An Analysis of Fall Protection Hazard’s At Auburn’s Briggs & Stratton Facility MISE Project Omar Whitfield September 31,2009

An Analysis of Fall Protection Hazard’s At Auburn’s Briggs & Stratton Facility MISE Project Omar Whitfield September 31,2009.

Dec 29, 2015

Welcome message from author

This document is posted to help you gain knowledge. Please leave a comment to let me know what you think about it! Share it to your friends and learn new things together.

Transcript

An Analysis of Fall Protection Hazard’s At Auburn’s Briggs & Stratton Facility

MISE ProjectOmar Whitfield

September 31,2009

AgendaAgenda

• Overview• Introduction• Applicable OSHA Standards• Purpose of Study• Objectives/Results• Countermeasures• Conclusion• Questions

OverviewOverview

• The Briggs & Stratton Corporation, which is headquartered in Milwaukee, Wisconsin, is the world’s largest manufacture of air-cooled gasoline engines.

• Today they manufacture everything from engines for generators, snow blowers, and lawn equipment.

• The Auburn plant was built in August 1995 and they have a workforce of about 540.

• Their main type of operation is to assemble and ship three types of engine models which are the Model 9, Model 20, and V-Twin.

IntroductionIntroduction• A primary concern of the Safety Engineer at

Auburn’s Briggs & Stratton facility are the

potential fall hazards that exist which could

potentially seriously injure personnel in addition

to being in violation of applicable Occupational

Safety and Health Administration (OSHA)

standards.

• Some hazards include:

• Inadequate guardrail protection

• Inadequate protection at ladder-way access

openings

Applicable OSHA StandardsApplicable OSHA Standards• 29 CFR 1910.23(a)(2): Every ladderway floor opening or

platform shall be guarded by a standard railing with standard toeboard on all exposed sides (except at entrance to opening), with the passage through the railing either providing with a swinging gate or so offset that a person cannot walk directly into the opening.

• 29 CFR 1926.501(b)(1): “Unprotected sides and edges”. Each employee on a walking/working surface (horizontal and vertical surface) with an unprotected side or edge which is 6 feet (1.8m) or more above a lower level shall be protected from falling by the use of guardrail systems, safety net systems, or personal fall arrest systems.

MethodsMethods

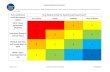

• Created a hybrid “Job Hazard Analysis” (JHA) form so that each hazard could be identified easily for the Safety Engineer as well as maintenance workers who may be asked to fixed the problem as well.

Purpose of ProjectPurpose of Project

• A fall hazard evaluations was performed to determine and/or verify whether Briggs & Stratton has policies, procedures, personal protective equipment, and devices in place to protect workers from all potential fall hazards at the facility.

• Objectives• Evaluate company fall protection standards and

compare against federal standards.• Perform safety audit for all applicable fall hazards.• Validate currently used PPE and safety devices

against federal standards.• Determine countermeasures for each fall hazard.

Objective 1Objective 11. Evaluate company fall protection

standards and compare against federal standards.

1. Guarding floor and wall openings and holes (29 CFR1910.23)

2. Scope, application, and definitions applicable to this subpart (29 CFR1926.500)

3. Duty to have fall protection (29 CFR1926.501)4. Fall protection systems criteria and practices

(29 CFR1926.502)5. Training requirements (29 CFR1926.503)

Results: Results: Evaluation of all applicable federal Evaluation of all applicable federal standardsstandards• Company fall protection policies correlated

directly with OSHA standards.• The company policy was essentially copied

verbatim from the OSHA fall protection standard.

• Policy failed to address hazards from 29 CFR 1910.23 walking/working surfaces (e.g. ladderway access openings.).

• Safety Engineer stated that each facility has a substantial amount of ladderway access openings.

Objective 2Objective 2

• Perform safety audit for all applicable fall hazards.

Results: Results: Outcome of Safety EvaluationOutcome of Safety Evaluation

• After the completion of the safety audits I documented a total of 30 fall hazard which are in direct violation of OSHA standards.

• Each fall hazard was either related to inadequate guardrail protection or inadequate protection at access openings.

• There were four access opening areas where the Safety Engineer felt a self-closing gate needed to be installed.

Example of Fall HazardsExample of Fall Hazards

ID NO. Location Potential Hazard Procedure or

Recommended

Action

1Dept. 312, Model 20 Assy. Lowrator Zone 7.

