Prepared by M.Ganesh Murugan 9715447621 1 MGM

5 s

Dec 23, 2014

5S is a method that uses five Japanese words which start with the letter S

Seiri – Sort

Seiton – Set in Order

Seiso – Shiny clean

Seiketsu – Standardized cleanup

Shitsuke - Sustain

Seiri – Sort

Seiton – Set in Order

Seiso – Shiny clean

Seiketsu – Standardized cleanup

Shitsuke - Sustain

Welcome message from author

This document is posted to help you gain knowledge. Please leave a comment to let me know what you think about it! Share it to your friends and learn new things together.

Transcript

Prepared byM.Ganesh Murugan

97154476211MGM

Necessity of 5S

SEIRI

SEITON SEIKETSUSEISO

SHITSUKE

Productivity improvement

Quality assurance Cost reduction

Secure production volume

Deadline observation

Happy workplace

Job satisfaction

Workplace improvementWorkplace improvement

2MGM

The 5 Words

5S is a method that uses five Japanese words which start with the letter S

3MGM

5 S5 Steps to a Better Workplace

4MGM

The Purpose of 5S is to promote a safe and efficient work environment Not just a cleaning campaign, 5S is

a way to set a new standard that we all agree on and help us get the discipline we need to maintain it.

By Implementing the 5S Opportunity to improve the own

workplace Team involvement & Problem

solving opportunities appears.5S gives visible and Motivating

Results First step in the implementation of

Lean Manufacturing, TPM an Kaizen.

Why 5 S?

5MGM

Improved SafetyNo items on the floorTherefore fewer slips or fallsSafety device in their right

placesLess dust

Reasons to implement 5S

6MGM

Improved SafetyFewer break downs

Fewer “strange ” errors from electronic systems

Less wear from dust or grit in moving parts

Reasons to implement 5S

7MGM

Improved SafetyFewer break downsBetter work Environment

A clean & well functioning workplace

Fix the unsafe & cluttered work stations

Reasons to implement 5S

8MGM

Improved SafetyFewer break downsBetter work EnvironmentLess Environmental Impact

Leakages such as oil will easily be spotted

Using less floor space may reduce energy consumption

Reasons to implement 5S

9MGM

Improved SafetyFewer break downsBetter work EnvironmentLess Environmental ImpactFew human errors

Easy to do it right than wrongSafety guards placed properlyLess clutter, fewer visual

distractions& easy access to tools and materials

Reasons to implement 5S

10MGM

Improved SafetyFewer break downsBetter work EnvironmentLess Environmental ImpactFew human errorsMay find problems earlier

When you do 5S , you inspect the same

Reasons to implement 5S

11MGM

Improved SafetyFewer break downsBetter work EnvironmentLess Environmental ImpactFew human errorsMay find problems earlierNo searching

Effective tools at the right place

Reasons to implement 5S

12MGM

Improved SafetyFewer break downsBetter work EnvironmentLess Environmental ImpactFew human errorsMay find problems earlierNo searchingHigher morale

Through teamwork and visible results

Reasons to implement 5S

13MGM

Improved SafetyFewer break downsBetter work EnvironmentLess Environmental ImpactFew human errorsMay find problems earlierNo searchingHigher moraleGoodwill

Helpfulness to create an impression.

