7QC tools for Experiment Design and Problem Solving Surang Judistprasert Bio-innova & Synchron co.,ltd

Welcome message from author

This document is posted to help you gain knowledge. Please leave a comment to let me know what you think about it! Share it to your friends and learn new things together.

Transcript

7QC tools for Experiment Design and

Problem Solving

Surang Judistprasert

Bio-innova & Synchron co.,ltd

QbD - Regulatory insights ICH Q8 (R2)

The product is designed to meet patient

requirements

The process is designed to consistently meet the product’s critical

quality attributes & is continuously monitored and updated to assure

consistent quality over time

The impact of starting materials and process parameters on

product quality is understood

Critical sources of process variability are identified and controlled

Good science leads to better quality product, fewer product rejects/recalls, and enhanced public

health protection

QbD - Regulatory insights ICH Q8

(R2) Pharmaceutical Development

“The level of development will depend on the complexity of

the process and the product and on the opportunities

chosen or wanted by the applicant.”

Proposed by applicant, and approved by regulator, based

on demonstrated product knowledge and process

understanding

Degree of regulatory flexibility is determined by the level and

relevance of the scientific knowledge provided

7 Quality Control Tools

◦ Pareto chart

◦ Histogram

◦ Process flow diagram

◦ Check sheet

◦ Scatter diagram

◦ Control chart

Run chart

◦ Cause and effect diagram

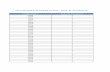

Check sheet

A series of multivariate analyses, including DoE, was

undertaken to investigate the relationship between the

input attributes, compression process parameters and

output attributes

DOE1 = screening all parameter for find no impact

parameters

DOE2 = investigate more fully impact parameter to

Quality attributes. Find target range of parameters

DOE3 = investigate impact of the range of input on

target process parameter

Scatter diagram

Example for investigate range of

compression parameter

Study of effect parameter X

on Y = scatter diagram e.g.

stability trend

Pareto diagram (80/20)

28

16

12 12

64 3

0

5

10

15

20

25

30

Loose

Threads

Stitching

flaws

Button

problems

Material

flaws

Vilfredo Pareto (1848-1923)

Italian economist

20% of the population has

80% of the wealth

Juran used the term “vital few,

trivial many”. He noted that 20%

of the quality problems caused

80% of the dollar loss.

Pareto Diagram

Pareto Diagram Pareto Diagram

( No. of Occurrences)

Pareto Diagram Pareto Diagram

( No. of Occurrences)

Used to prioritize

actions.(Used during

phases to monitor the

situation, analyze causes,

and review effectiveness of

an action.)

Used to identify and

prioritize a problem.

Used to review the effects of

an action taken.

Allows clarification of

important tasks.

Allows identification

of a starting point

(which task to start

with).

Allows projection of

the effects of a measure

to be taken

Method Usage Result

Benefit of 7QC tools

Identifies problems Give importance for planning Stress to importance of the process Priorities task Encourage everyone to think

systematically

Related Documents