Amit Ramji – A4 – University of Hertfordshire 1 COURSEWORK ASSIGNMENT Module Title: Mechanics and Properties of Materials Module Code: 6ACM0003 Assignment Title: Finite Element Analysis of a Wind Tunnel Model Individual Tutor: Dr Y Xu/Dr A Chrysanthou Internal Moderator: Dr. Yong Chen ASSIGNMENT SUBMISSION Students, this section must be completed before your work is submitted. Please print your forename and surname in capitals, provide your student registration number, your study year code (e.g. ASE1, EE1), and your signature in the spaces provided below. For Group work, each team member must complete this information. You may add or delete rows as required. Copyright Statement By completing the information below, I/we certify that this piece of assessment is my/our own work, that it is has not been copied from elsewhere, and that any extracts from books, papers, or other sources have been properly acknowledged as references or quotations. Forename: Family Name: SRN: Year Code: Signature: Amit Ramji 10241445 A4 Marks Awarded %: Marks Awarded after Lateness Penalty applied %: Penalties for Late Submissions • Late submission of any item of coursework will be capped at a minimum pass mark if received up to one week late. Any submission received more than one week late will be awarded a mark of zero. • Late submission of referred coursework will automatically be awarded a mark of zero. Guidance on avoiding academic assessment offences such as plagiarism and collusion is given at the URL: http://www.studynet.herts.ac.uk/ptl/common/LIS.nsf/lis/citing_menu

AmitRamji10241445FEA Report

Jul 18, 2015

Welcome message from author

This document is posted to help you gain knowledge. Please leave a comment to let me know what you think about it! Share it to your friends and learn new things together.

Transcript

Amit Ramji – A4 – University of Hertfordshire

1

COURSEWORK ASSIGNMENT

Module Title: Mechanics and Properties of Materials Module Code: 6ACM0003

Assignment Title: Finite Element Analysis of a Wind Tunnel Model Individual

Tutor: Dr Y Xu/Dr A Chrysanthou Internal Moderator: Dr. Yong Chen

ASSIGNMENT SUBMISSION Students, this section must be completed before your work is submitted.

Please print your forename and surname in capitals, provide your student registration number, your study year code (e.g. ASE1, EE1), and your signature in the spaces provided below. For Group work, each team member must complete this information. You may add or delete rows as required.

Copyright Statement

By completing the information below, I/we certify that this piece of assessment is my/our own work, that it is has not been copied from elsewhere, and that any extracts from books, papers, or other sources have been properly acknowledged as references or quotations.

Forename: Family Name: SRN: Year Code: Signature:

Amit Ramji 10241445 A4

Marks Awarded %:

Marks Awarded after Lateness Penalty applied %:

Penalties for Late Submissions

• Late submission of any item of coursework will be capped at a minimum pass mark if received up to one week late. Any submission received more than one week late will be awarded a mark of zero.

• Late submission of referred coursework will automatically be awarded a mark of zero.

Guidance on avoiding academic assessment offences such as plagiarism and collusion is given at the URL: http://www.studynet.herts.ac.uk/ptl/common/LIS.nsf/lis/citing_menu

Amit Ramji – A4 – University of Hertfordshire

2

ASSIGNMENT BRIEF Students, you should delete this section before submitting your work.

This Assignment assesses the following module Learning Outcomes:

4. Examine existing designs and actual components in engineering situations, using methods such as finite element analysis, photoelasticity, non-destructive testing and fractography. 5. Limit the occurrence of failure in materials by appropriate modelling, design and materials selection. 6. Apply analytical methods to structural components subjected to complex stress/strain fields. Assignment Brief:

In this assignment, you will create a finite element model of a wind tunnel model of a wing to be tested at supersonic speeds in order to assess its structural integrity. You should carry out the modelling and write a short report on your findings. Further details are provided on the attached sheets.

Submission Requirements:

Submission shall be through StudyNet

This assignment is worth 50 % of the overall in- course assessment for this module.

Marks Awarded for:

Validity of the FE results - 40%; Extent to which reporting requirements are met - 20%; concluding remarks section – 20%; presentation of report - 20%.

A note to the Students:

1. For undergraduate modules, a score above 40% represent a pass performance at honours level. 2. For postgraduate modules, a score of 50% or above represents a pass mark. 3. Modules may have several components of assessment and may require a pass in all elements.

For further details, please consult the relevant Module Guide or ask the Module Leader.