Reasons to implement 5S

14MGM

The 5 phases in 5S

15MGM

Step 1 - SortingSorting is a team activity

that will be carried out by the production an d maintenance personnel together

Sorting has two purposesRemove unnecessary

objectsReduce waste

16MGM

Remove unnecessary ObjectsGo through the whole

plantLook for

MaterialsBehind or under

machinesRejectsForgotten materials

17MGM

Remove unnecessary ObjectsGo through the whole

plantLook for

MaterialsTools

Not in useWorn out or broken“Custom-made” tools

(made of steel wire/tape/etc-Replace by real tools

18MGM

Remove unnecessary ObjectsGo through the whole

plantLook for

MaterialsToolsSpare parts

BrokenSurplus InventorySpare parts for machines

no longer in use

19MGM

Remove unnecessary ObjectsGo through the whole

plantLook for

MaterialsToolsSpare partsOut-of-date

Documentation InstructionsBindersManuals

20MGM

Remove unnecessary ObjectsGo through the whole

plantLook for

MaterialsToolsSpare partsOut-of-date

DocumentationBulletin board

Outdated notices Irrelevant information

21MGM

Remove unnecessary ObjectsGo through the whole plantLook for

MaterialsToolsSpare partsOut-of-date DocumentationBulletin boardOther stuff

Outdated computer hardware

Packing MaterialOutdated protective

equipment22MGM

Remove unnecessary Objects ?Look at each objectAsk yourself, Do we need it

at all?If not – Discard it or sell it

Ask yourself, Will we need it soon?If not – Put it in proper

storage eg:- spare parts, etc.Is it working , but..

Too difficult to useIn correct designToo time consuming to useHas a high risk for

injury/quality?Not easy to accessible

23MGM

Remove unnecessary Objects ?Each item to be discarded or

corrected is marked with a red tag

24MGM

Waste eliminationThe second purpose of

sorting is to reduce waste and generate ideas for improvements

We will try to identify every thing that is hindering us from working safely and efficiently

25MGM

Waste eliminationTry to identify every thing

that is hindering us from working safely and efficiently

Work instrutionsDo we have them?Are they up-to-date?Are they in use? If not – why

not?

26MGM

Waste eliminationTry to identify every thing

that is hindering us from working safely and efficiently

Work instructionsSafety

What measures should we take to eliminate the risk of fire and accidents?

Remove clutter Improve unsafe electrical

installationsReplace broken safety

devicesRepair broken components

27MGM

Waste eliminationTry to identify every thing

that is hindering us from working safely and efficiently

Work instructionsSafetyEnvironment

What measures do we need to minimize or prevent damage to the environment?

28MGM

Waste eliminationTry to identify every thing

that is hindering us from working safely and efficiently

Work instructionsSafetyEnvironmentTools and equipment

Anything missing ?Anything not working

properly ?Anything in need of

improvement? 29MGM

Waste eliminationTry to identify every thing

that is hindering us from working safely and efficiently

Work instructionsSafetyEnvironmentTools and equipmentInconvenient work positions

Seat & work s/f’s at the right height

Awkward angles for moving materials 30MGM

Waste eliminationTry to identify every thing

that is hindering us from working safely and efficiently

Work instructionsSafetyEnvironmentTools and equipmentInconvenient work positionsDeferred maintenance

Temporary repairs/not properly secured

Old equipments/technical errors

31MGM

Waste eliminationTry to identify every thing

that is hindering us from working safely and efficiently

Work instructionsSafetyEnvironmentTools and equipmentInconvenient work positionsDeferred maintenanceImprovement Proposals

Review prior suggestions32MGM

Waste eliminationAll identified waste items are

marked with an red tag

Machine tagged with errors and improved suggestions

33MGM

Tag no Item description Session tagged

Date

Tagged by

Responsible

Due date

5S Sort listEvery tag refers to a 5S Sort

list

Think break• Do we have any examples of deferred maintenance

in our plant?

34MGM

Question yourself – Seiri• Do you find items scattered at

your place?• Are any items left in

disorganized way?• Are all item sorted and kept in

designated place?• Are tools and stationeries

properly sorted and stored?

35MGM

Step 2 – Set in OrderEvery tag refers to a 5S Sort

list

36MGM

Missing letter ?Every tag refers to a 5S Sort

list

37MGM

Why-set in order?• The purpose of Seiton – set in

order is that everything that we regularly use should have a convenient placement

• Tools should be kept at the point of use

• No bending to pickup or move materials

• Alter flow paths to improve efficiency

38MGM

Placement

39MGM

Efficient layout and color coding• Make a drawing of the

current situation• Brainstorm to find an optimal

layout• Agree the color code• Mark the location(removable

tapes preferred) of all objects• Move the equipments if

necessary

40MGM

Question yourself – Seiton?• Are passages and storages

clearly indicated?• Commonly used tools &

stationeries separated from the seldom used?

