SIOEN INDUSTRIES I ANNUAL REPORT 2004 01

Annual report 2004 part 2

Mar 22, 2016

Annual report 2004 part 2

Welcome message from author

This document is posted to help you gain knowledge. Please leave a comment to let me know what you think about it! Share it to your friends and learn new things together.

Transcript

SIOEN INDUSTRIES I ANNUAL REPORT 2004

01

3 Sioen Industries, always and everywhere4/5 Key fi gures6 Profi le of Sioen Industries7 Key fi gures by division8/9 Mission and strategy 10/11 Important events & Prospects12/13 Letter to the shareholders14/15 Report of the Board of Directors16 Vertical integration17 Sioen worldwide 18 Group structure19/26 Coating Division27/32 Apparel Division33/38 Processing Division39/55 Corporate Governance57 Staff58 Environmental policy59 Quality60/61 R&D62/63 Share information

64/65 Financial review 97 Financial calendar98/99 Addresses

On, May 10, 2005, the Banking, Finance, and Insurance Commission authorized Sioen NV to use the present Annual Report as a reference document each time it publicly offers securities pursuant to the law of April 22, 2003 relating to public offerings of securities, by means of the procedure of dissociated information, and this until publication of its next Annual Report. In the context of this procedure, a transaction note needs to be attached to the Annual Report. The Annual Report, together with the transaction note, constitute the issue prospectus in the senseof Chapter IV of the law of April 22, 2003. In accordance with Article 14 of the law of April 22, 2003, this prospectus must be submitted to the Banking, Finance, and Insurance Commission.

Only the Dutch version of the annual report has evidential value. This version can be obtained on simple request from Sioen Industries’ head offi ce.

03

Navigation, fi shing industry and water sports Flotation suits, life jackets, protective aquatic clothing, infl atable boats, boat tarpaulins, yacht canvas, ship tarpaulins

Air and water treatment Filters, air conditioning and mine shaft air ducts

Public institutions Clothing, fi remen’s clothing, clothing for police and army,railways, airlines and post offi ces, tents and truck tarpaulins

Publicity and promotion Indoor and outdoor publicity banners, promotional clothing

Construction and road works Reinforcement for gyproc plates, insulation, road fortifi cation, rubble nets for scaffoldings, high visibility protective clothing,silos, storage tents, sun screens, sewage, fi lters

Interior decoration Yarns and pigments for carpets, wall coverings, insulation,ceilings, etc.

Corporate identity wear Clothing for courier services, electricity companies, petrol stations,breweries, telecom companies, airlines, etc.

TransportTruck tarpaulins and curtains, mud fl aps, infl atable containers, railway wagon tarpaulins, protective and industrial clothing for railway, bus, transport and airline companies

Tents Camping tents, party tents, awnings, canopies, halls, semi-perma-nent buildings, kadors

Sports Gym mats, buffers, partition walls in sports centres, children’s playing mats, clothing for hunters, golfers and fi shermen, motor-cyclist’s clothing, safety nets, refl ective clothing for joggers,cyclists and other outdoor sportsmen, pool covers and pool rein-forcement nets, camoufl age clothing for hunters, surfer’s, ski and skater’s clothing

Automobile Airbags, dashboards, sun shades, door panels, gearlever covers, fl oor mats, seats, fi lters, trunk curtains

Agriculture, horticulture, forestry and food industry Windbreak nets, drainage, protective clothing, damming fi lm,fi lters, pond foil, ultra-low temperature clothing, hygienic protec-tive clothing

Chemistry and petrochemistry Specifi c protective clothing, oil dams, fi lters

Medicalprotective clothing, air fi lters, mattress covers, pillow-cases

Sioen industries always and everywhere

‘93 ‘94 ‘95 ‘96 ‘97 ‘98 ‘99 ‘00 ‘01 ‘02 ‘03 ‘04

40

35

30

25

20

15

10

5

35

30

25

20

15

10

5

20%

16%

12%

8%

4%

‘93 ‘94 ‘95 ‘96 ‘97 ‘98 ‘99 ‘00 ‘01 ‘02 ‘03 ‘04

‘93 ‘94 ‘95 ‘96 ‘97 ‘98 ‘99 ‘00 ‘01 ‘02 ‘03 ‘04

100%

80%

60%

40%

20%

31-12

-’96

31-12

-’97

31-12

-’98

31-12

-’99

31-12

-’00

31-12

-’01

31-12

-’02

31-12

-’03

31-12

-’04

50

40

30

20

10

0

1.000

2.000

3.000

4.000

5.000

'94'93 '95 '96 '97 '98 '99 '00 '01 '02 '03 '04

4.500

3.638

862

‘93 ‘94 ‘95 ‘96 ‘97 ‘98 ‘99 ‘00 ‘01 ‘02 ‘03 ‘04

100

5050%

45%

200

150 55%

60%

65%250

300

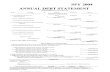

Key fi gures 1993/2004 (in millions of EUR)

Group profi t Consolidated cash fl ow EBIT EBIT/Turnover Cash fl ow/Turnover

Investments in 1993/2004 (in millions of EUR)

Added value Gross margin Turnover Gross margin %

Financing of assets 1993/2004 (in %)

Development of employment 1993/2004

Stock price (to 31 December 2004) (in EUR)

Total Workers Salaried employee& Management

ST liabilities Provisions

LT liabilities Capital & reserves/minority interests

Sioen Euro stoxx 50

05

CONSOLIDATED KEY FIGURES (in millions) 2004 2003 2002 2001 2000 1999 1998 1997 1996 1995 1994 EUR EUR EUR EUR EUR EUR EUR EUR EUR EUR EURTurnover 311,6 272,8 237,7 226,0 192,4 161,1 141,2 107,9 85,1 66,8 48,4Operating profi t 29,8 27,2 24,6 33,8 32,6 28,4 19,6 15,0 9,7 7,7 4,8Financial result (10,8) (11,0) (8,7) (6,7) (3,0) (1,3) (1,7) (1,2) (1,1) (1,9) (2,0)Profi t on ordinary activities before taxation 19,0 16,2 15,9 27,1 29,6 27,1 17,9 13,8 8,6 5,8 2,7Profi t on ordinary activities after taxation 13,8 8,9 11,0 17,3 19,0 17,6 12,3 9,1 6,8 4,5 2,2EBIT (9) 26,7 24,4 23,1 32,4 31,5 27,3 19,0 14,5 9,2 7,2 EBITDA (10) 49,8 52,8 42,8 50,9 45,0 37,8 27,1 19,6 13,2 10,3 Net profi t (group’s share) 11,6 8,6 10,0 16,9 18,8 18,6 12,2 9,0 6,5 4,3 2,0 Capital and reserves 129,2 123,5 125,3 123,9 112,0 97,5 79,8 33,6 25,1 18,6 14,7Minority interests 0,0 2,3 2,0 1,5 1,3 1,1 0,8 0,6 0,4 0,4 0,3Permanent capital (2) 205,4 224,4 231,5 220,4 191,2 166,7 132,7 75,1 59,3 35,8 26,2Long-term fi nancial debt 68,6 89,0 95,1 83,4 66,2 57,3 42,5 35,8 30,3 14,0 8,7Net fi nancial debt (3) 117,6 148,1 134,6 118,4 91,6 71,1 56,7 44,7 40,6 31,1 22,2Balance sheet total 331,8 346,9 331,8 310,3 262,9 227,6 185,3 112,6 89,5 70,1 51,9 Working capital (4) 88,3 108,9 118,5 117,3 101,4 81,4 73,6 43,6 40,7 31,7 20,9 Cash fl ow (5) 36,0 37,3 30,2 35,8 32,5 29,5 20,7 14,2 10,8 7,6 4,9Net investment in tangible fi xed assets (11) 7,1 11,9 30,6 27,1 27,4 28,3 22,4 15,6 10,9 4,5 0,7Fixed assets 167,1 175,8 153,1 138,9 115,7 99,5 73,6 40,7 29,1 21,9 19,0Depreciation & amortization 23,2 22,1 19,8 18,6 14,1 11,6 7,1 4,7 3,2 2,8 2,5Personnel costs 59,0 54,5 47,0 42,8 34,5 30,9 24,1 17,3 13,0 10,3 7,5Number of employees 4.500 4.689 4.271 3.924 3.420 2.857 2.555 1.552 1.231 930 725(in units) Ratios Liquidity (current assets/short-term debt) 1,30 1,40 1,78 1,91 2,05 2,11 2,12 1,92 2,00 1,40 1,28Solvency (capital and reserves/balance sheet total) 38,9% 35,6% 37,7% 39,9% 42,6% 42,8% 43,1% 29,8% 28,1% 26,5% 28,4%Net fi nancial debt/capital and reserves 0,91 1,20 1,07 0,96 0,82 0,73 0,71 1,33 1,62 1,68 1,51Return on equity (6) 9,4% 6,9% 8,1% 15,1% 19,3% 23,4% 36,3% 35,7% 34,8% 29,1% 15,7%ROCE (7) 10,5% 10,0% 9,6% 15,6% 18,1% 19,3% 23,3% 21,5% 18,3% 19,4% 13,5%Net profi t margin (8) 4,0% 3,3% 4,4% 7,6% 9,9% 11,8% 8,9% 8,5% 7,9% 6,8% 4,4%Cash fl ow/turnover 11,6% 13,7% 12,7% 15,8% 16,9% 18,3% 14,6% 13,2% 12,7% 11,4% 10,1%