Typical (hours) required by the student(s) to complete the assignment: 15 hours

Date Work handed out:

7th November 2013

Date Work to be handed in:

29th November 2013

Target Date for the return of the marked assignment:

7th January 2014

Type of Feedback to be given for this assignment:

General feedback on StudyNet and individual feedback for each report.

Amit Ramji – A4 – University of Hertfordshire

3

Finite Element Analysis

ANSYS Report

Group E

Amit Ramji 10241445

University of Hertfordshire - Aerospace Engineering

Year 4 – Mechanics and Properties of Materials - 6ACM0003

26th November 2013

Amit Ramji – A4 – University of Hertfordshire

4

Contents Introduction .......................................................................................................................................................................... 5 Preliminary Analysis ............................................................................................................................................................ 5 Finite Element Analysis (FEA) Procedure ........................................................................................................................... 5 Analysis: ............................................................................................................................................................................... 8 Alternative methods of analysis ........................................................................................................................................... 9 Conclusions: ....................................................................................................................................................................... 10 Discussion .......................................................................................................................................................................... 11 References .......................................................................................................................................................................... 12

Table of Figures Figure 1 – Cantilever Plate geometry ....................................................................................................................................... 5 Figure 2 – Material Properties Input ........................................................................................................................................ 6 Figure 3 - Uniform stiffness properties .................................................................................................................................... 6 Figure 4 - Uniform thickness properties .................................................................................................................................. 6 Figure 5 - Selection of fine mesh ............................................................................................................................................. 6 Figure 6 - Post meshing operation ............................................................................................................................................ 6 Figure 7 - Boundary conditions (Fix all DOF between Node ID’s E to F) .............................................................................. 7 Figure 8 - Applying Pressure Loading onto wind surface ....................................................................................................... 7 Figure 9 – Nodal Displacements stating Max Deflection at Wing Tip (CD) is 1.596mm ....................................................... 7 Figure 10 - Stress Intensity Showing Highest Stress at Node F, lowest at Node A as expected. ............................................ 8 Figure 11 - Von-Misses Stress peak at Node F as expected. ................................................................................................... 8 Data Tables Table 1 - Provided Parameters and calculated pressures ......................................................................................................... 5 Table 2 - Cantilever Plate Coordinates .................................................................................................................................... 5 Table 3 - Summary Material Properties ................................................................................................................................... 6 Table 4 - Raw material properties from sample tests ............................................................................................................... 6 Table 5 - Post Processor Output Summary Table of results .................................................................................................... 8 Table 6 - Roark's Stress and Strain simplification into Rectangular Plate. .............................................................................. 9

Amit Ramji – A4 – University of Hertfordshire

5

Introduction This study considers a single edge cantilever plate bending for interpretation and simplification of a model aircraft wing at supersonic speeds for wind tunnel testing. The objectives are to evaluate the pressure loads and analyse the structural integrity of the wing model to be tested. The relation to a real wing allows for identification of stress concentration centre and maximum stress regions which attention can be paid in more detail by further analysis, reinforcement or alternative modelling techniques. The Finite Element methods used in this report provide a basis for understanding the properties of thin plates under uniform pressure loads, however in reality the loading conditions and boundary conditions are very complex. Simple analytical methods do not exist for complex shapes such as a wing plan-‐form, hence a comparative study is shown using rectangular cantilever plates to display that the theory agrees but the values obtained are non comparable. Thus providing further significance to Finite Element Modelling (FEM) methods in order to analyse the part geometry chosen for design in haste, compared to non-‐conservative approximations such as rectangular plate methods described later in this report.

Table 1 - Provided Parameters and calculated pressures

Preliminary Analysis Sample Calculation of Pressure Loads

∆𝑝 = 𝑞!4

𝑀!! − 1

𝛼

Calculation of Max Pressure Loading from Mach No:

𝑀!" = 1.5 ∴ 𝑞!" = 260 𝑀𝑃𝑎 ∴ Δ𝑝!" = 𝑞!"4

𝑀!"! − 1

8!360

2𝜋= 129.881 𝑀𝑃𝑎

𝑀!" = 2.5 ∴ 𝑞!" = 275 𝑀𝑃𝑎 ∴ Δ𝑝!" = 𝑞!"4

𝑀!"! − 1

8!360

2𝜋= 67.032 𝑀𝑃𝑎

∴ Δ𝑝!"# = 𝑆.𝐹 × 𝑀𝐴𝑋 Δ𝑝!" Δ𝑝!" = 𝟏𝟗𝟒.𝟖𝟐𝟐 𝐌𝐏𝐚 (𝑊ℎ𝑒𝑟𝑒 𝑆.𝐹 = 1.5 𝑔𝑙𝑜𝑏𝑎𝑙)

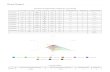

Finite Element Analysis (FEA) Procedure Initially set up the geometry of a flat plate with the dimensions as shown in Figure 1 and tabulated coordinates in Table 2. Later set up the plate geometry by selecting the points and creating the lines as in Figure 1.

