LJS\J:\scopes\06W003\10000\FVD Reports\Air Permit\r-Air use permit app.doc Appendix D Fugitive Dust Control Plan

Welcome message from author

This document is posted to help you gain knowledge. Please leave a comment to let me know what you think about it! Share it to your friends and learn new things together.

Transcript

LJS\J:\scopes\06W003\10000\FVD Reports\Air Permit\r-Air use permit app.doc

Appendix D

Fugitive Dust Control Plan

Humboldt Mill Fugitive Dust Control Plan

Project ID: 06W003

Prepared for Kennecott Eagle Minerals Company

ISO 14001:2004 Registered System

Prepared by Foth Infrastructure & Environment, LLC

December 2008

Foth Infrastructure & Environment, LLC 2008 2737 South Ridge Road, Suite 600 • P.O. Box 12326 • Green Bay, WI 54307-2326 • (920) 497-2500 • Fax: (920) 497-8516

J:\scopes\06W003\10000\FVD Reports\Air Permit\Fug Dust\R-Fugitive Dust Control Plan.doc ii

Fugitive Dust Control Plan

Contents Page List of Abbreviations, Acronyms, and Symbols............................................................................ iii 1 Introduction .............................................................................................................................1 2 Haul Truck Activities ..............................................................................................................2

2.1 Roadway Travel .............................................................................................................2 2.2 Unloading Operations ....................................................................................................2

3 Ore Storage and Handling .......................................................................................................3 4 Concentrate Storage, Handling, and Load-Out .......................................................................4 5 Routine Maintenance...............................................................................................................5 6 Recordkeeping.........................................................................................................................6

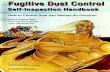

Figures Figure 1-1 Site Plan

Appendices Appendix A Inspection Forms

LJS\J:\scopes\06W003\10000\FVD Reports\Air Permit\Fug Dust\R-Fugitive Dust Control Plan.doc iii

Humboldt Mill Fugitive Dust Control Plan

List of Abbreviations, Acronyms, and Symbols

COSA Coarse Ore Storage Area Foth Foth Infrastructure & Environment, LLC KEMC Kennecott Eagle Minerals Company MDEQ Michigan Department of Environmental Quality PTI Air Permit to Install SIC Standard Industrial Classification tpd tons per day

LJS\J:\scopes\06W003\10000\FVD Reports\Air Permit\Fug Dust\R-Fugitive Dust Control Plan.doc Foth Infrastructure & Environment • 1

1 Introduction Pursuant to R336.1371 of Part 3, Emission Limitations and Prohibitions – Particulate Matter, a Fugitive Dust Control Plan may be required for any fugitive dust source involved in processing, storing, transporting, and conveying bulk materials such as metal ores. The proposed Humboldt Mill Project will be classified as Standard Industrial Classification (SIC) 1021, and therefore, may be subject to these requirements. The major requirements for dust control under this regulation are the following:

♦ A written Fugitive Dust Control Program

♦ Maintenance of records consistent with activities to be implemented under the program.

♦ Identification of control technologies and methods that will be implemented as part of the program. Control methods must be selected for activities listed in R 336.1372.

This Fugitive Dust Control Plan has been prepared by Foth Infrastructure & Environment (Foth) on behalf of Kennecott Eagle Minerals Company (KEMC) as part of the Air Permit to Install Application (PTI) for proposed nickel/copper ore processing operations at the Humboldt Mill Project Site located in Humboldt Township, Marquette County, Michigan. This plan addresses information on best management practices and controls to minimize fugitive dust from the sources at this facility. Potential sources of fugitive dust include:

♦ Haul truck activities; ♦ Ore storage and handling; and ♦ Concentrate storage, handling, and load-out.

LJS\J:\scopes\06W003\10000\FVD Reports\Air Permit\Fug Dust\R-Fugitive Dust Control Plan.doc Foth Infrastructure & Environment • 2

2 Haul Truck Activities Haul trucks bringing mined ore to the facility can be a fugitive emission source in several ways:

♦ Roadway travel, ♦ Unloading operations.

