Rudarsko Rudarsko - - geolo geolo š š ko ko - -naftni fakultet naftni fakultet DRILLING TECHNIQUE DRILLING TECHNIQUE Prof. dr. Davorin Matanovi ć Prof. dr. Davorin Matanovi ć

Welcome message from author

This document is posted to help you gain knowledge. Please leave a comment to let me know what you think about it! Share it to your friends and learn new things together.

Transcript

7/30/2019 1 Drilling Rig

http://slidepdf.com/reader/full/1-drilling-rig 1/97

RudarskoRudarsko--geologeološškoko --naftni fakultetnaftni fakultet

DRILLING TECHNIQUEDRILLING TECHNIQUE

Prof. dr. Davorin MatanovićProf. dr. Davorin Matanović

7/30/2019 1 Drilling Rig

http://slidepdf.com/reader/full/1-drilling-rig 2/97

2RudarskoRudarsko--geologeološškoko --naftni fakultetnaftni fakultet

Drilling rig

• The purpose of drilling rig is-to

enable drilling the hole.

•The difference to stationary

facilities is that such rigs aremobile, because they have to

be moved frequently.

•That requirement can not limitthe ability of the rig to drill

desired hole.

7/30/2019 1 Drilling Rig

http://slidepdf.com/reader/full/1-drilling-rig 3/97

3RudarskoRudarsko--geologeološškoko --naftni fakultetnaftni fakultet

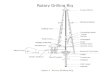

Drilling rigCROWN BLOCK

WIRE ROPE

TRAVELING BLOCK

HOOK

SWIVEL

ROTARY TABLE

DRAWWORK AND

BRAKES

MUD PUMP

7/30/2019 1 Drilling Rig

http://slidepdf.com/reader/full/1-drilling-rig 4/974RudarskoRudarsko--geologeološškoko --naftni fakultetnaftni fakultet

Drilling rig

• The hole is a “mining object” that has minor diameter compared to the

length.

•It serves as the conduit for hydrocarbons from the layer to the surface.

•Drilling of the hole is accomplished by:

- connecting the bit and drill string,- adding the pipes as the bit progresses,

- work of bit or crown at the bottom of the hole (drilling), along

with circulating mud to take out drilled particles

- withdrawing the drill string (e.g. to change worn bit).

7/30/2019 1 Drilling Rig

http://slidepdf.com/reader/full/1-drilling-rig 5/975RudarskoRudarsko--geologeološškoko --naftni fakultetnaftni fakultet

1. Bit

2. Sub: bit – drill collar 3. Drill collars

4. Drill pipes

5. Sub: drill pipe - kelly

6. Kelly7. Preventer stuck

8. Rotary hose

9. Swivel

10. Rotary table11. Draw work

12. Power engines and transmission

13. Mud pumps

14. Mud tanks

15. Hook and traveling block16. Mast/derrick

17. Wire rope/drilling line

18. Crown block

7/30/2019 1 Drilling Rig

http://slidepdf.com/reader/full/1-drilling-rig 6/97

7/30/2019 1 Drilling Rig

http://slidepdf.com/reader/full/1-drilling-rig 7/97

7RudarskoRudarsko--geologeološškoko --naftni fakultetnaftni fakultet

Drilling rig

• To drill the hole it is necessary to:

- rotate the bit or crown,

- put weight on bit,- remove drilled formation from the bottom of the

hole, to enable bit contact with clean surface of intact

formation.

• Drilling is unique mechanical and hydraulically processthat defines drilling rig construction and energy

transmission.

7/30/2019 1 Drilling Rig

http://slidepdf.com/reader/full/1-drilling-rig 8/97

8RudarskoRudarsko--geologeološškoko --naftni fakultetnaftni fakultet

Bit rotation

• There are three ways to rotate

the bit:

- with rotary table,- top drive and

- down hole motor.

•When rotation is generated

from the surface, all drill pipes

and drill collars with the bit arerotated:

• by the use of rotary table

(needs kelly),

• or by top drive (no kelly).

7/30/2019 1 Drilling Rig

http://slidepdf.com/reader/full/1-drilling-rig 9/97

9RudarskoRudarsko--geologeološškoko --naftni fakultetnaftni fakultet

Weight on the bit

• To penetrate with destructing

elements of the bit, certain

amount of the weight must beobtained on the bit.

•The weight is achieved by the

use of the weight of the part of drill collar, and the rest of the

weight of the bit, drill pipes,

kelly, swivel, traveling block

and hook are suspended onthe drill line and the draw work

through friction effect of the

brake.

7/30/2019 1 Drilling Rig

http://slidepdf.com/reader/full/1-drilling-rig 10/97

10RudarskoRudarsko--geologeološškoko --naftni fakultetnaftni fakultet

Removing parts of drilled formation

from the bottom of the hole• When bit rotates and is

weighted with certain axial force

his teeth or inserts crush or cutthe rock.

•Formation cuttings have to be

removed from the bottom holeimmediately.

•That enables bit contact with

intact rock and prevents pipestacking.

•That is the third component that

completes the term drilling in

basic sense.

7/30/2019 1 Drilling Rig

http://slidepdf.com/reader/full/1-drilling-rig 11/97

7/30/2019 1 Drilling Rig

http://slidepdf.com/reader/full/1-drilling-rig 12/97

12RudarskoRudarsko--geologeološškoko --naftni fakultetnaftni fakultet

Derrick (mast)

•Derrick is trussed steel construction, that

serves as a carrying structure while drilling.