Table 2 - Cantilever Plate Coordinates

Figure 1 – Cantilever Plate geometry

Given Parameters Angle of attack, 𝛼 (deg) 8.0 7.0 6.0 5.0 4.0 3.0 2.0 1.0

Angle of attack, 𝛼 (rad) 0.13963 0.12217 0.10472 0.08727 0.06981 0.05236 0.03491 0.01745 M01 1.5 M02 2.5 S.F (Safety Factor) 1.5 Δ𝑝!"For M01 129881.0 113645.9 97410.8 81175.6 64940.5 48705.4 32470.3 16235.1 Δ𝑝!" For M02 67031.7 58652.8 50273.8 41894.8 33515.9 25136.9 16757.9 8379.0

Node ID X (m) Y (m) A 0 0.180 B 0 0 C 0.080 0.080 D 0.030 0.080 E 0 0.150 F 0 0.025

Amit Ramji – A4 – University of Hertfordshire

6

Secondly set up the linear elastic isotropic material properties as shown below in Figure 2 and Table 3, where the steel plate is assumed to perfectly manufactured with uniform (isotropic) properties in all directions, perfectly elastic, and without consideration of thermal expansion as the plate dimensions are relatively small.

Table 3 - Summary Material Properties

Table 4 - Raw material properties from sample tests

Figure 2 – Material Properties Input Next set up the thickness properties of the plate to account for the stiffness properties, again this assumes the material stiffness is uniform in all directions, which isn’t the case for all material scenarios.

Figure 3 - Uniform stiffness properties Figure 4 - Uniform thickness properties

Subsequently set up a Fine 4 Node quadrilateral mesh using the surface selection tool. This type of mesh can be used for analysis of plane stress or strain, thin plate bending and for shear analysis of plates. Other mesh types are explained in Table 5.1 of literature [1], also in [2] and new approaches found in [3-‐6]. Package specific FEA guides also explain the use and types of mesh’s and their applications whereas tools such as Abaqus, Hypermesh and MSC PATRAN can allow specific mesh optimisation in key areas, however is out of the scope in this application of simple cantilever plate bending.

Figure 5 - Selection of fine mesh Figure 6 - Post meshing operation

Steel Plate [Rolled: tmin<3mm<tmax] Units Young’s modulus, E 200 Gpa Poisson’s Ratio, v 0.30 -‐ Tensile strength (Yield), 𝝈𝑻𝒀𝑺 600 Mpa Tensile strength (Ultimate) 𝝈𝑼𝑻𝑺 800 Mpa

Amit Ramji – A4 – University of Hertfordshire

7

Following meshing, apply boundary conditions and load cases into the pre-‐processor menu, where the wing root is treated as fixed in all Degrees of Freedom (DOF) and apply the uniform maximum pressure load (Δp!"#) as calculated in the Preliminary Analysis section of this report. The direction of the pressure load is to be applied normal to the wing surface, however as the analysis is linear, geometry above and below the mid-‐plane is symmetric, weight direction is not considered, therefore the loading direction does not affect the results.

Figure 7 - Boundary conditions (Fix all DOF between Node ID’s E to F)

Figure 8 - Applying Pressure Loading onto wind surface

Finally proceed with simulation of the load case and view the solution as nodal for Displacements, Stress intensity and Von-‐Misses stress.

Figure 9 – Nodal Displacements stating Max Deflection at Wing Tip (CD) is 1.596mm

Amit Ramji – A4 – University of Hertfordshire

8

Figure 10 - Stress Intensity Showing Highest Stress at Node F, lowest at Node A as expected.

Figure 11 - Von-Misses Stress peak at Node F as expected.

