The Pennsylvania State University The Graduate School College of Engineering A STUDY OF THE TURNING OF AUSTEMPERED DUCTILE IRON (ADI) GRADES WITH COATED CARBIDE TOOLS A Thesis in Industrial Engineering by Pei-Long,Ting © 2016 Pei-Long,Ting Submitted in Partial Fulfillment of the Requirements for the Degree of Master of Science December 2016

Welcome message from author

This document is posted to help you gain knowledge. Please leave a comment to let me know what you think about it! Share it to your friends and learn new things together.

Transcript

The Pennsylvania State University

The Graduate School

College of Engineering

A STUDY OF THE TURNING OF AUSTEMPERED DUCTILE IRON (ADI)

GRADES WITH COATED CARBIDE TOOLS

A Thesis in

Industrial Engineering

by

Pei-Long,Ting

© 2016 Pei-Long,Ting

Submitted in Partial Fulfillment of the Requirements

for the Degree of

Master of Science

December 2016

ii

The thesis of Pei-Long, Ting was reviewed and approved* by the following:

Robert Voigt

Professor of Industrial Engineering Thesis Advisor

Edward De Meter Professor of Industrial and mechanical Engineering

Janis Terpenny Professor of Industrial Engineering Head of the Department of Department or Graduate Program

*Signatures are on file in the Graduate School

iii

ABSTRACT

Austempered Ductile Iron (ADI) is a relatively new material with the highest hardness and

strength of any material in the cast iron family. Through the unique heat treatment -

austempering, the “ausferrite” microstructure of ferrite and carbon-stabilized austenite along with

graphite nodules is formed. Multiple strength levels can be produced by varying the austempering

temperature or time. In general, ADI has a high strength-weight ratio, good toughness, and very

high wear resistance compared to other ductile iron grades. In addition, the density of ADI is

lower than steel but with approximately the same strength. These unique properties make ADI as

an ideal material for manufacturing products requiring light weight but with high strength and

toughness. On the other hand, ADI is difficult to machine because of its high hardness. This has

impeded the application and the growth of market applications of ADI.

The primary objective of this study was to evaluate the machinability of different grades of ADI

(GR900, GR1050, GR1200) during high speed turning with coolant. Comprehensive turning

experiments were conducted under a range of different machining conditions. The influence of

cutting speed on tool life, surface roughness, and chip formation were analyzed during turning

with coated carbide tools. The turning experiments were conducted on large diameter

commercially produced, pre-machined cylinder castings at a constant feed rate of 0.012 ipr and

depth of cut of 0.06 inches. The cutting speed was varied for the different grades of ADI, from

250-1000 fpm and tool wear was measured at various time intervals. A Taylor tool life model was

developed by measuring the tool life for a range of cutting speeds. This model was then used to

generate general turning guidelines for the various grades of ADI based on tool life. Lastly, in

order to benchmark the turning of ADI with other materials, turning studies with conventional

Ductile Iron grade 100-70-03 were also investigated under similar cutting conditions.

iv

The chip formation for all grades of ADI and DI 100-70-03 were discovered in the form of

discontinuous c-shaped chips. As expected increasing cutting speeds accelerated the rate of tool

wear. The surface roughness trend when machining GR900 and GR1050 are similar – decreased

cutting speed improved surface finish but a very low cutting speeds the surface finish of grade

1200 ADI also decreased.

v

TABLE OF CONTENTS

LIST OF FIGURES ............................................................................................................... vii

LIST OF TABLES ................................................................................................................. x

ACKNOWLEDGEMENTS .................................................................................................. xiii

Chapter 1 INTRODUCTION ................................................................................................... 1

Background ...................................................................................................................... 1 Problem statement ............................................................................................................ 1 Objectives......................................................................................................................... 2

Chapter 2 BACKGOUND ....................................................................................................... 3

Machining ........................................................................................................................ 3 Cutting force ............................................................................................................. 7 Chip formation ......................................................................................................... 11

Turning ............................................................................................................................. 14 Machinability ................................................................................................................... 19 Development of ADI ........................................................................................................ 27

Production of ADI .................................................................................................... 29

Chapter 3 PREVIOUS RESEARCH ....................................................................................... 36

Machining of ADI ............................................................................................................ 36 Cutting speed ............................................................................................................ 37 Cutting tool ............................................................................................................... 38 Depth of cut .............................................................................................................. 39 Chips formation and feed rate .................................................................................. 39

Chapter 4 RESEARCH PLAN ................................................................................................. 41

Workpiece material characteristics .......................................................................... 41 Experimental platform .............................................................................................. 44 Machinability metrics ............................................................................................... 49

Chapter 5 RESULTS................................................................................................................ 54

Chip formation ......................................................................................................... 54 Tool life .................................................................................................................... 56 Surface roughness .................................................................................................... 66

Chapter 6 DISCUSSION ......................................................................................................... 73

Chapter 7 CONCLUSION AND FUTURE WORK ................................................................ 76

References ................................................................................................................................ 78

vi

Appendix A - Tool wear measurements .................................................................................. 82

Appendix B - Surface roughness measurements ...................................................................... 91

Appendix C - Insert identification charts ................................................................................. 109

Appendix D – Tool Wear Measurement Method ..................................................................... 111

vii

LIST OF FIGURES

Figure 1: Illustration of a two-dimensional cutting process (orthogonal cutting) (a) with a

well-defined shear plane (b) without a well-defined shear plane. [1] .............................. 4

Figure 2: Oblique cutting. [2] .................................................................................................. 5

Figure 3: The relationship of velocity 𝑉𝑠, V and 𝑉𝑐 for orthogonal cutting. [4] ..................... 7

Figure 4: Free body diagram of orthogonal cutting. [4] .......................................................... 8

Figure 5: Merchant’s circular force diagram. [4] ..................................................................... 9

Figure 6: Basic types of chips produced in metal cutting: (a) continuous chip with

narrow, straight primary shear zone; (b) secondary shear zone at the tool-chip

interface; (c) continuous chip with built-up edge; (d) segmented or nonhomogeneous

chip; and (e) discontinuous chip. [1] ................................................................................ 13

Figure 7: Basic operations performed on a lathe. (a)facing (b)straight turning (c)taper

turning (d)grooving and cutting off (e)threading (f)tracer turning (g)drilling

(h)reaming (i) boring [3] .................................................................................................. 15

Figure 8: Typical cutting conditions for common external turning operations. [6] ................. 16

Figure 9: Proper selection of inserts geometry for turning operations. [6] ............................ 16

Figure 10: Crater wear of a turning tool. [1] ............................................................................ 22

Figure 11: Taylor tool life model (ln-ln coordinates) [3] ......................................................... 23

Figure 12: Typical tool wear curves for different cutting velocities (𝑉5 > 𝑉4 > 𝑉3 >𝑉2 > 𝑉1) [3] .................................................................................................................... 24

Figure 13: Flank wear features for single-point-tool wear in turning operations [8] ............... 24

Figure 14: Surface finish representation: Arithmetical roughness [3] ..................................... 25

Figure 15: Austempered ductile iron heat treatment cycle ...................................................... 30

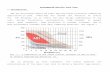

Figure 16: The austempering reaction ADI processing window (a) High austempering

temperature (b) Low austempering temperature .............................................................. 31

Figure 17: The microstructure of each ADI grade ................................................................... 43

Figure 18: SECO CNMG 120408-M5 TK2001 insert used in turning studies ........................ 45

Figure 19: the SECO DCLNR2525M12-M tool holder fixed on the HAAS lathe turret ........ 46

Figure 20: The experimental ADI test cylinders prior to pre – turning ................................... 47

viii

Figure 21: An ADI workpiece after initial surface removal prior to turning tests ................... 47

Figure 22: The Westover Portable Refractometer model RHB-32 used for cutting fluid

characterization ................................................................................................................ 48

Figure 23: The procedure for measuring coolant concentration shown schematically ............ 48

Figure 24: Test cylinder placement for turning studies ........................................................... 49