(2) Capital and reserves + minority interests + provisions for liabilities and charges + amounts payable after one year.(3) Financial debt – cash deposits and cash at bank and in hand (4) Financial fi xed assets + current assets (minus cash deposits and cash at bank and in hand) – non fi nancial debt up one year – accrued charges and deferred income.(5) Consolidated net profi t + depreciation & amortization + provisions for liabilities and charges + write-downs (6) Profi t for the year (group’s share) /capital and reserves at end of previous fi nancial year. (7) Operating profi t/ ((capital and reserves + minority interests + provisions for liabilities and charges + net fi nancial debt) at the start of the period).(8) Net profi t /turnover for the fi nancial year.(9) Earnings Before Interest and Taxes = Operating profi t – Amortization of consolidation differences (goodwill)(10) Earnings Before Interest, Taxes, Depreciation and Amortisation = Operating profi t + depreciation & amortization + provisions for liabilities and provisions + write-downs .(11) Purchases of tangible fi xed assets - transfers and decommissionings and booking out of related depreciation

Consolidated key fi gures per share (2) 2004 2003 2002 2001 2000 1999 1998 1997 1996 1995 1994 EUR EUR EUR EUR EUR EUR EUR EUR EUR EUR EUROperating profi t 1,39 1,27 1,15 1,58 1,52 1,33 0,92 0,75 0,48 0,38 0,24Profi t on ordinary activities after taxation 0,65 0,42 0,52 1,27 0,89 0,82 0,58 0,43 0,32 0,21 0,10Net profi t (group’s share) 0,54 0,40 0,47 0,79 0,88 0,87 0,57 0,45 0,32 0,21 0,10Cash fl ow 1,68 1,74 1,41 1,67 1,52 1,38 0,97 0,71 0,54 0,38 0,24Consolidated capital and reserves 6,04 5,77 5,86 5,79 5,24 4,56 3,73 1,68 1,26 0,93 0,74Gross dividend 0,22 0,20 0,17 0,16 0,14 0,12 0,09 0,07 0,05 - -Net dividend 0,16 0,15 0,13 0,12 0,11 0,09 0,07 0,05 0,04 - -Pay-out (%) 40,7% 49,8% 35,9% 20,2% 15,8% 14,2% 15,7% 15,5% 14,5% - -Maximum share price 10,70 9,16 14,95 23,51 33,65 47,5 43,13 10,68 4,02 - -Minimum share price 8,24 4,70 6,00 10,1 18,4 28,5 9,92 3,92 3,84 Price at Dec. 31. (3) 10,29 8,24 7,65 11,50 20,90 33,00 38,18 9,97 3,92 - -Change in share price (5) 35% 8% -33% (45%) (36,7%) (14%) 283% 154% 13% - -Price/Earnings ratio (6) 19,1 20,5 16,4 14,5 23,8 37,9 67,0 22,1 12,1 - -Price/Cash fl ow ratio (7) 6,1 4,7 5,4 6,9 13,8 23,9 39,4 14,0 7,3 - -Average daily trading volume (no. of shares) (4) 6.550 4.406 5.310 5.104 9.548 13.216 26.671 20.950 43.410 - -Average monthly trading volume (no. of shares) (4) 137.559 92.895 112.837 107.194 199.710 277.530 557.863 434.762 855.860 - -Annual trading volume (in EUR millions ) 16,2 8,3 10,4 20,7 63,7 122,5 162,6 33,9 8,2 - -Number of Sioen Industries shares outstanding (in thousands) (2) 21.391 21.391 21.391 21.391 21.391 21.391 21.391 19.965 19.965 19.965 19.965Stock market capitalisation (in EUR millions) (5) 220,1 176,3 163,6 246,0 447,1 705,9 816,6 199,0 78,2 - -

(2) Recalculated after the 1 to 55 share split by 55 on 13/09/96 and the 1 to 10 split on 05/11/98.(3) On March 31, 2005 the price of the Sioen Industries share was EUR 9.65 per share.(4) 1996 data are strongly infl uenced by the high volumes just after the stock market fl otation of 18 October 1996.(5) Price at end-December.(6) Share price/net profi t (group share) per share(7) Share price/cash fl ow per share

Spreading risk through diversifi cationThe products that Sioen Industries brings onto the market are varied but have technical complexity as their common denomi-nator. Our company slogan is: ‘Protection through innovation’. We protect people and property with high-tech protective clothing for all industrial sectors and with technical textiles for truck tarpaulins and curtains, airbags, swimming pool covers, tents and structu-res, windbreak nets, water tanks, oil dams, road reinforcements, etc.

Permanent research and developmentSioen Industries is an innovative company in terms both of pro-duction techniques and of applications and markets. With input from a high-performing sales and marketing team and develop-ment work by a quality R&D team, we are constantly identifying new applications. A good R&D policy is essential for a knowledge-intensive company such as Sioen Industries. We are acutely aware that innovation is possible only with new know-how ac-quired through a systematic search for solutions to practical pro-blems. This combination of business ideas and research leads to completely new or improved products and production proces-ses.This work is carried out by Sioen Industries’ own research and development staff, either alone or in cooperation with other com-panies, research institutions and universities.

Financial strength Sioen Industries has an excellent fi nancial base. Turnover has ri-sen by 93% in the past 5 years to EUR 311.60 million in 2004. In the same period capital and reserves have increased from EUR 97.5 million to EUR 129.2 million and operating cash fl ow (EBIT-DA) from EUR 37.8 to EUR 49.8 million (+ 32%).

Expertise and experience: 45 years of SioenIn 1960, now 45 years ago, Mr Jean-Jacques Sioen started the fi rst coating line in Beveren (Belgium). It was a line with two workers, but it marked the beginning of Sioen Industries as we know it today - a solid listed company with some 35 sales and production sites, 4,500 employees and turnover of EUR 311.6 million. Since then, Sioen Industries has become the global mar-ket leader in coated technical textiles, European market leader in industrial protective clothing, a niche specialist in fi ne chemicals, and processes technical textiles into semi-fi nished products and technical fi nal products.

Three divisions under one roofThe Coating division is the global market leader in the integra-ted coating of technical textiles and controls the entire production process from the extrusion of yarn (spinning), through the weaving of technical cloth and production of pigment pastes and granules to coating with various materials. This vertical integration is an undeniable competitive advantage.

The Apparel division is the market leader in the design and production of high-value protective clothing for both industrial and recreational applications. Quality and fl exibility characterize Sioen’s reputation in this fi eld.

The Processing division is responsible for processing coated fa-brics and PVC fi lms. The division includes all of the group’s heavy confection activities: pond foil, kadors, airbags, side curtains and tarpaulins, fi lters, sliding gates, etc. Sioen is also one of the largest global players in these activities.

Activities were partially reorganized in 2004 with the integration of the production of pigment pastes and granules into the coating division. Vertical integration in this division is now complete.

A global player operating worldwideSioen Industries has facilities in 15 different countries, sells in 68 countries and has 19 nationalities among its staff.

Profi le of Sioen Industries

Key fi gures per division

07

Turnover by geographical markets.

Coating division Apparel division Processing division 01 Benelux 18,4% 23,3% 20,2% 02 France 20,4% 31,6% 12,1% 03 Germany 12,3% 7,8% 47,3% 04 UK 6,1% 16,2% 8,7% 05 Spain 4,9% 0,7% 0,4% 06 Scandinavia 4,1% 1,7% 0,9% 07 Switzerland 1,7% 2,8% 0,1% 08 Eastern bloc countries 12,0% 0,5% 2,6% 09 Austria 1,5% 2,1% 0,4% 10 Ireland 0,5% 4,0% 0,1% 11 USA 0,6% 4,6% 3,7% 12 Italy 7,7% 0,7% 1,3% 13 Other 9,9% 4,0% 2,3%

‘93 ‘94 ‘95 ‘96 ‘97 ‘98 ‘99 ‘00 ‘01 ‘02 ‘03 ‘04

1630,1

43,754,9

70,486,9

100,4

119,1134 139,7

151,6

172

Key fi gures 2004 2003 2002 2001 2000 1999 1998 1997 1996 1995 1994 EUR EUR EUR EUR EUR EUR EUR EUR EUR EUR EUR

Coating division *Third party turnover (in millions) 172,0 151,6 139,7 134,0 119,1 100,4 86,9 70,4 54,9 43,7 30,1Investments 5,5 10,0 25,3 21,8 21,2 20,2 17,6 12,4 10,2Employees on 31/12 764 749 637 621 625 461 387 226 172 121 98

Apparel divisionThird party turnover (in millions) 68,2 71,5 71,9 75,8 62,0 48,6 44,8 31,4 24,6 21,1 17,0Investments 0,9 1,2 3,5 5,3 3,8 4,8 2,3 1,5 0,7 Employees on 31/12 2.921 3.186 3.207 3.151 2.659 2.271 2.062 1.234 992 777 598

Processing divisionThird party turnover (in millions) 71,4 49,6 26,0 16,2 11,3 12,0 9,4 6,1 5,7 2,0 1,3 Investments 0,2 0,3 1,7 0,0 1,8 3,1 1,7 1,4 0,1 Employees on 31/12 766 717 143 120 104 93 84 72 51 17 17

* Coating division including EMB & Inducolor for all years.