2.1 Roadway Travel

The mill access road entering the facility from County Road (CR) 601 will be used for haul trucks delivering ore, receiving deliverables, and general traffic. The haul truck traffic will be the most significant source of roadway fugitive emissions. The haul truck route into and out of the site is shown on Figure 1-1. Most of the haul truck route is on pavement, however, the last 1000 feet exiting the facility is unpaved. Snow cover is anticipated approximately four to six months of the year keeping dust levels to insignificant levels. To minimize roadway dust during drier times of the year, the facility will implement control measures. During periods of ore delivery, roadway segments will be evaluated for the need to apply water. The evaluation will be based on the moistness of the roadway material, weather conditions expected (temperature, solar intensity, cloud cover, and wind conditions) and whether the roadway will be adequately moist during the upcoming operating period. When needed, a water truck will distribute water evenly across the roadway to maintain the pavement in a moist state during operational periods when truck traffic may occur. The watering program will be in effect along the haul truck route shown on Figure 1-1. The goal of the watering program is to reduce fugitive dust emissions sufficiently to achieve an opacity of 5% or less for these sources. Additional control measures will include use of a road sweeper. Roadway areas on the haul route will be swept as needed. Documentation of roadway watering, inspecting, and sweeping activities will be done using a form similar to the On-Site Roadway Watering and Sweeping Documentation form in Appendix A. For unpaved portions, roadway aggregate will be installed and maintained to keep the silt content at a minimal level. The aggregate will be replaced on an as-needed basis. 2.2 Unloading Operations

Haul trucks will arrive at the site covered with a hard cover reducing potential for fugitive dust generation from the payload. The ore payload is expected to have a silt content routinely less than 1%. Haul trucks will back up to the COSA on the west side of the building and the roll-up door will be opened. Unloading will take place, then the door will be closed. The cover on the empty truck will be checked before the truck proceeds.

LJS\J:\scopes\06W003\10000\FVD Reports\Air Permit\Fug Dust\R-Fugitive Dust Control Plan.doc Foth Infrastructure & Environment • 3

3 Ore Storage and Handling Ore delivered to the Humboldt Mill site will be transported to the COSA, an enclosed storage area with four walls and a roof to protect the ore piles from exposure to precipitation and reduce the impact of wind. Doors will be kept closed except when trucks are unloading the ore. It is anticipated the enclosure will result in 95% control of dust emissions from activities within the COSA. Individual emission controls will be applied to ore processing activities including water sprays on the incoming ore dump, dump hopper loading, rock breaking, primary crusher, and end transfer point. Water sprays are expected to reduce emissions from those activities by 90%. Within the COSA, the front end loader will manage the ore piles and feed the dump hopper. This may generate emissions from the tires moving across the floor causing dispersion of loose material. To reduce emissions, a floor cleaning program will be implemented. During each day of crushing and/or ore delivery, the COSA floor will be swept. Floor sweeping will be performed on all open areas (those areas free from ore piles where the loader can travel). Floor sweeping will be performed with an industrial floor sweeper or broom. Debris will be collected and added to the ore pile. A COSA Floor Inspection and Cleaning Program Sweeping Schedule (or similar) appears in Appendix A. The Secondary Crusher Building will be totally enclosed providing a 95% reduction of emissions from activities within this building. In addition, the secondary and tertiary crushers and conveyor transfer points will be ventilated to the secondary crusher building dust collector, which is expected to reduce captured emissions by at least 99.5%. Operations in the mill and transfer station will be totally enclosed providing a 90% reduction of emissions from activities within these buildings. The mill building transfer points and fine ore bins will be ventilated to a baghouse, mill building dust collector No. 1. This control is expected to reduce captured emissions by at least 99.5%. The transfer station emissions and emissions from feeders leading from the fine ore bins to the grinding mill will be equipped with a water spray system. This control is expected to reduce those emissions by at least 90%. Visible emissions from the COSA and secondary crusher building are expected to meet the MDEQ opacity requirements of 5% opacity. Maintenance procedures for control devices will be performed as described in Section 5 of this plan. Inspection and maintenance checklists (or similar) are provided in Appendix A.