• Are containers, boxes, materials and fire extinguishers stocked up properly?

• Are there grooves, cracks or bumps on the floor which hinder work or safely?

41MGM

Step 3 – Shiny cleanNext step in 5S is to carry out a Shiny clean event

42MGM

Shiny clean• To keep your area clean on

a continuing basis• Clean all machines

thorough• Clean all equipments,

fixtures, and tools• Clean the floor, walls,

cabinets, shelves etc.

43MGM

Why – Seiso?• To prevent the area from

getting dirty in the first place, so we don’t have to clean it up afterward

• A clean workplace is indicative of a quality product and process

• Dust and dirt cause potential health hazards

• Things to remember :-• Sweep/Vacuum• Dust / Mop 44MGM

Guidelines – Seiso?• Divide areas into zones

• Define responsibilities for cleaning

• Tools and equipment must be owned by an

individual

• Focus on removing the need to clean

45MGM

Question yourself – Seiso?• Are machines and equipments

dirty?

• Are pipes dirty and corroded?

• Are nozzles dirtied by

lubricants and ink?

• Are shades, lights, bulbs, and

light reflectors dirty?

46MGM

Step 4 – Standardized cleanupContinue sorting, storing and cleaning to maintain

serene atmosphere at all times

47MGM

Why – Seiketsu?• Prevents regression back to an

unclean/disorganized environment• Things to remember :-

• Develop schedules, checklists• Periodically evaluate area using 5”S” Audit sheet• Continually improve neatness

48MGM

Phases of Seiketsu?• Clarification of vital points for management Things

to remember :-• What are the minute defects?• Basic conditions: Cleanliness, refueling, replace

tightly bind fast, dirt, looseness• Operating conditions: pressure, temperature, time,

flow volume, weight, Equipment, jigs and tools, sub-materials

1

49MGM

Phases of Seiketsu?• Prepare standards for the conditions

• Objectification of judgment standards for normal versus abnormal

• Judgment without using measurement, knowledge, intuition and knack

2

50MGM

Phases of Seiketsu?• Judgment standards for abnormalities

• Inspection methods that can be used by anybody• Methods for actions against abnormalities

3

51MGM

Question yourself – Seiketsu?• Are there sufficient light?• Is there noise/light in your

place causing discomfort?• Do people work at

designated way?• Is there any leakage?

52MGM

Step 5 - Shitsuke

53MGM

Shitsuke• To maintain discipline, we

need to practice and repeat until it becomes a way of life

54MGM

Shitsuke• Make sure you stick to standard

procedures and make them a habit • Be disciplined to follow rules and

regulations to maintain standards

55MGM

Why – Shitsuke?• To build “housekeeping” into every day process• Makes the 7 wastes visible• Gets everyone involved• Things to remember :-

• Training everyone is vital• Involvement from all is necessary• Commitment and discipline toward housekeeping is

essential in taking the first step in being World Class

• 5 “S” RATING• 0= Poor (Unacceptable)• 2= Satisfactory• 4= Excellent ( World Class Environment) 56MGM

Question yourself – Shitsuke?• If 4S done?• Are regular 5s check

conducted?• Do people involved without

reminder?• Do assemble at time?

57MGM

Action Plan for Implementing 5SAwareness programme of 5s for all employees, supervisors,

engineers and managers.

Form steering committee

Application programme on 5S for all Employees

Steering committee periodically evaluates all cells, scores displayed

on the display board

Display posters on house keeping, distribute cards on 5S to all

employees

Annual award for the best cell

58MGM

Advantages of 5S If tools and materials are conveniently located in uncluttered work areas

Operators spend less time looking for items

This leads to higher workstation efficiency, a fundamental goal in mass production

A clean and tidy workplace leads to greater well being and increased motivation

Company image improves

Time saving

Quick retrieval

Accidents & mistakes minimized

Increases space

Creates workplace ownership

Foundation of all qc tools

Continuous quality improvement

Lean manufacturing

Visual management system

Results in a place easier to manage

Smooth working no obstruction 59MGM

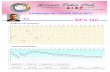

Checking System

60MGM

5S AuditThree purposes of conducting regular 5S Audit

reviews are:

• Review compliance to the 5S standards for your

factory

• Note and address non-compliance – to fix what is

wrong!