• Sheave blocks suspended on the drilling line

in such structure, carry drill stem during

drilling process or maneuver.

•A standard derrick is a structure with four

supporting legs situated on the picks of the

square supporting base.

7/30/2019 1 Drilling Rig

http://slidepdf.com/reader/full/1-drilling-rig 13/97

13RudarskoRudarsko--geologeološškoko --naftni fakultetnaftni fakultet

Derrick (mast)

•There are two different ways of

installing the derrick on the workingplace (location):

- first is to assembly the derrick of the segments in stand up position,

- second is to assembly thesegments when laying on the ground

and that erect the mast by the use of

own draw work and transmission.

7/30/2019 1 Drilling Rig

http://slidepdf.com/reader/full/1-drilling-rig 14/97

7/30/2019 1 Drilling Rig

http://slidepdf.com/reader/full/1-drilling-rig 15/97

15RudarskoRudarsko--geologeološškoko --naftni fakultetnaftni fakultet

• Substructure supports full

derrick load, rotary table load,and the load of the drill stem that

can be suspended in the hole by

the slips, on the hook, or rests ifinger.

•When lowering casing in the hole

special spider serves toaccommodate pipes of large

diameter.

• Working floor also

accommodates draw work, rotary

table, control panels and auxiliary

equipment.

7/30/2019 1 Drilling Rig

http://slidepdf.com/reader/full/1-drilling-rig 16/97

7/30/2019 1 Drilling Rig

http://slidepdf.com/reader/full/1-drilling-rig 17/97

7/30/2019 1 Drilling Rig

http://slidepdf.com/reader/full/1-drilling-rig 18/97

7/30/2019 1 Drilling Rig

http://slidepdf.com/reader/full/1-drilling-rig 19/97

7/30/2019 1 Drilling Rig

http://slidepdf.com/reader/full/1-drilling-rig 20/97

7/30/2019 1 Drilling Rig

http://slidepdf.com/reader/full/1-drilling-rig 21/97

7/30/2019 1 Drilling Rig

http://slidepdf.com/reader/full/1-drilling-rig 22/97

Power• On a diesel electric rig diesel

7/30/2019 1 Drilling Rig

http://slidepdf.com/reader/full/1-drilling-rig 23/97

23RudarskoRudarsko--geologeološškoko --naftni fakultetnaftni fakultet

Power

transmission

• On a diesel-electric rig, diesel

engines, which on land rigs are located

at ground level, away from the rig floor,

drive electric generators.

• Produced electricity is sent through

cables to electric switch and control

station.

• Thereof, through additional cables

electricity goes to electric motors that

are attached directly to the drive shaftof the user; mud pumps, draw work,

rotary table .

• Main advantage of such energy

transmission is in avoiding complicated

mechanical compound, that needs

precise aligning.

7/30/2019 1 Drilling Rig

http://slidepdf.com/reader/full/1-drilling-rig 24/97

Pipe manipulation system – Hoisting

7/30/2019 1 Drilling Rig

http://slidepdf.com/reader/full/1-drilling-rig 25/97

25RudarskoRudarsko--geologeološškoko --naftni fakultetnaftni fakultet

Pipe manipulation system – Hoisting

system

•Draw work is a huge piece of

machinery that consists of adrum with spooled wire rope,

additional drum called cathead

spool with catheads on either end.

• To facilitate speed anddirection change, several other

shafts, clutches, chain-and-gear

drives are used.

Pipe manipulation system – Hoisting

7/30/2019 1 Drilling Rig

http://slidepdf.com/reader/full/1-drilling-rig 26/97

26RudarskoRudarsko--geologeološškoko --naftni fakultetnaftni fakultet

Pipe manipulation system – Hoisting

system

•Two main purposes of the

drawworks are:

• to lift pipes out of the hole,

and

• to lower the pipes back in the

hole.

•Work of hoisting system is done

by spooling (wrapping) wire rope

on the drum.

•When lowering, the gravitation is

used to initiate pipe movement.

7/30/2019 1 Drilling Rig

http://slidepdf.com/reader/full/1-drilling-rig 27/97

7/30/2019 1 Drilling Rig

http://slidepdf.com/reader/full/1-drilling-rig 28/97

7/30/2019 1 Drilling Rig

http://slidepdf.com/reader/full/1-drilling-rig 29/97

29RudarskoRudarsko--geologeološškoko --naftni fakultetnaftni fakultet

Drawworks - Catheads

• Another feature of the drawworks

is achieved through cat shafts and

catheads.

•The makeup or spinning, cathead

on driller’s side is used to spinand tighten drill pipe joints.

•The other on opposite side –breakout cathead is used to

loosen the drill pipe when pulled

from the hole

7/30/2019 1 Drilling Rig

http://slidepdf.com/reader/full/1-drilling-rig 30/97

Bl k

7/30/2019 1 Drilling Rig

http://slidepdf.com/reader/full/1-drilling-rig 31/97

31RudarskoRudarsko--geologeološškoko --naftni fakultetnaftni fakultet

Blocks

• The traveling block, crown block, and

drilling line are the three components are

essential in pipe manipulation.

• Their function is to support the load of

pipe in the derrick or mast as it is lowered

into or withdrawn from the hole.

• During drilling operations, this loadconsists of the hook, swivel, kelly, drill pipe,

drill collars, and a bit attached to the bottom

of the drill collars.