LJS\J:\scopes\06W003\10000\FVD Reports\Air Permit\Fug Dust\R-Fugitive Dust Control Plan.doc Foth Infrastructure & Environment • 4

4 Concentrate Storage, Handling, and Load-Out All concentrate operations will be totally enclosed in the concentrate load-out building providing a 95% reduction of emissions from activities within this building. Although the concentrate material will be very moist (about 15% moisture), ventilation to a baghouse will be used to control potential dust emissions at drop points within the building. This control is expected to reduce captured emissions by at least 99.5%. To reduce potential emissions from the rail cars, concentrate loading will be performed within the building, whether by conveyor load-out or auxiliary load-out method. Roll-up doors will be installed at the east and west ends of the building and will be open only to allow rail car entry or exit. Prior to a loaded rail car exiting the building, the wheels and body of the car will be inspected for material clinging to the exterior. If present, loose material will be brushed off. During auxiliary load-out, a front end loader will transfer concentrate from the floor to a rail car. Similar to the COSA operations, material present on the floor may be dispersed into the air from the vehicle tires. To reduce these emissions, a floor cleaning program will be implemented. Prior to operation of the front end loader, the concentrate/load-out building floor will be evaluated. Floor sweeping will be performed as needed on areas free from concentrate piles where the vehicle travels. Floor sweeping will be performed with an industrial sweeper or broom. Debris will be collected and added to the concentrate pile. A Concentrate Load-Out Building Floor Cleaning Program Inspection and Sweeping Schedule (or similar) appears in Appendix A. Visible emissions from the concentrate load-out building are expected to meet the MDEQ opacity requirement of 5% opacity. Maintenance procedures for control devices in the building will be performed as described in Section 5 and inspection and maintenance checklists (or similar) are provided in Appendix A.

LJS\J:\scopes\06W003\10000\FVD Reports\Air Permit\Fug Dust\R-Fugitive Dust Control Plan.doc Foth Infrastructure & Environment • 5

5 Routine Maintenance To ensure proper operation of the baghouses, a manometer will be installed on each unit to measure pressure drop across the bags. The baghouses will be operated within the specifications recommended by the manufacturer. The manometers will be checked and recorded on a regular basis to ensure the control devices are operating within these specifications. A regular maintenance program for the baghouses will be implemented. Baghouse inspection and maintenance checklists are provided in Appendix A. Sufficient replacement parts and supplies will be kept on-site to replace equipment in the baghouses. These parts and supplies may include spare hoses and bags. This equipment will be available in the event a repair to the control equipment is necessary. Visual inspection of the fabric filters will take place at a minimum of once per month. Additional inspections and/or investigations will take place whenever an obvious rip, tear or hole is suspected or observed from a visual inspection. Routine replacement of bags and other equipment will take place on a schedule recommended by the manufacturer. Sample maintenance checklists are included in Appendix A to be used a guide to maintaining the baghouses. Sufficient replacement parts and supplies will be retained on-site for the air pollution and supporting equipment. Conveyor belts will be equipped with belt scrapers to reduce carry back of material across idlers on the conveyor line. Carry back is that portion of the material that sticks to the belt instead of falling off at the head pulley. Belt scrapers will be checked and adjusted as necessary and any accumulations in conveyor belt enclosures will be removed periodically.

LJS\J:\scopes\06W003\10000\FVD Reports\Air Permit\Fug Dust\R-Fugitive Dust Control Plan.doc Foth Infrastructure & Environment • 6

6 Recordkeeping To ensure the Fugitive Dust Control Plan is effective, records will be maintained for the following activities:

♦ Log sheets will be maintained on-site to document inspections of pressure drop across the baghouses. The form will document what action was taken if one of the baghouses is determined to be outside of operating specifications.

♦ Inspection sheets will be maintained on-site that document periodic maintenance

inspections of the baghouses, including replacement of bags or other pertinent equipment that is associated with proper operation of the baghouse units.

♦ Log sheets will be maintained to record on-site haul truck roadway watering, and

approximate volumes of water used and roadway sweeping. If water is not applied or sweeping performed due to precipitation, snow pack or freezing weather, this information should also be recorded on the form.

