network (non-polymerizable ligand) or it canbe directly involved in the polymerization process, if it containspolymerizable groups (polymerizable ligand). The first situation ismore versatile because of the large variety of available ligands; onthe other hand, more stable and reusable matrices are obtained,by chemically binding the ligand to the polymer network. Afterpolymerization, the template ion is removed from the polymericparticles, by leaching with mineral acid; this step leaves cavities or“imprinted sites” in the polymer, that are complementary in shapeand size to the target ion. The obtained material can be used assorbent phase for selective separation and enrichment of imprintmetal ion from dilute aqueous solutions. Metal ions bind to thefunctional groups of the polymer, through coordinative interac-tions. The choice of a complexing ligand is of great importance,as it directly influences selectivity of the resin. Selectivity is alsoinfluenced by (a) the metal ion’s properties (i.e. size, charge, oxida-tion state, coordination number and geometry), (b) the amount ofpolymerization solvent and size of its molecules and (c) the degreeof cross-linking of polymer network. In recent years, the IIPs havebeen successfully applied in solid-phase extractions, sensors andmembrane separations [121–131].

In general, the sorbing properties of imprinted polymers havebeen modelled by one or more of the approaches described below.

3. Modelling the sorption phenomena

As underlined in Section 2, many papers dealing with novel sor-bent solid phases have been published. Most of authors treat thistopic from a purely descriptive and operational point of view, dis-cussing the application of the new materials as solid phases for avariety of purposes: separation and preconcentration for SPE, spe-cific chromatographic applications, recognition and sensing. In thiscontext, the authors generally focus on the best empirical condi-tions for performance optimization and are scarcely interested inthe study of the chemical and physical aspects of the sorption itself[12,14,23,29,40,47,61,62,108,110].

In a second direction, many authors endeavor to delve intothe characterisation of the sorption process, defining proper-ties that characterize the retention of chemicals on sorbents[18,38,44,51–54,56,58,122,127,128,130].

Nevertheless any rigorous thermodynamic approaches, adoptedfor equilibrium chemistry in solution, cannot be easily translatedinto biphasic equilibria owing to undefined standard and referencestates for solid phase. The properties of the solid are largely deducedfrom changes of the liquid phase and the solid phase remains basi-cally inaccessible.

For that reason, empirical design procedures based on sorptionequilibrium data are the most common methods to predict theperformance of the sorbent [4]. The empirical models are simplemathematical relationships, characterised by a limited number ofadjustable parameters, giving a good description of the experimen-tal behaviour in a large range of operating conditions.

These models can be very useful and their employment often

unavoidable to understand and predict the mobility of sorbed sub-stances. However, while acceptable from the macroscopic point ofview, such an approach cannot exhaustively depict the complicatedmechanisms involved.3 hemis

tdatthmr

3

ctp

gwcit

(wtc

occ(

q

V(b[

ooapeRsotoemwan

waos

iaehG

2 G. Alberti et al. / Coordination C

Very few studies are devoted to deeply characterize the sorp-ion equilibria; furthermore they have been mostly proposed toescribe the retention of different substances on natural solids suchs soils, clay and sediments with the aim to predict the mobility ofhese substances in the environment [132] As commented below,hese models, based on a rigorous physical–chemical approach,ave been applied in the geological field and have not been imple-ented for synthetic polymers such as ion-exchange and chelating

esins or MIPs.

.1. Sorption isotherms

Sorption isotherms are widely used to characterize retention ofhemicals in solid phase. The importance of using isotherm equa-ions is reflected by their incorporation into chemical speciationrograms, such as MINTEQA2 [133].

When the retention of a solute on solid material is investi-ated, the remaining solute concentration C (mol L−1) is comparedith the concentration of the compound retained on solid parti-

les q (mmol g−1). The relationship q = f(C) is named the “sorptionsotherm”. The uniqueness of this relation requires several condi-ions to be met:

(i) The various reaction equilibria must have been reached, andii) all other physico-chemical parameters must be constant. Theord “isotherm” was specifically chosen because of the influence of

he temperature on sorption reactions; temperature must be keptonstant and specified.

Most of the time, the concentration of the compound retainedn the solid is calculated by difference between the initial soluteoncentration C0 and the final solute concentration C, so the con-entration in the solid at equilibrium q (mmol g−1) is given by Eq.1):

= (C0 − C)V

m+ q0 (1)

being the volume of solution (L), m the solid mass (g) and q0mmol g−1) the concentration of the compound initially retainedy the solid, which must be measured or shown to be negligible132].

In 1888, this strategy to represent solute retention on solids wasriginally proposed by Van Bemmelen [134]. The main drawbackf this approach is that the isotherm cannot provide informationbout the type of reaction involved, the effect of ionic strength,H and composition of the media. The most commonly usedmpirical adsorption models are the Langmuir, Freundlich andedlich–Peterson isotherms. Although these models cannot repre-ent the effect of pH on sorption data as they are able to fit only databtained at constant pH conditions, they are still largely employedo describe the sorption of several organic and inorganic analytesn novel synthetic solid phases. For example, in the study of Zengt al. [18] the sorption of phenol on a novel post-crosslinked poly-eric adsorbent was explained only by the Freundlich isothermithout considering any other model. The Freundlich equation was

lso used by Gierak et al. to describe the adsorption of phenol andaphthalene on synthetic active carbons [38].

The comparison between Freundlich and Langmuir isothermsas generally the most common approach to study the sorption of

nalytes on carbon nanotubes [44], on mesoporous silica [58] andn molecular and ion imprinted polymers (as reported in differenttudies by Shamsipur [127,128,135] and by Guan et al. [136,137]).