• During cementing operations, a string of

special pipe called casing, often a heavier

load than the drill pipe and collars, has to

be lowered into the hole and cemented.DRUM

BRAKE

FASTLINE

CROWN

BLOCK

DEADLINE

TRAVELINGBLOCK

WIREROPE

α

Blocks and drilling

7/30/2019 1 Drilling Rig

http://slidepdf.com/reader/full/1-drilling-rig 32/97

32RudarskoRudarsko--geologeološškoko --naftni fakultetnaftni fakultet

Blocks and drilling

line• Three main parts of the

system are:•traveling block

•crown block, and

•drilling line

• The purpose of the system is

to accept all pipe loadssuspended on hook and

transfer them to the drawworks.

7/30/2019 1 Drilling Rig

http://slidepdf.com/reader/full/1-drilling-rig 33/97

7/30/2019 1 Drilling Rig

http://slidepdf.com/reader/full/1-drilling-rig 34/97

34RudarskoRudarsko--geologeološškoko --naftni fakultetnaftni fakultet

Drilling line – wire rope

• One end of the rope is

suspended in the brake crest.

•The other end is fixed in the

dead line anchor

Blocks

7/30/2019 1 Drilling Rig

http://slidepdf.com/reader/full/1-drilling-rig 35/97

35RudarskoRudarsko--geologeološškoko --naftni fakultetnaftni fakultet

Blocks

• Large pulleys or sheaves mounted

on a framework through which thedrilling line is fitted are up to 1,32 m

(52”) in diameter, and their axes up

to 0,3048 m (1ft).

•Number of sheaves in traveling

block is always for one sheave les

than in crown block (dead linesheave).

Blocks

7/30/2019 1 Drilling Rig

http://slidepdf.com/reader/full/1-drilling-rig 36/97

36RudarskoRudarsko--geologeološškoko --naftni fakultetnaftni fakultet

oc s

•The hook is suspended on the

traveling block.

-Hook can be an integral part of the

traveling block or can be hung on

the bail.

-Bail is also used to hung up the

swivel on the hook.

-On both sides of the hook are two

additional bails that bear elevator,

that serves in pipe manipulation.

The rotating

7/30/2019 1 Drilling Rig

http://slidepdf.com/reader/full/1-drilling-rig 37/97

37RudarskoRudarsko--geologeološškoko --naftni fakultetnaftni fakultet

gequipment

• The rotating equipment from topto bottom consists of the:1. swivel,

2. the kelly,3. the rotary table,4. the drill stem and5. the bit.

The rotating

7/30/2019 1 Drilling Rig

http://slidepdf.com/reader/full/1-drilling-rig 38/97

38RudarskoRudarsko--geologeološškoko --naftni fakultetnaftni fakultet

gequipment

• The drill stem is the assembly of equipment between the swiveland the bit; including the:- kelly,- drill pipe, and- drill collars.

• The term drill string simply refers

to the drill pipe and drill collars;however, in the oil patch drill string is often used to mean the

whole works.

Swivel

7/30/2019 1 Drilling Rig

http://slidepdf.com/reader/full/1-drilling-rig 39/97

39RudarskoRudarsko--geologeološškoko --naftni fakultetnaftni fakultet

Swivel

• A swivel is a remarkablemechanical device.

• It is attached to thetraveling block by a largebail .

• The swivel has three main

functions:1. it supports the weight of the drill

stem;2. it allows the drill stem to rotate;

and3. it provides a pressure-tight seal

and passageway for the drillingmud to be pumped down theinside of the drill stem.

Swivel

7/30/2019 1 Drilling Rig

http://slidepdf.com/reader/full/1-drilling-rig 40/97

40RudarskoRudarsko--geologeološškoko --naftni fakultetnaftni fakultet

Swivel

• The drilling fluid is underextreme pressure -

sometimes exceeding 21 MPa(3,000 pounds per squareinch (psi)).

• The fluid comes in through

the gooseneck , a curved pipethat connects the swivel to ahose carrying the drilling fluidfrom the mud pump.

• The fluid then passes throughthe washpipe , a vertical tubein the center of the swivelbody, and into the kelly and

drill string.

Kelly and Rotary Table

7/30/2019 1 Drilling Rig

http://slidepdf.com/reader/full/1-drilling-rig 41/97

41RudarskoRudarsko--geologeološškoko --naftni fakultetnaftni fakultet

Kelly and Rotary Table

• The kelly is a three-, four-, orsix-sided length of pipe, about12,19 m (40 feet) long, that is

the upper part of the drill stem. – It serves as a passageway for thedrilling fluid on its way into the holeand transmits the rotary movement

to the drill pipe and bit.

K ll d R t T bl

7/30/2019 1 Drilling Rig

http://slidepdf.com/reader/full/1-drilling-rig 42/97

42RudarskoRudarsko--geologeološškoko --naftni fakultetnaftni fakultet

Kelly and Rotary Table

• The kelly's upper end isconnected to the swivel,

and its lower end isconnected to the drillpipe.

• The drill pipe screws ontoa device called a kelly saver sub , or a saver sub .

• The sub is a short,

connecting fitting thatscrews onto the bottomof the kelly.

K ll d R t T bl

7/30/2019 1 Drilling Rig

http://slidepdf.com/reader/full/1-drilling-rig 43/97

43RudarskoRudarsko--geologeološškoko --naftni fakultetnaftni fakultet

Kelly and Rotary Table

• The kelly fits into acorresponding square or

hexagonal opening in adevice called a kelly, ordrive, bushing . – The kelly bushing fits into a

part of the rotary tablecalled the master, orrotary, bushng .