Figure 25: Nikon SMZ800 stereoscope and fixtures used for tool wear measurement. .......... 52

Figure 26: Mahr Pocket Surf III profilometer and the calibration piece EPL-1691 Riser

Plate used for surface roughness measurements. ............................................................. 53

Figure 29: Tool wear progressions for GR1200 at different cutting speeds, (Depth of cut

= 0.06 in, feed rate = 0.012 ipr) ....................................................................................... 59

Figure 30: Tool wear progressions for GR1050 at different cutting speeds, (Depth of cut

= 0.06 in, feed rate = 0.012 ipr) ....................................................................................... 59

Figure 31: Tool wear progressions for GR900 at different cutting speeds, (Depth of cut =

0.06 in, feed rate = 0.012 ipr) ........................................................................................... 60

Figure 32: Tool wear progressions for DI 100-70-03 at different cutting speeds, (Depth of

cut = 0.06 in, feed rate = 0.012 ipr) .................................................................................. 60

Figure 33: Tool wear progressions for GR900, GR1050 and GR1200 at V = 375 fpm,

(Depth of cut = 0.06 in, feed rate = 0.012 ipr) ................................................................. 62

Figure 34: Tool wear progressions for GR900, GR1050 and GR1200 at V = 500 fpm,

(Depth of cut = 0.06 in, feed rate = 0.012 ipr) ................................................................. 63

Figure 35: Effect of cutting speed on tool life for each grade of ADI and DI 100-70-03.

(in terms of cutting time) (Depth of cut = 0.06 in, feed rate = 0.012 ipr) ........................ 64

Figure 36: Effect of cutting speed on tool life for each grade of ADI and DI 100-70-03.

(in terms of cutting length) (Depth of cut = 0.06 in, feed rate = 0.012 ipr) ..................... 64

Figure 37: Ln-Ln tool life plot for developing the Taylor tool life equation ........................... 66

Figure 38: Effect of cutting length on surface roughness (Ra) for ADI GR900 at different

cutting speeds (Depth of cut = 0.06 in, feed rate = 0.012 ipr).......................................... 68

Figure 39: Effect of cutting length on surface roughness (Ra) for ADI GR1050 at

different cutting speeds (Depth of cut = 0.06 in, feed rate = 0.012 ipr). .......................... 68

Figure 40: Effect of cutting length on surface roughness (Ra) for ADI GR1200 at

different cutting speeds (Depth of cut = 0.06 in, feed rate = 0.012 ipr). .......................... 69

ix

Figure 41: Effect of cutting length on surface roughness (Ra) for DI 100-70-03 at

different cutting speeds (Depth of cut = 0.06 in, feed rate = 0.012 ipr). .......................... 70

Figure 42: Effect of cutting speed on surface roughness (Ra) for all grades of ADI and DI

100-70-03 (Depth of cut = 0.06 in, feed rate = 0.012 ipr). ............................................... 70

x

LIST OF TABLES

Table 1: Comparison of Brinell hardness ranges for the various ADI grades ......................... 28

Table 2: Comparison of ISO, ASTM, SAE, and GB standard grades for ADI tensile

strength (MPa) – yield strength (MPa) – elongation (%) ................................................. 29

Table 3: Chemical composition of ductile irons used in this study ......................................... 42

Table 4: Ferrite and austenite volume fraction of each ADI grade after heat treated as

measured by X – ray diffraction ....................................................................................... 42

Table 5: Brinell hardness of each t material tested .................................................................. 44

Table 6: Cutting parameters used in this study for each grade of ADI and for ....................... 51

Table 7: Effect of cutting speed on chip form for ADI grades and DI 100-70-03 (Depth

of cut = 0.06 in, feed rate = 0.012 ipr) ............................................................................. 55

Table 8: Tool wear progression polynomial fit equations and R2 values for different the

grades of ADI and DI 100-70-03 ..................................................................................... 58

Table 9: Effect of cutting speed on tool life for each grade of ADI and DI 100-70-03 in

terms of cutting time and cutting length (Depth of cut = 0.06 in, feed rate = 0.012

ipr) .................................................................................................................................... 71

Table 10: Average surface roughness (Ra) for grades of ADI and DI 100-70-03 (Depth

of cut = 0.06 in, feed rate = 0.012 ipr) ............................................................................. 72

Table 11: Flank wear for ADI GR900 at 375 fpm (Depth of cut = 0.06 in, feed rate =

0.012 ipr) .......................................................................................................................... 82

Table 12: Flank wear for ADI GR900 at 500 fpm (Depth of cut = 0.06 in, feed rate =

0.012 ipr) .......................................................................................................................... 82

Table 13: Flank wear for ADI GR900 at 750 fpm (Depth of cut = 0.06 in, feed rate =

0.012 ipr) .......................................................................................................................... 83

Table 14: Flank wear for ADI GR900 at 1000 fpm (Depth of cut = 0.06 in, feed rate =

0.012 ipr) .......................................................................................................................... 83

Table 15: Flank wear for ADI GR1050 at 375 fpm (Depth of cut = 0.06 in, feed rate =

0.012 ipr) .......................................................................................................................... 83

Table 16: Flank wear for ADI GR1050 at 500 fpm (Depth of cut = 0.06 in, feed rate =

0.012 ipr) .......................................................................................................................... 84

xi

Table 17: Flank wear for ADI GR1050 at 750 fpm (Depth of cut = 0.06 in, feed rate =

0.012 ipr) .......................................................................................................................... 84

Table 18: Flank wear for ADI GR1050 at 1000 fpm (Depth of cut = 0.06 in, feed rate =

0.012 ipr) .......................................................................................................................... 84

Table 19: Flank wear for ADI GR1200 at 250 fpm (Depth of cut = 0.06 in, feed rate =

0.012 ipr) .......................................................................................................................... 85

Table 20: Flank wear for ADI GR1200 at 300 fpm (Depth of cut = 0.06 in, feed rate =

0.012 ipr) .......................................................................................................................... 86

Table 21: Flank wear for ADI GR1200 at 375 fpm (Depth of cut = 0.06 in, feed rate =

0.012 ipr) .......................................................................................................................... 86

Table 22: Flank wear for ADI GR1200 at 400 fpm (Depth of cut = 0.06 in, feed rate =

0.012 ipr) .......................................................................................................................... 87

Table 23: Flank wear for ADI GR1200 at 500 fpm (Depth of cut = 0.06 in, feed rate =

0.012 ipr) .......................................................................................................................... 87

Table 24: Flank wear for DI 100-70-03 at 500 fpm (Depth of cut = 0.06 in, feed rate =

0.012 ipr) .......................................................................................................................... 88

Table 25: Flank wear for DI 100-70-03 at 750 fpm (Depth of cut = 0.06 in, feed rate =

0.012 ipr) .......................................................................................................................... 89

Table 26: Flank wear for DI 100-70-03 at 1000 fpm (Depth of cut = 0.06 in, feed rate =

0.012 ipr) .......................................................................................................................... 90

Table 27: Effect of cutting speed on tool life for ADI grades in terms of cutting time for

all trials (Depth of cut = 0.06 in, feed rate = 0.012 ipr) ................................................... 90

Table 28: Average surface roughness for ADI GR900 (Depth of cut = 0.06 in, feed rate =

0.012 ipr) .......................................................................................................................... 91

Table 29: Average surface roughness for ADI GR1050 (Depth of cut = 0.06 in, feed rate

= 0.012 ipr) ....................................................................................................................... 91

Table 30: Average surface roughness for ADI GR1200 (Depth of cut = 0.06 in, feed rate

= 0.012 ipr) ....................................................................................................................... 92

Table 31: Average surface roughness for DI 100-70-03 (Depth of cut = 0.06 in, feed rate

= 0.012 ipr) ....................................................................................................................... 92

Table 32: Surface roughness measurements for ADI GR900 at 375 fpm (Depth of cut =

0.06 in, feed rate = 0.012 ipr) ........................................................................................... 93

Table 33: Surface roughness measurements for ADI GR900 at 500 fpm (Depth of cut =