It was not unusual to find papers that interpret the sorption onon-exchange and chelating sorbent by means of these simplistic

nd empirical models, as for example the work by Sairam Sundaramt al. concerning the fluoride sorption using organic–inorganicybrid type ion-exchangers [138], or the study of the sorption ofeO32− on a synthetic anion exchange polymer by Chirkst et al.:

try Reviews 256 (2012) 28– 45

the thermodynamic description of the sorption isotherms by ananalogue of the Langmuir equation was suggested [139]. The sorp-tion of cefotaxime sodium salt on polymer coated ion-exchangeresin microparticles was investigated by Vasiliu et al. Also in thiscase the Langmuir, Freundlich, Temkin and Dubinin-Radushkevichisotherms were used to model the sorption mechanism [140].

Sometimes, empirical models have been modified to considerthe competition between different species in solution by extend-ing the classical adsorption models reported above and introducingadditional correction coefficients [141].

Very few studies were devoted to characterize the sorption equi-libria; some of them were proposed to describe the retention ofdifferent substances on natural solids such as soils, clay and sedi-ments with the aim to predict the mobility of these substances inthe environment [132], as already underlined above. These mecha-nistic models are usually based on a preliminary characterisation ofthe solid phase and in the following formulation of a set of hypoth-esized reactions among the sorbent sites and the analytes.

Mechanistic models have been markedly improved during thelast 20 years and are often used to construct sorption isotherms andto gain rigorous interpretation of them, including the influence ofionic background. These models are based on inner- or outer spherecomplexation, and can be distinguished from each other by the waythey represent the distribution of the electric potential around thecharged surfaces. The main historical are: the triple-layer model[142], the ligand exchange model [143], the one-pK model [144],the charge distribution model [145]. All of them were applied ingeological field; they are based on a rigorous physical–chemicalapproach but they are not implemented for synthetic polymers,therefore they will not be further described.

On the contrary, the knowledge of equilibrium constants ofthe sorption on synthetic materials is an important topic in thedesign of separation processes based in these polymers. In the caseof ion exchange processes, in the literature, different thermody-namic models can be found that describe the sorption definingion-exchange equilibrium constants and evaluating exchange coef-ficients at different conditions [146]. The most commonly usedare the three-parameter model, developed by Hogfeldt [147–149],the Gibbs-Donnan model (Gregor [150], Marinsky [151], Pesavento[152–162]), the surface complex formation model [163–165], andthat based on the Wilson equation for the estimation of non-idealities in the resin phase [166,167].

In this paper the principle of the models proposed are criticallyreviewed.

3.1.1. Classification and modelling of sorption isothermsDifferent models have been proposed to describe experimen-

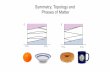

tal sorption data. An attempt of classification of sorption isothermshas been proposed by Giles et al. [168,169]. Four particular caseswere identified, corresponding to the 4 shapes commonly observed(Fig. 1); in particular they distinguished between high affinity “H”,Langmuir “L”, constant partition “C”, and sigmoidal-shaped “S”isotherm classes.

This phenomenological classification is based on pure obser-vation and does not reveal the processes that lead to differentisotherm shapes, nevertheless Giles et al. [168,169] used this clas-sification to describe data rather than equations and qualitativecriteria lacking mathematical formalism [133].

From a mathematical point of view, isotherm equations can begrouped into rational, power, and transcendental functions. Giles’classification and most of the isotherm equations are fully compat-ible with mathematical properties of rational functions. Most of the

commonly used isotherm equations are indeed rational functionsderived from the theory of adsorption processes. Furthermore, asecond class of equations involving power laws can efficientlydescribe a wide range of isotherm types. Transcendental functionsG. Alberti et al. / Coordination Chemistry Reviews 256 (2012) 28– 45 33

The "C" isotherm

0.0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.050.040.030.020.010.00

C (mol/l)

q(mmol/g)

The "L" isotherm

0.00.10.20.30.40.50.60.70.80.9

0.050.040.030.020.010.00

C (mol/l)

q(mmol/g)

The "H" isotherm

0.0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.050.040.030.020.010.00

q(mmol/g)

The "S" isotherm

0.0

0.2

0.4

0.6

0.8

1.0

1.2

0.100.080.060.040.020.00

q(mmol/g)

with strict plateau

without strict plateau

ain ty

as

aecca

3

sent

q

wa(

ncd

ak

ts

M

C (mol/l)

Fig. 1. The four m

re also used and can describe some of the sorption phenomena inoil, although, they are seldom used [133].

Sposito [170] discussed the interpretation of this classificationnd its significance for sorption of chemicals to soils and presentedxamples for each group. An extensive list of isotherms of organicompounds in soil is provided also by Weber and Miller [171]. Theylassified isotherms according to Giles et al. and showed that C, L,nd H isotherms are most common.

.1.1.1. Two parameter isotherms.3.1.1.1.1. The Freundlich isotherm. In 1906, Freundlich pre-

ented the earliest known sorption isotherm equation [172]. Thismpirical model can be applied to non ideal sorption on heteroge-eous surfaces as well as multilayer sorption and is expressed byhe following equation:

= KFC1/n (2)

here KF is the empirical constant indicative of sorption capacitynd n is the empirical parameter indicative of sorption intensitywith n > 0).

The Freundlich isotherm has been derived by assuming an expo-entially decaying sorption site energy distribution. It is oftenriticized for lacking a fundamental thermodynamic basis since itoes not reduce to Henry’s law at low concentrations.

3.1.1.1.2. The Langmuir isotherm. In 1916 Langmuir developed theoretical equilibrium isotherm and this is probably the bestnown and most widely applied sorption isotherm model [173].

