1.Introduction to Highway Engineering Overview Road transport is one of the most common mode of transport. Roads in the form of trackways, human pathways etc. were used even from the pre-historic times. Since then many experiments were going on to make the riding safe and comfort. Thus road construction became an inseparable part of many civilizations and empires. In this chapter we will see the different generations of road and their characteristic features. Also we will discuss about the highway planning in India. Functions of IRC, CRRI, and Roads wing of Surface Transportation. 1. Appointment of the Jayakar Committee: In 1927 central Govt. appointed an Indian Road development committee under the chairmanship of M.R. Jayakar to report on the existing road conditions, and suggestion for their future developments. The Jayakar committee submitted its report on 1928 with the recommendations that since the provincial governments and the local bodies are not able to look after all the roads; the road development in the country should be taken up by the Central Government. 2. Indian Roads Congress (I.R.C.): The Indian Roads Congress was established by the Central Government in 1934 as per the recommendations of the Jayakar Committee. The I.R.C. was constituted to provide a forum for the regular pooling the technical ideas, experiences and knowhow for the panning of the development of the roads throughout the country. I.R.C. provides the recommended specifications regarding the design and

Welcome message from author

This document is posted to help you gain knowledge. Please leave a comment to let me know what you think about it! Share it to your friends and learn new things together.

Transcript

1.Introduction to Highway Engineering

Overview

Road transport is one of the most common mode of transport. Roads in the form

of trackways, human pathways etc. were used even from the pre-historic times.

Since then many experiments were going on to make the riding safe and comfort.

Thus road construction became an inseparable part of many civilizations and

empires. In this chapter we will see the different generations of road and their

characteristic features. Also we will discuss about the highway planning in India.

Functions of IRC, CRRI, and Roads wing of Surface Transportation.

1. Appointment of the Jayakar Committee:

In 1927 central Govt. appointed an Indian Road development committee under the

chairmanship of

M.R. Jayakar to report on the existing road conditions, and suggestion for their future

developments.

The Jayakar committee submitted its report on 1928 with the

recommendations that since the provincial governments and the local

bodies are not able to look after all the roads; the road development in the

country should be taken up by the Central Government.

2. Indian Roads Congress (I.R.C.):

The Indian Roads Congress was established by the Central Government in 1934 as

per the recommendations of the Jayakar Committee. The I.R.C. was constituted to

provide a forum for the regular pooling the technical ideas, experiences and

knowhow for the panning of the development of the roads throughout the country.

I.R.C. provides the recommended specifications regarding the design and

construction of the roads in the country.

IRC has collaborated with the road wing of the ministry of the surface

transportation of Govt. of India. It publishes journals, standard specifications and

guidelines on various aspects of highway engineering.

- Functions of Indian Roads Congress (IRC):

IRC a body of professional highway engineers provides the following services:

(i) It provides a forum for expression of collective opinion of its members for all

matters affecting the construction and maintenance of roads in India.

(ii) It promotes the use of the standard specifications and practices.

(iii) It provided with the suggestions for the better methods of planning,

designing, construction, administration and maintenance of roads.

(iv) It conducts periodical meetings to discuss technical problems regarding roads.

(v) It makes the laws for the development, improvement and protection of the roads.

(vi) It furnishes and maintains libraries and museums for encouraging the science of road

making.

Functions of Central Road Research Institute (CRRI):

CRRI was started by the Central Government in 1950, for the research work in the

highway engineering. CRRI is a series of laboratories under the council of

scientific and industrial research in India. It offers the following services:

(1) Carries basic and applied research for the design, construction and maintenance of the

highways.

(2) Carries research on traffic safety and transport economics.

(3) Carries research on economical utilization of locally available materials

for construction and maintenance of roads.

(4) Research for the development of the new machinery, tools equipment

and instruments for highway engineering.

(5) To provide technical advice and consultancy services to various organizations.

(6) To provide library and documentation services.

3. Roads wing of ministry of surface transport:

The roads wing of the ministry of Surface Transport handles the road matters of

the Central Govt. It is headed by a Director General.

The Director General is assisted by two additional Director Generals(one for

roads and one for bridges), a numbers of Chief Engineers, Superintending

Engineers, Executive Engineers and Asst.

Executive Engineers. The roads wing has a chief Engineer for the North-East

region posted at Guwahati and a Liaison-cum-Inspectorate organization consisting

of S.E’s and E.E’s in the various states. The functions of the roads wing of

Surface Transport are:

(a) To control funds approved by Central Government for the development of National

Highways.

(b) To control the central road fund.

(c) To prepare plans for development and maintenance of National Highways in

consultation with state PWD’s.