‘93 ‘94 ‘95 ‘96 ‘97 ‘98 ‘99 ‘00 ‘01 ‘02 ‘03 ‘04

1317

21,124,6

31,4

44,848,6

62

75,8 71,9 71,568,2

‘93 ‘94 ‘95 ‘96 ‘97 ‘98 ‘99 ‘00 ‘01 ‘02 ‘03 ‘04

1,1 1,3 25,7 6,1

9,4 12 11,316,2

26

49,6

71,4

Turnover 1993-2004 (in millions of euros)After eliminating intra-divisional sales

Coating division Apparel division Processing division

1

2

345

67

8

91011

12

131

23

4

56789

1011

12 131

2

3

45689111213

Mission and Strategy

Diversifi cation and market penetrationMarket sectors:Sioen Industries is loyal to its policy of vertical and horizontal integration through the development of new products and the acquisition of complementary companies. Geographical spread:Sioen Industries explores new markets and develops existing ones.

Innovation: development and investmentSioen Industries wishes to maintain and develop its technical lead in all the sectors in which it operates.The development and research team is continuously reinforced and supported with people, materials, buildings and test lines. Processes at existing plants are constantly evaluated and adapted to the latest technological developments.Sioen Industries invests in new sites and in modernising existing ones.

People and the environmentSioen Industries creates a stimulating working environment with career opportunities and space for entrepreneurship andcreativity.Sioen Industries has an active environmental policy and invests in recycling and energy recovery technology.

MissionSioen Industries: protection through innovation.

We have a strong profi le in the production, development and sales of coated technical textiles, protective clothing and fi nechemicals. Quality and fl exibility go hand in hand with cost-effectiveness and added value.

StrategySioen Industries’ long-term strategy is one of vertical integrati-on with a focus on sustainable growth, quality, innovation and profi tability. In our case, vertical integration means having the complete production process from raw material to the fi nished product in our own hands: we spin, weave, coat, make pigments and cut and process technical textiles.

Herdfg jhfhfyf

09

Important events & prospects

Important events in 2004At the end of 2004 Sioen acquired the 25% minority interests in Coatex, Saint Frères Confection and Bacam. The acquisition price was EUR 5.8 million, of which EUR 2.9 million has been recognized under consolidation differences. The minority interest in the 2004 net profi t is EUR 0.8 million.

Signifi cant events after the balance sheet dateFollowing a strategy change at the Mercator Verzekeringeninsurance group, it was agreed by mutual consultation on February21, 2005 to terminate the shareholders agreement between Mercator Verzekeringen and Sihold n.v.. At that date, Mercator Verzekeringen held 2.8% of Sioen Industries n.v..

MJS Consulting bvba, whose permanent representative is MicheleSioen, was appointed as Managing Director of Sioen Industries n.v. on March 22, 2005.

ProspectsIn a more general context we can state that the focus for 2005 lies on further improving the group’s profi tability. Each company that has diffi culties in achieving the internally defi ned profi tability criteria will be examined in detail, and appropriate action will be taken.

At the same time we can assume that the revival in the truck sec-tor will be refl ected in direct coating (Coating division) and the associated production of truck and train tarpaulins (Processingdivision). R&D is of central importance in both divisions: Sioen has developed a zip system for advertising on truck side curtains (Publicity banners are zipped onto truck side curtains. In this way the advertising message can be changed quickly without having to replace the entire curtain), improved the siosteel concept (anti-vandalism cloth for trucks) and patented a high-tech anti-radar net. These and many other developments will reinforce Sioen’s market leadership even further.

In the Apparel division, the group intends to continue to focus on high-quality technical products. ‘Protection through innova-tion’ in the Apparel division means further development of niche markets with high added value where technical complexity isimportant, i.e. intelligent clothing, bullet and knife-proof vests, etc. It has also been decided to exploit this know-how in non-industrial markets. Sioen recently competed successfully for an order for the French army on this basis.

11

Letter to the shareholders

FocusDuring the past 2 years Sioen Industries has focused on im-proving the company’s creditworthiness. Balance sheet control has been an absolute priority and in 2004 the results of theseefforts can be described as more than satisfactory. Over two years, working capital has fallen from around 50% of turnover to under 30%. The net fi nancial debt position has been pushed down from EUR 148 million to EUR 118 million and ‘capitalemployed’(1) has reduced to 83 eurocent per euro of turnover. The goals of two years ago have thus been convincingly reached.

Entrepreneurship means constantly setting goals and realisingthese. In the coming years we wish to put the focus on‘profi tability’. This is fully in line with the group’s strategy (see page 8), where the challenge is again to continue achievinghigher turnover with an improved ROCE.(1) working capital + fi xed assets

Customer relations and marketsSioen Industries was very successful in developing customer relations and growing turnover in 2004. The internal growth in turnover in 2004 is the result of partnerships with existing cus-tomers (that is, close cooperation between Sioen and the cus-tomer-partner in planning, logistics, sales efforts, IT, promotion and communication), active prospecting and acquisition of new customers. The group will certainly continue to pursue the same course in coming years. A more intensive effort will also be made to win tenders. In 2004 the Apparel division gained an important contract to supply protective clothing for the French army (total revenues over 5 years: EUR 42 million).

Sioen has a strong presence in the traditional West European markets where market penetration is high. It nonetheless plans further growth in these markets through product developments. Turnover in Eastern Europe has risen spectacularly in recent years due to intensive sales and marketing efforts. We will continue to grow here in the coming years with our existing and new pro-ducts. The US will also gain in importance in the next few years with the establishment of an additional sales offi ce there (begin-ning of 2005). Sioen also continues to profi le itself as a quality supplier of technical textiles in Asia.

Dear Shareholder,

We are pleased to present the 2004 annual report for yourattention.

Turnover rose by 14.23% to EUR 311.6 million. This strong and largely internally generated (8.65%) growth is the result of the investments made by the group in recent years. EBITDA and cash fl ow were EUR 49.8 million (16% of turnover) and EUR 36.0 million (11.6% of turnover) respectively. Net profi t after taxation was EUR 12.4 million, up no less than 38% compared with last year.

13

New Managing DirectorThe new corporate governance charter which comes into force after the May 2005 general shareholders’ general meeting, pro-vides among other things for a separation of the functions of chairman and CEO. As a result, I and my wife Jacqueline Sioen-Zoete have resigned as Managing Director of Sioen Industries and MJS-Consulting bvba, whose permanent representative is Michèle Sioen, has been appointed as Managing Director.

The 2004 results and the long-term strategy that we are imple-menting undoubtedly herald an attractive future. Sioen Industries will continue to respect the fundamental values that we have already promoted for 45 years.

It is clear that we are unable to achieve our goals, the pursuit of long-term profi tability and the creation of value for our sharehol-ders without the contribution of over 4,500 employees world-wide.

J.J. Sioen ChairmanManaging Director

J.N. Sioen-Zoete

Managing Director

PortfolioProduct diversifi cation has always been on the agenda at Sioen. You can read the sectors in which Sioen operates on page 3 of this annual report. The new products the group has developed are the result of intensive R&D. The research and development team works in close consultation with customers, sales staff, marketing specialists, production managers, buyers, universities and external research centres to achieve new ‘ready for market’ products.

Sioen’s success stories in 2004 included the development of a new type of trunk curtain for cars, an updated version of Siosteel (an anti-vandalism side curtain for trucks), bullet and knife-proof vests, a unique breathing fl otation suit, coated airbags and apatented anti-radar net.

Product development is a permanent process, where the group’s vertical integration is an important advantage.

Production processThe group’s production system plays an important role in the operating result. Optimisation, speed, planning and effi ciency are the keys to success in a production-driven company such as Sioen. The course has been set to achieve an even better perfor-mance in existing production plants than in 2004. A well-thought out investment policy will lead to even greater cost analysis and control.