0.06 in, feed rate = 0.012 ipr) ........................................................................................... 94

xii

Table 34: Surface roughness measurements for ADI GR900 at 750 fpm (Depth of cut =

0.06 in, feed rate = 0.012 ipr) ........................................................................................... 95

Table 35: Surface roughness measurements for ADI GR900 at 1000 fpm (Depth of cut =

0.06 in, feed rate = 0.012 ipr) ........................................................................................... 96

Table 36: Surface roughness measurements for ADI GR1050 at 375 fpm (Depth of cut =

0.06 in, feed rate = 0.012 ipr) ........................................................................................... 96

Table 37: Surface roughness measurements for ADI GR1050 at 500 fpm (Depth of cut =

0.06 in, feed rate = 0.012 ipr) ........................................................................................... 97

Table 38: Surface roughness measurements for ADI GR1050 at 750 fpm (Depth of cut =

0.06 in, feed rate = 0.012 ipr) ........................................................................................... 98

Table 39: Surface roughness measurements for ADI GR1050 at 1000 fpm (Depth of cut =

0.06 in, feed rate = 0.012 ipr) ........................................................................................... 98

Table 40: Surface roughness measurements for ADI GR1200 at 250 fpm (Depth of cut =

0.06 in, feed rate = 0.012 ipr) ........................................................................................... 99

Table 41: Surface roughness measurements for ADI GR1200 at 300 fpm (Depth of cut =

0.06 in, feed rate = 0.012 ipr) ........................................................................................... 101

Table 42: Surface roughness measurements for ADI GR1200 at 375 fpm (Depth of cut =

0.06 in, feed rate = 0.012 ipr) ........................................................................................... 102

Table 43: Surface roughness measurements for ADI GR1200 at 400 fpm (Depth of cut =

0.06 in, feed rate = 0.012 ipr) ........................................................................................... 103

Table 44: Surface roughness measurements for ADI GR1200 at 500 fpm (Depth of cut =

0.06 in, feed rate = 0.012 ipr) ........................................................................................... 103

Table 45: Surface roughness measurements for DI 100-70-03 at 500 fpm (Depth of cut =

0.06 in, feed rate = 0.012 ipr) ........................................................................................... 104

Table 46: Surface roughness measurements for ADI GR1200 at 750 fpm (Depth of cut =

0.06 in, feed rate = 0.012 ipr) ........................................................................................... 107

Table 47: Surface roughness measurements for ADI GR1200 at 1000 fpm (Depth of cut =

0.06 in, feed rate = 0.012 ipr) ........................................................................................... 108

Table 48: Identification chart for inserts used to machine ADI GR900 .................................. 109

Table 49: Identification chart for inserts used to machine ADI GR1050 ................................ 109

Table 50: Identification chart for inserts used to machine ADI GR1200 ................................ 110

Table 51: Identification chart for inserts used to machine DI 100-70-03 ................................ 110

xiii

ACKNOWLEDGEMENTS

I would like to first acknowledge my appreciation for my adviser, Professor Voigt. His helpful

comments on this paper and his patience over the past two years became the most crucial factor to

complete this thesis.

Also, I would like to thank and recognize the contributions of my senior Dika Handayani, support

specialists Dan Supko and Travis Richner for their help in platform setup, experiment design,

knowledge of manipulating the machine, and guidance in the analyzing methods used in this study

In addition, I would like to express my thanks to Professor Edward De Meter for his assistance to

review this study. This project was supported by Applied Process, Quaker Chemical Corp., and

SECO Tools. My thanks also goes out to Kathy Hayryen, the advisor from Applied Process, for her

suggestion, profession and guidance.

Last but not least, I want to thank my parents, Sea-Chang, Ting and Wu Hsiang-Chun, Ting, who

have supported me all the time and made this happen.

1

Chapter 1

INTRODUCTION

Background

Austempered ductile iron (ADI) is a relatively new material in cast iron family. In recent

years, ADI has been much more widely used in industry. ADI use is driven by its special

mechanical properties. Compared to ductile iron, ADI has improved strength, toughness and wear

resistance that are developed during on austempering heat treatment. In addition, ADI has other

advantages comparing to other competing materials. ADI components can often be produced at

costs that are less than forged steel, with similar strength levels and lower density. Also, the

strength, fatigue resistance, and wear resistance of ADI are higher than for aluminum alloys. With

these advantages, ADI has quickly developing into an important automotive material as well as

an important material in the railroad and defense industries for applications such as gears and

ordinance. ADI casting can be processed by variety of machining process such as turning,

milling, and drilling; however, its high hardness makes it difficult to machine. Even when rough

machining is performed prior to heat treatment, final machining after heat treatment can be

difficult.

Problem statement

In many cases, current and future applications of ADI are limited by difficulties in

machining the material. There is incomplete information in the proper cutting speeds and feed

rates when machining the various grades of ADI to achieve the desirable tool life and surface

2

finish to reduce machining cost. Therefore, manufacturers are often hesitant to completely

machine castings after austempering treatment. In order to decrease the overall cost and increase

the machining efficiency of the different grades of ADI, machinability studies must be conducted

to develop effective machining guidelines.

Objectives

The primary object of this study is to characterize the turning behavior of common grades

of ADI (GR900, GR1050, GR1200) under production turning conditions. Turning studies with

contemporary coated carbide tools, coolant, and fixed feed rates and depths of cut were

performed to develop the relationship between tool life and cutting speed. In addition, the effect

of the different cutting speeds on surface finish and chip formation will also be evaluated.

3

Chapter 2

BACKGOUND

Machining

Machining is a cutting process where in the surface layer of a work piece will be removed by the

cutting tool in chip form. [1] Figure 1 [1] shows this schematically. The unnecessary material is

removed and slides along the rake face of the cutting tool with a new face being formed by the

flank face. [1] Based on the geometric relationship of the tool to the workpiece, the cutting process

can classify into two different type of process - orthogonal cutting and oblique cutting. [1] The

orthogonal cutting is a fundamental two-force cutting geometry with the cutting edge oriented

perpendicular to the cutting direction. The analysis of orthogonal cutting is relatively simple

comparing to oblique cutting, because the cutting force can be modeled in only two dimensional.

Because it is easier to build and evaluate cutting models, the orthogonal cutting is widely using in

theoretical and experimental work. However, the majority of machining process are three-

dimensional oblique cutting. [1] [2] Unlike orthogonal cutting, in oblique cutting there is an

inclination angle to the cutting edge. In other words, the cutting edge is not perpendicular to the

cutting direction as showing in the Figure 2. [2]

4

Figure 1: Illustration of a two-dimensional cutting process (orthogonal cutting) (a) with a well-

defined shear plane (b) without a well-defined shear plane. [1]

5

Figure 2: Oblique cutting. [2]

Machining mechanics

The mechanism of metal cutting is dominated by localized shear deformation in the workpiece at

the cutting edge of the tool. Two different types of deformation could be classified during

machining. [3] The primary deformation is the interaction between the cutting tool and the

workpiece causing shear deformation and ultimate fracture which forms the chip. The secondary

deformation is when chips passed over the rake face of the cutting tool resulting in additional

deformation because of shearing and sliding of the chip against the tool. [3] These two

deformations are mutually dependence. Because the material that rubs the rake face generates

heat and plastic deformation during the primary process, the secondary deformation will be

affected by the formation of a shear plane. On the other hand, the shear direction is affected by

deformation and friction at the rake face which effects the heat and strain of the chips in the

primary process. [3] During machining, the chips is formed by the interaction of the tool and the

workpiece. The cutting process is shown schematically in Figure 1. [1] In this illustration, the tool

is assumed to travel relative to the workpiece with a velocity V, the cutting speed. The tool

6

geometry is defined by the tool rake angle α and tool clearance angle γ. The shear process occurs

in the shear plane with a shear angle ϕ and a shear velocity𝐹𝑠. Also, the uncut chip thickness,

𝑡0and the chip thickness which is assumed without deformation, 𝑡𝑐 both are shown in the figure.