(d) To oversee technically the quality of works executed by the agencies.

(e) To administer matters regarding road research.

(f) To examine technically the projects of roads and bridges prepared by the PWD

4. National Highways Authority of India

The National Highways Authority of India (NHAI) is an autonomous agency of the

Government of India, responsible for management of a network of over 50,000 km

of National Highways out of 1,15,000 km in India.[5] It is a nodal agency of the

Ministry of Road Transport and Highways. NHAI has signed a memorandum of

understanding (MoU) with the Indian Space Research Organisation for satellite

mapping of highways.[6].

Abbreviation -

NHAI

Formation -

1988

Type -Autonomous government agency

Purpose -Development and maintenance of

National Highways Chairman -Yudhvir Singh

Malik, IAS

Parent organisation -Ministry of Road Transport and Highways

# Classification or Types of Roads

The roads are classified based on many

factors as follows. 1 Materials

2 Location &

function 3

Traffic volume

4 Width

5 Economy

6 Traffic type

7 Rigidity

8 Topography

Types of Roads Based on

Materials Earthen roads

Gravel roads

Murrum roads

Kankar roads

WBM roads

Bituminous

roads

Concrete road

1 Earthen Roads

Earthen roads are laid with soil. They are cheaper of all types of roads. This type

of road is provided for less traffic areas and or for countryside areas. Good drainage

system should be required which reflects good performance for longer period.

2. Gravel Roads

Gravel roads are also low quality roads but they are good when compared to earthen

roads. Compacted mixture of gravel and earth is used as pavement material in this

case.

3. Murrum Roads

Murrum is a matter obtained from the disintegration of igneous rocks by

weathering agencies. This is used to make roads called as murrum roads.

4. Kankar Roads

Kankar is nothing but impure form of lime stone. Kankar roads are provided

where lime is available in good quantity. These are also low quality and

performance wise they are similar to gravel and murrum roads.

5. WBM Roads

Water Bound Macadam (WBM) roads contain crushed stone aggregate in

its base course. The aggregates are spread on the surface and these are

rolled after sprinkling water.

WBM roads provides better performance compared to earthen, gravel, murrum and kankar

roads.

roads are laid as layers about 10cm thickness of each layer. They are very rough

and maid disintegrate immediately under traffic.

6. Bituminous Roads

Bituminous roads are very popular roads around the world. They are most used

roads in the world. They are low in cost and good for driving conditions. They are

flexible and thickness of bituminous roads depends upon the subgrade soil

conditions.

7. Concrete Roads

Cement concrete is used to construct the pavements in case of concrete roads.

These are very popular and costlier than all other types of roads. They are not

flexible so, they require less maintenance.

Concrete roads are suitable for high traffic areas. Concrete roads are laid

with joints and time of construction is more.

Types of Roads Based on Location

and Function National highways

State

highways

District

roads

Rural roads or village roads

1.National Highways

National highways are main roads of a particular country. They connects all major

cities to the capital of the country. They run throughout the length and breadth of

the country. Minimum two lane road is provided for national highways.

2 State Highways

State highways are second main roads which connect major parts of state with

in it. State highway ultimately connects to the national highways.

3. District Roads

District roads are provided with in the cities and connects markets and

production places to state and national highways. Two types of district roads are

there namely,

4. Major district roads

Major district roads connect headquarters of neighboring district with main parts

of district while minor district roads are laid with in the district.

5. Rural Roads or Village Roads

Village roads connects the nearby villages with each other. They lead to nearby

town or district roads. Usually low quality roads are provided as village roads

because of low traffic.

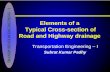

Unit 2 road geometry

The geometric design of roads is the branch of highway engineering concerned

with the positioning of the physical elements of the roadway according to

standards and constraints. The basic objectives in geometric design are to

optimize efficiency and safety while minimizing cost and environmental damage.

Right of way

of Way (ROW) can be simply defined as a rite of passage to another person's

land or property. This is a common term often used by land surveyors and civil

engineers and is usually associated in land usage rights.

Formation width

Width of formation. Width of formation or roadway width is the sum of the

widths of pavements or carriage way including separators and shoulders. This

does not include the extra land in formation/cutting.

Shoulder

shoulder is an emergency stopping lane by the verge of a road or motorway, on

the right in countries which drive on the right, or on the left side in India, Japan,

the UK, Australia, and other left-side driving countries. Wikipedia

Carriage Way:

It is the width of the road which is used by the traffic for moving on it. It is

generally central portion of the total land width and is paved and surfaced with the

bituminous concrete for service to the road users. Width of the carriage way

depends on the number of the lanes in the road which again depends on the class

of the highway. If it is higher level road like NH then it will need more numbers of

lanes and therefore the carriageway width will be more.