– As the master bushing

rotates, the kelly rotates;and as the kelly rotates,the drill string and bitrotate.

K ll d R t T bl

7/30/2019 1 Drilling Rig

http://slidepdf.com/reader/full/1-drilling-rig 44/97

44RudarskoRudarsko--geologeološškoko --naftni fakultetnaftni fakultet

Kelly and Rotary Table

• The bottom threads onthe sub are temporarily

joined with threads onthe top of each length of drill pipe that is added tothe stem.

• The sub saves wear onthe threads of the kelly;when the threads of the

sub become worn, thesub is replaced orrethreaded.

Uppe kell cock

7/30/2019 1 Drilling Rig

http://slidepdf.com/reader/full/1-drilling-rig 45/97

45RudarskoRudarsko--geologeološškoko --naftni fakultetnaftni fakultet

Upper kelly cock

• An upper kelly cock is a specialvalve that can often be

recognized as a bulge on theupper part of the kelly. – The kelly cock can be closed to

shut off well pressure coming upfrom inside the drill stem.

– Most kelly cocks require a specialwrench to operate the closing

valve, and the driller should makesure that the kelly cock wrench iskept in one place and that every

crew member knows where tofind it.

Lower kelly cock

7/30/2019 1 Drilling Rig

http://slidepdf.com/reader/full/1-drilling-rig 46/97

46RudarskoRudarsko--geologeološškoko --naftni fakultetnaftni fakultet

Lower kelly cock

• A lower kelly cock (also called a drill pipe safety valve or a drill stem

valve ) is usually made up betweenthe lower end of the kelly and the top joint of drill pipe.

– When the kelly is pulled up high abovethe rotary table, as it usually is when a joint of pipe is being added to the drillstem (i.e., when a connection is being

made), the upper kelly cock cannot bereached easily should it be necessary toclose in the drill stem.

– However, the lower kelly cock is readilyaccessible when the kelly is raised.

Rotary table

7/30/2019 1 Drilling Rig

http://slidepdf.com/reader/full/1-drilling-rig 47/97

47RudarskoRudarsko--geologeološškoko --naftni fakultetnaftni fakultet

Rotary table

• Rotary drilling derives its name

from the rotary table. – The rotary table is powered by the

compound or by its own electricmotor.

– The rotary table also accommodatesthe slips - a tapered device lined withstrong, teeth like gripping elementsthat hold the pipe suspended in the

hole when the kelly is disconnected.

Rotary table

7/30/2019 1 Drilling Rig

http://slidepdf.com/reader/full/1-drilling-rig 48/97

48RudarskoRudarsko--geologeološškoko --naftni fakultetnaftni fakultet

Rotary table

– The rotary table alsoaccommodates the slips - a tapered device lined withstrong, teeth like grippingelements that hold the pipesuspended in the holewhen the kelly isdisconnected.

Drill String• The drill string is made

7/30/2019 1 Drilling Rig

http://slidepdf.com/reader/full/1-drilling-rig 49/97

49RudarskoRudarsko--geologeološškoko --naftni fakultetnaftni fakultet

Drill Stringe d st g s adeup of the drill pipe andspecial, heavy-walledpipe called drill collars. – Each length of drill pipe is

about 9,14 m (30 feet)long and is called a jointof pipe.

– Each end of each joint isthreaded.

– The end of the joint withthe interior threads isknown as the box , andthe end of the joint withthe exterior threads is

called a pin .

Drill String

7/30/2019 1 Drilling Rig

http://slidepdf.com/reader/full/1-drilling-rig 50/97

50RudarskoRudarsko--geologeološškoko --naftni fakultetnaftni fakultet

Drill String

– When pipe is made up(joined together), the pin is

stabbed into the box and theconnection is tightened.

– The threaded ends of the

pipe are called tool jointsand are actually separateparts that are welded ontothe outside of the drill pipe

body by the manufacturerwho cuts the threads toindustry specifications.

7/30/2019 1 Drilling Rig

http://slidepdf.com/reader/full/1-drilling-rig 51/97

Bits

7/30/2019 1 Drilling Rig

http://slidepdf.com/reader/full/1-drilling-rig 52/97

52RudarskoRudarsko--geologeološškoko --naftni fakultetnaftni fakultet

• Two main types of bits have beendeveloped through the years for more

efficient drilling. – Roller cone , or rock bits have cone-shaped

steel devices called cones that are free to

turn as the bit rotates. – Most bits have three cones, although

some have two and some have four.

– Bit manufacturers either cut teeth out of the cones or insert very hard tungstencarbide buttons into the cones.

Bits

7/30/2019 1 Drilling Rig

http://slidepdf.com/reader/full/1-drilling-rig 53/97

53RudarskoRudarsko--geologeološškoko --naftni fakultetnaftni fakultet

• The teeth are responsiblefor actually cutting or

gouging out the formationas the bit is rotated. – All bits have passages drilled

through them to permitdrilling fluid to exit.

– Most bits have nozzles that

direct a high-velocity streamor jet of drilling fluid to thesides and bottom of eachcone so that rock cuttings are

swept out of the way as thebit drills.

7/30/2019 1 Drilling Rig

http://slidepdf.com/reader/full/1-drilling-rig 54/97

Polycrystalline

di d bit

7/30/2019 1 Drilling Rig

http://slidepdf.com/reader/full/1-drilling-rig 55/97

55RudarskoRudarsko--geologeološškoko --naftni fakultetnaftni fakultet

diamond bits

• PDC bit cutting elementshave polycrystalline diamond

cutter with transitional layer for strike absorption.