The chips have a velocity 𝑉𝑐. Figure 2 shows that the 𝑉𝑠 is the vector velocity of V and 𝑉𝑐. [4]

The cutting ratio, or chip-thickness ratio r is important and useful for evaluating the cutting

condition as a parameter, and is always greater than unity. [1] The cutting ratio is defined by

relationships between the rake angle and the shear angle. Therefore the cutting ratio can also be

presented in the form of velocity and chip thickness as well, equation 1 and 2:

Tan ϕ = R Cosα / (1 - R Sinα) (equation 1)

R = 𝑡0/𝑡𝑐 = Sin ϕ / Cos (ϕ - α) = 𝑉𝑐 / V (equation 2) [4]

Note that since the R is always greater than one, the chip velocity is greater than the cutting

velocity. The velocities are also very important in estimating the power, temperature and

vibration analysis associated with chatter during chip formation. Velocity relationship can be also

be described with respect to the rake angle α and shear angle ϕ in Figure 3 [4]. The equation of

the relationship of the three velocities can be expressed as:

V / Cos (ϕ - α) = 𝑉𝑠 / Cos α = 𝑉𝑐 / Sin ϕ (equation 3)

The shear strain, γ on the shear plane in cutting can also be expressed as:

7

γ = Cot ϕ + Tan (ϕ - α) (equation 4)

The resultant strain rate γ𝑟 can be expressed as:

γ𝑟 = 𝑉𝑠 / ∆Y = [Cos α / Cos (ϕ - α)]* (V/∆Y) (equation 5)

Figure 3: The relationship of velocity 𝑽𝒔, V and 𝑽𝒄 for orthogonal cutting. [4]

Cutting force

The cutting force is a critical factor because it starts the process of chip formation and controls

both the flow of the chips and the thermal gradients involved in machining. [32] The interaction

of chip formation and other machining variables has a significant influence on cutting force.

Generally, the cutting forces are less for discontinuous chips than continuous chips. Also when

cutting force decreases, the relative chip thickness also decreases because of an increase in

8

cutting ratio or shear angle. [2]

For orthogonal cutting, the entire force system lies in a single plane as depicted in Figure 4.[4]

Overall the cutting force could be separated into two basic forces - the friction force F and the

normal force N acting on the tool-chip interface contact area. The resultant force R can also be

resolved into two forces - shear force 𝐹𝑠 and normal force 𝐹𝑛 acting on the shear plane area As.[4]

Figure 4: Free body diagram of orthogonal cutting. [4]

However, neither of these two sets of forces can be measured directly. Merchant’s circular force

diagram (Figure 5) can be used to analyze the resultant force R. As shown in the Figure 5, the

cutting force, R could be separated by cutting force 𝐹𝑐 and the tangential force𝐹𝑡, which are

measurable. The two forces 𝐹𝑐 and 𝐹𝑡 can then be used to calculate the resultant cutting force by

9

Equation 6:

F= √𝐹𝑐2 + 𝐹𝑡

2 (equation 6)

Figure 5: Merchant’s circular force diagram. [4]

The relations between the measurable forces (𝐹𝑐, 𝐹𝑡) and the other components of the resultant

force during orthogonal machining helps to calculate the forces in the primary and secondary

deformation zones. [28] The friction forces F and the normal forces N is shown in Equation 7 and

8:

F= (𝐹𝑐 Sin α) + (𝐹𝑡 Cos α) (equation 7)

N = (𝐹𝑐 Cos α) − (𝐹𝑡 Sin α) (equation 8)

10

The forces parallel and perpendicular to the shear plane can be described as:

𝐹𝑠= (𝐹𝑐 cos ϕ) - (𝐹𝑡 sin ϕ) (equation 9)

𝐹𝑛= (𝐹𝑐 sin ϕ) + (𝐹𝑡 cos ϕ) (equation 10)

Where ϕ is the shear angle and α is the rake angle.

The shear stress 𝜏𝑠 can be defined by equation 11 and 12:

𝜏𝑠 = 𝐹𝑠/𝐴𝑠 (equation 11)

Where 𝐴𝑠 is the shear plane area, could be expressed as equation 12:

𝐴𝑠 = 𝑡0w / sin ϕ (equation 12)

Note that 𝑡0 was the uncut chip thickness and w was the width of the workpiece. The shear stress

can also be expressed as:

𝜏𝑠 = (𝐹𝑐 Cos ϕ Sin ϕ -𝐹𝑡 Sin ϕ2) / 𝑡0w (equation 13)

11

Chip formation

The surfaces of chip formed by machining are different in the constrained and unconstrained

surfaces. The chip surface contacting with rake surface has a shiny appearance and is smooth.

The unconstrained surface is rough. The basic nature of the chips forming during machining can

be classified into four different types - continuous, build up edge (BUE), discontinuous, and

serrated (segment). [1]

Continuous chips usually form when machining a ductile material at high cutting speeds with

high rake angle tools. [1] The deformation of the workpiece occurs in a narrow shear zone, which

is called the primary deformation zone (Figure 6a) [1]. Continuous chips can potentially cause a

second deformation zone due to the high friction at the rake surface. The continuous chip usually

result in good surface finish of the workpiece. [1] However, continuous chip are typically not

desirable. Continuous chip may tangle around the tool holder, workpiece and the disposal system.

Tangling can result in stoppage time to clean the chip tangle. Tangling can be surmised by

changing the cutting parameter such as cutting speed, feed, depth of cut or using cutting fluid. [1]

The BUE chip is named because it has a layer of the material from the workpiece which is

progressively deposited on the tip of the cutting tool as shown in Figure 6c. [1] When the BUE

chip becomes larger, it will be unstable and break off the tool. Part of the BUE is carried away

from the tool side of the chip and randomly deposited on the workpiece surface. This cycle of

BUE formation and destruction will repeat continuously during machining. [1] The BUE

effectively changes the geometry of the cutting edge and makes it “dull”. Therefore, it has a

negative effect on the surface finish. However, if the BUE is stable, the tool wear will actually

decrease by protecting the rake face of the tool from wear. The tendency of BUE formation is

generally decreased by increasing cutting speed, rake angle and decreasing the depth of cut.

12

Using the sharp cutting tool and proper cutting fluid also decreases the tendency of BUE

formation. [1]

A discontinuous chip, shown in Figure 6e, is defined as chip segments connected firmly or

loosely to each other. [1] Discontinuous chip formation during the machining is because of a

series of discrete chip segments that fracture as stress concentrates in the workpiece. [2]

Discontinuous chip formation usually takes place when machining a material with inclusions, or

points of stress concentration such as cast iron due to the brittle graphite phase that doesn’t have

the capacity to undergo the high shear strain involved in cutting. [1] [2] Certain cutting conditions

increase the tendency of forming discontinuous chips. The conditions of very low or very high

cutting speed, large depth of cut, low rake angles and lack of proper cutting fluid will all increase

the tendency of discontinuous chip formation. [1]

Sometimes a discontinuous chip has a semi-continuous appearance such as in Figure 6d which is

called a serrated (segmented, nonhomogeneous) chip. The serrated chip has large zones of low

shear strain and small zones of high shear strain. (Shear localization). The serrated chip usually

occurs when machining low thermal conductivity and low strength materials decreasing

significantly with temperature (thermal softening) such as titanium, resulting in a sawtooth like

chip during machining. [1]

13

Figure 6: Basic types of chips produced in metal cutting: (a) continuous chip with narrow,

straight primary shear zone; (b) secondary shear zone at the tool-chip interface; (c) continuous

chip with built-up edge; (d) segmented or nonhomogeneous chip; and (e) discontinuous chip. [1]

Due to the structure of discontinuous and serrated chips, the cutting force will oscillate when

producing those types of chips. [1] Consequently, the stiffness or rigidity of the cutting equipment

such as the tool holder, the workpiece holding device, and the cutting tool are important. If the

stiffness of the equipment is not sufficient, the cutting tool will vibrate and chatter, leading to

poor surface finish, poor dimensional accuracy, and premature tool wear. [1]

14

Turning

Turning is a widely used material removal process generally rotating the workpiece on a lathe and

feeding the cutting tool mounted on the lathe into the workpiece to remove the unnecessary part

of workpiece to the required shape. [2] All turning operations can be divided into two categories -

the workpiece is situated in the center between chucks or fixed at the one end without support at

the other end. [3] The workpiece is held and rotated as the cutting tool moves with a certain depth

of cut travel in one direction under the certain velocity. Other than the depth of cut and cutting

speed (velocity), feed rate is also an important cutting parameter of turning. The feed rate is the

distance of tool travels horizontally or vertically per unit revolution of the workpiece. [2] Figure 7

showing the common operations performing that could be achieved by turning on lathe with

different kinds of cutting equipment. [3] The common machining process could be done by lathe

are:

1. Turning: to produce straight, conical, curved or grooved of workpiece such as shafts,

spindle, and pins.