The Langmuir equation can be obtained with the assumption

hat the chemical equilibrium is a coordination reaction with 1:1toichiometry such as:+ LML (3)

C (mol/l)

pes of isotherms.

The Langmuir isotherm theory assumes that the sorption takesplace at specific homogeneous sites within the adsorbent, i.e. once asorbate molecule occupies a site, no further sorption can take placeat that site. The activities of the surface sites are proportional totheir concentration and the number of sorption sites is fixed; thesorption process occurs in a monolayer that covers the surface ofthe material.

q = qmax · KL · C

1 + KL · C(4)

where qmax (mmol g−1) is the monolayer saturation capacity at agiven pH and KL (L mol−1) is the Langmuir constant.

One can readily deduce that at low sorbate concentrations iteffectively reduces to a linear isotherm and thus follows Henry’slaw. Alternatively, at high sorbate concentrations, it predicts aconstant-monolayer-sorption capacity.

3.1.1.1.3. The Jovanovic isotherm. Of lesser use in physicaladsorption is the Jovanovich equation. It is applicable to mobile andlocalized sorption. Although it is not as popular as the other empir-ical equations proposed so far, it is nevertheless a useful empiricalequation:

q = qmax(1 − e−KJC ) (5)

At low loading, the equation above will become q ≈ qmax KJC.Thus, this equation reduces to the Henry’s law. At high sorbates con-centrations, it reaches the saturation limit. The Jovanovich equation

has a slower approach towards the saturation than that of the Lang-muir equation [174].3.1.1.1.4. The Temkin isotherm. Another empirical isotherm isthe Temkin equation proposed originally by Slygin and Frumkin.

3 hemis

Tf

q

wra

su

3

maa

q

w(

twe0a

mamtc

p

q

btHs

tew

q

pnhit

eoi

4 G. Alberti et al. / Coordination C

he Temkin isotherm has generally been applied in the followingorm:

= RT

bTln(aTC) (6)

here aT is the Temkin isotherm constant and bT the parameterelated to heat of sorption (J/mol), R the gas constant (8.314 J/mol K)nd T is the temperature (K).

The logarithmic Temkin isotherm is often used to describe theorption on solid surfaces, and the equation is derived using molec-lar statistical theory [175].

.1.1.2. Three (or more) parameter isotherms.3.1.1.2.1. The Redlich–Peterson isotherm. Jossens et al. [176]

odified the three parameter isotherm first proposed by Redlichnd Peterson [177] to incorporate features of both the Langmuirnd Freundlich equations. It can be described as follows:

= qmax · KRP · C

1 + aRP · Cˇ(7)

here, qmax (mmol g−1) is the saturation capacity at a given pH, KRPL mol−1) is the constant and aRP and are empirical coefficients.

The Redlich–Peterson adsorption isotherm model approacheshe Freundlich model at high concentrations. It is in agreementith the low concentration limit of the Langmuir equation. In the

xpression for this isotherm, is an exponent which lies between and 1. For = 1, the equation reduces to the Langmuir equationnd for = 0, it reduces to Henry’s equation.

3.1.1.2.2. The Sips (or Langmuir–Freundlich) isotherm. Lang-uir also examined the case of a molecule occupying two sites

nd a derivative of the original Langmuir isotherm can be deter-ined assuming the rates of sorption and desorption proportional

o (1 − �)2 and �2, respectively, where � is the fractional surfaceoverage. Therefore, the rate equation becomes:

d�

dt= kaC(1 − �)2 − kd�2 (8)

Generalizing to more than one site and assuming equilibriumroduces the Sips sorption isotherm [178]:

= qmax (KS · C)1/n

1 + (KS · C)1/n(9)

The Langmuir–Freundlich name derives from the limitingehaviour of the equation. At low sorbate concentrations it effec-ively reduces to a Freundlich isotherm and thus does not obeyenry’s law. At high sorbate concentrations, it predicts a monolayer

orption capacity characteristic of the Langmuir isotherm.3.1.1.2.3. The Tóth isotherm. Derived from potential theory,

his isotherm [179] has proven useful in describing sorption in het-rogeneous systems. This equation describes well many systemsith sub-monolayer coverage, and it has the following form:

= qmax KT · C[1 + (KT · C)n

]1/n(10)

Here n is a parameter which is usually less than unity. Thearameter n and KT are specific for sorbate–sorbent pairs. When

= 1, the Tóth isotherm reduces to the famous Langmuir equation;ence, like the Sips equation, the parameter n is said to character-

ze the system heterogeneity. If it deviates further away from unity,he system is said to be more heterogeneous [174].

3.1.1.2.4. The Unilan isotherm. Unilan equation is anothermpirical relation obtained by assuming a patch wise topographyn the surface and each patch is ideal such that the local Langmuirsotherm is applicable on each patch. The term Unilan comes from

try Reviews 256 (2012) 28– 45

Uniform distribution and Langmuir local isotherm and the equationhas the following form:

q = qmax

2s· ln(

1 + KU · C · es

1 + KU · C · e−s

); s = Emax − Emin

2RT(11)

Here Emax and Emin are the maximum and minimum energies ofthe distribution. The parameter s characterises the heterogeneity ofthe system: the larger this parameter is, the more heterogeneous isthe system. If s = 0, the Unilan equation (11) reduces to the classicalLangmuir equation as in this limit the range of energy distributionis zero.

For large value of s, the slope of the isotherm is initiallylarge, then it decreases rapidly as the loading increases, indicatingadsorption at low concentrations is favourable at stronger energysites and then adsorption takes place on progressively weakerenergy sites.