• They are embedded in bitbody and some

manufacturers make theminterchangeable.

• Are produced with steel

bodies or with impregnatedmatrix.

• PDC bits haveinterchangeable jet nozzlesmade of tungsten carbide.

Circulating System

7/30/2019 1 Drilling Rig

http://slidepdf.com/reader/full/1-drilling-rig 56/97

56RudarskoRudarsko--geologeološškoko --naftni fakultetnaftni fakultet

Circulating System

• One of the essentials of rotary

drilling is a circulating system. – For the rotary drilling system tofunction, fluid must be circulateddownward through the drill stem,around the bit, and upward in theannular space between the drill stemand the wall of the hole or the

casing. borehole.

Circulating System

7/30/2019 1 Drilling Rig

http://slidepdf.com/reader/full/1-drilling-rig 57/97

57RudarskoRudarsko--geologeološškoko --naftni fakultetnaftni fakultet

Circulating System

• The principal purposes of circulation

fluid are to:1. clean the bottom of the hole;

2. cool the bit;

3. flush cuttings from the hole;

4. support the walls of the well so that they do

not cave in; and5. prevent the entry of formation fluid into the

borehole.

Drilling Fluid

7/30/2019 1 Drilling Rig

http://slidepdf.com/reader/full/1-drilling-rig 58/97

58RudarskoRudarsko--geologeološškoko --naftni fakultetnaftni fakultet

Drilling Fluid

• The circulation fluid is usually a liquid

but can also be air or gas. (Remember,a fluid can be either a liquid or gas.)

– If the circulating, or drilling, fluid is a liquid,

it is made up mostly of water, althoughoccasionally oil is the major component.

– Both types of drilling fluids are called muds,or drilling muds, because that is what theyappear to be.

Drilling Fluid

7/30/2019 1 Drilling Rig

http://slidepdf.com/reader/full/1-drilling-rig 59/97

59RudarskoRudarsko--geologeološškoko --naftni fakultetnaftni fakultet

Drilling Fluid

• Nevertheless, some drilling muds are quite abit more than just muds; literally scores of

special chemical additives and weightingmaterials are put into them in order to achievetheir purpose with the greatest efficiency.

– Special clays are used to give body to the mud, andbarite -a heavy mineral- is added to increase thedensity of the mud.

– Chemicals are used to control the thickness, orviscosity, of the mud and to improve the ability of the solid particles in the mud to deposit a layer, orcake, on the wall of the hole.

Drilling Fluid

7/30/2019 1 Drilling Rig

http://slidepdf.com/reader/full/1-drilling-rig 60/97

60RudarskoRudarsko--geologeološškoko --naftni fakultetnaftni fakultet

Drilling Fluid

• In perhaps 1 percent of all oilwells drilled,compressed air or natural gas is used as thecirculating fluid instead of mud.

– Conditions are usually such that air drilling,although a very efficient drilling method, cannot beused.

– Circulating with a liquid is less efficient but offersthe advantages of hydraulic lift (such as its ability

to lift cuttings made by the bit), pressure buildupas depth increases, and so on.

Mud Tanks and Pumps

7/30/2019 1 Drilling Rig

http://slidepdf.com/reader/full/1-drilling-rig 61/97

61RudarskoRudarsko--geologeološškoko --naftni fakultetnaftni fakultet

Mud Tanks and Pumps• The mud is mixed in the

mud tanks (often calledmud pits) with the helpof a mud hopper intowhich most of the dryingredients for the mud

are poured. (It is veryimportant to note thatsome dry ingredients,

especially one calledcaustic, should never beadded to the mud

through the hopper.

Mud Tanks and Pumps

7/30/2019 1 Drilling Rig

http://slidepdf.com/reader/full/1-drilling-rig 62/97

62RudarskoRudarsko--geologeološškoko --naftni fakultetnaftni fakultet

Mud Tanks and Pumps• The hopper works in such a

way that it often throwsout a little of the

ingredients being added toit. Since caustic is just that-caustic- one can easily

receive a severe burn fromsuch ejected particles.)

– The tanks contain agitators

(paddle like projections) and jets that mix the mud.

– The mud is mixed with eitheroil or water, depending onthe mud properties needed.

Mud• The mud pump is the

7/30/2019 1 Drilling Rig

http://slidepdf.com/reader/full/1-drilling-rig 63/97

63RudarskoRudarsko--geologeološškoko --naftni fakultetnaftni fakultet

Pumpsprimary component of anyfluid-circulating system. – Pumps are either powered by

electric motors attacheddirectly to them, or driven bythe compound.

– The pumps for rotary drilling

rigs have high ratings andare capable of moving largevolumes of fluid at very highpressures.

– When circulating with air orgas, the pump is replaced bycompressors, and mud tanks

are not required.

7/30/2019 1 Drilling Rig

http://slidepdf.com/reader/full/1-drilling-rig 64/97

The Mud Cycle

7/30/2019 1 Drilling Rig

http://slidepdf.com/reader/full/1-drilling-rig 65/97

65RudarskoRudarsko--geologeološškoko --naftni fakultetnaftni fakultet

y

• The rotary hose isconnected to the swivel.

– The mud enters the swivel ,flows down through the kelly ,drill pipe and drill collars , and

exits at the bit . – It then does a sharp U-turnand heads back up the holethrough the annulus , a space

between the outside of thedrill string and wall of thehole.