2. Facing: to produce a flat surface which is parallel to the rotating direction at the end of

the workpiece for the parts needed to be assembled with other components.

3. Boring: to enlarge a hole or cylindrical cavity made by previous process or to produce

circular internal grooves.

4. Drilling: to produce a hole or improve the dimensional accuracy and surface finish of

boring hole.

5. Parting: (as cut off); the process is to cut a piece from the end of the workpiece.

15

Figure 7: Basic operations performed on a lathe. (a)facing (b)straight turning (c)taper turning

(d)grooving and cutting off (e)threading (f)tracer turning (g)drilling (h)reaming (i) boring [3]

Cutting tool geometry

Most turning is done as single-point turning. [1] [4] Single point of turning could be further

classified into rough and finish turning based on the different feed rate and depth of cut. [1] [6]

Finish turning is after initial roughing cuts improve dimensional accuracy and improves surface

finish. [1] [4] The tool geometry is important to effectively control chip formation. [6]

Rake angle controls the chip flow direction and the tool tip strength. In general, positive rake

angles reduce cutting force and temperature. However, positive rake angles have the risk of

16

premature tool chipping and failure. For brittle, high strength materials, the rake angle should be

negative. Increasing the wedge angle (the angle between the top face and the clearance angle) will

create a stronger cutting edge but require greater power to machine. [6] The clearance angle is

also important. If the clearance angle is too large, chipping is more likely. However, if it is too

small, the flank wear would increase and the finish surface will be adversely affected.

Another important factor of tool geometry is nose radius. Nose radius can significantly affect the

surface finish and tool tip strength. Smaller nose radius will reduce surface finish at high feed

rates. [1] When roughing the workpiece, the nose radi should be larger to increase the strength of

the tool point, Figure 9. [6] In addition, the machining with bigger nose radi is more desirable at

higher feed rates. [6] In general, it is recommended that the feed rate for roughing should be 50%

of the size of the nose radius in order to have expected surface finish. [6]

Figure 8: Typical cutting conditions for common external turning operations. [6]

Figure 9: Proper selection of inserts geometry for turning operations. [6]

17

Cutting parameters and material removal rates

The key cutting parameter in turning are cutting speed, feed rate and depth of cut. [4] The surface

cutting speed is built on the RPM of the rotating workpiece and diameter of the workpiece

𝑉𝑚𝑎𝑥 = π 𝐷0𝑁𝑠 (equation 14)

Where 𝐷0 is the original cutting diameter (mm/in) during turning process, 𝑁𝑠 is the rotation speed

of the workpiece. (rpm)

Or 𝑉𝑎𝑣𝑔 = π 𝐷𝑎𝑣𝑔𝑁𝑠 (equation 15)

Where 𝐷𝑎𝑣𝑔is the average cutting diameter (mm/in) during turning process, the 𝐷𝑎𝑣𝑔 could be

calculated by equation 16:

𝐷𝑎𝑣𝑔 = (𝐷0 +𝐷𝑓 ) / 2 (equation 16)

Where 𝐷𝑓 (mm/in) is the final diameter.

The feed rate, the distance of tool travels per unit revolution (𝐹𝑟) is given by equation 17:

18

d = DOC = (𝑑1 +𝑑2 ) / 2 (mm/in) (equation 17)

Note that 𝑑1 is the original diameter before cutting and 𝑑2 is the new diameter after machining.

The length of cut is not only the distance traveled parallel to the perpendicular axis of machining

the workpiece but also the sum of allowance or overrun distance before or after machining. [4]

The cutting time (T), can be calculate by equation 18:

T = (L+A) / 𝐹𝑟𝑁𝑠 (equation 18)

Where Ns is the rotation speed of workpiece (RPM), A is the distance before or after machining.

[4]

The material removal rate (MRR) is the volume of material removed per unit time (𝑚𝑚3 or

𝑖𝑛𝑐ℎ3 / min), as follows:

MMR = volume removed / time = π [(𝑑1/2)2 - (𝑑2/2)2] 𝐹𝑟𝑁𝑠 (equation 19)

If the average MRR is required, the average diameter is used instead of the single diameter of a

particular cut. The average MRR can be described as:

MRR = π 𝐷𝑎𝑣𝑔 d 𝐹𝑟𝑁𝑠 or d 𝐹𝑟V (equation 20)

19

Cutting fluid

The cutting fluid is also a very important during turning. The basic two functions of cutting fluid

are cooling and lubrication which decreasing the friction force and temperature of the interface

between tool and workpiece. [3] At moderate cutting the lubrication and cooling are both

important, and for low speed cutting, the function of cutting fluid is mainly for lubrication. [3]

Compared to dry cutting, use of a cutting fluid can increase the productivity and reduce the cost

by making possible of using higher the depth of cut, cutting speed, and feed rate. The effective

application of cutting fluid can increase the tool life, dimensional accuracy, as well as decrease

the surface roughness and power consumption. The choice and effectiveness of cutting fluid can

be determined by the condition of the machine tool, cutting parameters (speed, feed rate, depth of

cut), composition, finish, geometry of the cutting tool, mode of fluid application, geometry of

material is machined, surface coatings, and the composition microstructure, and residual stress

distribution of the workpiece. [3]

Machinability

The machinability of a material is not only based on the metallurgical properties such as hardness,

microstructure, and chemical composition but also on compatibility with the machining process

including the shape of cut, the cutting tool and the cutting fluid. Different machining

environments can have a significant effect on machinability rankings. [2] Furthermore, no single

dependent variable in machining is universally accepted as a measure of machinability. As a

result, machinability ratings for a material will vary depending on the different methods used to

evaluate machinability such as surface finish, tool life, cutting force, and chip formation.

20

Chip formation

The shape of chip formation, can be an important indicator of machinability. The formation of

short chips are considered as a better result than long, unbroken or small, powder like chips. [28]

A ductile material that forms long, unbroken, or continuous chip has more tendency to burrs,

especially as tools wear. [5] The burr formation are often used to evaluate the machinability of

soft, ductile materials such as aluminum. In addition, comparing chip type (the continuous chip or

discontinuous chip) indicates ease of chip recycling and tendency to clog the machine. [26]

Cutting force

The cutting force is another method used to evaluate machinability. Various cutting parameters

have a significant influence on cutting force. Typically the feed rate, depth of cut has more of an

effect on cutting forces than cutting speed. [5] The cutting forces increase significantly with flank

wear. In general, low cutting force result in the longer tool life and improved dimensional

accuracy. [5] The tool geometry also affect the cutting force. The cutting force is reduced when

the rake angle increases. [5] In general, the use of force as an indicator of relative machinability is

based on the assumption that more difficult to machine metals require more cutting force. [2]

However, the tool force is not typically used as the sole measurement of machining quality. [2]

[7]

Tool life

Tool life studies are the most direct method to evaluate the machinability of materials. When tool

life increases, the effective machinability also increases. [28] However, tool wear can occur by

various mechanism: abrasion, adhesion, diffusion, chemical wear, and oxidation wear. [2]

Abrasion wear takes place when hard material and hard particles on the surface of the chip slide

on the tool faces and remove tool material. The hard particles could be fragments of the BUE or