Post Processor Outputs Output (unit) Output (Required unit) Displacement (Normal to Wing surface) 0.001596 (m) 1.596 (mm) Stress Intensity (Node F) 729,000,000 (Pa) 729 (MPa) Von-‐Misses (Node F) 694,000,000 (Pa) 694 (MPa) Table 5 - Post Processor Output Summary Table of results

Analysis: From the Finite Element method above, the results state that the maximum stress is seen at Node F, which agrees with classical static mechanics. Node F is the point that is surrounded by most of the perpendicular area from the root chord therefore will have the highest stress concentration. Additionally the method of constraint for the FE modelling means that this area is showing to fail and go beyond the elastic region of the material, however the truth may be that the part will not fail in this region and is a property of the constraint method used in modelling. Furthermore the stress distribution will become smaller as the leading edge (AC) is approached until the stress is the same as the wing loading pressure. In the lateral direction moving from the root to the tip, the stress levels will decrease as the constraint is moved further away from the area of interest. Thus the stress distribution in the lateral direction will decrease to the pressure loading value (wing tip) as this case is considering a cantilever solution. The maximum deflection nodes are also as expected as the wing tip is furthest from the support of the root structure, hence will be prone to relatively high levels of deflections. The slope of deflection at the root will be greatest as once again the constraint is present in this region from EF.

Amit Ramji – A4 – University of Hertfordshire

9

Overall the FE model does correctly describes what is true regarding cantilever plate bending and justifies a reason to conduct further analysis in the constraint region at Node F. The possibility of gradual increased cross section can be justified or a reinforcement wing spar added. However for this analysis, the Von Misses stress is shown to be 694 MPa (Table 5), the material Tensile Yield Strength (σ!"#)=600MPa (Table 3), therefore suggests this cantilever plate has exceeded its elastic limits and could potentially fail rapidly under plastic fast fracture. This is the most extreme case, judging from the stress difference between beginning of plastic region and maximum Von-‐Misses stress, the difference is 94 MPa, therefore requires further investigation if reinforcement is not to be carried out. Alternative methods of analysis There can be many methods, which attempt to calculate the stress for a non-‐rectangular cantilever plate to calculate the stress at different locations. Using integration methods to work out the areas in different locations over the wing and discretizing the areas into dy and dx of which the product is a small element area. The slope of the leading edge and trailing edge will lead one to encounter a function of geometry for the integration limits. Later the pressure loading is multiplied to acquire a loading function per dydx area. Subsequently a function for moment arm is required which cantilever beam bending theory provides for uniform load distribution. However this is the exact same as discretising the problem into 4 Node Quad Elements, which FEA has provided a solution for in a shorter time. Other methods found in chapter 7 of reference [7] by Megson, considers a pure analytical approach is methods using Kirchhoff-‐Love plate representation, Navier Solutions, Mildlins methods for thicker plates, or the most appropriate for the current case would be to utilise Reissner-‐Stein Cantilever plates. [1, 7-‐13]

Rectangular plate approximation An attempt to show the trend has been made below which utilises methods based on stiffness constants of flat plates through experimental means and problem simplification into a rectangular plate. The same solution is not reached, as the real solution would require an iterative and element wise approach as FE provides and is explained above. This does however provide a justification of classic mechanics of perpendicular moment arms being kept constant and the wing root (parameter “a” below) being increased.

Table 6 - Roark's Stress and Strain simplification into Rectangular Plate.

From the above, increasing root length has very shallow stress climb rate compared with perpendicular distance (Span) increase, thus confirming classic beam bending theory.

Roarks [Table 11.4] (Simplification of wing into Flat Rectangular Cantilever Plate to observe trend) [1] t (mm) 3 a (mm) 50 80 120 160 240 b (mm) 80 a/b 0.625 1 1.5 2 3

Δ𝑝!"# (MPa) -‐0.194821529 𝛽! 0.38 0.665 1.282 1.804 2.45 𝛽! 0.386 0.565 0.73 0.688 0.434 𝛾! 0.541 0.701 0.919 1.018 1.055 𝛾! 0.526 0.832 1.491 1.979 2.401

𝜎 =−𝛽!Δ𝑝!"#𝑏!

𝑡!

(at centre of fixed edge) (MPa) 52.6451 92.1289 177.6080 249.9257 339.4224 𝑅 = 𝛾!Δ𝑝!"#𝑏

(at centre of fixed edge) (mm) 8.4319 10.9256 14.3233 15.8663 16.4429

𝜎 =−𝛽!Δ𝑝!"#𝑏!

𝑡!