Like the Sips and Tóth equation, the Unilan is a three-parameterisotherm, and they are commonly used to correlate sorption equi-librium data of many solids, such as activated carbon and zeolite[174].

3.1.1.2.5. The Dubinin–Radushkevich isotherm. Radushkevichand Dubinin have reported that the characteristic sorption curveis related to the porous structure of the sorbent [180].

The Dubinin–Radushkevich isotherm model is generally appliedto identify physical or chemical processes in sorption. The relatedequation is:

q = qmax exp(−KDε2

); ε = RT ·

(1 + 1

C

)(12)

where KD (mol2/kJ2) is the constant which is related to the calcu-lated average sorption energy E, ε (kJ mol−1) is the Polanyi potential.R is the gas constant and T the absolute temperature.

The average sorption energy E is calculated as: E = (2KD)−0.5

As an index of consumed energy, E represents the free energy permole of metal ions transferring from infinity in solution to the sor-bent surface. If the magnitude of E is less than 8 kJ mol−1, suggestingthat the physical process dominates in sorption; if the value of E isbetween 8 and 16 kJ mol−1, the adsorption would have a chemicalnature [181].

3.1.1.2.6. The Radke–Prausnitz isotherm. The Radke–Prausnitzisotherm is represented by Eq. (13) and has three adjustable param-eters: KRPI, qmax and ˇ:

q = qmax KRPI · C

(1 + KRPI · C)ˇ(13)

At low concentrations it reduces to Henry’s law and at higherconcentrations it becomes the Freundlich equation. Furthermore,the Langmuir equation emerges from Eq. (13) in the special casethat the parameter is identically one [182].

3.1.1.2.7. The Fritz–Schlünder isotherm. The Fritz-Schlünder isa empirical model proposed by Fritz and Schlünder in 1974 [183]to explain the simultaneous sorption equilibria of organic solutesin dilute aqueous solutions on activated carbon.

For a solution containing a single solute, a four parametersmodel is proposed. The equation may be expressed as [184]:

q = ˛1 · Cˇ1

(1 + ˛2 · Cˇ2)(14)

where ˛1, ˛2, ˇ1,and ˇ2 are Fritz–Schlünder isotherms constants. Inthe particular case of ˇ1 and ˇ2 equal to 1, it becomes the Langmuirmodel.

3.1.1.2.8. Extended Langmuir isotherm. Originally, the Lang-muir model was intended for monolayer adsorption with nointeraction between adsorbed molecules. Thus, its ability to corre-late experimental data is limited. The extended Langmuir model is

hemis

as

q

wmiTett

waiee

q

wcniaeapi

ti

fcit

q

w

iifats[

3cmbni

tGbes

G. Alberti et al. / Coordination C

modified three-parameter version of the Langmuir model whichometimes can provide a better fit to the experimental data [185]:

= qmax KEL · C(1 + KEL · C + kEL

√KEL · C

) (15)

here the parameters are qmax, KEL and kEL. The extended Lang-uir model improves significantly over the Langmuir model and

s better than or comparable to the Langmuir–Freundlich and theóth models in terms of accuracy in fitting experimental sorptionquilibrium data. The extended Langmuir model preserves some ofhe basic features of the Langmuir model and is simple enough sohat its parameters can be easily obtained [185].

3.1.1.2.9. Generalized modelling of any isotherm. In most caseshere the concentration of the studied compound is higher than

trace concentration, neither the Langmuir nor the Freundlichsotherms are consistent with the data and more complicated mod-ls must be applied. Hinz in 2001 [133] proposed a flexible rationalquation that could describe any type of isotherm:

= qmax

w∑i=1

fi

�i∏j=1

(Ai,j · Cpi,j

1 + Bi,j · Cri,j

)si,j

(16)

here qmax denotes the asymptotic amount of sorption at high con-entrations, fi is the fraction of sites of type i (whereas the totalumber of different types of site is w), and �i gives the number of

nteraction terms between the different types of sites. Ai,j and Bi,jre empirical affinity constants and pi,j, ri,j and si,j are dimensionlessmpirical parameters. It should be emphasized that the parametersre empirical coefficients when Eq. (16) is used for pure descriptiveurposes. Only for very well-defined systems parameters can be

nterpreted as meaningful system properties. [132,133].Although this equation is fully empirical and includes many fit-

ing parameters, it has the advantage of decomposing any isothermnto different types of sites [132].

On the basis of the Langmuir model, another generalized modelor any isotherm was developed [170,186]. The basic idea is toonsider any isotherm as an integral of Langmuir equations: thisntegral has a density function g(L) which corresponds to the sta-istical distribution of the affinity constant L:

=∫ +∞

−∞g(L)

LC

1 + LCdL (17)

ith g being a miscellaneous density function.Conceptually, each sorption site provides an elementary

sotherm having its own affinity L and capacity g(L). The completesotherm is seen as the sum of all the elementary isotherms. Theunction g has been named a “weighting function” [170], a “siteffinity distribution function” [187], or a “frequency distribution ofhe local affinity coefficient L” [188]. By choosing the accurate den-ity function g, any type of isotherm can be described by Eq. (17)133,170].

.1.1.3. Ion-exchanger equilibrium modelling. The thermodynamicharacterisation of ion-exchange and chelating materials is funda-ental to the design of separation processes and to predict the

ehaviour of these materials in different systems. Many thermody-amic and empirical models were proposed for the description of

on-exchange.As previously reported, the most commonly used are the

hree-parameter model, developed by Hogfeldt [147–149], the

ibbs–Donnan model proposed by Gregor [150], first appliedy Marinsky [151] to characterize protonation of the solid ion-xchangers, implemented by Pesavento to also describe theorption of metal ions [152–162], the surface complex formationtry Reviews 256 (2012) 28– 45 35

model [163–165], and the one based on the Wilson equation forthe estimation of non-idealities in the resin phase [166,167].