21

abrasive inclusions within the workpiece material. [2] Adhesion wear occurs when the frictional

environment at the interface between the tool and chip, caused by pressure and high temperature,

causes welding at the interface of chips and tool face. When the welds fracture, a small part of

tool material is carried away with the chips. [2] Diffusion wear occurs when the atoms of a

metallic crystal lattice diffuse from an area of high atomic concentration in the workpiece to an

area of low concentration in the tool, due to the high temperature at the interface between the tool

and the chip on the workpiece. Chemical wear is a chemical reaction that wears the tool by

corrosion. The oxidation wear occurs at very high temperature at the point at which the structure

of the cutting tool is weakened through oxidation reactions. The high temperature softens the

microstructure of cutting tool and weakens the edge of the cutting tool. [2]

The tool wear can be classified into many different types, such as flank wear, crater wear, nose

wear, notching, plastic deformation of the tool tip, chipping and gross fracture. [1] Among the

various type of wear, flank wear and crater wear are commonly used to characterize tool wear in

most studies, Figure 10 [1] shows characteristic of crater wear and the flank wear on a turning

tool. [1] [3] Crater wear is observed on the rake face of the cutting tool and flank wear is occurred

on relief face of the cutting tool. Crater wear is a result of both of abrasion and diffusion [6] and

is believed to be a thermochemical reaction. [2] The evaluation of crater wear can be done by

measuring the location of the maximum depth of the crater, KT, Figure 10. KT is also coincides

with the location of the maximum temperature at the tool-chip interface. [1] Crater wear is

normally generated by diffusion mechanisms. With the increased tool temperature, the crater

wear increases as well. [1] Crater wear is normally used for evaluating tool wear in extreme

conditions. [28] However, flank wear is more typically used to evaluate tool wear. [40]

Flank wear generation is caused by the rubbing of the tool along the machined surface causing

adhesive and/or abrasive wear. [1] Various tool life models have been used to predict the tool life

22

based on tool wear. One of the earliest successful tool life model was developed by F.W Taylor in

1907. In this model, the relationship between cutting velocity and tool life is used and to optimize

the tool performance during machining. The Taylor’s tool life equation is generally expressed as:

[3]

V𝑇𝑛 = C (equation 21)

Where T is the tool life, V is cutting speed, and C and n are material constants. When time to

develop a given amount of flank wear is fixed, recommended cutting speeds can be estimated. [1]

The constants n and C are obtained by testing cutting tools at different cutting conditions and

using the tool life criterion to establish a point at which the defined end of tool life is achieved.

[3] The exponent n primarily depends on the tool material and other factors such as workpiece

material and cutting conditions. [1] The n value range for common tool materials are: 0.08-0.2 for

high-speed steels, 0.2-0.5 for carbides, 0.4-0.6 for coated carbides, and 0.5-0.7 for ceramic cutting

tool. [1] The constant C is numerically equal to the value of the cutting speed when T is equal to

one minute. It is widely used as a measure of machinability for particular cutting tools and cutting

conditions. [3]

Figure 10: Crater wear of a turning tool. [1]

23

Figure 12 [3] shows typical tool wear curves at different cutting velocities. The shape of the curve

can be broken into three sections - initial wear, where the sharp edge wears quickly, the steady-

state wear in the middle, where wear progresses at a constant rate, and accelerated wear, where

the tool wear rapidly increases just before total failure. Flank wear (W1, Figure 12) is typically

the criteria for limiting tool wear. The width of flank wear land is an appropriate wear criteria for

single point cutting. The wear land can be classified into three zones. The first zone, C, is located

at the tool corner. The second and third, zones B and A, are on the cutting faces, which stop at the

zone N. In the zone B, the wear land is relatively uniform. Two different wear land width can be

identified, the maximum width of flank wear 𝑉𝐵𝐵max and the average wear land width VB.

Either criteria can be considered identified as critical indicators of tool wear. [8] When the wear

land is uniform, the VB criteria is used for measuring the tool life. If the uniform wear land width

reaches the value of 0.3mm, it is considered as tool failure. When the wear land is not uniform,

𝑉𝐵𝐵max is considered. When the 𝑉𝐵𝐵max reaches 0.6mm, the tool is considered as reaching the

end of its life. [8]

Figure 11: Taylor tool life model (ln-ln coordinates) [3]

24

Figure 12: Typical tool wear curves for different cutting velocities (𝑽𝟓 > 𝑽𝟒 > 𝑽𝟑 >𝑽𝟐 > 𝑽𝟏) [3]

Figure 13: Flank wear features for single-point-tool wear in turning operations [8]

25

Surface finish

Surface finish plays an important role in influencing the dimensional accuracy, properties, and

performance of machined parts. [1] The surface finish is typically characterized by measuring

surface roughness. The surface roughness has many different designations, including the

arithmetical roughness 𝑅𝑎, root mean square (rms) roughness 𝑅𝑞, maximum peak to valley

roughness height, 𝑅𝑦 or 𝑅𝑚𝑎𝑥, ten-points height, 𝑅𝑧. [3] Among the various designations, the

arithmetical roughness Ra is the most common method of designating surface roughness in the

US. [3] The 𝑅𝑎 is the average of absolute deviation of the workpiece surface from the centerline

as shown in the Figure 14 [3] and can be expressed as:

𝑅𝑎=1

𝐿∫ |𝑦|

𝐿

0dx (equation 24)

Where L is length of the measurement and y is the ordinate of profile from the centerline.

Figure 14: Surface finish representation: Arithmetical roughness [3]

26

Surface roughness is a function of tool feed and the geometry and is also influenced by BUE,

chatter and inaccuracies in machine tool movement. [9] [10] The roughness value is also

influenced by the feed rate and tool nose radius. The equation of ideal surface roughness is shown

in equation 25 [3]:

𝑅𝑎 = 0.0321f 2 / r (equation 25)

The theoretical surface roughness can be estimated from feed rate, tool radius, and cutting edge

angle for cases when the feed rate does not exceed the theoretical (nose radius) limit. If feed rates

exceed the limit, the resulting scallop is not a strict function of the nose radius but also depends

on the end cutting edge angle. The actual surface using a given tool could be worse than

estimated because of BUE generation during the machining process. [3] However, in other

situations, the actual surface roughness is also less than the theoretical surface roughness because

of tool wear on the cutting edge that produces a finer finished surface. The wear land of the tool

provides the wiping action that tend to smooth out the surface irregularities. [3] Good surface

finish is an indicator of machinability. With its significant influence on tool-tip, the BUE profile

can also have a great effect on the surface finished. [1] Therefore, ceramic and diamond tools

generate better surface finishes than other tools due to the in lower tendency to form a BUE. [1]

The tool tip radius is typically large in relation to the depth of cut. Otherwise the tool will rub

over the surface and generate heat and residual surface stress sometimes causing tearing and

cracking. As a result, depth of cut should be larger than the radius of cutting edge. In addition,

27

vibration and chatter during machining can also adversely affect surface finish because vibration

and chatter of the tool will periodically change the dimension of the cut. [1]

Development of ADI

ADI develops an “ausferrite” matrix structure after heat treatment, a mixed microstructure of

acicular ferrite and carbon – enriched stabled austenite. The austempering process was first

developed by 2 researchers working of United States Steel Laboratories, Davenport and Bain, in

the early 1930’s for heat treating steels. [22] Much later, the unique ausferrite banite

microstructure of cast iron was discovered. [24] However, commercialization of austempered cast

irons has lagged. [23]

In 1948, ductile iron (DI) was first developed by British Cast Iron Research Association. Ductile

iron is a unique material with spherical shaped graphite structure. DI has high strength, has higher

elastic modulus and substantial ductility. Soon after DI was developed, International Harvester

and General Motors started to use the austempering process on DI in research studies in the

1960’s.[26] However, ADI was not produced commercially until the early 1970’s. In 1972, the

Tecumseh Products announced the first commercial ADI product – a compressor crankshaft. [27]