Redefi nition of the divisionsSioen Industries comprises 3 divisions (coating, apparel and pro-cessing) and an umbrella group structure (IT, fi nance, HR, legal department and marketing). IFRS has provided the impetus for a logical restructuring of activities within the Sioen group.Apart from a few shifts, the three divisions remain unchanged, each with its own core activities. The Coating division encompas-ses all activities leading to the production of coated technical textile (see pages 19-25): spinning, weaving, dyeing (pigment pastes, granules and varnishes) and coating. The Apparel division includes the production and sale of protective clothing. Finally, the Processing division includes all heavy confection activities. This latter division becomes the ‘Industrial applications’ division as from 2005.

Report of the Board of Directors

- To complete the product range and to secure our commercial position, “low end” products were imported from the Far East and placed on the market here at a competitive price.- Prices of the main raw materials spiralled to their highest levels for fi ve years.- A fairly signifi cant change in sales mix. Pennel and Roltrans, two companies operating in markets with traditionally lower gross margins, were included in the consolidation scope this year for 12 months. Also affecting gross margin was theevolution of Coatex from a services supplier to subcontractor status, where both base material and services are invoiced.

The increase in costs of “services and other goods“ (+EUR 6m) and “personnel costs” (+EUR 4m) can be attributed to the variablecharacter of these costs in relation to the turnover, and to the companies taken over in 2003 and which are now consolidated for a full year.

Depreciation also rose slightly (+EUR 0.7m) in comparison with 2003 as a result of the above-mentioned enlargement of the consolidation scope.

Write-downs on inventory and customer receivables amounted to EUR 0.98m as against EUR 3.4m in 2003(1). Last year a new and quite strict rating system was established. After some neces-sary catching up in 2003, the system is now running at cruising speed.

Provisions for liabilities and charges included three provisionsfor pending disputes amounting to EUR 0.56m. Also under thisheading, a provision(2) built up in previous years to cover a taxdispute was reversed following an out-of-court settlement (EUR 1.7m), with a positive impact of EUR 1m on operating profi t. The cost of the settlement (EUR 1m) is recorded under the taxes heading.

Other operating charges are mainly local taxes, which are not profi t-related, such as the “taxe professionnelle” in France and property tax in Belgium.

Operating profi t, at EUR 29.8m, is up 9.44% on 2003.

Operating cash fl ow (EBITDA) comes to EUR 49.8m or approxi-mately 16% of turnover. This slight dip of 5,7% in comparison with 2003 can be fully ascribed to a changed competitive envi-ronment and the associated fall in gross margin % on turnover.

Dear Shareholder,

The Board of Directors is pleased to report to you on the activities of the Sioen Industries group and to submit the annual accounts for the year ended on December 31, 2004 to the general mee-ting of shareholders for approval.

In 2004 the Sioen Industries group achieved a turnover of 311.6m compared with EUR 272.8m in 2003. Of this 14.23% growth, 8.65% or EUR 23.6m was internally generated, the re-maining 5.58% or EUR 15.2m is external growth.

The coating division increased turnover to 172m, up 13% on last year’s (restated) fi gures. This fi gure includes the turnovergenerated by EMB, which is included this year in the coatingdivision as part of the integrated chain, whereas last year it was still part of the processing division. (EMB or European Master Batch is a Sioen Industries subsidiary specialised in the produc-tion of pigment pastes and granulates.) With one exception, the coating division posted good growth in all product lines, especi-ally “truck” and “textile architecture”, which grew 22% and 34% respectively. The coating division features a high level of vertical integration, enabling it to achieve greater added value on its pro-ducts. Activities are not limited to coating but also include the spinning and weaving of fabric. The coating division now has fi ve coating techniques, each for specifi c technical applications.

Turnover in the apparel division was 68.2m as against 71.5m in 2003. This downward movement can be explained by the continuing commercial pressure on high-volume, low-technicitymarkets. Sioen is focusing on high-technicity products andapplications such as bullet- and knifeproof vests, fl otation suits, fi refi ghting suits, protective clothing for the petrochemical sector, clothing for forest workers, ...

The processing division maintained its strong momentum with turnover of EUR 71.4m in 2004 as against EUR 49.6m in 2003 (after EMB reclassifi cation). This substantial growth of 44% was mainly achieved by Coatex, which specialises in cutting and proces-sing technical textiles, by Nordifa, which produces fi lters and fi ltercloths, and by the Roltrans group where the recent restructuring is producing tangible results.

Group resultsGross margin of 51.7% as against 55% in 2003 was substanti-ally infl uenced by the following parameters:

15

“Next prime” and “Next Economy” segments to publish their con-solidated results from 01/01/2005 onwards in accordance with International Financial Reporting Standards (IFRS).

The interim report for the fi rst quarter of 2005 will be the fi rst fi nancial report presented under the new IFRS rules. For this pur-pose the opening balance drawn up under Belgian accounting principles at 1 January 2004 has been restated to produce the IFRS opening balance at 1 January 2004. The effects of this res-tatement have already been audited and are explained in detail in the 2004 annual report. A reconciliation of the 2004 income statement drawn up according to Belgian accounting principles and the income statement for the same period drawn up ac-cording to IFRS will be given in the interim report for the fi rst quarter of 2005.

DividendThe Board of Directors will be proposing to the general sharehol-ders’ meeting that the company distribute a gross dividend for 2004 of EUR 4.7m or EUR 0.22 per share, an increase of 10% on the previous year.

Minority interestsThe 25% minority interest in the companies Coatex, Saint Frères Confection and Bacam were acquired by the group at the end of the fi nancial year. The minority interest in the profi t for the present fi nancial year amounts to EUR 0.8m.

Mercator bank en verzekeringen As a result of a strategy revision within the Mercator Bank en Verzekeringen insurance group it was mutually agreed on 21 Fe-bruary 2005 to end the shareholder agreement. The shareholder percentage on that date amounted to 2.8%.

Future prospects In a more general context we can state that the focus for 2005 lies in further improving the profi tability of the group. This means that any company which has diffi culties in reaching the internally established profi tability criteria will be subject to a thorough exa-mination, after which appropriate measures will be taken.

At the same time we can assume that the revival in the truck sector will be refl ected in direct coating (coating division) and in related heavy-duty confection, namely the production of tar-paulins for trains and trucks (processing division). R&D is central to both divisions: Sioen patented a zip system for advertising on retractable truck curtains, improved the siosteel concept (a vandalproof cloth for trucks) and developed a hi-tech anti-radar net. These are but a few of the developments which will further reinforce Sioen’s market lead.

In the apparel division, the group intends to concentrate further on high-value, technical products. ‘Protection through innovation’ means for the apparel division a further extension of the niche value-added markets - intelligent clothing, bullet- and knifeproof vests, etc. - in which technicity is important. It has also been de-cided to take advantage of this know-how in other than industrial markets. An example of this is the recently successful bid for an order for the French army.

(1) Last year this item also included the reclassifi cation of EUR 2.2 million from the gross margin to amounts written off inventory(2) 2003: kEUR 213; 2002: kEUR 180(3) working capital + fi xed assets

Net fi nancial charges (excluding amortisation of consolidation goodwill) run to EUR 7.7m as against EUR 8.2m in 2003. This decrease is the logical consequence of a reduction of the group’s net debt position.

Adequate provisions are set aside for all known risks. Under the group’s internal guidelines, foreign exchange risks are covered by forward contracts for the account of Sioen Industries n.v. The total nominal value of these contracts, which run for under one year, is EUR 6.89 million. The market value of forward contracts amounted as of December 31, 2004 to EUR -0.1 million and is fully recognized in the income statement. All forward contracts cover underlying transactions. In no event are derivatives used for speculative purposes.

Under extraordinary charges are grouped a number of one-off provisions and costs totalling EUR 2.2m relating to the reorgani-sation programmes at the Roltrans group, which are now coming to an end. These include the payment of EUR 1.5m of redun-dancy compensation and a further provision of EUR 0.7m.

Profi t before tax for the past year amounts to EUR 16.8m as against EUR 16.3m in 2003, or a rise of approximately 3%.

Income taxes in 2004 amount to approximately EUR 4.4m as against EUR 7.4m in 2003. This decrease is due principally to the offsetting of deferred tax claims on the transferred tax los-ses of the Roltrans group (EUR 3.2m). This deferred tax claim implies that, with the offsetting of fi scally transferable losses from the past, no tax will be payable on future taxable profi ts of the Roltrans group. The Roltrans group’s present and future opera-ting profi ts justify the recognition of this tax asset. For 2004 the Roltrans group can already present a positive operating result, and is expected to make a substantial contribution to group profi t in 2005.

The net profi t after tax amounts to EUR 12.4m as against EUR 8.9m in 2003, or a rise of 38%.

Balance sheetAll the internal objectives set by the Board of Directors in terms of balance sheet structure were achieved. Working capital was pared back to 30.1% of turnover from 40% in 2003, and approxima-tely 50% two years ago. Coupled with this, “capital employed”(3) was brought down to EUR 260m (2003: EUR 283.6m), or 0.83 eurocent per euro of turnover. The net fi nancial debt position was also signifi cantly improved, and now stands at EUR 118m as against EUR 148m in 2003.