The Mud Cycle

7/30/2019 1 Drilling Rig

http://slidepdf.com/reader/full/1-drilling-rig 66/97

66RudarskoRudarsko--geologeološškoko --naftni fakultetnaftni fakultet

y

• Finally, the mud leaves thehole through a steel pipe or

trough, called the mud return line , and falls over avibrating, screen like device

called the shale shaker . – The shaker screens out the

cuttings and dumps them into

a reserve pit . – The mud then drains back into the mud tanks and isrecycled back down the hole

by the mud pump.

7/30/2019 1 Drilling Rig

http://slidepdf.com/reader/full/1-drilling-rig 67/97

67RudarskoRudarsko--geologeološškoko --naftni fakultetnaftni fakultet

• If fine silt or sand is beingdrilled, devices calleddesilters and desanders aremounted on the mud pits toremove these very small

particles. – Recirculating silt and sand

back down the hole makes the

mud heavier than desired andmight erode the drill string andother components.

Mud-Gas Separator

7/30/2019 1 Drilling Rig

http://slidepdf.com/reader/full/1-drilling-rig 68/97

68RudarskoRudarsko--geologeološškoko --naftni fakultetnaftni fakultet

p

• A mud-gas separator isan essential item of rig

equipment for handling agas kick. – The mud-gas separator

saves the usable mudcoming out of the wellwhile a kick is beingcirculated out and

separates the flammablegas so it can be burned ata safe distance from the

rig.

Mud-Gas Separator

7/30/2019 1 Drilling Rig

http://slidepdf.com/reader/full/1-drilling-rig 69/97

69RudarskoRudarsko--geologeološškoko --naftni fakultetnaftni fakultet

p

• Most mud-gas separators are made of a length of large-diameter pipe.

– Interior baffles are used to slow down the mud-gasstream, and a gooseneck arrangement at the bottompermits the mud to flow to the shaker tank whilemaintaining a fluid head to hold the gas at the top.

– The gas vent pipe at the top permits the gas to be flaredwithout too much back-pressure on the mud.

• And, if a formation containing small amountsof gas is encountered, a degasser is often

7/30/2019 1 Drilling Rig

http://slidepdf.com/reader/full/1-drilling-rig 70/97

70RudarskoRudarsko--geologeološškoko --naftni fakultetnaftni fakultet

employed to remove the gas from the mudbefore it is recirculated into the hole.

– Mud containing gas (gas-cut mud) should not be

recirculated because it decreases the density of themud, which could lead to a blowout.

7/30/2019 1 Drilling Rig

http://slidepdf.com/reader/full/1-drilling-rig 71/97

Well Control Equipment

7/30/2019 1 Drilling Rig

http://slidepdf.com/reader/full/1-drilling-rig 72/97

72RudarskoRudarsko--geologeološškoko --naftni fakultetnaftni fakultet

• Fluid (either liquid or gas)erupts from the well, usually

with great force, and oftenignites into a roaring inferno,especially if the fluid is gas.

– The trouble arises when thepressure in the formation ishigher than that in the well.

– The pressure in the well ismaintained by the type andamount of drilling fluid beingcirculated through it.

Well Control Equipment

7/30/2019 1 Drilling Rig

http://slidepdf.com/reader/full/1-drilling-rig 73/97

73RudarskoRudarsko--geologeološškoko --naftni fakultetnaftni fakultet

• Ordinarily, the drilling mud prevents the formationfluid from getting into the borehole and blowingout, but under certain conditions fluid sometimesenters the hole and causes difficulties. – The well kicks-that is, formation fluid enters the hole,

and some of the drilling mud is forced from the hole. – If the crew does not take prompt and proper action at

the first indications of a kick, then eventually all of the

mud could be spewed out of the hole, allowing theformation fluid to flow uncontrolled to the surface.

– The result is a blowout .

Blowout Preventers

7/30/2019 1 Drilling Rig

http://slidepdf.com/reader/full/1-drilling-rig 74/97

74RudarskoRudarsko--geologeološškoko --naftni fakultetnaftni fakultet

• Blowout preventers (BOPs),in conjunction with otherequipment and techniques,

are used to close the well inand allow the crew to controla kick before it becomes a

blowout. – The two basic types of

blowout preventers on a

drilling rig are annular preventers and ram preventers .

Blowout Preventers

7/30/2019 1 Drilling Rig

http://slidepdf.com/reader/full/1-drilling-rig 75/97

75RudarskoRudarsko--geologeološškoko --naftni fakultetnaftni fakultet

• An annular preventer has

a rubber sealing element that, when activated,closes tightly around the

kelly, drill pipe, or drillcollars; or, if no part of the drill stem is in the

hole, it closes on the open hole .

Blowout Preventers

7/30/2019 1 Drilling Rig

http://slidepdf.com/reader/full/1-drilling-rig 76/97

76RudarskoRudarsko--geologeološškoko --naftni fakultetnaftni fakultet

• Ram preventers consist of large, steel valves (the rams )that have sealing elements.

– One type of ram preventer iscalled a pipe ram because itcloses on the drill pipe and is

not able to affect a seal on anopen hole.

– Blind-ram preventers are usedto close an open hole.

– Shear rams , used mostly inoffshore drilling, cut the drillpipe completely, thus sealing

the hole.