♦ Log sheets will be kept showing sweeping performed in the COSA and concentrate load-

out building. Copies of these inspection forms (or similar) are found in Appendix A.

S

1625.3

1594.4

1586.2

1580.9

1578.5

1575.5

1577.2

1577.7

1575.6

1574.4

1567.3

1562.9

1582.3

1578.7

1577.5

1573.61572.5

1572.31572.6

1581.3

1568.6

1574.41569.2

1571.9

1572.5

1572.8

1571.7

1572.3

1570.8

1569.5

1571.8

1577.7

1569.2

1573.2

1571.3

1570.4

1569.8

1575.7

1570.8

1571.8

1571.7

1577.01572.4

1571.4 1570.5

1575.1

1575.0

1581.3

1546.7

1554.11562.7

1553.5

1633.1

1580.3

1583.9

1571.7

1573.2

1579.8

1580.6

1579.8

1575.21581.5

1578.2

1583.2

1573.6

1583.3

1571.6

1573.4

1587.1

1625.1

1661.3

1584.9

1720.81722.8

1742.9

1737.0

1740.1

1538.1

W.E.

1563.5

1600.9

1576.5

1585.01587.6

1594.9

1597.6

1604.5

1651.8

1586.3

1587.1

1582.5

1621.5

1698.6

1686.8

1690.4

1662.51720.7

1713.8

1640.9

1738.8

1739.7

1749.5

1716.6

1760.2

1770.9

1750.9

1758.3

1757.3

1781.5

1775.1

1792.3

1779.7

1797.0

1777.0

1786.6

1791.5

1755.7

1589.3

1589.2

1598.2

1601.5

1593.31594.6 1591.7

1599.5

1591.9

1587.6

1592.41595.0

1593.7

1595.4

1594.7

1605.1

1604.9

1726.2

1752.6

1705.3

1795.9

1732.2

1782.7

1784.8

1788.2

1793.5

1794.9

1790.9

1802.1

1795.1

1796.5

1762.4

1736.3 1723.2

1754.9

1777.8

1781.9

1785.1

1769.9

1778.7

1777.3

1787.0

1785.0

1787.2

1776.9

1689.2

1601.6

1614.3

1612.5

1603.0

1600.3

1606.5

W.E.

1797.2

W.E.

P

W.E.

W.E.

1721.9

V-90

1587.50

H-84

1569.8

1569.2

1572.3

1568.6

1573.8

1570.5

1571.1

1576.9

1574.4

1572.5

1567.9

1570.5

1577.1

1567.9

1570.6

1568.4

1568.6

1568.4

1567.9

SWAMP ELEV

1570 1604.3

1598.9

1592.8

1589.2

1603.9

1579.0

1600.2

1610.1

1590.1

1607.1

1611.2

1607.9

W.E.

W.E.

L:\06w003\Fuguitive_dust_plan\fug_dust_site_plan.dgn

bjw112/16/2008

Scale: Date:

REVISED DATE BY DESCRIPTION

CHECKED BY:

APPROVED BY:

APPROVED BY:

DATE:

DATE:

DATE: 06W003

Foth Infrastructure & Environment, LLC

Prepared By: Project No.

AUG. ’08

AUG. ’08 AUGUST, 2008

X X X XX X X

AS SHOWN

JOW

1.

2.

3.

UNPAVED ROAD

TREE

TREE LINE

LEGEND

NOTES:

STREAM/LAKE

BUILDING

TRAIL

PAVED ROAD

4. CONTOUR INTERVAL SHOWN IS 2 FOOT.

1570

1705.3 SPOT ELEVATION

SURFACE WATER

KEMC PROPECT LOCATION

ELECTRICAL

SUBSTATION

FORMER

PELLET

PLANT

WATER TANKS

MILL FEED

CONVEYOR

BITUMINOUS PAVED AREA

CMP CULVERT

FENCE

CONTOUR INTERVAL BASED ON NORTH AMERICAN

VERTICAL DATUM OF 1988. HORIZONTAL DATUM

BASED ON NAD 83/96. HORIZONTAL COORDINATES

BASED ON MICHIGAN STATE PLANE.