After implementing and validating the necessary assumptions, future prospects and analyses, the Board of Directors is of the opinion that no permanent reductions in value need to be ap-plied to the consolidated annual accounts.

All new investment opportunities are systematically evaluated and their impact on the balance sheet structure simulated in or-der to maintain a healthy balance sheet structure; and with an eye to future growth.

IFRSIn accordance with the European regulation adopted on 19 July 2002 (1606/2002), Euronext requires listed enterprises in the

Vertical integration

EXTRUSION YARN

WEAVING

COATING

DISTRIBUTION

CUSTOMER

DESIGN

MANUFACTURE/PRODUCTION

DISTRIBUTION

CUSTOMER

DISTRIBUTION

CUSTOMER

PASTES AND GRANULES

PROCESSING

17

Sioen worldwide

Coating Division

Apparel Divis

ion

Processing Divis

ion

1 Sioen Coating Division - Sioen Apparel Division Siotec - Veranneman TT Sioen Coating Distribution - ARDOOIE 2 Coatex - POPERINGE 3 Sioen Fibres - distribution/spinning - Sioen Fabrics - weaving and coating - MOUSCRON 4 TIS - KERKSKEN 5 European Masterbatch/EMB - BORNEM 6 Sioen - Baleno® - ANTWERP 7 Sioen Nordifa - LIÈGE 8 Inducolor - MESLIN-L’EVÊQUE

19 Sioen Tunisie - CTS - Sioen Zaghouan - TUNIS 20 Siofab - PORTUGAL 21 P.T.Sungintex - BEKASI BARAT 22 P.T.Sioen Indonesia - JAKARTA 23 Sioen Shanghai - SHANGHAI 24 Sioen - UK 25 Pennel - ROUBAIX 26 Roltrans Group America - TEXAS 27 Roland Ukraine - RIVNE

924

10

17

16 15

19

21

22

23

20

2511

13 1218

27

25

7

8

43

1

6

26

9 Donegal Protective Clothing - DONEGAL 10 Mullion Manufacturing Ltd. - SCUNTHORPE 11 Saint Frères - Saint Frères Confection Bacam - FLIXECOURT 12 Roland International - TEGELEN 13 Roland Tilts UK - BRADFORD 14 Giesemann - Sioen GmbH - WERLTE 15 Sioen France - NARBONNE 16 SIP® protection - FOIX 17 Vidal protection - GRAULHET 18 Roltrans Group Polska - KONIN

14

Group structure(1)

Coating Division

Apparel Divis

ion

Processing Divis

ion

Coating Division

Sioen Coating n.v.(2)

Direct Coating Belgium

Saint Frères s.a.s.Direct Coating France

Sioen GmbHSales Offi ce Germany

Sioen Coating Distribution n.v.Sales Offi ce Belgium

Sioen Fabrics s.a.(2)

Weaving/Transfer Coating Belgium

Sioen Fibres s.a.Spinning Belgium

Sioen Shanghai(3) Sales Offi ce China

Siofab s.a. Transfer Coating Portugal

TIS n.v.Weaving/Direct Coating Belgium

Veranneman TT n.v.Weaving/Direct Coating Belgium Pennel Automotive s.a.s.Calendering France

European Masterbatch n.v.(2)

Production of Masterbatches Belgium

Inducolor s.a. Production pigments pastes Belgium

Processing Division

Coatex n.v.Processing of coated fabrics andfoils Belgium

Saint Frères Confection s.a.s.Heavy Manufacture France

Sioen Nordifa s.a.Production of industrial fi lters Belgium

Bacam s.a.s.Heavy manufacturing France

Roland International(7) b.v.

Roltrans Group America Inc

Giesemann LKWPlanen GmbH

Roltrans Group Polska sp.z.o.o.

JV Roland Ukraine llc

Roland Tilts UK ltd

1) The stated percentages have been rounded, situation on March 22, 2004. 2) Sioen Industries also has a 99.1% stake in Sirec SA, the group’s reinsurance company. Sioen Coating nv, Sioen Fabrics sa and EMB nv each hold 0.3%. 3) The offi cial name is: Sioen Coated Fabrics Shanghai Trading Ltd. 4) The offi cial name is: Gairmeidi Caomhnaithe Dhun na nGall Teoranta. 5) Via Sioen Coating nv. 6) 5% via P.T. Sungintex 7) Via Monal s.a. and Roltrans Group b.v. respectively. Activities taken over in March 2003 8) Merged with Vidal Protection s.a.s. and Sip Protection s.a.s. in December 2004 and January 2005 respectively.

Apparel Division

Sioen n.v.Apparel Belgium

Confection Tunisiennede Sécurité s.a. Apparel Tunisia

Donegal ProtectiveClothing Ltd. (4) Apparel Ireland

Mullion Manufacturing Ltd.Apparel UK

P.T. Sioen IndonesiaApparel Indonesia

P.T. SungintexApparel Indonesia

Sioen Fibres s.a. Central distribution and dispatching centre - B

Sioen France s.a.s.(8)

Sales Offi ce France

Sioen Tunisie s.a.Sales Offi ce Tunisia

Sioen UK Ltd.Sales Offi ce UK

Sioen Zaghouan s.a.Apparel Tunisia

Siotec b.v.b.a.CAD/CAM-services Belgium

Sioen USA Inc.(6)

Sales Offi ce USA

99%

100%

96%

100%

100%

100%

100%

100%

100%

99%

100%

90%10% (5)

100%

99%

100%

95%

95%

100%

100%

100%

99%

95%

100%

100%

100%

100%

99%

100%

5%

5%

100%

99%

100%

100%

100%

100%

60%

100%

19

COAT

ING

DIV

ISIO

N

World market leader through vertical integration

The Coating Division is the world leader in the integrated coating of synthetic fabrics and forms the fi rst pillar of the Sioen Industries group.

Coating, a defi nitionSioen has specialized in coating (literally covering) textiles for 45 years. Described simply, coating is covering a carrier with a protective layer. Carriers treated with PVC, PU, silicon or another plastic acquire specifi c technical qualities, becoming waterproof, microporous, fi reproof, anti-static, breathing, printable, etc. and offering protection against water, wind, cold and chemical pro-ducts.There are 4 key terms in this description:• the coating layer or protective layer, consisting of polymers in

liquid or solid form• the carrier or substrate, in the form of a woven or knitted fabric

or non-woven item (such as needle felt)• the coating technology: this includes the entire process of

applying the coating layer to the substrate• the technical textile or end result.

Vertical integrationSioen takes responsibility for the entire production process, from the raw fabric and pigment pastes to coating and processing the technical textile. This provides the group with an undoubted competitive advantage. Capacity and fl exibility, a highly automa-ted production system, a permanent concern for quality, a strong spirit of innovation and a targeted research and development policy together characterize the Coating division.

Vertical integration: the coating layerThe coating layer can consist of PVC, polyurethane, silicon or other polymers. Sioen produces the pigment pastes and granules used to dye the coating layer itself in its EMB and Inducolor faci-lities, which were part of the Processing division up to 2004 but now belong fully to the Coating division. The pastes are mixed in fully automated paste preparation units and then brought to the coating line by robots.

EMB and Inducolor produce masterbatches. These are pigment pastes and granules that are used as a raw material for dyeing all types of materials. EMB also produces special varnishes, com-pounds and all types of lacquers. In addition to a robust standard range both companies have a strong position in the production of tailored products. An individual approach at the level of deve-lopment, sales and production is central to both companies. CO

ATIN

G D

IVIS

ION

Pigment pastesThe pastes are used to dye various kinds of plastics (polyuretha-ne, silicone, water and PVC coatings, paints, epoxies, etc.).Applications include technical and industrial textiles, PU foams, cars, fl oors, etc.

GranulesThe EMB granules are used in injection moulding, sheet extru-sion, fi lm and fi bres, and blow moulding. All kinds of technical polymers (PP, PE, PS, PET,ABS, etc.) are coloured with these granules. Finished products can be found in textiles (e.g. carpet fi bres), packaging, plastics and many other sectors of industry.

Both EMB and Inducolor are part of the Coating division. In ad-dition to outside sales, pigment pastes and granules are used intensively in the Coating division: pigment pastes for dyeing the pastes used in direct, transfer and online coating, granules for extrusion coating and calendering.

In a market with many chemicals giants, EMB and Inducolor are genuine niche specialists. They have distinguished themselves for over 20 years as rapid, fl exible and service-oriented suppliers of tailor-made products. This customer focus, combined with ex-pertise and know-how and the ability to deliver small, medium-sized and large volumes and products tailored to the customer’s needs, give EMB and Inducolor a strong reputation as a niche specialist.