A test of an ion-exchange model is the ability to accurately pre-dict the composition of one phase that is in equilibrium with theanother phase of known composition.

Different calculation methodologies have been reported for thedetermination of the equilibrium constants and parameters of themodels; nevertheless, it is unusual to see a comparison of the resultsobtained applying different models to the same experimental dataset. Hogfeldt compared his models with those of other authorsusing the same experimental data sets, but other such comparisonsare rarely found in the literature [149].

There is a need for such comparisons to be made in order to reacha model of general applicability in ion-exchange. For this reason itis necessary to obtain suitable experimental data for making thecomparison and drawing conclusions [146].

3.1.1.3.1. The three-parameter model. Among the differentstudies appeared in literature that propose models to describe ion-exchange equilibria, there are Hogfeldt studies [148]. This authorhas developed a mathematical model where a selectivity coefficientcorresponding to the ion-exchange of two ions can be expressedas a function of the fraction in the resin of one of the exchange-able ions with the aid of a three-parameter equation. Hogfeldt hasapplied this strategy to various ion-exchange equilibria and varioussupports, generally studying equilibria in diluted solutions.

The model deals with the three kinds of pairs appearing in amixture of components A and B, i.e., A–A, B–B and A–B. If compo-nent A is surrounded by A only, any molar property Y has the sameproperty as in pure A. This quantity is denoted yA. Similarly for com-ponent B, yB refers to B surrounded by B only. When surrounded byboth A and B the property has the value ym.

According to Guggenheim’s zeroth approximation [189] thenumber of A–A pairs is proportional to xA

2 (xA = mole fraction of Ain the mixture) and the number of B–B pairs is proportional to xB

2

(xB = mole fraction of B in the mixture). The number of A–B (=B–A)pairs is proportional to 2xAxB Thus:

Y = yAx2A + yBx2

B + 2ymxAxB (18)

In the literature, Y is plotted against xA or xB, not against xA2 or

(xB2). It is then convenient to introduce the equation

Y = yAxA + yBxB + BxAxB (19)

where B is an empirical constant.Application of this model to ion-exchange gives for any molar

thermodynamic property Y:

Y = yAxA + yBxB + BxAxB (20)

where xA and xB are the equivalent fractions in the exchanger; yA,yB are properties for the pure components, while ym refers to themixture. The barred quantities (here and everywhere in the text)refer to the solid phase.

By fitting experimental data to Eq. (20) by least-squares meth-ods, the parameters yA and yB and the empirical constant B areobtained. The third parameter ym is then obtained from:

ym = 12

(yA + yB + B) (21)

(Eq. (21) is obtained by setting Eq. (19) identical to Eq. (20) andconsidering xA + xB = 1).

For the generic ion-exchange reaction:

z+ +

(1/z)M + HL � (1/z)MLz + H (22)where Mz+ is the metal ion, HL the protonated form of the activesite of the chelating sorbent. In both phases equivalent fractions areused.

3 hemis

c

�

bd

b

�

l

laea

l

m

l

Gbsatrtt

ctg

a

wwcccw

toann

M

wsr

6 G. Alberti et al. / Coordination C

The equilibrium quotient, � (not to be confused with a kineticonstant), is given by:

= x1/zM xH

xHx1/zM

(23)

The activity coefficient ratio in the aqueous phase is assumed toe practically constant and included in �. Application of Eq. (20) toata for log �(xM) gives: yA = log �(M) and yB = log �(H).

The logarithm of � is related to the free energy of reaction (22)y:

G0 = −RT log � (24)

From Eq. (20):

og � = log �(M)xM + log �(H)(1 − xM) + BxM(1 − xM) (25)

The parameters log �(M) and log � (H) are the limiting values ofog � for xM = 1 and xM = 0. They are not directly experimentallyvailable and they are obtained by curve fitting, together with thempirical constant B. Then the third parameter, log �m, is obtainedpplying Eq. (24), i.e.:

og �m = 12

(log �(M) + log �(H) + B) (26)

The integral free energy of reaction (22) expressed as a “ther-odynamic” equilibrium constant (log K) is obtained from:

og K =1∫0

log �(xM)dxM = 13

[log �(M) + log �(H) + log �m] (27)

3.1.1.3.2. The Gibbs–Donnan model. The model is based on theibbs–Donnan description of ion-exchangers [150,151]. The sor-ent is represented as a water phase, separated from the externalolution by an interface through which water, neutral moleculesnd ions can diffuse, but the active groups, permanently linked tohe solid matrix, cannot. For the resin phase, the same standard andeference state of the external water solution are assumed. Due tohe different mobilities of ions, a potential difference is set up athe interface [190], referred to as the Donnan potential.

At equilibrium, the chemical potential of each of the mobileomponents is the same in both phases and, for each couple of ionshat can diffuse through the interface, the Donnan equilibrium isiven by:

AaC = aAaC aA/aB = aA/aB (28)

here ai is the activity of species i (in mol kg−1), A and C are ionsith charges of opposite sign, on the contrary A and B are ions with

harge of the same sign. For simplicity the charges are omitted andonsidered monovalent. The activity of an ion inside the sorbentannot ever be measured, but it can be evaluated from Eq. (28)hich is of basic importance for the proposed model.

In a practical application of SPE, the sorbent and consequentlyhe active sites are in large excess with respect to the metal ion,ften at trace or sub-trace levels. Under this condition, it can bessumed that mechanisms, other than formation of complexes, areegligible [159,161] and that the concentration of active sites doesot depend on complex formation.