7/30/2019 1 Drilling Rig

http://slidepdf.com/reader/full/1-drilling-rig 77/97

Accumulator

7/30/2019 1 Drilling Rig

http://slidepdf.com/reader/full/1-drilling-rig 78/97

78RudarskoRudarsko--geologeološškoko --naftni fakultetnaftni fakultet

“Koomey”• Blowout preventers are

opened and closed byhydraulic fluid, which isstored under pressure in a

device called an accumulator – Several bottle-shaped or ball-shaped containers are located

on the operating unit, andhydraulic fluid is stored inthese containers.

7/30/2019 1 Drilling Rig

http://slidepdf.com/reader/full/1-drilling-rig 79/97

Choke Manifold

7/30/2019 1 Drilling Rig

http://slidepdf.com/reader/full/1-drilling-rig 80/97

80RudarskoRudarsko--geologeološškoko --naftni fakultetnaftni fakultet

• When a kick is incurred, closing in the well

with one or more of the blowoutpreventers is only the first step that mustbe taken.

– In order to resume drilling, the kick must becirculated out, and mud of the proper weightmust be circulated in (i.e., the well must be

killed , or brought under control). – Therefore, a series of valves called the choke

manifold is installed as part of the system.

ChokeManifold

• The chokemanifold is

7/30/2019 1 Drilling Rig

http://slidepdf.com/reader/full/1-drilling-rig 81/97

81RudarskoRudarsko--geologeološškoko --naftni fakultetnaftni fakultet

connected to theblowoutpreventer stack

with a choke line . – When the well is

closed in with the

blowoutpreventers, themud and intrudedformation fluid

are circulated outthe choke lineand through thechoke manifold.

• A choke is simply avalve. Choke

7/30/2019 1 Drilling Rig

http://slidepdf.com/reader/full/1-drilling-rig 82/97

82RudarskoRudarsko--geologeološškoko --naftni fakultetnaftni fakultet

– There are adjustablechokes and fixedchokes.

– An adjustable choke isoperated pneumaticallyor hydraulically and

has an opening that iscapable of beingrestricted or pinchedin; it may be infinitelyvariable in sizebetween full open andclosed.

Choke – A fixed choke has a

flow restriction of

7/30/2019 1 Drilling Rig

http://slidepdf.com/reader/full/1-drilling-rig 83/97

83RudarskoRudarsko--geologeološškoko --naftni fakultetnaftni fakultet

permanent size. – In either case, the idea

is that the well can becirculated "through thechoke" and adequate

back-pressure held onthe well to prevent thefurther entry of

formation fluids whilewell-killing proceduresare being carried out.

Auxiliaries

7/30/2019 1 Drilling Rig

http://slidepdf.com/reader/full/1-drilling-rig 84/97

84RudarskoRudarsko--geologeološškoko --naftni fakultetnaftni fakultet

• In addition to the major assemblies of equipment that make up a drilling rig, a

great number of minor pieces of equipment are necessary to carry on thework. – Some of these auxiliaries are:

• generators,

• air compressors,• mud storage facilities, and

• various instruments.

Electricity Generators

7/30/2019 1 Drilling Rig

http://slidepdf.com/reader/full/1-drilling-rig 85/97

85RudarskoRudarsko--geologeološškoko --naftni fakultetnaftni fakultet

• Modern rotary rigs are provided with alternating-current generators, nearly always diesel powered.

– Most of these generators have capacities of 50 to 100kilowatts, although larger units are sometimes installed.

– They have enough capacity to carry the main power load

of the rig-excluding hoisting, pumping, and rotating-usingonly one unit.

– Alternating-current electricity is used for rig lighting, shale

shaker motors, mud pit agitators, centrifugal pumps, rig instruments, engine-cooling fans, and air conditioning forthe bunkhouses furnished on many large rigs.

Air Compressors

7/30/2019 1 Drilling Rig

http://slidepdf.com/reader/full/1-drilling-rig 86/97

86RudarskoRudarsko--geologeološškoko --naftni fakultetnaftni fakultet

• On mechanical rigs, a small compressor is usuallymounted on the engine compound to supply air for

the pneumatic controls and clutches. – The compressor has a volume tank to allow reserve

storage of compressed air.

– Diesel-electric rigs usually have an electrically poweredcompressor to furnish high-pressure air to pneumaticcontrols and for other purposes, including starting the

main engines and operating the air-powered hoists, airslips, air pumps on the BOP-operating equipment, waterwells, air-operated tools, and the like.

Mud Storage Facility

7/30/2019 1 Drilling Rig

http://slidepdf.com/reader/full/1-drilling-rig 87/97

87RudarskoRudarsko--geologeološškoko --naftni fakultetnaftni fakultet

• A complete mud system for a heavy-dutydrilling rig usually includes not only settling

tanks, or pits, but suction tanks, or pits, towhich the pump is connected.

– It also frequently includes a reserve or waste pitwhere surplus mud and cuttings are accumulatedas drilling progresses.

– Some form of storage for the dry and liquid mudmaterials that are to be added as the drillingprogresses is found on most rigs.

Mud Storage Facility

7/30/2019 1 Drilling Rig

http://slidepdf.com/reader/full/1-drilling-rig 88/97

88RudarskoRudarsko--geologeološškoko --naftni fakultetnaftni fakultet

• Dry mud storage bins, an oil tank, andcentrifugal pumps for mud mixing arenecessary for the circulating system. – If a rig is in a remote location, adequate storage

for the dry components of the drilling mud is

especially desirable so that the mud may betreated readily without waiting for a mud companyto deliver a supply from its warehouse.