Vertical integration: the carrier

Yarn (spinning/extruding)Sioen has the world’s most modern spinning mill for the produc-tion of polyester high tenacity yarns and polyamide yarns. Part of the fi bres are then twisted in the twisting mill. The spinning mill has an output of ±15,000 tonnes of polyester and/or polyamide high tenacity yarns. Woven fabricsThe yarns are supplied as a raw material to the group’s three weaving mills which all have their own specialisation: sailcloth, open structure textiles, polyester high tenacity textiles, airbag tex-tiles, etc. The fabrics all meet high technical requirements for tensile strength, tear resistance, etc. Sioen has also acquired the necessary certifi cation for automotive applications.

21

Non-wovenSioen produces needle felt in its plant in Liège. This needle felt is then used among other things as a carrier for extrusion coating in the coating division.

Vertical integration: technology and technical textileSioen focuses on various coating processes, each serving a dif-ferent market. Sioen Industries has a total of seven coating plants (4 in Belgium, 2 in France and 1 in Portugal), with the most advanced production lines in the world. Extreme fl exibility and short lead times enable Sioen to produce both large and small runs in all colours and widths that the customer selects. All plants are equipped with the most modern machinery and are highly automated. Direct coatingDirect coating means that the PVC coating paste is directly ap-plied to the cloth. The coated fabric is used for tarpaulins and side curtains for trucks and railway wagons, publicity banners, textile architecture (buildings made with cloth), camping tents, gym mats, pool covers, covers, infl atable silos, fl exible containers, container tops, etc.

Transfer coatingIn two Sioen production units the coating paste (polyurethane, silicone, etc.) is applied to a fabric via a paper support. This coa-ted fabric is used for protective clothing, outdoor sports wear, shoe protectors, mattress covers, airbags, handbags, body bags and self-adhesive fi lm. Online coatingIn on-line coating the fabric is immersed directly from the loom into a coating bath.Veranneman Technical Textiles uses this technique to manufac-ture open structure textiles. There are many applications for this process: geogrids, pool covers, reinforcement nets, wind-breaking nets, fi lters, publicity banners, grinding mills, etc. Extrusion coatingThis multifunctional coating technique allows us to use other base materials (textiles, non woven, knitted fabrics, etc.) and to coat them with various polymers. The granules are melted in extruders and pressed into a film that is then laid on a car-rier. Applications: ventilation ducts, pond foils, window foils, drainage renovation, etc. CO

ATIN

G D

IVIS

ION

Rolling/CalenderingPennel Automotive, part of the group since March 2003, producesTPO (Thermoplastic Polyolefi n) and PVC fi lms. These fi lms are then passed through a press to obtain the desired motif/texture. The fi lms are used in the vehicle industry for dashboards, door panels, backs of car seats, sun shades, etc.

Turnover The Coating division’s turnover rose again by 13% in 2004 to EUR 172 million of which 4% external growth through 4months Pennel Automotive and 9 months Plastylon. The Coatingdivision grew in almost every segment and all its geographical markets.

SalesThe Coating Division’s products are sold worldwide under the reputed brand name Sio-Line®. In addition to the permanent sales staff operating out of the Ardooie headquarters and the Mouscron facility and a number of local agents, the Coating di-vision has its own sales offi ce in Germany (Sioen GmbH) and separate sales units in France, China (Sioen Shanghai) and from 2005 also in the USA (Sioen Coating USA). A keen and dynamic internal/external sales team with many years’ knowledge and ex-perience provides a permanent line of communication between the market and the company.

Applications and sectorsSioen technical textiles can be found in nearly every sector:agriculture, horticulture, transport, publicity, recreation, food and clothing, cars, medicine, sports, petrochemicals, construction,etc.

Sioen’s technical textiles are used, among other purposes, for tar-paulins and side curtains for trucks and railway wagons, publicity banners, textile architecture (buildings made with cloth), camping tents, gym mats, pool covers, covers, infl atable silos, fl exible con-tainers, container tops, protective clothing, outdoor sports wear, shoe protectors, mattress covers, handbags, body-bags and self-adhesive fi lm, geo-grids, pool covers, reinforcement nets, wind-break nets, fi lters, advertising banners, grinding mills, ventilation pipes, pond foil, window foil, sewer renovation, dashboards, door panels, the rear of car seats and sun shades, etc.

With approximately 36% of the external turnover of the Coating division, the market for PVC coated tarpaulins and side curtains for trucks and railway wagons is the most important segment.

23

Sioen is the undisputed market leader here with an estimated 50% market share. This market, of both new and replacement tarpaulins and side curtains, is mainly located in Western Europe, where the large trailer builders are situated. Sioen maintains good customer contacts with both trailer manu-facturers and side curtains manufacturers. The use of PVC coated textiles has not yet become customary in the American market, where trailers are usually hard-bodied. A strong reputation for quality, fl exibility, large standard range and market knowledge are Sioen’s most important trump cards.

Each year Sioen succeeds in increasing turnover in this segment, expanding its market share and reinforcing its competitive posi-tion through product innovation. This includes Siosteel, a com-bination of PVC coated technical textile with a coated steel net, which Sioen has introduced onto this market. Side curtains in this material offer better protection against vandalism. Sales of this product increased rapidly in 2004 with certain insurance compa-nies offering cheaper insurance premiums to hauliers that equip their trucks with Siosteel.

11% of the Coating division’s production is for the automotive sector: TPO and PVC fi lms for car interiors, trunk canvas and air-bags. The technical textile for car interiors is produced and sold by Pennel Automotive, a long-established French company with a strong presence in its home market. Pennel Automotive has an estimated market share of 20%. In 2004, a restructuring program was started in order to reach the internally imposed profi tability criteria in the future. The future growth of this segment lies both in geographical expansion to other markets such as Germany and in product innovation.

Sioen profi les itself as a full service supplier in the airbags market. Here again, vertical integration is an unmistakeable plus. Sioen extrudes the polyamide yarn in its own spinning mill, weaves it into a carrier and coats it in one of its plants. As an extra service Sioen cuts the fabric with high tech laser cutters in its Coatex plant (a part of the Processing division). This production process was optimised completely in 2004, opening up attractive pros-pects for the coming years.

Another 6% of turnover is in geo-textiles and roofi ngs. The tech-nical textile is used as reinforcement netting for roads, roofs and all types of plates. With approximately 50% of the market Sioen is also the European market leader in this segment. Geographical expansion to the US and elsewhere is one of the goals for the CO

ATIN

G D

IVIS

ION

coming years. The Coating division will be opening a sales offi ce in the US in 2005, which will promote open structure fabrics along with closed technical textiles.

Two growth markets for Sioen, Sign and textile architecture, accounting for 7% and 5% of the Coating division’s turnover respectively, will be able to reap the benefi ts of R&D efforts in coming years. Sign is the collective name for all types of publicity banners: technically coated textile that can be both silkscreen and digitally printed. In this price-sensitive market Sioen profi les itself as a service-oriented quality supplier. Textile architecture is understood as technical textiles for tents and structures.Sioen has developed here a range which can compete with niche specialists.

10% of the coating division’s turnover is in fl exible, breathing technical textile used for clothing and mattress covers. Thanks to its modern production system, large volumes, R&D and know-how and the advantages of vertical integration, Sioen can be suc-cesful in this nonetheless competition-sensitive market (Asia).

Sioen is the global market leader in technical textiles for swim-ming pool covers and aboveground pools. This segment repre-sents 7% of turnover and a market share of 71%.The greater proportion of the turnover comes from France, where the major producers of swimming pool covers and overground pools are located. Once again the focus is on technical know-ledge, market knowledge, service and quality as the basis for success.

In the past 10 years Sioen has succeeded in limiting its depen-dence on its largest segment through product diversifi cation. Even so, this segment continues to grow. Its product diversifi cation and success in the ‘new’ niche markets is the result of intensiveefforts at the level of R&D, sales, marketing and production.

25

Competitive positionSioen accounts for 41% of all large width coating capacity in Europe, with the remaining 59% distributed between a German competitor and many small local competitors in Spain, Italy, Au-stria, Germany, France, Scandinavia, etc. Whereas all of these smaller coaters operated in the same segments up to a few years ago, we now observe a trend towards specialisation. One com-pany focuses on textile architecture, another on publicity banners (Sign) and another again on geo-textiles.You can read more about the situation in different countries and segments in the ‘applications and sectors’ and ‘geographical dis-tribution’ sections.

New products and developmentsThe coating division can pride itself on a well performing R&D centre. Here professionals focus on product development and innovation, but also on process enhancement. Product optimi-sation is a constant factor in this. Research and development (R&D) are important for a company like Sioen. Staying ahead in the market means investing permanently in research and de-velopment. An example of this is the central R&D unit at our Ardooie headquarters. This research operation not only has the most modern facilities; it can also pride itself on its employees’ expertise and experience.Apart from this central R&D unit Sioen has a further ten research centres worldwide. The main production sites each have their own laboratory where specifi c research and product tests are car-ried out. The work of the various research centres is coordinated and steered from the R&D centre in Ardooie.