(at centre of free edge) (MPa) -‐53.4763 -‐78.2750 -‐101.1340 -‐95.3154 -‐60.1263 𝑅 = 𝛾!Δ𝑝!"#𝑏

(at end of free edge) (mm) 8.1981 12.9673 23.2383 30.8441 37.4213

Amit Ramji – A4 – University of Hertfordshire

10

Conclusions: By observing the Maximum Von Misses stress of 694 MPa from Table 5, one can observe that some areas have indeed surpassed the elastic limit of steel with the current geometry of which the yield limit is shown in Table 3 of 600 MPa. This may be due to modelling constraints as discusses earlier, where the maximum stressed area is amplified by the presence of constraint features. This has the same effect as stress concentration factors where stresses are amplified based on geometry, further reading can be found in Petersons et al [14] for stress concentrations factors (Kt) based on geometry. The structural integrity of the plate wing model in the wind tunnel will be effected as the stressed material would yield in some places as indicated by FEA, therefore may exhibit fast fracture. To reduce the chances of failure and damage to the wind tunnel, this case should be investigated further by; Non-‐Linear FEA, a better representation of constraints, possible structural improvements such as a thicker plate, thicker wing root, adding a stiffener spar or spreading the loads through the cantilever over a larger root chord distance if possible. In actuality the structural integrity of the wind tunnel will be fine as the safety factor will not cause the part to fail during testing, however the wing plate will need to be checked regularly if left as is, there will be some permanent deformation which could progressively worsen. Non-‐strength related issues identified with the FEA is with the use of constrains. Use of nodal elements to constrain the root of the wing has identified and amplified a potential highly stressed region as stated previously. Material is said to be failing by surpassing the steel’s elastic yield limit. This indicates a high stress concentration when in actual fact more information is required on the part. A static deflection experiment can be conducted to prove or disprove the FEA and is usually what is done on actual aircraft skins. The use of strain rosettes and bonded strain gauges on aircraft test skins can identify experimental strains which can be later input back into the FEA model for comparison. Checking by analytical methods is a lengthy task and the solution will not always be accurate as the number of iterations can never be matched to that carried out by FEA. Some analytical methods are shown above and their limitations on the real geometry of the plate. The objective of this FE investigation was to determine the structural integrity of a test wing to be tested at supersonic speeds in a wind tunnel. The analysis shows that further investigation is required as the material would be prone to yielding in some areas. Therefore simply based on that evidence, justification for FEA is complete as it avoids potential damage to the wind tunnel, saves on costs for development as components can be sized to withstand the loads imparted on them without testing. For the case of Cantilever thin plates, analytical methods exist for rectangular shapes however the boundary conditions for simply supported plates cannot be applied in this application directly. Cantilever beam bending theory can be used to determine the maximum Bending Moment (BM) at the root; however often in most cases the faster and accurate solution will be by FEM methods. The maximum deflection of this plate during peak loading conditions was approximately 1.6mm as shown in Table 5. Which means it has a deflection ratio of approximately 2% over the span of 80mm. This is a reasonable deflection and can be calculated with cantilever beam bending functions. (A clamped 15 cm steel rule will also help to understand the static mechanics of this wing loading problem). To improve deflection the real wing is given a thickness, with reinforcement stringers, spars and ribs, thus provides a larger Second Moment of Area (I) and enables the skins to be in pure tension or compression. Composites can therefore be introduced in order to use this geometry and loading condition to one’s advantage.

Amit Ramji – A4 – University of Hertfordshire

11

Discussion The direction of pressure loads as described in the Finite Element Analysis (FEA) Procedure section of this report explains how direction is important. However for this simplification of a thin cantilever plate, the mid plane symmetry and combination of not considering weight means this analysis is valid if a +ve or –ve pressure is applied. Other investigations including sinusoidal loading due to shock waves, ground interference, weather gusts or microbursts may be considered for wing loading along with frequency analysis of sustained engine imbalance and its effects on fatigue. Plate modelling can be used for fuselage and wing skin loading analysis alongside other applications using composite structures and sandwich panels [15-‐18]. Consideration of cantilever plate methods have also been made in gear tooth analysis as reported by Wellauer et al [19]. Composite modelling with isotropic properties can also be made simple with thin plate analogies where minimum strength values are input into the model to identify stress hot-‐spots, delamination and surface effects for further consideration and fibre orientation and design sizing. [16, 18, 20, 21] From Table 1, one can see how the pressure loading is increasing as the angle of attack is increased and at lower Mach No’s. The benefit of FEM methods is that one can input all these complex combinations into the model as separate load cases and run the analysis in a very short amount of time. Therefore the sizing and analysis can be carried out on the components with consideration to a wide range of input variables/cases. The same applies for frequency and vibration analysis, a range band can be set for each load case and studied further in the post-‐processor or numerically through direct output files. It may be interesting to investigate increases in aircraft pitch angle, thus Mach No decreases, meaning from the range considered in Table 1, the combination of these flight characteristics could worsen the loading on the wing.