Since then, more and more companies have started to use ADI. The Finnish company

KymiKymmene Metal used ADI to replace forged steel for a set of gears in the early 1970’s. In

late 1970’s, General Motors replaced a wide range of steel gears, pinions, and velocity joints in

light vehicles with ADI. [27]

Since the 1980’s ADI applications have been continuous increasing in North America. The

Cummins Engine started to make ADI timing gears produced to AGMA class 8 standards, in their

B and C series diesel engines in 1984. [27] The main reason for the market expansion is cost

28

reduction. The price per unit of mass for ductile iron was typically half that of steel. When the

extra cost of austempering process was added, the ADI products are still much more economical

than steel. [26] Because of the increasing application of ADI in 1980’s, ADI material

specifications were developed. In 1990, the first US standards - ASTM 897/897M for ADI were

released. [26] In this standard various grades of ADI are specified for many applications. Updated

ADI standards were released in 2000’s. Currently, there are four common standards - ASTM

(A897/A879M) first issued in 2002, SAE (J2477) issued in 2003, ISO (17804) issued in 2005,

and China standard GB/T24733 issued in 2009. The Table 1 shows the comparison of the

hardness of the different standard grades. Table 2 shows the yield strength (MPa) - elongation

(%) for the various grades.

Table 1: Comparison of Brinell hardness ranges for the various ADI grades

Hardness Range (HB)

Grades ISO 17804 SAE J2477 ASTM

A897/A897M

800 250-310

850 269-321

900 280-340 269-341

1050 320-380 302-375 302-363

1200 340-420 341-444 341-444

1400 380-480 388-477 388-477

1600 402-512 444-512

*Based on tensile strength (MPA)

29

Table 2: Comparison of ISO, ASTM, SAE, and GB standard grades for ADI

tensile strength (MPa) – yield strength (MPa) – elongation (%)

ISO 17804

Issued 2005

SAE J2477

Issued 2003

Revised 2004

ASTM

A897/A879M

2006

GB/T24733

Issued 2009

800-500-10 750-500-11 750-500-11 800-500-10

900-600-08 900-650-09 900-650-09 900-600-08

1050-700-06 1050-750-07 1050-750-07 1050-700-06

1200-850-03 1200-850-04 1200-850-04 1200-850-03

1400-1100-01 1400-1100-02 1400-1100-02 1400-1100-01

1600-1300-01 1600-1300-01

In 2003, the annual worldwide production of ADI was estimated as 125,000 tons and it was

predicted to exceed 300,000 tons by 2020. However, the annual world production of ADI has

grown at a faster pace. In the 2009, the estimated annual world production of ADI had already

reached 300,000 tons in the end of 2010. [25] Today, ADI is widely used for agricultural

equipment, construction equipment and gear or powertrain components. Also heavy truck or

trailers, light vehicles and buses, mining or forestry equipment, railway, equipment, farm and

oilfield machinery, conveyor and tooling equipment, defense, energy generation and sporting

goods all have ADI components. Without a doubt, the production and application of ADI will

continue to grow in future. [28]

Production of ADI

The production of ADI is a two-stage isothermal heat treatment process – austenitization

followed by austempering. During the austenitizing stage, the matrix microstructure of ductile

iron will be transformed into austenite followed by rapid cooling to the austempering

temperature. In the austempering process stage, the reaction is transformation of austenite (𝛾) to

form ferrite (𝛼) and carbon- enriched stabilised austenite (𝛾𝑠). Excessive holding at the

30

austempering temperature will result in the carbon- enriched stabilised austenite decomposing to

ferrite and carbide (conventional bainite). The entire production process could be separated into

five stage, shown in Figure 15 [14]. In the first austenitization stage (section A-B and B-C in

Figure 15) [14], the casting is heated to an austenitizing temperature of between 1550 ℉ to

1750 ℉ for sufficient time (one to three hours) in order to completely austenitize the

microstructure.

Figure 15: Austempered ductile iron heat treatment cycle

The next step is the quenching stage, the section of C-D in Figure 15 [14]. The temperature of

casting must be dropped to 450 ℉ to 750 ℉ in the austempering temperature range. In this stage,

the quenching rate is very important. The quenching rate must be high as possible to reach the

austempering temperature without transforming any of the austenite to pearlite.

31

After reaching to the temperature between 450 ℉ and 750 ℉. The components held for a period

of time (D-E in figure X). This is known as the austempering time. The holding time in this stage

is very crucial due to the heat treatment processing window, showing in the Figure 16, is defined

as the gap of time period between the first reaction is completed ( 𝛾 → 𝛼 + 𝛾𝑠+𝑐) and the before

the second reaction starts, ( 𝛾 → 𝛼 + 𝐹𝑒3𝐶). During the austempering stage, because of the

silicon content of ductile iron, the conventional bainite reaction that occurs in is suppressed,

causing the carbon rejected by bainite to ferrite enrich the carbon content of remaining austenite

until the austenite matrix is stabilized. [20] To achieve desirable properties, the austempering

time should stop before the second stage starts. However, if the austempering time is too short,

the higher carbon content austenite is not fully stabilized and will transform into martensite upon

cooling. The bainite and martensite structures, which should be avoided, would both affect the

mechanical properties of ADI. The last stage (E to F, in Figure 15) is cooling to room

temperature, resulting in a matrix of ausferrite, consisting of ferrite needles in carbon- enriched,

stabilized austenite.

Figure 16: The austempering reaction ADI processing window (a) High austempering

temperature (b) Low austempering temperature

32

The three main factors that affect success are austempering time and temperature, austenitizing

time and temperature and a cooling rate sufficient for the casting/alloy combination. [27] The

Austenitizing time and temperature are factors that cannot be ignored when producing ADI. The

austenitizing temperature is related to dissolved carbon, and the reduction in the rate of

austempering. [28] The purpose of the austenitizing is to saturate the austenite matrix with

carbon. Austenitizing temperature affects the final carbon content of the austenite. Increasing the

austenitizing temperature causes an increase in the carbon content of austenite, leading to higher

hardness and strength after austempering, [27] but slowing the transformation during

austempering and sometimes reducing the mechanical properties after austempering. High carbon

content austenite needs more time to transform to ausferrite [27]. During the austempering

process, decreasing the austempering temperature will delay the austempering transformation

start and completion times. At lower temperature the austenite structure may not complete

stabilize. [28] On the other hand, lower temperature also create lower austenite contents with fine

ferrite needles with some bainitic ausferrite formation. The higher austempering temperature

leads to a coarser ausferrite microstructure, which consist of coarse and distinct bainitic ferrite

needles, with more ductility but less strength and hardness than ADI’s transformed at lower

austempering temperatures [29].

The proper austenitizing temperature is dependent on the chemical composition of DI. Elements

such as manganese, silicon and molybdenum play an important role in selecting the proper

austenitizing temperature. [18] The upper critical austenitizing temperature (UCT) is the lowest

temperature for forming austenite + graphite (γ + G) as described on the Fe – C phase diagram.

The manganese will decrease the UTC while the silicon and molybdenum will raise it. [18].

However, if the austenitizing is performed below the UTC, proeutectoid ferrite will be present in

33

the final microstructure, resulting in a lower strength and hardness material after austempering.

[20]

The time of austenitization is also very important. Insufficient holding time would result in an

austenite matrix that is not fully saturated with carbon. The time is affected by composition;

heavily alloyed irons will take more time to austenitize. [18] Han claims that an austenitization

temperature at 900 ℃ for 1.5 hours will increase the size of austempering process window and

will shorten the time for decomposition of austenite. [30]

The austempering temperature and time also have a significant effect on ADI performance. These

two factors will influence the mechanical properties, because they affect the composition of the

micro – constituents. Figure 16 [29] shows the influence of temperature on microstructure. At low

austempering temperatures, the carbon diffusion rate is low, resulting in a limited amount of

austenite carbon enrichment in stage 1 and accompanied by the co-precipitation of carbides in the

ferrite. On the other hand, high austempering temperatures will increase the diffusion rate of

carbon. Therefore, these microstructure would have more carbon - enriched stabilised austenite.