Camber:

Camber is the transverse slope provided to the road surface for the drainage of

the rainwater for the better performance of the road. Camber can be written as 1

in n or x%.

Drainage of the rainwater is necessary

(1) To maintain the safe value of the friction between the road surface and the tyres

(2) To maintain the strength and durability of the surface concrete

(3) To maintain the durability and strength of the sub-grade soil which can be

harmed if the infiltration of the water takes place to it.

There are generally three types of the cambers: (a) Straight Camber (b) Parabolic

Camber (c) Mixed Camber.

Types of Camber

(a) Straight Camber: This type of camber is provided by meeting two straight

surfaces at the crown. Crown is the central and top most point on the surface of

the road. The edge shape produces inconvenience to the traffic so it is not used

in general.

(b) Parabolic Camber: Parabolic camber is provided by providing a parabolic shape

to the surface of the road. It is also not used in general because it has steep slopes

towards the edges, which can create the outward thrust to the vehicles.

(c) Mixed Camber: Mixed camber is formed by use of the straight surfaces at the

edges but parabolic surface at the centre. It is mostly used for the road construction

because both the problem of the earlier two are solved if we use this camber.

Gradient: It is the slope provided to the surface of the road in the longitudinal

direction for the vertical alignment of the road. There are three kinds of gradients:

A vehicle on ascending gradient

(a) Ruling Gradient (b) Limiting Gradient (c) Exceptional Gradient (d) Minimum Gradient.

Ruling gradient is the design gradient, so it is used to design the road in the vertical alignment.

Limiting and exceptional gradients are provided in the limited stretch of the roads where necessary and

in case of the emergencies or exceptional cases when such need arises respectively.

Minimum gradient is the gradient which is required as the minimum from the drainage point of view in

case of the plane areas.

Sight Distance: Sight distance at any instance is the distance along the centerline of the road which is

visible to the eye of a driver at an height of 1.2 m from the road surface such that an obstruction of

height 0.15 m is visible to him. The heights of the eye of the driver and the obstruction is standardized

by the Indian Roads Congress.

Sight Distance

Most important sight distance which are necessary to be studied here in the design point of view are:

(a) Stopping Sight distance

(b) Overtaking sight Distance

Stopping sight distance(SSD): SSD is the sight distance which is necessary for a driver to stop a vehicle

from the design speed to the 0 speed without any collision with the obstruction on the road. It is also

known as the absolute minimum sight distance so this much sight distance is provided at all the cross

section of the road.

Overtaking Sight Distance(OSD): OSD is the sight distance which is necessary for a vehicle running at the

design speed to overtake a slower moving vehicle without collision with the vehicles coming from the

opposite direction. Generally It is not possible to provide the OSD at every cross section of the road so, it

is provided after a stretch of the road.

Super- Elevation: The outer edge of the road with respect to the inner edge of the road is raised in case

of the horizontal curves, this is called super-elevation. Super-elev

Curves

Road curves are regular bends in roads to bring a gradual change of direction.

Similar curves are on railways and canals.

Curves provided in the horizontal plane are known as horizontal curves and are

circular or parabolic.

-Four types of circular curves are on roads:

Simple curve

Compound curve

Reverse or serpentine curve

Deviation curve

Unit 3

Highway survey and plan

The aim of location survey is to select a route with the following points kept in

mind.

With reasonable economy it should meet the minimum requirement regarding

curvature and grades.

To produce an easy riding (traveling), free flowing traffic artery that has a high

capacity and it meets all the safety standards.

The location survey should recognize and evaluate the routes impact on already

existing industries, business, and residential values and on future development.

Before field survey for any highway location is started, tentative decision,

regarding the design speed of the route, its cross-section, and the maximum

grade must be made. These decision made are based on the;

Estimated of amount, character and hourly distribution of traffic, along with

Knowledge of the area is traversed.

And available funds.

RESULTING ROUTE: After comparison of the different alternative design, the route

is selected which has cheapest overall cost, considering capital investment,

maintenance, expense and saving to the road user.

ENGINEERING DATA:

All details of the topography, soil and problems like drainage and maintenance,

should be investigated before a scientific plan programmed can be suggested. The

engineering data includes following things;

Topographic and geological maps.

Stream and drainage basin maps.

Climatic records.

Preliminary survey maps of previous projects.

Traffic surveys and capacity studies.

RECONNAISSANCE SURVEY REPORT:

This report must consist of;

Total length of line.

The elevation of main and intermediate summit

All adverse grades.

Stream crossing.

Nature of construction.