The general exchange equilibrium is:

+ nH L � MH L + sH (29)

r p nhere M is the metal ion, HrL the r-protonated form of the activeite of the chelating sorbent, H the proton. s is the number of protonseleased s = n–p.

try Reviews 256 (2012) 28– 45

The exchange coefficient, ˇ1npex, is given by:

ˇ1,n,p,ex = [MHpLn] · [H]s

[M] · HrL(30)

The exchange coefficients depend on the pH and concentra-tion of the counter ion in the solution and are not constant. Onthe other hand, the thermodynamic complexation constants in thesolid phase, defined by Eq. (31):

ˇ1npT = aMHpLn asH

aMaHr L(31)

are not assessable quantities, the activity coefficients of the activesites in any of its protonated and complexed forms remaining non-measurable. For this reason the intrinsic complexation constant(ˇ1npi) is defined as follows [154,155,157–162]:

ˇ1npi = ˇ1npT�Hr L

�MHpLn

� (m−s)C = ˇ1npex · �s

H · � (m−s)C

�M· [C](m−s)

[C](m−s)

= ˇ1npex ·sol�

[C](m−s)

[C](m−s)

(32)

which is on the contrary a computable quantity, still independentof the composition of the solution, so able to characterize the sorp-tion. Moreover for the assumption of the model, as the ratio of theactivity coefficients in the resin phase is ≈1, the intrinsic complex-ation constant will be close to that of a monomeric soluble ligandthat mimics the active site.

In Eq. (32), m is the charge of the metal e �X indicates the activitycoefficients of the species X. C is a cation, monovalent for simplicity,which is called counter ion, if a cation-exchange complexing resin

is considered,sol = (�s

H� (m−s)C )/�M is the ratio of the activity coeffi-

cients in the solution phase. The concentration of the counter ion inthe resin phase is an independent quantity that can be calculatedthrough an iterative procedure [161]. Similar relations hold for theprotonation equilibria and for any chelating sorbent.

The intrinsic complexation constants are evaluated from theexpression for the fraction of metal ion sorbed on the solid phase,f. It is given by the following relationship:

f = c

ctot= [MHpLn]w

[MHpLn]w + ˛M(I)[M]V

= 1

1 + ˛M(I)[H]qV(ˇ1npi[C]

(m−q)/

sol� [C](m−q)

)[Hr L]

nw

= 1

1 + ˛M(I)VK∗w

(33)

where w is the mass water contained in the sorbent, V the volumeof the solution, ctot the total concentration of the metal in the sam-ple, c the concentration of the metal ion sorbed on the solid phase;here ˛M(I) represents the reaction coefficient [191] of the free metalion in the solution phase following equilibration with the sorbent.˛M(I) is the ratio of the total metal concentration in solution (freeand complexed with a ligand I present in solution), and the con-centration of the free metal ion: ˛M(I) = (

∑[MI]/[M]). ˛M(I) is equal

to one when the metal is only present as a free hydrated ion in theaqueous solution.

[HrL] is evaluated from the total concentration of the free activegroups inside the sorbent (cL) and its concentration is in analytical

excess with respect to the total metal ion concentration.Eq. (33), defined for the formation of one complex, can beextended to the formation of other complexes, as accounted forin the last term on the r.h.s. of Eq. (33).

hemis

fg

K

m

aosiiosct(

tccw

mp(s

rtnltascdtpoa

isupsc

tttgba

R

wra

G. Alberti et al. / Coordination C

K* represents the ratio of total metal ion in the solid phase to theree metal ion in solution. It is indeed a partition coefficient and isiven by the following relation:

∗ = c V

[M] w=∑ ˇ1npi

sol�

[C](m−s)

[C](m−s)

[HrL]n

[H]s (34)

The summation is extended to all the complexes formed by theetal ion with the active groups of the sorbent [152,153].If the concentration of the active sites in the solid phase and ˛M(I)

re known, from fitting of the experimental values of f as functionf pH of the solution, ˇ1npi and s can be determined. The strategy forelecting the sorption reactions is to first consider the simplest sto-chiometries and reactions equal to those of the monomeric unitsn solution. To select the proper set, the effect of the ionic median the exchange coefficients (see Eq. (31)) is examined, and con-equently similar experiments are run at different ionic strengthoncentrations. Further indications are obtained from the evolu-ion of profiles observed adding a competitive ligand to the solutionsee Eq. (33)), so that the effect of different ˛M(I) is observed.

Conversely, Eq. (33) not only graphically shows the ability ofhe model to describe the experimental data, but once the intrinsicomplexation constants were determined, the expected values of fan be calculated at any particular condition. In this way Eq. (33)orks to build up an “a priori” sorption model.

3.1.1.3.3. The surface complex formation model (SCM). Theodel is known as the theory of formation of surface com-

lexes, because it assumes that near the surface of a sorbention-exchanger) each kind of counterion is located in the form of aurface complex within an individual Stern layer [145].

In this model’s concept, the ion-exchanger resin matrix isegarded as a planar sheet with functional sites uniformly dis-ributed over the surface. The electrical charge of the fixed sites iseutralized by counterions which are arranged in individual Stern

ayers. It is assumed that there are no interactions between coun-erions within the same or different layers. Further counterionsre distributed in a diffuse layer that contains also co-ions. Fixedites and counterions form electric double layers called surfaceomplexes. The expression “surface complexes” is only a formalesignation, and which must not be understood to imply any par-icular bonding. Due to its electric charge, the surface has a negativeotential s which drops to the potential st,s in the Stern layers, tod in the diffuse layer and finally to zero in the free solution. Each

f the layers, therefore, has a surface charge and as a consequence,ny two layers can be considered as an electric capacitor [163,165].