The matrix of ADI can have up to 50% of carbon - enriched stabilised austenite. [29]

The austempering temperature is normally controlled between 450 ℉ and 750 ℉. If the

temperature dropping too low during the quenching stage, it will generate martensite. Martensite

will adversely affect the mechanical properties of ADI. Therefore the austempering temperature

must be controlled above the martensite start temperature. On the other hand, if austempering

temperature is too high or the quenching process is slow, pearlite will form instead of ausferrite.

[16]

Due to the different proportion of austenite and ferrite in microstructure at different austempering

temperatures, the mechanical properties vary as austempering temperature changes. At high

34

austempering temperature larger proportions of stabilized austenite are produced and the hardness

and strength are lower but the ductility is improved. [11] [12] [13] [29] [31]

The austempering time is another critical factor to affect the production of ADI. Insufficient

austempering holding time causes insufficient carbon stabilisation of austenite and transforms the

microstructure to martensite during subsequent cooling to room temperature. The formation of

martensite will increase the strength and hardness, but will significantly decrease the ductility

resulting in brittle performance. [14] [28] [29] [32] Also, long austempering time should be

avoided. Excessive austempering times will lead to decomposition of stabilised austenite to form

ferrite and carbide [29] [33] and decrease the ductility and toughness [29], but not significantly

affect the hardness and strength. [11] [15] [33] The desired ADI matrix should be thought of as a

metastable or intermediate microstructure of ferrite and stabilized austenite with a temperature –

time austempering processing window defining successful heat treatment. [29]

The austempering stage 1 (within the processing window) and undesirable Stage 2 reactions (over

- austempering) are shown in Figure 16.

Stage 1: 𝛾 (𝐴𝑢𝑠𝑡𝑒𝑛𝑖𝑡𝑒) → 𝛼 (𝐹𝑒𝑟𝑟𝑖𝑡𝑒) + 𝛾𝑠 (𝑐𝑎𝑟𝑏𝑜𝑛 − 𝑒𝑛𝑟𝑖𝑐ℎ𝑒𝑑 𝑠𝑡𝑎𝑏𝑖𝑙𝑖𝑠𝑒𝑑 𝑎𝑢𝑠𝑡𝑒𝑛𝑖𝑡𝑒)

Stage 2: 𝛾𝑠(𝑐𝑎𝑟𝑏𝑜𝑛 − 𝑒𝑛𝑟𝑖𝑐ℎ𝑒𝑑 𝑠𝑡𝑎𝑏𝑖𝑙𝑖𝑠𝑒𝑑 𝑎𝑢𝑠𝑡𝑒𝑛𝑖𝑡𝑒) → 𝛼 (𝐹𝑒𝑟𝑟𝑖𝑡𝑒) + 𝜀 (𝐶𝑎𝑟𝑏𝑖𝑑𝑒)

Alloy elements influence the size of the heat treatment processing window for ADI and thus can

have a significant influence on the microstructure and mechanical properties. [31] Alloying

element in ADI help to prevent pearlite and ferrite formation upon cooling from the austenitizing

temperature and make the ADI production easier to control in the processing widow by shifting it

35

to the right and delaying carbide precipitation during the bainitic transformation. [21] However,

an improper alloy composition would cause significant alloy segregation, which will affect the

microstructure and mechanical properties adversely. Ni, Si, Mn, Cu, Mo are the common alloying

elements that have significant effect on ADI. [30] Nickel (Ni) tends to prolong the decomposition

of the carbon with austenite during the austempering process. The use Ni is limited because of its

high cost.

The roles of Manganese (Mn) and Molybdenum (Mo) are similar. They are used for preventing

pearlite during the austempering process and stabilised the austenite, making the carbon difficult

to decompose. However, Mn and Mo can also cause the serious segregation and formation of

martensite, which will limit mechanical properties. Since Mo segregates more than Mn, the

amount of Mo should be controlled carefully. The amount of Mo is normally limited to between

0.01 - 0.3wt%. Copper (Cu) can also be used for slowing the second stage of austempering

process, creating a wider process window with only a small influence the mechanical properties.

Silicon (Si) is an important element for production of DI as well as for controlling the

austempering reaction. The main function of Si during austempering process is to stabilize the

austenite and decrease the carbide formation at the second stage. The amount of Si normally

limited between 2.0% and 2.5% for effective DI production. [30]

36

Chapter 3

PREVIOUS RESEARCH

Machining of ADI

The machinability of a metal is very important in industry. During the past thirty years, many ADI

machining studies have published. Most of these studies have focused on the lower strength grades

of ADI. However, the growth of ADI markets are still impeded due to insufficient information on

the machining of ADI.

There are three different strategies for machining ADI. [14] [35] [36] The three strategies are:

1. Machining before heat treatment

2. Rough machining prior to heat treatment followed by final machining after heat treatment.

3. Machining after heat treatment.

The first method is primary to circumvent the difficulty of machining ADI. The process can be

widely used depending on the proper design and predictable part growth during the austempering

process of the component. Normally, this method is using for wide dimensional tolerance parts.

The second method is using when tight tolerance and surface finishes can’t held during heat

treatment. One of the advantage for using this method is improvement of final part fatigue

strength. However, the process is costly and can cause logistical problems. [14] Machining after

heat treatment avoids the logistical problems and cost of machining twice while maintain tight

tolerances and good surface finish. [14]

The two main difficulties when machining ADI are the high hardness of ADI and the strain-

induced transformation from the austenite structure to the harder and more brittle martensite on

37

the surface of the ADI component. [14] [36] Strain-induced transformation of ADI is because the

austenite structure will transform to martensite structure under plastic strain directly beneath and

ahead of the cutting tool. The strain induced transformation of ADI severely resists further fine

machining, leading to overall poor tool life and tool failure. [41]

From the view of material removal rates, ADI is not as easily machined as pearlitic or ferritic

ductile irons, but does machine comparably to 30Rc hardened steel [14]. The recommended

material removal rates of ADI are reported to be 75% of that of pearlitic ductile irons [36]. Also,

the recommended setting machining parameters for machining ADI are 50% less speed and 50%

deeper depth of cut when compared to other materials with similar hardnesses. [14] [36]

The effect of different cutting parameters on the machinability is one of the main targets of this

ADI turning research. Turning tool life depends on speed, feed rate, cutting tool material and depth

of cut. The choice of cutting tool is also a critical factor affecting machinability. [37] [38]

Cutting speed

The cutting speed has a significant influence on turning tool life. The evaluation of

turning tool life is typically based the tool wear. [39] Flank wear is typically used to evaluate tool

wear instead of crater wear because the flank wear during turning directly affects the accuracy of

the product. [40] As cutting speed increases, the tool life will decrease significantly. [31] [32]

[33] [34] [35] The cutting speed will also influence chip formation. Austenite on ADI surface

transforms to martensite due to the associated high surface strains. The brittle, hard martensite

that forms accelerates tool wear and forms discontinuous chips. [44]. The surface roughness will

also be influenced by cutting speed because high cutting speeds result in higher temperatures on

the surface of tool and at tool-chip interface. [41] [42] [45] Ucun and Gök used CBN cutting tools

at various cutting speeds (200, 300,400 m/min) to machine ADI austempered at different

38

austempering temperatures (250, 350℃). The result shows that the higher cutting speed and

associated high strain rates, lead to the formation of martensite and discontinuous, smaller chips

and shorten tool life. [44] In research by Aslantas and Ucun [45], two type of cutting tools (nose

radius 0.4 mm) - ceramic (Al2O3 based) and cermet (TiCN+TiN coated), were compared under

various cutting speeds, constant depth of cut and feed rate when machining two different grades

of ADI. The results show that from the view of tool life, ceramic tools performed better than

cermet tools. Ceramic cutting tools were not suitable for machining ADI at low cutting speeds

based on the criteria of tool life and surface roughness. However both ceramic and cermet tools

were suitable at high cutting speeds. [45]

Cutting tool