Right of way circumstances.

Soil conditions.

Unusual or troublesome condition.

Approximate estimate of cost.

PRELIMINARY LOCATION SURVEY:

After the preferred location has been established, the preliminary location survey

serves as basis for fixing the actual highway location.

Conventionally the baseline of preliminary survey i.e. P-line should follow as

closely as possible to the expected final line.

The surrounding are then related to this P-line.

Elevations - At 100ft and at breaks in the ground provide data for profile and

serve as starting point for cross-sections that covers a strip of land on each side of

P-line.

Cross-section - are of width 100’ to 800’, depending upon;

Standard of accuracy

Speed of work and instrument used.

However accurate measurements are used for checking the accuracy of final

location.

The next step is to plot plan and profile of the preliminary line.

FINAL LOCATION SURVEY:

Final location is essentially fixing of the details of the projected highway. It serves

the dual purpose of

Permanently establishing the center-line.

Collecting information necessary for preparation of plans for construction.

The line should be established as closely as is practical to the line drawn on the

preliminary map. It should conform the major and minor control points and the

alignment that was previously determined.

Staking out on the ground of the center line of the projected road provides

opportunity for minor correction like small shift of the line.

It is useful to make a new profile and accurate cross-section from which

excavation and embankment quantities can be measured.

Sufficient points of curvature and tangency, BMs at relatively close interval and in

position free from disturbance by construction activities.

Direction of all property lines, distance to property corners and location of

building, fences and other improvements.

It is important to keep notes on alignment and levels i.e. notes taken in field

during the final location survey usually becomes part of permanent record.

The final location survey is complete when all necessary information in available

and ready for designer to use. It in insured that all information required

preparation of complete construction.

All information pertaining to

Alignment

Topography

Bench mark levels

Cross sections

Section corner ties and other land ties

Drainage and utilities

Unit 4

Road materials

The various MATERIALS used for the construction of road pavement are termed as road materials.

Different types of road materials

1. Soil

2. Aggregates

3. Binders.

1. Soil - Types of soil tests for road construction project requires the site

investigation to be carried out to understand the soil profile. For road

construction works, the properties of soil at subgrade level are required.

The common soil test for road construction includes classification of soil, particle

size distribution, moisture content determination, specific gravity, liquid limit

and plastic limit tests. Moisture content, particle size and specific gravity tests

on soils are used for the calculation of soil properties such as degree of

saturation.

The soil tests can be laboratory tests or in-situ tests. The laboratory tests

should be carried out on every sample taken for determination of particle size

and moisture content.

The most common soils are

Clay, silt , sand, loam, marl, shale

Clay 10-20%

Silt 5 -15%

Sand 65 -75%

2. Aggregates

Types of soil tests for road construction project requires the site investigation to

be carried out to understand the soil profile. For road construction works, the

properties of soil at subgrade level are required.

The common soil test for road construction includes classification of soil, particle

size distribution, moisture content determination, specific gravity, liquid limit

and plastic limit tests. Moisture content, particle size and specific gravity tests

on soils are used for the calculation of soil properties such as degree of

saturation.

The soil tests can be laboratory tests or in-situ tests. The laboratory tests

should be carried out on every sample taken for determination of particle size

and moisture content.

Natural aggregates- 1 crushed rocks

2- gravels

3- sand

Artificial aggregates

1.Brick aggregates

2.Blast furnace slag

3.Fly ash

3- Binders-

The material used in binding the road aggregates and providing the smooth and impermeable

surface for movement of vehicles is called binders

Common binders are --

Cement , bitumen , tar

1. Bitumen –

Asphalt, also known as bitumen is a sticky, black, and highly viscous liquid or semi-solid form of petroleum. It may be found in natural deposits or may be a refined product, and is classed as a pitch. Before the 20th century, the term asphaltum was also used.[2] The word is derived from the Ancient Greek ἄσφαλτος ásphaltos.

The primary use (70%) of asphalt is in road construction, where it is used as the glue or binder mixed with aggregate particles to create asphalt concrete. Its other main uses are for bituminous waterproofing products, including production of roofing felt and for sealing flat roofs.[3]

The terms "asphalt" and "bitumen" are often used interchangeably to mean both natural and manufactured forms of the substance. In American English, "asphalt" (or "asphalt cement") is commonly used for a refined residue from the distillation process of selected crude oils. Outside the United States, the product is often called "bitumen", and geologists worldwide often prefer the term for the naturally occurring variety. Common colloquial usage often refers to various forms of asphalt as "tar", as in the name of the La Brea Tar Pits.