Gathering knowledge and putting it into practice is a permanent process of sowing and reaping. The past year can be characteri-sed as a period of sowing, in which a great deal of time and ener-gy was dedicated to developing and professionalising the R&D team, deepening knowledge of markets and products, expanding our product portfolio and perfecting a number of developments made in the past years. Sioen perfected its technical textiles for car boots and successfully launched the fi rst bulk production. We developed a high-quality technical textile with fl ame retardant characteristics. The complete airbag production process was fi ne-tuned and production is now operating at full speed. Sioen also developed and perfected technical textiles for ventilation pipes and launched large production runs, etc.

Geographical markets The key fi gures given on page 7 of this annual report show that 75% of the Coating division’s turnover is located in the traditio-nal Western European countries. France, Sioen’s most important sales territory, is the front runner with 20% of turnover. Germany and Benelux are traditionally strong counties, followed closely by the UK.

The geographical distribution refl ects the location of the fi nal producers. A number of large trailer manufacturers are based in Germany and the UK and Germany has a rich tradition of using geo-textiles, France has a large number of swimming pool cover and mattress cover makers, the largest digital printers are based in Western Europe and Pennel Automotive has a long history of contacts with French car producers.

Although the traditional Western European countries comprise the largest proportion of turnover, the Eastern European market has again become important in 2004. Technical textiles for digital printing and truck tarpaulins and side curtains in particular are fi nding their way to Eastern European customers.

Despite competition from cheaper local laminate producers (a weaker alternative to coated textiles), Sioen is continuing to grow in Asian markets. Sioen is primarily focusing on the Sign (pu-blicity banners) and Textile architecture (tents and structures) segments. Sio-line has now become a quality brand that digital printers and manufacturers can no longer ignore. In addition to this quality reputation, our knowledge of the local distribution market is playing a major role in this growth.

Our in-house experience and knowledge at all levels give us a head start over our competitors in prospecting and selling in po-tentially large sales markets. Our sales structure enables us to maintain a constant feel for the market and to respond optimally to customer needs.

27

APPA

REL

DIV

ISIO

N

Market leadership through know-how and quality

Sioen is the market leader in protective clothing for industrial and leisure applications.

Protective clothing: safety and comfortA few years after the establishment of the coating line in 1960, Sioen expanded its activities with protective clothing apparel. Trousers and jackets with in-house coated technical textile were produced for industrial use. Now, many years later, Sioen is the market leader in technical protective clothing.

‘Protection through innovation’ is not outmoded here either. At Sioen we know that working in safe and comfortable circum-stances is a prerequisite, the best price/quality ratio a must and that speed, reliability and fl exibility are a self-evident requirement. Sioen’s protective clothing meets all of these demands.

Protection through innovation: R&DThe R&D team develops new materials, techniques and applica-tions. Researchers, textile engineers and designers always work closely together. Development and tests of new materials, the best specialists, perfecting the production processes, thorough market knowledge and know-how, the best performing test equipment,excellent experience and knowledge of standards and rules, etc. make Sioen a strong player in the protective clothing sector. With 45 years of experience we have in-house expertise in both de-sign and production. Our technical services carry out risk analy-ses and studies that guarantee perfectly personalised protective clothing to the highest specifi cations. Moreover, vertical integra-tion enables Sioen to respond faster and more adequately to its markets.

Protection through innovation: designA team of creative designers and textile engineers designs tech-nical protective clothing that meets the customer’s needs. The result is a comfortable and elegant garment which meets all legal regulations and technical requirements. With an eye for detail, creativity, and expert knowledge of production techniques and raw materials, fi tting, sitting comfort, etc., our designers develop functional and comfortable protective clothing to ensure a greateryield from labour.

Protection through innovation: productionEach design is produced carefully to the strictest quality standards in one of our modern production centres. Sioen Indonesia, for example, is one of the most effi cient production centres in the world. AP

PARE

L D

IVIS

ION

The apparel workshops in Tunisia and Indonesia and elsewhere have high-tech machines: heat presses, computer technologies, stitching and seaming machines, plotter systems, test equip-ment, etc. We are continually investing in the latest technologies to enable us to meet the highest quality standards. Sioen has the most recent ISO 9002/ EN 29001 certifi cation as well as the AQAP Certifi cate.

Quality is a constant factor at Sioen. The Apparel division makes maximum use of coated technical textiles produced by the Coa-ting division and of fabrics and liners produced in-house. Brand names such as Flexothane and Siopor are recognised worldwide and the world of industrial protective clothing and outdoor sports clothing can no longer be imagined without them.

In addition to production of its own brands, Sioen is also a valued partner for reputed ski and sportswear brands.

Sales and distributionThe sale of protective clothing is centralised at the headquarters in Ardooie, from where a team of specialist sales staff guide the sales effort. Sioen apparel also has a number of local sales offi -ces in France, Scandinavia, Indonesia, Germany and the UK from where local staff and agents serve the market.

88% of products are sold under the group’s own brand names. The fi nished products are shipped from the various production centres to a fully automated dispatch and distribution centre in Mouscron. Customers are supplied with models, colours and sizes according to their wishes. This dispatch and distribution centreguarantees rapid effi cient delivery in each case.

TurnoverThe Apparel division realised a turnover of EUR 68.2 million this year compared with EUR 71.5 million last year, refl ecting sustained commercial pressure on large-volume, low technicity markets. Sioen is focusing on products and applications with a high degree of technical complexity such as bullet and knife proof vests, fl otation suits, fi re fi ghting suits, protective clothing for the petrochemicals sector, forestry clothing, etc.

29

APPA

REL

DIV

ISIO

N

The range: applications and sectorsSioen develops and produces a complete range of personal pro-tective clothing in which functionality, comfort, look and security are of central importance. In addition to a wide standard range Sioen also produces completely customised protective clothing in accordance with the customer’s wishes. The application areas for the standard range are as divergent as they are extensive: Sioen protective clothing is used in the petrochemicals industry, the food sector, road construction and public works, agriculture, gardening and the fi sheries sector. Sioen serves public authorities(municipal services, police, army, postal services, etc.) andprivate companies and even private individuals via specialistdistributors.

In 2004 Sioen completed development of its ILS (Interchange-able Lining System), a multi-lining concept designed to allow wearers to work comfortably in all weather conditions. The custo-mer himself selects the removable lining, jacket and bodywarmer that suits him. The lining, fl eece and bodywarmer fi t perfectly into the jacket and the sleeves are attached with push fasteners. This means the jacket can be worn for the entire year.

The Industry range: description and market situationThe Industry range accounts for 75% of the Apparel Division’s turnover. It includes protective clothing ranging from simple rain-wear to extremely technical protective clothing. The competition, which primarily comes from Asia, and the associated price pres-sure, are felt most keenly in the technically least complex pro-ducts, and with clothing that is replaced relatively quickly. In this segment Sioen is now sourcing cheaper products from outside suppliers (1.5% of turnover) and focusing its own production increasingly on products and applications with high technical complexity. A strategy was developed and a structure set up for this purpose in 2004. High tech This clothing line offers protection against rain, wind and low tem-peratures. It includes trousers, coats, anoraks and overalls that protect those working in bad weather. This range also includes S.E.P.P., the abbreviation for Sioen Extreme Product Program.This is a total package comprising a basic layer (absorbent, warm and dry), an insulating layer (comfortable, keeps the wearer warm) and a top layer (protects against all weather conditions). Although each layer can be worn separately, together they make an elegant and comfortable unit.

High visibilitySeeing and being seen is a matter of life and death in many working situations.Sioen has therefore developed a full range of high visibility clothing.It is comfortable, easy to maintain and, like all other protective clothing, complies with the legal regulations. Chemicals and electricityAnyone working with or near chemicals or electricity should have extra protection. Sioen’s high tech clothing is not only wind and waterproof, it is also fi re and chemical resistant. AgricultureFarmers and market gardeners are always at work, even in rain, storm, snow, wind, frost and hail. Sioen has designed clothing which protects them even in these extreme weather conditions. FoodHygiene is extremely important in the food industry. The Sioen ‘kleen line’ has been developed to be wind and waterproof, yet comfortable, even after being washed at a high temperature. Wor-king conditions in the fi shing industry are often more extreme. Sioen makes aprons, sleeves, coats, trousers, overalls and fl eeces specifi cally for this industry. Sioen has created a special range of high tech protective clothing under the brand name Nicewear that offers protection in extremely low temperatures, such as in deepfreeze units in the food industry or on cold continents. Sio-fi tUnderwear and T-shirts complete the Sioen range. Whether ther-mal, highly visible or fl ame-retardant, they are part of a standardpersonal protective outfi t.

Niche products range: description and market situationSioen focuses on very specifi c and extremely technical protective clothing for shipping, fi re fi ghting, the police, the army, forestry, etc. Vertical integration, an effi cient production system, a high performance R&D department and specialist product manage-ment have reinforced Sioen’s market position in these technical niches. This range now accounts for 20% of the Apparel divisi-on’s turnover (17% en 2003). The technical complexity of these products means that competition is more limited, and with in-ternational and European standards and regulations becoming increasingly stringent, demand for these products is continuing to rise.