• Provide a formal opportunity to suggest

improvements61MGM

The Basic Steps• Plan for the audit by dividing the workplace into

various areas, probably the same ones where different teams conducted the various 5S stages.

• Make a checklist for each area, based on the standards that were set during 5S.

• Find out the list of known problems in each area. From the initial 5S sweep, this may include:

• Machines needing repair• Tool racks• Signage on tool racks or cabinets or storage shelves;

warning signs; “keep clear” markings for corridors; or instruction pages

• Surplus equipment or materials which were not immediately removed

62MGM

During the audit, three key tasksONE• Determine whether known problems have been

addressed: • Does this machine still leak lubricants?• Has the required tool rack been installed in this area? Is it

labeled? Is it full? Are tools still left on workbenches?• Is the warning sign in place so people will not walk under

this crane?• Why is this outdated drill press still in the corner?

63MGM

During the audit, three key tasksTWO• See that standards are being met:

• Are tools left on workbenches?• Is something missing from a tool rack?• Is dirt accumulating somewhere?• Are existing labels still visible and easily read? (This is

especially important for signs that may be obscured by dust, and for lines painted on floors where they can be scuffed)

• Are there new sounds or smells that indicate that gears are grinding or fluids are leaking?

64MGM

During the audit, three key tasksTHREE• Note what has not yet been standardized – this is

the most creative and difficult part, because it may involve seeing what is missing in an area that seems tidy:

• Why is there no sign over the neat stack of work-in-process materials on that shelf? (How will the next shift know what is there, or what should go there?)

• Tools that are not yet labeled• Is there a limit to how high those barrels can be stacked?

Why don’t we show that information on the sign for that storage area?

• Do we need all those cans of wing nuts in this assembly area? How many are used in one day? Should the rest of the month’s supply be stored elsewhere?

65MGM

Safety infractions should also be part of the 5S audit

• Are WHMIS (Workplace Hazardous Materials Information System) labels used properly?

• Are fire exits visible and clear? Are the fire extinguishers charged and inspected on schedule?

• Are stairs and ladders safe?• Do we notice unsafe behavior regarding heights and

falls? Climbing a ladder without maintaining three points of contact? Working on a height without the required safety tether?

66MGM

To follow up on each 5S audit• Write up a work order to deal with each deficiency• Update the next check list:

• Check off what was corrected• Add new deficiencies to be reviewed

• Determine the score:• Deduct for each deficiency• Add a point for each correction• Add a point for each suggestion for improvement• If the previous audit had found deficiencies, the goal

is to eradicate them• The ultimate goal is to regularly achieve zero

outstanding deficiencies 67MGM

How often should audits be Performed?Regular audits lead to the best results:• Weekly “self-check” audits by teams of workers,

reviewing their own areas• This might be the best way to generate suggestions

for improvements

• Monthly audits by the area supervisor• Ensure that the weekly audits catch any problems

with the daily or weekly cleanups• Pay special attention to the less-frequent cleaning

tasks• Try to notice what is missing: new tools that do not

yet have a place in a rack; materials stored neatly but not well-labeled

68MGM

How often should audits be Performed?• Quarterly audits by the plant manager

• Ensure that standards are being met• If there are deficiencies, ask “why”: try to determine

the root causes• Ensure that resources are allocated to repairs and to

making the long-term improvements

• Without audits, it is impossible to ensure compliance.

69MGM

5S Audit check sheet

Model follows

70MGM

71MGM

Prepared byM.Ganesh Murugan

9715447621

72MGM

Related Documents

![S«k²|¬³¦S£'©] `¥[¬»©5°r£K¦S S¢ ©5£*¬| r«k¢§ ¹k£*¹/¬³² ...jmckalex.org/files/publications/spatial-evolution.pdf · 2016. 5. 18. · ²³£'©] S¢r§* k](https://static.cupdf.com/doc/110x72/6094cde5b9d5cb317b4be013/sks-5rks-s-5-rk-k.jpg)