Naturally occurring asphalt is sometimes specified by the term "crude bitumen". Its viscosity is similar to that of cold molasses[4][5] while the material obtained from the fractional distillation of crude oil boiling at 525 °C (977 °F) is sometimes referred to as "refined bitumen". The

2. cement –

cement is a binder, a substance used for construction that sets, hardens, and adheres to

other materials to bind them together. Cement is seldom used on its own, but rather to bind sand

and gravel (aggregate) together. Cement mixed with fine aggregate produces mortar for masonry,

or with sand and gravel, produces concrete.

Cements used in construction are usually inorganic, often lime or calcium silicate based, and can

be characterized as either hydraulic or non-hydraulic, depending on the ability of the cement to

set in the presence of water (see hydraulic and non-hydraulic lime plaster).

Non-hydraulic cement does not set in wet conditions or under water. Rather, it sets as it dries

and reacts with carbon dioxide in the air. It is resistant to attack by chemicals after setting.

Hydraulic cements (e.g., Portland cement) set and become adhesive due to a chemical

reaction between the dry ingredients and water. The chemical reaction results in

mineral hydrates that are not very water-soluble and so are quite durable in water and safe from

chemical attack. This allows setting in wet conditions or under water and further protects the

hardened material from chemical attack. The chemical process for hydraulic cement found by

ancient Romans used volcanic ash (pozzolana) with added lime (calcium oxide).

The word "cement" can be traced back to the Roman term opus caementicium, used to

describe masonry resembling modern concrete that was made from crushed rock with burnt

lime as binder. The volcanic ash and pulverized brick supplements that were added to the burnt

lime, to obtain a hydraulic binder, were later referred to as cementum, cimentum, cäment,

and cement. In modern times, organic polymers are sometimes used as cements in concrete.

3- Tar

Tar is a dark brown or black viscous liquid of hydrocarbons and free carbon, obtained from a wide variety of organic materials through destructive distillation. Tar can be produced from coal, wood, petroleum, or peat.[1] Production and trade in pine-derived tar was a major contributor in the economies of Northern Europe[2] and Colonial America. Its main use was in preserving wooden sailing vessels against rot. The largest user was the Royal Navy. Demand for tar declined with the advent of iron and steel ships.

Tar-like products can also be produced from other forms of organic matter, such as peat. Mineral products resembling tar can be produced from fossil hydrocarbons, such as petroleum. Coal tar is produced from coal as a byproduct of coke production.

-Cut back -

Cutback Bitumen ( Liquid Bitumen ) is Bitumen that is dissolved in a solvent . Typical

solvents include Naptha, gasoline and kerosene, white spirit etc. The type of solvent

controls the curing time while the amount determines the viscosity of the Cutback

Bitumen.

The advantage Cutbacks have over Emulsions is a much higher residual Bitumen

percent, typically over 80% compares with over 40-65% for Bitumen emulsions. The

result is more Bitumen left on the roadway after curing, for the same volume of binder

applied.

Cutback Classification

Cutbacks are divided into two classifications, Rapid-Curing (RC) and Medium-Curing

(MC) depending on the solvent used. They are further defined by a number which

indicates the minimum kinematic viscosity (fluidity) of the cutback.

Grades & Properties

Grade Curing Speed Viscosity Penetration of Residue

MC 30 Medium 30-60 120- 150

MC 70 Medium 70-140 120- 150

MC 250 Medium 250- 500 120- 150

MC 800 Medium 800- 1600 120- 150

MC 3000 Medium 3000- 6000 120- 150

RC 70 Rapid 70-140 80- 120

RC 250 Rapid 250-500 80- 120

RC 800 Rapid 800- 1600 80- 120

RC 3000 Rapid 3000- 6000 80- 120

*Kinematic Viscosity at 140 deg F ( 60 deg C), in Centistokes , Penetration of Residue at 77 deg F (25 deg C) , 100 grams, 5 seconds.

Application

Cutback bitumen’s suitable for primer sealing can also be used in the manufacture

ofpre-mix asphalt, which is used in patch repairs.Cutback bitumen’s are used

extensively in sprayed sealingapplications, particularly in cooler weather where

theyprovide improved initial stone retention due to their lower viscosity. Typically, a

single application of the appropriate cutback bitumen is sprayed onto the primed

pavement ontowhich aggregate is laid.

What is Bitumen Emulsion?

Bitumen emulsion is a mixture of fine droplets of bitumen and water. But as the

bitumen is a petroleum product it doesn’t mix with water and as it is sticky in

nature, it doesn’t easily gets disintegrated into fine droplets. To overcome this

problem an emulsifier is used.