SEPTIC SYSTEM

STORMWATER

OUTFALL

FACILITY

WATER TOWER

RAILROAD SPUR

HUMBOLDT TAILINGS

DISPOSAL FACILITY (TDF)

FIGURE 1-1

CED1

KEMC PROPERTY BOUNDARY WITHIN

SECTIONS 2 AND 11 T47N, R29W, HUMBOLDT

TOWNSHIP, MARQUETTE COUNTY, MICHIGAN.

EXISTING ELEV.

CONTOUR IN FEET

0 150’ 300’

HUMBOLDT MILL PROJECT

SITE PLAN

622,000 N

621,000 N

26,018,000 E 26,020,000 E 26,021,000 E26,019,000 E

623,000 N

RAILROAD

SPUREMPLOYEE/

VISITOR PARKING

GATE HOUSE

MILL

ENTRANCE

TRANSFER

STATION

5. LOCATION OF FENCE LINE HAS BEEN ESTABLISHED

FOR PURPOSES OF AIR PERMIT APPLICATION ONLY.

ACTUAL FENCE LINE MAY EXTEND FURTHER NORTH

AROUND ENTIRE HTDF. RECEPTORS FOR

AIR DISPERSION MODELING WILL BE PLACED

OUTSIDE THE FENCE AREA.

STACK LOCATIONS

CONCENTRATE

CONVEYORS

CONCENTRATE

LOADOUT BUILDING

MILL

BUILDING

TOPOGRAPHIC AND PLANIMETRIC DATA SUPPLIED

BY AERO-METRIC ENGINEERING, SHEBOYGAN,

WISCONSIN. DATE OF PHOTOGRAPHY:

APRIL 27, 2006.

OLD CRUSHER BUILDING

SECONDARY CRUSHER

TERTIARY CRUSHER

DUMP POCKET/PRIMARY CRUSHER

GRAVEL SURFACE

HUMBOLDTTAILINGSDISPOSALFACILITY

GRAVEL

ROAD

AKM

SCALE

HAUL TRUCK ROUTE

WWTP

LJS\J:\scopes\06W003\10000\FVD Reports\Air Permit\Fug Dust\R-Fugitive Dust Control Plan.doc

Appendix A

Inspection Forms

LJS\J:\scopes\06W003\10000\FVD Reports\Air Permit\Fug Dust\R-Fugitive Dust Control Plan.doc

On-Site Roadway Watering and Sweeping Documentation Form Ore Truck Route

Date: ________ Roadway Segment: ________________________

Name of Employee: ______________________ 1. Was watering applied to this segment on this day? Yes ___ No ___ 2. If yes to the above, what was the watering schedule? First Shift _______________________ Second Shift _______________________ 3. What was the approximate volume of water used? Gallons ________________________ 4. If water was not used, identify the reason: Precipitation Snow Pack or Freezing Conditions No traffic during the entire period 5. Was sweeping performed on this segment on this day? Yes ___ No ___ Note time: _____________________________ Comments: ______________________________________________________________________________ ______________________________________________________________________________ ______________________________________________________________________________

LJS\J:\scopes\06W003\10000\FVD Reports\Air Permit\Fug Dust\R-Fugitive Dust Control Plan.doc

COSA Floor Inspection and Cleaning Program Sweeping Schedule

Date Time Employee Task Description Used

(check one or both)

Comment: Industrial Sweeper Broom

Comment:

Industrial Sweeper Broom

Comment:

Industrial Sweeper Broom

Comment:

Industrial Sweeper Broom

Comment:

Industrial Sweeper Broom

Comment:

Industrial Sweeper Broom

Comment:

Industrial Sweeper Broom

Comment:

Industrial Sweeper Broom

Comment:

Industrial Sweeper Broom

Comment:

Industrial Sweeper Broom

Comment:

Industrial Sweeper Broom

Comment:

Industrial Sweeper Broom

Comment:

Industrial Sweeper Broom

Comment:

Industrial Sweeper Broom

Comment:

Industrial Sweeper Broom

Comment:

Industrial Sweeper Broom

Comment:

Industrial Sweeper Broom

Comment:

Industrial Sweeper Broom

Comment:

Industrial Sweeper Broom

Comment:

Industrial Sweeper Broom

LJS\J:\scopes\06W003\10000\FVD Reports\Air Permit\Fug Dust\R-Fugitive Dust Control Plan.doc

Concentrate Load-Out Building Floor Inspection and Cleaning Program Sweeping Schedule

Date Time Employee Task Description Used

(check one or both)

Comment: Industrial Sweeper Broom

Comment:

Industrial Sweeper Broom

Comment:

Industrial Sweeper Broom

Comment:

Industrial Sweeper Broom

Comment:

Industrial Sweeper Broom

Comment:

Industrial Sweeper Broom

Comment:

Industrial Sweeper Broom

Comment:

Industrial Sweeper Broom

Comment:

Industrial Sweeper Broom

Comment:

Industrial Sweeper Broom

Comment:

Industrial Sweeper Broom

Comment:

Industrial Sweeper Broom

Comment:

Industrial Sweeper Broom

Comment:

Industrial Sweeper Broom

Comment:

Industrial Sweeper Broom

Comment:

Industrial Sweeper Broom

Comment:

Industrial Sweeper Broom

Comment:

Industrial Sweeper Broom

Comment:

Industrial Sweeper Broom

LJS\J:\scopes\06W003\10000\FVD Reports\Air Permit\Fug Dust\R-Fugitive Dust Control Plan.doc

Baghouse Pressure Drop Inspection Checklist

Baghouse Identification:______________________ Date of Inspection:______________________ Name of Inspector:______________________ Baghouse Manometer Reading: ___________ inches of water 1. Was baghouse manometer reading within manufacturer’s specifications? Yes ___ No ___ 2. If not, was corrective action performed to determine cause of the malfunction? (Describe results of the investigation in the Comments section below) Yes ___ No ___ 3. Were there any visible emissions from the baghouse? (If yes, describe below in the Comments section the corrective action that was taken) Yes ___ No ___ Comments:____________________________________________________________________ _____________________________________________________________________________ _____________________________________________________________________________ _____________________________________________________________________________ _____________________________________________________________________________

LJS\J:\scopes\06W003\10000\FVD Reports\Air Permit\Fug Dust\R-Fugitive Dust Control Plan.doc

Baghouse Maintenance Checklist

Baghouse Identification:______________________ Date of Inspection:______________________ Name of Inspector:______________________ Daily Maintenance 1. Check pressure drop _____ 2. Monitor gas flow rate _____ 3. Observe baghouse outlet visually _____ 4. Walk through baghouse area to check for abnormal and audible conditions _____ Weekly Maintenance 1. Check all moving parts on the discharge system _____ 2. Check damper operation; bypass, isolation, etc. _____ 3. Spot check bag tensioning for reverse-air and shaker bags _____ 4. Check compressed air lines including line oilers and filters _____ 5. Blow out any dust from manometer lines _____ 6. Verify temperature-indicating equipment _____ 7. Check bag-cleaning sequence to see that all valves are seating properly _____ 8. Check drive components on fan _____ Monthly Maintenance 1. Spot check bag-seating condition _____ 2. Check fan for corrosion and blade wear _____ 3. Check all hoses and clamps _____ 4. Spot check for bag leaks and holes _____

LJS\J:\scopes\06W003\10000\FVD Reports\Air Permit\Fug Dust\R-Fugitive Dust Control Plan.doc

Quarterly Maintenance 1. Thoroughly inspect bags _____ 2. Check bag for dust buildup _____ 3. Observe damper valves for proper seating _____ 4. Check gaskets on all doors _____ 5. Inspect baffle plate for wear _____ 6. Clean conveyor belts _____ Annual Maintenance 1. Check all welds and bolts _____ 2. Check hopper for wear _____ 3. Replace high-wear parts on cleaning system _____ Comments:____________________________________________________________________ _____________________________________________________________________________ _____________________________________________________________________________ _____________________________________________________________________________ _____________________________________________________________________________

Related Documents