The equilibrium relationships in the SCM were derived assum-ng that: functional groups are uniformly distributed across a planarurface; activity coefficients in the ion-exchanger phase are equalnity; any ion-exchange is treated as replacement of a surface com-lex by a new one. As a consequence, the charge of the surfaceorption sites (zR) is defined as the least common multiple of theharges of the counterions involved in the exchange process [145].

For example, the binary ion-exchange equilibria between pro-ons and divalent metal ions on resins can be represented in SCM inerms of the replacement of one surface complex formed betweenwo protons from the corresponding Stern layer and two activeroups from the resin surface with another surface complex formedy one divalent ion from the Stern layer of the metallic ions and twoctive groups [163–165]:

− HwH + wM(M2+)St,M � R − MwM + wH(H+)St,H (35)

here R designates the resin phase and wH, wM are the stoichiomet-ic coefficients defined as the ratio between the resin valence z(R)nd the corresponding counter-ion valence z(i), wi = −z(R)/z(i) with

try Reviews 256 (2012) 28– 45 37

i = H+, M2+. The formation of the two surface complexes is describedby the equations:

R2− + 2(H+)St,H � R − H2 and R2− + (M2+)St,M � R − M (36)

The stability constants of the two surface complexes are respec-tively:

KH =[RH2]

[H+]2 ·

[R2−] and KM =

[RM]

[M2+][R2−

] (37)

In the above relationships it is assumed that the activity coeffi-cients are equal to unity and expressed in terms of concentrations.The ratio of these constants characterizes the ion-exchange equi-librium between the two counter-ions on a certain resin:

KMH =[RM] [

H+]2[RH2] [

M2+] (38)

Assuming a Boltzmann distribution of ions in the electrical field,the concentration of the free counter-ions in the correspondingStern layer was expressed as a function of their concentrationsin the liquid phase and the electric potential in the Stern layer.Supposing that the Stern layer formed by M2+ is the first layernext to the resin surface and the protons are located in the sec-ond Stern layer, and using the electric capacitance of the capacitorformed by the two Stern layers and of the charge density in theStern layer formed by protons, the following equation was obtained[145,163–165,192]:

log Q MH = log

yM2+ ·[H+]2

yH+ ·[M2+] = log KM

H +∣∣z(R)∣∣

ln 10· F2qmax

A0C(M, H)RT· yH+

= log KMH + m(M,H) · yH+ (39)

The ratio Q MH was called the generalized separation factor and

can be obtained measuring the equivalent ionic fraction of metalions (yM2+ ) and protons (yH+ ) in the resin phase, and the molarconcentrations of the two counter-ions in the external solutionat equilibrium. If the order of the two Stern layers is correctlyassumed, than the plot of logarithm of the generalized separationfactor versus the proton equivalent ionic fraction (the ion in thesecond Stern layer) is linear and has a positive slope. The interceptis the logarithm of the ion-exchange constant. The slope dependson known constants and measurable (qmax) or unknown (A0 andC(M,H)) quantities. The slope of Eq. (39) increases if the specific elec-trical capacitance C(M,H) decreases, if the distance between the twoStern layers increases (for constant charge density in the layers).The variation of the slope for a series of ion-exchange processesgives information about the degree of hydration of counter-ionsin the given conditions of equilibrium. The constants KM

H and theslopes m(M,H) are the SCM constants for binary systems at a giventemperature and total equivalent concentration [192]; these quan-tity are independent of the pH value or the ionic strength of thesolution, they also remain constant in multicomponent systems forwhich simple binary equilibria can be calculated for a wide rangeof experimental conditions [145].

3.1.1.3.4. Models based on Wilson’s equation. Severalapproaches of this type have been proposed in the literature;

Shallcross et al. [167] reviewed several such models and, proposedto use the Pitzer equation [193] to describe single ion activitycoefficients in the liquid phase and the Wilson model [194] for theactivity coefficients in the solid phase.3 hemis

rc

2

K

wb

y

c

cim[

wad

sp�

l

cbcli

l�HM

ymH

ma

3

at

8 G. Alberti et al. / Coordination C

For example, in the case of the binary ion-exchange equilib-ia between protons and divalent metal ions on ion-exchange andhelating resins:

R − H + M2+ � R − M + 2H+ (40)

The thermodynamic equilibrium constant for this reaction is:

M,H =aR−M · a2

H+

a2R−H

· aM2+= �R−MyM(�H+ [H+])2

�M2+ [M2+]( �R−HyH)2(41)

here yi, the equivalent ionic fraction of the counterion i, is definedy:

i = ziymi∑ziymi

(42)

ymi is the mole fraction of the species i and the summation isarried out over all counterions.

Although the activity coefficients in the liquid phase may bealculated easily using the Pitzer equation, the solid phase activ-ty coefficients must be evaluated in a more complicated way. The

ethod based upon the Wilson model for excess Gibbs free energy194] can be applied. The Wilson equation is:

�GE

RT=

M∑i=1

ymi ln

⎛⎝ M∑

j=1

�ijymi

⎞⎠ (43)

here M is the number of exchanging counterion species and �ij,re the Wilson binary interaction parameters. These parameters areefined such that �ij = 1 when i = j and �ij > 0 when i /= j.