Emulsifier can be defined as a surface-active agent. Emulsifier keeps the

bitumen in its fine droplet state by disallowing it to mix with other droplets. As

the droplets are very fine they suspend in water.

“Therefore, bitumen emulsion is a dispersed liquid consisting of three

products, i.e. water, bitumen and emulsion”.

a) Slow setting emulsion

In this type of emulsion, a special type of emulsifier is used to slow the process

of water evaporation. This type of emulsifier are relatively stable.

b) Medium setting emulsion

This type of bitumen emulsion doesn’t break as when applied on aggregate. The

process of evaporation starts when the fine dust of mineral are mixed with the

aggregate emulsion mix.

c) Rapid setting emulsion

This type of bitumen emulsion breaks down rapidly as it comes with contact

with aggregate helping in fast setting and rapid curing.

# Tests of road materials-

1. Test for soil subgrade

California Bearing Ratio Test on Subgrade Soil -

The California Bearing Ratio(CBR) test is a measure of resistance of a material

to penetration of standard plunger under controlled density and moisture

conditions. It was developed by the California Division of Highways as a method

of classifying and evaluating soil- subgrade and base course materials for

flexible pavements.

CBR test may be conducted in remoulded or undisturbed sample. Test consists

of causing a cylindrical plunger of 50mm diameter to penetrate a pavement

component material at 1.25mm/minute.

The loads for 2.5mm and 5mm are recorded. This load is expressed as a

percentage of standard load value at a respective deformation level to obtain

CBR value.

Table of Contents

California Bearing Ratio Test on Subgrade Soil

The aim of this test is the determination of California Bearing Ratio value of the

subgrade soil.

Apparatus for CBR Test

Loading machine-any compression machine can operate at constant rate of

1.25mm per minute can be used. Cylindrical moulds- moulds of 150mm

diameter and 175mm height provided with a collar of about 50mm length and

detachable perforated base.

Compaction rammer, surcharge weight-annular weights each of 2.5kg and

147mm diameter. IS sieve 20mm, Coarse filter paper, balance etc.

Procedure of California Bearing Ratio Test

Sieve the sample through 20mm IS sieve. Take 5 kg of the sample of soil

specimen. Add water to the soil in the quantity such that optimum moisture

content or field moisture content is reached.

Then soil and water are mixed thoroughly. Spacer disc is placed over the base

plate at the bottom of mould and a coarse filter paper is placed over the spacer

disc.

The prepared soil water mix is divided into five. The mould is cleaned and oil is

applied. Then fill one fifth of the mould with the prepared soil. That layer is

compacted by giving 56 evenly distributed blows using a hammer of weight

4.89kg.

The top layer of the compacted soil is scratched. Again second layer is filled and

process is repeated. After 3rd layer, collar is also attached to the mould and

process is continued.

After fifth layer collar is removed and excess soil is struck off. Remove base

plate and invert the mould. Then it is clamped to baseplate.

Surcharge weights of 2.5kg is placed on top surface of soil. Mould containing

specimen is placed in position on the testing machine.

The penetration plunger is brought in contact with the soil and a load of

4kg(seating load) is applied so that contact between soil and plunger is

established. Then dial readings are adjusted to zero.

Load is applied such that penetration rate is 1.25mm per minute. Load at

penetration of 0.5, 1, 1.5, 2, 2.5, 3, 4, 5, 7.5, 10 and 12.5mm are noted.

Standard Load Values for CBR Test

Penetration(mm) Standard Load(kg) Unit Standard Load(kg/cm2)

2.5 1370 70

5 2055 105

2- tests for aggregates

1. Los Angeles Abrasion Test on Aggregates -Values for

Pavements and Roads

Los Angeles abrasion test on aggregates is the measure of aggregate toughness

and abrasion resistance such as crushing, degradation and disintegration. This

test is carried out by AASHTO T 96 or ASTM C 131: Resistance to Degradation

of Small-Size Coarse Aggregate by Abrasion and Impact in the Los Angeles

Machine.

The aggregate used in surface course of the highway pavements are subjected

to wearing due to movement of traffic.

When vehicles move on the road, the soil particles present between the

pneumatic tyres and road surface cause abrasion of road aggregates. The steel

rimmed wheels of animal driven vehicles also cause considerable abrasion of the

road surface.

Therefore, the road aggregates should be hard enough to resist abrasion.

Resistance to abrasion of aggregate is determined in laboratory by Los Angeles

test machine.

The principle of Los Angeles abrasion test is to produce abrasive action by use

of standard steel balls which when mixed with aggregates and rotated in a drum

for specific number of revolutions also causes impact on aggregates.

The percentage wear of the aggregates due to rubbing with steel balls is

determined and is known as Los Angeles Abrasion Value.