– Sacked mud materials and chemicals are usuallystored under cover for protection from severeweather.

Drilling Instruments

7/30/2019 1 Drilling Rig

http://slidepdf.com/reader/full/1-drilling-rig 89/97

89RudarskoRudarsko--geologeološškoko --naftni fakultetnaftni fakultet

• An instrumentation system is akey part of almost all rigs today. – It may be no more than one simple

weight indicator , or it may include agreat variety of things such as a

mud level recorder , a mud density recorder , torque indicators and recorders , and logging devices tokeep a continuous graphic record of work being done on the rig,particularly the depth being drilled.

Drilling Instruments

7/30/2019 1 Drilling Rig

http://slidepdf.com/reader/full/1-drilling-rig 90/97

90RudarskoRudarsko--geologeološškoko --naftni fakultetnaftni fakultet

• Figure shows the instrumentsplaced at the driller's position

for observing drill stemweight, mud pit level, pumppressure, rotary speed, tong-

line pull, and other variables. – A mud logging unit, generally

supplied by a contracting

service company, may be usedto keep track of any indicationsof oil and gas brought up in thecirculating fluid.

Other Facilities

ll l ll l d h f l f l

7/30/2019 1 Drilling Rig

http://slidepdf.com/reader/full/1-drilling-rig 91/97

91RudarskoRudarsko--geologeološškoko --naftni fakultetnaftni fakultet

• Drilling rigs also generally include such facilities as fuel storage installations ; a change house (a place for rigworkers to change from their work clothes to streetclothes); a doghouse (a small structure on the rigfloor that serves as an office for the driller and as astorage place for small tools); a tool house (a place tostore spare parts for the pumps and otherequipment); and other facilities. Rigs located inremote areas frequently have a bunkhouse where the

rig crews live while on duty. – Sometimes, the tool pusher is provided with a trailer that serves as an

office with a telephone and radio for communication with the head officeand as his living quarters while on duty.

Other Facilities

Off h i id d ith l i t

7/30/2019 1 Drilling Rig

http://slidepdf.com/reader/full/1-drilling-rig 92/97

92RudarskoRudarsko--geologeološškoko --naftni fakultetnaftni fakultet

• Offshore rigs are provided with sleeping quarters,mess facilities, electric power, water supply, andsewage facilities, as well as storage for enough drymud, chemicals, cement, oil, and other supplies tooperate the rig for many days. – Most large rigs are equipped to continuously transmit

operation data by radio to the company headquarters.

– Good rig housekeeping requires that there be a place foreverything while drilling is underway.

– Pipe racks and casing racks are standard items used fortemporary storage.

– Provisions are made for moving and storing hand tools used

in rig maintenance.

The Crew

7/30/2019 1 Drilling Rig

http://slidepdf.com/reader/full/1-drilling-rig 93/97

93RudarskoRudarsko--geologeološškoko --naftni fakultetnaftni fakultet

• Although not a component of the rig assuch, the crew is a very important part of

the rig. Without the individuals in thecrew, the equipment for rotary drilling

would be worthless.• Crews may consist of four, five, six, or

more individuals, depending on the sizeand service rating of the rig itself.

The Crew

Th t l h l ll d i i

7/30/2019 1 Drilling Rig

http://slidepdf.com/reader/full/1-drilling-rig 94/97

94RudarskoRudarsko--geologeološškoko --naftni fakultetnaftni fakultet

• The tool pusher also called rig manager – isthe man in charge. – His experience includes years of work on a drilling

rig as a crewman and driller;

– He has expert knowledge of well drilling, rigmachinery, tools and equipment.

– He directs the actual operation of the drilling rigand the work performed by the drilling crew,authorizes the employment of the crew and

coordinates the affairs of the operating companyand drilling contractor.

The Crew

Th d ill i i h f

7/30/2019 1 Drilling Rig

http://slidepdf.com/reader/full/1-drilling-rig 95/97

95RudarskoRudarsko--geologeološškoko --naftni fakultetnaftni fakultet

• The driller is in charge of drilling; he operates the

drilling machinery. – He is under the direct

supervision of the tool pusher

and is the overall supervisorof the floor men.

– The driller gives the actual

instructions concerning work on the rig to the other five orsix crew members.

The Crew

The derrick man works on the

7/30/2019 1 Drilling Rig

http://slidepdf.com/reader/full/1-drilling-rig 96/97

96RudarskoRudarsko--geologeološškoko --naftni fakultetnaftni fakultet

• The derrick man works on themonkey board, a small platformlocated up in the derrick at alevel even with the upper end of a stand of drill pipe. – When the pipe is being tripped in

or out, he handles the upper endof the pipe, guiding it to and fromthe finger.

– When drilling is going on he isresponsible for maintaining thedrilling fluid or repairing thepumps and other circulating

equipment.

• The motorman is responsiblefor the engines, fuel, andauxiliaries.

• Electrician maintains and

7/30/2019 1 Drilling Rig

http://slidepdf.com/reader/full/1-drilling-rig 97/97

97RudarskoRudarsko--geologeološškoko --naftni fakultetnaftni fakultet

The Crew

• Electrician maintains andrepairs the electrical generatingand distribution system on the

rig.• The floor man ; rotary helper or

roughneck, is responsible for

handling the lower end of thedrill pipe when it is beingtripped in or out of the hole,

handle the tongs, maintainequipment, keep it clean andpainted, and keep the rig in

general repair.

Related Documents