Inadequate protection at access opening.

Install a self-closing swinging gate, or redesign the work area such that the access opening will offset so that a person cannot walk directly into the opening.

4(b)Dept. 312, Model 20 Assy. Pallet Washer.

Inadequate guardrail protection.

*An adequate guardrail system should be installed on the machine to meet OSHA's requirements. *A warning line/controlled access zone program can be implemented. *Install a portable Anchorage Connector System. *Install a Horizontal Lifeline System*Require employees to wear appropriate PPE.*Install a Safety Net

Example of Fall Hazards Example of Fall Hazards (Cont’d)(Cont’d)

Example of Fall Hazards Example of Fall Hazards (Cont’d)(Cont’d)

Example of Fall Hazards Example of Fall Hazards (Cont’d)(Cont’d)

Objective 3Objective 3

• Validate currently used PPE and safety devices against federal standards.

Results: Results: Validate currently used PPE and safety Validate currently used PPE and safety devices against federal standards.devices against federal standards.

• For many of the listed hazards no type‘s of devices were used.

• There was about four instances were a swinging gate could be improved upon by making it self-closing.

• Personnel did wear some form of Personal Protective Equipment (PPE) while working at elevated heights.

• Limited form of PPE still not adequate because it does not satisfy the requirements in the standards.

CountermeasuresCountermeasures

• For unprotected sides and edges• Guardrail System• Safety Net System• Anchorage System• Warning Line System• Personal Fall Arrest System such as a

“Vertical Lifeline System”

Countermeasures (Cont’d)Countermeasures (Cont’d)

• For inadequate protection at access openings:• Self-Closing Swinging Gate.

Countermeasures (Cont’d)Countermeasures (Cont’d)

• There are a number of ways for Briggs & Stratton to come into compliance with all applicable federal standards.

• Guardrail System would be my first choice.• With a guardrail system it is stable and it

eliminates the hazard of someone walking directly off of an unprotected edge.

Countermeasures (Cont’d)Countermeasures (Cont’d)

• Safety Net System is good but not better than a guardrail system in my opinion.

• Safety Net System does eliminate the hazard of someone walking directly off of the edge of an unprotected hazard but not as “stable” as guardrail system.

Countermeasures (Cont’d)Countermeasures (Cont’d)

• Portable Anchorage System is okay. • This solution does not eliminate the hazard.• You are counting on the employee to “do

the right thing” by staying 100% tied off at all times.

• Can the work platform surface support the weight of an stationary anchorage system?

Countermeasures (Cont’d)Countermeasures (Cont’d)

• Controlled access zones is okay but not great.

• Does not eliminate the hazard.• It puts the trust of having the employee

make the choice of “doing the right thing.”

• Is probably the most “cost effective” solution.

Countermeasures (Cont’d)Countermeasures (Cont’d)

• Vertical Lifeline System is okay but not great.• You are counting on the employee to “do the

right thing” by staying 100% tied off at all times.

• It is one of the more cost effective measures as it would be simple to implement.

• Periodic testing would need to be done to ensure the quality of the lifelines.

Countermeasures (Cont’d)Countermeasures (Cont’d)

• Self-Closing Swinging Gate• OSHA offers no wiggle room with this standard.• 29 CFR 1910.23(a)(2) specifically states that an

swinging gate must be used over all ladderway access openings so that someone could not fall directly into that opening.

• Furthermore OSHA requires that the swinging gate must be equivalent to that of a guardrail.

Guardrail SystemGuardrail System

Safety Net SystemSafety Net System

Anchorage ConnectorAnchorage Connector

Controlled Access Zone ProgramControlled Access Zone Program

Vertical LifelinesVertical Lifelines

Self-Closing Swinging Gate & Add-Self-Closing Swinging Gate & Add-On SpringOn Spring

ConclusionsConclusions

• There were a total of 34 Fall Hazards that the Safety Engineer and I felt needed to be addressed.

• The most cost effective method is the warning line system but is the most least effective.

• Best solution is a guardrail system.

Conclusions (Cont’d)Conclusions (Cont’d)

• Federal standards offers no alternative solutions to access openings at ladderway openings.

• A swinging gate must be used and it must be equivalent to that of a regular guardrail.

• The Safety Engineer and I determined that at 4 existing openings with swinging gate in place that they could be improved by making them self-closing.

Questions???Questions???

Related Documents