2. Specific Gravity and Water Absorption Tests on Aggregates Specific gravity test of aggregates is done to measure the strength or quality of

the material while water absorption test determines the water holding capacity

of the coarse and fine aggregates.

The main objective of these test is to,

1. To measure the strength or quality of the material.

2. To determine the water absorption of aggregates.

Aggregate Sample

Specific Gravity is the ratio of the weight of a given volume of aggregate to

the weight of an equal volume of water. It is the measure of strength or quality

of the specific material. Aggregates having low specific gravity are generally

weaker than those with higher specific gravity values.

Table of Contents

Procedure of Water Absorption and Specific

Gravity Test on Aggregates

There are three methods of testing for the determination of the specific gravity

of aggregates, according to the size of the aggregates larger than 10 mm, 40

mm and smaller than 10 mm. For Samples larger than 10 mm, 40 mm, the

below given test method is used and for samples smaller than 10 mm

Pycnometer test is done.

3. Determination of Aggregate Impact Value – Impact Test on

Aggregates Determination of Aggregate Impact Value – Impact Test on Aggregates is done

to carry out to:

Determine the impact value of the road aggregates,

Assess their suitability in road construction on the basis of impact

value.

Table of Contents

Aggregate Impact Value on Coarse Aggregates

Apparatus for Aggregate Impact Test

The apparatus as per IS: 2386 (Part IV) – 1963 consists of:

(i) A testing machine weighing 45 to 60 kg and having a metal base with a

painted lower surface of not less than 30 cm in diameter. It is supported on

level and plane concrete floor of minimum 45 cm thickness. The machine should

also have provisions for fixing its base.

(ii) A cylindrical steel cup of internal diameter 102 mm, depth 50 mm and

minimum thickness 6.3 mm. .

(iii) A metal hammer or tup weighing 13.5 to 14.0 kg the lower end being

cylindrical in shape, 50 mm long, 100.0 mm in diameter, with a 2 mm chamfer

at the lower edge and case hardened. The hammer should slide freely between

vertical guides and be concentric with the cup. Free fall of hammer should be

within 380±5 mm.

(iv) A cylindrical metal measure having internal diameter 75 mm and depth 50

mm for measuring aggregates.

(v) Tamping rod 10 mm in diameter and 230 mm long, rounded at one end.

(vi) A balance of capacity not less than 500g, readable and accurate up to 0.1

g.

Theory of Aggregate Impact Test

The property of a material to resist impact is known as toughness. Due to

movement of vehicles on the road the aggregates are subjected to impact

resulting in their breaking down into smaller pieces.

The aggregates should therefore have sufficient toughness to resist their

disintegration due to impact. This characteristic is measured by impact value

test.

The aggregate impact value is a measure of resistance to sudden impact or

shock, which may differ from its resistance to gradually applied compressive

#.Tests for bitumen

Various Lab Tests on Bitumen for Pavement Construction

Various laboratory tests on bitumen is conducted to check quality and different

properties of bitumen for pavement construction. Bitumen is a black or brown

mixture of hydrocarbons obtained by partial distillation of crude petroleum.

Bitumen is insoluble in water. It composes 87% carbon, 11% hydrogen and 2%

oxygen by weight. It is obtained in solid or semi-solid state. It is generally used

as surface coarse for roads, roof coverings etc.

Table of Contents

Tests on Bitumen to Check Quality and

Properties for Pavement

To ensure the quality of bitumen several tests are performed which are as

follows.

Ductility test

Flash and Fire point test

Float test

Loss on heating test

Penetration test

Softening point test

Specific gravity test

Viscosity test

Water content test

Ductility Tests on Bitumen

The property of bitumen which allows it to undergo deformation or elongation is

called ductility of bitumen. The ductility of bitumen is measured by the distance

in Cm (centimeter), to which the bitumen sample will elongate before breaking

when it is pulled by standard specimen at specified speed and temperature.

Firstly the bitumen sample is heated to 75-100oC and melted completely. This is

poured into the assembled mold which is placed on brass plate. To prevent

sticking the mold and plate are coated with glycerin and dextrin. After filling the

mold, placed it in room temperature for 30-40 minutes and then placed it in

water for 30 minutes.

Then take it out and cut the excess amount of bitumen with the help of hot

knife and level the surface. Then place the whole assembly in water bath of

ductility machine for 85 to 95 minutes. Then detach the brass plate and the

hooks of mold are fixed to machine and operate the machine.

The machine pulls the two clips of the mold horizontally and then bitumen

elongates. The distance up to the point of breaking from the starting point is

noted as ductility value of bitumen. The minimum value should be 75cm.