Amit Ramji – A4 – University of Hertfordshire

12

References [1] Young, W., Budynas R. Roark’s formulas for stress and strain. 7. 2002, McGraw-Hill. [2] Jaehwan, K., et al., Finite-element modeling of a smart cantilever plate and comparison with experiments. Smart

Materials and Structures, 1996. 5(2): p. 165. [3] Clough, R.W. and C.A. Felippa, A refined quadrilateral element for analysis of plate bending. 1968, DTIC

Document. [4] Batoz, J.L., An explicit formulation for an efficient triangular plate-bending element. International Journal for

Numerical Methods in Engineering, 1982. 18(7): p. 1077-1089. [5] Batoz, J.L., K.J. Bathe, and L.W. Ho, A study of three-node triangular plate bending elements. International

Journal for Numerical Methods in Engineering, 1980. 15(12): p. 1771-1812. [6] Hughes, T.J.R., R.L. Taylor, and W. Kanoknukulchai, A simple and efficient finite element for plate bending.

International Journal for Numerical Methods in Engineering, 1977. 11(10): p. 1529-1543. [7] Megson, T.H.G., Chapter 7 - Bending of thin plates, in Aircraft Structures for Engineering Students (Fifth

Edition), T.H.G. Megson, Editor. 2013, Butterworth-Heinemann: Boston. p. 233-266. [8] Wang, W. and M.X. Shi, Thick plate theory based on general solutions of elasticity. Acta mechanica, 1997.

123(1): p. 27-36. [9] Arnold, D.N. and R.S. Falk. Edge effects in the Reissner-Mindlin plate theory. in Presented at the winter annual

meeting of the American Society of Mechanical Engineers. 1989. [10] Karam, V.J. and J.C.F. Telles, On boundary elements for Reissner's plate theory. Engineering Analysis, 1988.

5(1): p. 21-27. [11] Fo-van, C., Bending of uniformly cantilever rectangular plates. Applied Mathematics and Mechanics, 1980. 1(3):

p. 371-383. [12] Reissner, E. and M. Stein, Torsion and transverse bending of cantilever plates. 1951: National Advisory

Committee for Aeronautics. [13] Reissner, E., On bending of elastic plates. Quart. Appl. Math, 1947. 5(1): p. 55-68. [14] Pilkey, W.D. and D.F. Pilkey, Peterson's stress concentration factors. 2008: John Wiley & Sons. [15] Thomsen, O.T. and W. Rits, Analysis and design of sandwich plates with inserts—a high-order sandwich plate

theory approach. Composites Part B: Engineering, 1998. 29(6): p. 795-807. [16] Lu, P., et al., Thin plate theory including surface effects. International Journal of Solids and Structures, 2006.

43(16): p. 4631-4647. [17] Barbero, E.J., J.N. Reddy, and J. Teply, An accurate determination of stresses in thick laminates using a

generalized plate theory. International journal for numerical methods in engineering, 1990. 29(1): p. 1-14. [18] Barbero, E.J. and J.N. Reddy, Modeling of delamination in composite laminates using a layer-wise plate theory.

International Journal of Solids and Structures, 1991. 28(3): p. 373-388. [19] Wellauer, E.J. and A. Seireg, Bending strength of gear teeth by cantilever-plate theory. Journal of Engineering

for Industry, 1960. 82: p. 213. [20] Newman Jr, J.C. and I.S. Raju, Analyses of Surface Cracks in Finite Plates Under Tension or Bending Loads.

1979, DTIC Document. [21] Reddy, J.N., E.J. Barbero, and J.L. Teply, A plate bending element based on a generalized laminate plate theory.

International Journal for Numerical Methods in Engineering, 1989. 28(10): p. 2275-2292.

Related Documents

![[MS-RPL]: Report Page Layout (RPL) Binary Stream Format€¦ · MS-RPL] —. stream report. report page. report report report](https://static.cupdf.com/doc/110x72/5fd9f7a7a90b7c34145fa364/ms-rpl-report-page-layout-rpl-binary-stream-format-ms-rpl-a-stream-report.jpg)

![For The Region: Report, Report, Report [Eng]](https://static.cupdf.com/doc/110x72/579079761a28ab6874c751c6/for-the-region-report-report-report-eng.jpg)