Differentiation of Eq. (43) with respect to the number of moles ofpecies i in the resin phase yields an equation from which the resinhase activity coefficient, �i, may be calculated if the parameters,ij, are known:

n �i = 1 −

⎡⎣ M∑

j=1

ymi�ij

⎤⎦−

M∑k=1

⎡⎢⎢⎢⎢⎢⎣

ymk�ki

M∑j=1

ymj�kj

⎤⎥⎥⎥⎥⎥⎦ (44)

Then, to evaluate the equilibrium constant, the following pro-edure proposed by Smith and Woodburn [195], and then usedy Vazquez Una et al. [196] and Shallcross et al. [166,167], can beonsidered. Smith and Woodburn begin by introducing the ‘equi-ibrium quotient’, . For the reaction (40) the equilibrium quotients defined as:

M,H =(

�H+ [H+])2 · ymM2+(

�M2+ [M2+])

· ymH+= KM,H

�2H+

�M2+(45)

Substitution of Eq. (44) into Eq. (45) yields upon rearrangement:

n M,H = ln KM,H −[

1 − ln(ymH+ + ymM2+ �HM) −(

ymH+

ymH+ + ymM2+

+ 2

[1 − ln(ymH+ �MH + ymM2+ ) −

(ymH+ �HM

ymH+ + ymM2+ �HM+

The values of the equilibrium quotient �M,H are fitted vs. theolar fractions (ymH+ and ymM

2+), so the equilibrium constant KM,Hnd the Wilson parameters �HM and �MH can be estimated.

.1.2. Advantages and disadvantages of the different modelsAs previously highlighted, sorption isotherms are widely

pplied to characterize retention of chemicals in solid phase. Sorp-ion isotherms are often used as empirical models, which do not

try Reviews 256 (2012) 28– 45

+ ymM2+ �MH

ymH+ �MH + ymM2+

)]

ymM2+

+ �MH + ymM2+

)](46)

make statements about the underlying mechanisms and mea-sured variables. A sorption isotherm does not have any intrinsicthermodynamic definition: its significance depends on the con-ditions from which it is obtained. However, at least in the caseof natural media, they are such complicated mixtures of numer-ous mineral and organic compounds that empirical approaches,such as the “sorption isotherm”, will be still used for a longtime [132].

Unquestionably, this kind of modelling seems too simplisticto describe the sorption behaviour of ion-exchange and com-plexing resins or new polymers with well characterised activegroups.

The thermodynamic study of ion-exchange and chelating mate-rials is fundamental to the design of separation processes and topredict the behaviour of these materials in different systems.

The methods above described, in the paragraph “Ion-exchangerequilibrium modelling” are all based on a rigorous approach andin several cases they have been effectively applied, giving a prettygood fitting of experimental data.

They are all able to describe binary equilibria in a particular setof experimental conditions and to predict the sorbents behaviour ofmulti-component systems. For example the surface complexationmodel treats multi-component equilibria as a kind of superposi-tion of several simple equilibria and allows them to be calculatedusing the parameters obtained from binary subsystems [145]. AlsoHogfeldt stated that by the three parameters model it is possible topredict ternary system from the binary ones [148] and Shallcrosset al. [166,167] developed a method based on Wilson equation,to predict multi-component ion-exchange equilibria based uponbinary system data.

All these models consider the formation of a single complexbetween an ion and the active sites of the sorbent, assuming a1:1 stoichiometry. This approximation can be true when high con-centrations of the solute are dequilibrate with the solid phase, butwhen the analyte in solution is a trace levels, and/or when the sor-bent is equilibrated with solutions at basic pH, it was demonstratedthan other complexes with different stoichiometry can be formed insolid phase [152,153,157,161,162]; in particular the Gibbs–Donnanmodel, at present, is the only approach considering thisaspect.

3.2. Kinetic sorption modelling

One of the main terms to be defined in a process where chemicalspecies distribute between two phases is the time for the system toachieve the thermodynamic stability. Whereas the extent of sorp-tion depends only from the difference between the initial and thefinal equilibrium state, the rate of sorption depends on the waythat leads from the initial to the final step. The overall sorptionrate is limited by the ability of sorbate molecules to diffuse into theparticle interior.

3.2.1. Sorption kinetic model based on reaction mechanism

Generally the sorption process includes four main steps, as fol-lows:

(1) Transport in the bulk

hemis

(

(

(

ocwfsbtdm

[driad

thcasamopbSiVoar

3esp

gt

f

wteuotc

ea

T

G. Alberti et al. / Coordination C

2) Diffusion from the bulk through the liquid film (or the boundarylayer), surrounding the surface of the particle (film diffusion orexternal mass transfer)

3) Diffusion of ions or molecules through the sorbate or the parti-cle (intraparticle diffusion)

4) Chemical reaction with the functional groups attached to thematrix.

One of the steps usually offers much greater resistance than thethers, so it can be considered as the rate limiting step of the pro-ess. Normally the first two steps are rapid processes in comparisonith intra-particle diffusion and the binding reaction on the sur-

ace sites: an adequate mixing of the solution in contact with theolid leads to the suppression of the boundary layer around the sor-ate and consequently only the second two processes may controlhe sorption kinetic mechanism. This behaviour has been currentlyescribed in the case of natural materials and derivatized naturalaterials [197].On the other side, for ion-exchange on synthetic polymers

198,199] when convection in the solution is slight and/or theegree of polymer cross-linking is low, it is likely that the mainesistance to diffusion can be found in the liquid phase. Converselyn case of high degree of cross-linking, the resins and the materialsre more compact, so the mass transfer inside the particles is moreifficult.

There is no surprise to find many attempts to rationalizehe experimental evidence and a variety of simplified modelsas been proposed, sometimes derived from rigorous theoreti-al approaches, every so often merely empirical models. Cortinand co-workers [198] commented that techniques of analy-is for the concentration profile inside isolated resin particles,s shelf-radiography, scanning electronic microscopy and X-rayicroanalysis, have revealed that even the more sophisticated the-