Flash and Fire Point Tests on Bitumen

Flash point of bitumen is defined as the point of lowest temperature at which

bitumen catches vapors of test flame and fires in the form of flash. Fire point of

bitumen is defined as the point of lowest temperature at which the bitumen

ignites and burns at least for 5 second under specific conditions of test.

Flash and fire point test helps to control fire accidents in bitumen coated areas.

By this test we can decide the bitumen grade with respect to temperature for

particular areas of high temperatures.

Float Tests on Bitumen

Float test is used to determine the consistency of bitumen. But we generally use

penetration test and viscosity test to find out the consistency of bitumen except

for certain range of consistencies. The float test apparatus consists of aluminum

float and brass collars as shown in below figure.

These collars are filled with melted bitumen sample and cooled to 5oC and then

attached them into aluminum floats and this assembly is placed in water bath at

a temperature of 50oC. Note down the time in seconds from the instant the float

is put on the water bath until the water breaks the material and enters the float.

Loss on Heating Tests on Bitumen

When the bitumen is heated, water content present in the bitumen is

evaporated and bitumen becomes brittle which can be damaged easily. So, to

know the amount of loss ness we will perform this test. In this test, take the

bitumen sample and note down its weight to 0.01gm accuracy at room

temperature.

Then place the sample in oven and heat it for 5 hours at 163oC. After that take

out the sample and cooled it to room temperature and take the weight to

0.01gm accuracy and note down the value. Then for the two values of weight

before and after heating we can compute the loss of mass. The loss should be

less than 5% of total weight otherwise it is not preferred for construction.

Penetration Test on Bitumen

The penetration value of bitumen is measured by distance in tenths of mm that

a standard needle would penetrate vertically into bitumen sample under

standard conditions of test. By this test we can determine the hardness or

softness value of bitumen.

In this test, firstly heat the bitumen above its softening point and pour it into a

container of depth attest 15mm. bitumen should be stirred wisely to remove air

bubbles. Then cool it to room temperature for 90 minutes and then placed it in

water bath for 90 minutes.

Then place the container in penetration machine adjust the needle to make

contact with surface of sample. Make dial reading zero and release the needle

for exactly 5 seconds and note down the penetration value of needle for that 5

seconds. Just repeat the procedure thrice and note down the average value.

Softening Point Test on Bitumen

Softening point of bitumen indicates the point at which bitumen attains a

particular degree of softening under specified conditions of the test. Take small

amount of bitumen sample and heat it up to 75-100oC. Ring and ball apparatus

is used to conduct this test. Heat the rings and apply glycerin to prevent from

sticking. Fill this rings with bitumen and remove the excess material with hot

sharp knife.

Assemble the apparatus parts, balls are arranged in guided position that is on

the top of bitumen sample. And fill the beaker with boiled distilled water. Then

apply temperature @ 5oC per minute. At certain temperature bitumen softens

and ball slowly move downwards and touches the bottom plate, this point is

noted as softening point.

Specific Gravity Test on Bitumen

Specific gravity of bitumen is the ration of mass of given volume of bitumen to

the mass of equal volume of water at specified temperature. Specific gravity is

the good indicator of quality of binder. It can be determined by pycnometer

method.

In this method, take clean and dry specific gravity bottle and take its

weight(w1).in the 2ndcase, fill the bottle with distilled water and dip it in water

bath for 30 minutes and note down the weight(w2). Next, fill half the bottle with

bitumen sample and weigh (w3).

Finally fill the bottle with half water and half portion with bitumen and weigh

(w4). Now we can find out specific gravity from the formulae.

Viscosity Test on Bitumen

Viscosity is the property of bitumen which influences the ability of bitumen to

spread, penetrate into the voids and also coat the aggregates. That is it

influences the fluid property of bitumen. If viscosity of bitumen is higher,

compactive effort of bitumen reduces and heterogeneous mixture arises.

If viscosity is lower, then it will lubricate the aggregate particles. Viscosity is

determined by using tar viscometer. The viscosity of bitumen is expressed in

seconds is the time required for the 50 ml bitumen sample to pass through the

orifice of a cup, under standard conditions of test and at specified temperature.

Water Content Test on Bitumen

When bitumen is heated above the boiling point of water, sometimes foaming of

bitumen occurs. To prevent this bitumen should have minimum water content in

it. Water content in bitumen is determined by dean and stark method. In this

method, the bitumen sample is kept in 500ml heat resistant glass container.

Container is heated to just above the boiling point of water. The evaporated

water is condensed and collected. This collected water is expressed in terms of

mass percentage of sample. It should not more than 0.2% by weight.

Related Documents