31

Mullion: protection on and near waterThe Mullion range protects everyone participating in sports or working on or around water. Its fl otation jackets, coats, trousers, suits, life jackets, etc. are technically perfect articles made bySioen. Sip Protection: forestryIn forestry some parts of the body must have extra protection. Sioen has developed a clothing line that protects against rain and low temperatures, as well as against the impact of a chainsaw.Sioen also offers special eye, head, foot and hand protection gear. Vidal Protection / Sio-fi re: fi re fi ghtingFire-fi ghters deserve the best available protection. This is the starting point adopted by Sioen, which has developed a special range of specifi c fi re fi ghting clothing for them under the brand name Vidal Protection/Sio-fi re. SAT: bullet and knife proof vestsSAT, Sioen Armour Technology, offers high-technology, quality bullet and knife-proof vests. We produce customised protective vests in accordance with the users’ exact requirements. The dis-creet, tactical and semi-tactical vest models meet the strictest protection standards. SAT also goes a step further in complete protection and has developed a multi-layer system with under-wear, rainwear and bullet proof vests.

Active outerwear: description and market situationBaleno is the brand name for fashionable, comfortable and func-tional outdoor sports and recreational wear, including specifi c protective clothing for hunters, anglers, horse riders, motorcy-clists, cyclists, hikers and golfers. Baleno is also functional and elegant everyday wear. Baleno has as well a collection of pro-motional clothing, suitable for hostesses, employees, stewards, or as business gifts.

Geographical markets The geographical distribution of sales remained unchanged, with the majority of sales to traditional Western European markets where strict standards for professional protective clothing apply. The Apparel division’s largest sales market is France, which ac-counts for 31.6% of turnover. In Benelux, Sioen’s home mar-ket, turnover is continuing to rise. Benelux contributes 23.3% to turnover. The UK and Germany account for 16.2% and 7.8% of turnover respectively. You can fi nd the complete country distribu-tion on page 7 of this annual report.

33

PRO

CES

SIN

G D

IVIS

ION

Customer loyalty through specialisation, service and fl exibility

PRO

CES

SIN

G D

IVIS

ION

The Processing Division specialises in processing coatedfabrics and PVC foil and in the production of fi lters forindustrial applications.

The Processing division becomesIndustrial ApplicationsActivities have been reorganised to a certain extent in the context of the new IFRS standards: production of pigment pastes and granules will form an integral part of the Coating division, which means that vertical integration in this division will be complete.As of 2005, the Processing division becomes the ‘Industrial Ap-plications’ division where heavy manufacturing holds a central position.The processing division continues to surge ahead, with turnover of EUR 71.4 million in 2004 compared with EUR 49.6 million in 2003 (after reclassifi cation of EMB). The main contributors to this strong 44% growth (of which 18% external growth of 3 months Roltrans Group) are Coatex, which specializes in cutting and processing technical textiles, Sioen-Nordifa, a producer offi lters and fi lter cloths, and the Roltrans group where the resultsof the recent restructuring are clearly visible. In addition tomarkets in Western Europe and Australia, Eastern Europeancountries are signifi cant growth areas for the Processing Division.

Processing: an example of vertical integration anddiversifi cationThe processing companies in the Processing division each have their speciality and form the fi nal link in Sioen Industries’ vertical integration. These companies process technical textiles produced in-house and other materials into fi nished products. The markets in which they operate are as extensive as they are divergent: the automotive industry, the leisure sector, the food industry, heavy industry and chemicals, transport, construction, etc.

KadorsCoatex in Poperinge processes the coated technical textileproduced in Coating division companies. The company hasdeveloped a global reputation in kadors and offers both a standard range and customised solutions. A kador is the tent canvas component that slips into a metal profi le.In 2004 Coatex supplied the kadors for the prestigious ‘The Gates’ project in New York’s Central Park created by the artists Christo and Jeanne-Claude (see photo).Worldwide there are only a few producers of such kadors, made of a fl exible PVC tube with a technically coated textile around it. Coatex is one of the biggest producers in the world and has extremely modern machinery.

35

PRO

CES

SIN

G D

IVIS

ION

Sio-steelSio-steel is a patented composite made of a PVC coated steel net and a double-sided PVC coated polyester fabric. The steel, strengthened with carbon, offers very good protection without affecting the fl exibility of the cloth. Sio-steel is therefore perfect for curtains and tarpaulins for trucks and open containers. The steel net is welded onto the cloth and makes sure that possible damage is restricted to max. 10 x 10 cm. Besides offering protec-tion against theft and vandalism, Sio-steel has another important advantage: trucks are not immobilized and therefore achieve hi-gher effi ciency. Printing (digital, painting, screen print, adhesive letters, etc.) is still possible.

Sio-steel is unique and is being exploited more and more fre-quently. In France and elsewhere, insurers are already offering discounts on trucks fi tted with Sio-steel.

Cutting and punchingWith its expertise in cutting and punching all types of materials,the Coatex plant at Poperinge supplies tailored cutting fortechnical textiles coated by the Coating division. Coatex also cuts car interior and other materials.

Laser cuttingAirbags are one of the items cut on the 4 high tech laser cutters. This array of machinery is unique and offers one of the best per-formances anywhere in the world. Several layers are cut at once, enabling large quantities to be handled very quickly.

In 2004 Coatex became a ‘system supplier’ in airbag cutting for a major producer in the automotive sector. This means that Coatex looks after purchasing the raw material (airbag cloth), managing the inventory and cutting the material.

Pond and dam foilsCoatex cuts, welds and packs pond and water tank foils forcustomers worldwide. Coatex PVC foils are exploited in theindustrial and recreation sectors to produce, among other things, recreational ponds and industrial basins, agricultural fl oors and dam foils.

37

Filters and fi lter cloths Nordifa specialises in the total production of fi lters and fi lter cloths. Its Lainyl®, Clartex® and Nordifa® brands enjoy an excellentinternational reputation. Applications exist in the foodindustry (water and air treatment in sugar refi neries, breweries, etc.), heavy industry (metallurgy, coke industry, mining, power stations, paper processing, cement, etc.), chemicals (dye produc-tion), urban water purifi cation and post-combustion installations.

Tents, covering systems, sliding gates, wagon covers and silosAt Saint Frères Confection the in-house coated textile is proces-sed into fi nished products for high technological niches such as the armed forces, the railways, the aeronautics industry and con-struction.

Camoufl age clothBacam specialises in the design, production and marketing of camoufl age cloth and multi-spectral camoufl age nets.

This high-tech market demands signifi cant technical expertise plus research and development. Only a few companies operate in this segment worldwide.

Side curtains and tarpaulinsRoland International (This is the main and holding company of the Roltrans Group. Both Roland International and Roltrans are brandnames) has been a member of the group since March 2003 and is the market leader for the production of curtains and tarpaulins for trucks and containers. Roland International uses the technical textiles from the Coating Division for this purpose.

Roland International is the European market leader with some 45% of the market for tarpaulins and side curtains for newtrailers. The company focuses on large volume series production.

Corporate governance

39

The Sioen family has surrounded itself with external, independent directors since 1986. Their expertise and experience contribute to the proper and effective management of thecompany.

On March 22, 2005 the Board of Directors adopted a Corporate Governance Charter incompliance with the Belgian Corporate Governance Code. This charter, which comes into effect as from the 2005 General Meeting of Shareholders, can be consulted on the Sioen Industries website (www.sioen.com).

The present chapter on Corporate Governance relates to the 2004 fi nancial year, when the Corporate Governance Charter was not yet in effect. Where possible, however, the information is communicated in the manner prescribed by the Belgian Corporate Governance Code.

Composition of the Board of Directors (situation on May 1, 2005)*The directors’ terms of offi ce expire at the 2008 general shareholders’ meeting.

Mr. J.J. Sioen(1), chairman/director of various other companies

MJS Consulting b.v.b.a.,represented by its business manager, Ms M. Sioen(1)

a director of various other companies

Ms J.N. Sioen-Zoete(1), a director of various other companies

D-Lance b.v.b.a.,represented by its manager, Ms D. Parein-Sioen(1)

a director of various other companiesP. Company b.v.b.a.,represented by its manager, Ms P. Sioen(1)

a director of various other companiesP. Bamelis n.v.,represented by its managing director, Mr P. Bamelis(2) (3)

Chairman of the Board of Directors of Agfa-Gevaert n.v.; director ofvarious other companiesRevam b.v.b.a.,represented by its manager, Mr W. Vandepoel(2)

Managing Director of Lessius Corporate Finance n.v.; director of various other companiesSheng n.v.,represented by its managing director, Mr L.H. Verbeke(2)

Lawyer-partner in Allen & Overy; chairman/director of various other companiesK.E.M.P. n.v.represented by its Chairman, Mr Luc Sterckx(2) (3)

director of various other companiesVean n.v.,represented by its Managing Director, Mr L. Vansteenkiste(2) (3)