-

8/10/2019 02.Crystal Growth

1/13

bkdas1

OnlyforuseofBPUTM.TechStudents

Necking and dislocation free CZ crystalgrowth Maximum growth rate and diameter

control Segregation of impurities along length

and diameter Defects in CZ crystals FZ Crystal growth

CRYSTAL GROWTH

bkdas2

OnlyforuseofBPUTM.TechStudents

Miniaturisation and Crystal Growth

As channel length decreases from 10m 1m 0.1m1. Silicon crystal needs to be purer.

Dopant impurity causing shallow levels - P, B, Al, As, SbIntrinsic carrier concentration ~ 1.5x1016/m3

Before crystal growth, silicon is chemically purified and used as

feedstock for crystal growth..Impure SiSiHCl3 Distill Pure SiHCl3CVD pure Si

Heavy metals causing deep level Cu, Fe, Ti, Ni, V, etc. C, N, O

Purification done to get dopant impurity level to 1018/m3

(eq. To 1000 ohm-cm silicon)

2. Defect concentration to be low.Planar Defects stacking faults and twins

Line Defects dislocationsPoint defects vacancies, interstitials and clusters

This is done by the Czochralski (CZ) Crystal Growth amethod named after J.Czochralski discovered in 1916.

bkdas3

OnlyforuseofBPUTM.TechStudents

Single Crystal Growth

Homogeneous nucleation :As a liquid cools, several crystals will nucleate

and grow if nucleation is homogeneous.Ultimately a polycrystal will form.

Heterogeneous nucleation :

If a seed crystal is introduced into the melt andif the supercooling (Tm-T) is low, a singlecrystal will grow on the seed crystal with same

orientation. This will give a single crystal.

To grow a single crystal: One has to decrease the nucleation

rate.

Introduce a seed crystal to promote

heteregnenous nucleation and growth

seed

-

8/10/2019 02.Crystal Growth

2/13

bkdas4

OnlyforuseofBPUTM.TechStudents

Screw Dislocation & Crystal Growth

Presence of screw dislocation

provides an easy growth mechanismfor crystal growth since

atoms/molecules find a ready placewhere they can position themselves inthe crystal making it grow. No

nucleation is necessary.

Actual crystal facesSchematic

bkdas6

OnlyforuseofBPUTM.TechStudents

Crystal GrowthBridgman Method: Melt is held inside a crucible. Crucible is lowered through a temp gradient. Nucleation starts from bottom & a favorable

nuclei outgrows others to give a crystal.

Problem is contamination and stress created oncrystal due to crucible.

Czochralski Method: Dip a seed crystal into the melt nad withdraw

Crystal will grow at the solid-liquid interface. No stress in the crystal

Some contamination from crucible

Float Zone Method: Melt part of the solid.

Molten part is moved slowly from the seed side

No contamination Stress in the crystal and slow process

furnaceL

S

L

seed

melt

Seed

Crystal

bkdas7

OnlyforuseofBPUTM.TechStudents

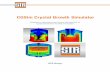

Czochralski Silicon Crystal Growth

fused quartz

crucible

CZ Crystal Growth Process:

Silicon melt is held inside afused quartz crucible that issupported by a graphitecrucible.

Heating is done using agraphite heater or induction.

Crucible has to be raisedwhile pulling the crystal since

we want the thermalconditions at the growthinterface same throughout.

Both crucible and the crystalsare rotated in opposite

directions to stir the melt.graphiteheater

graphite

crucible

C

Z

SiCrystal

Si melt~1450C

Crystalrotation

s

Cruciblerotation

c

pull

raise

Ar

SiO

Ar+CO+SiO

CO

Ar

-

8/10/2019 02.Crystal Growth

3/13

bkdas8

OnlyforuseofBPUTM.TechStudents

Czochralski Silicon Crystal Growth

Method:A seed crystal is

dipped into a meltand withdrawn. The

crystal is grown on

the seed.

Advantages:It does not require acrucible to hold the

crystal. So very littlestress present in the

crystal.

bkdas9

OnlyforuseofBPUTM.TechStudents

Czochralski Silicon Crystal Growth

Parameters to be controlled :1. Temperature of the melt (i.e., superheat T=T-Tmelting)2. Variation in temperature of the melt

3. Temperature gradient in the crucible4. Pull rate of the crystal/seed5. Rate of raising the crucible

6. Rotation of the crystal/seed7. Rotation of the crucible

8. Argon gas flow

9. Crucible material and dimensions

Diameter of the Crystal :The diameter is controlled by :

1. Pull rate of the crystal

2. Rate of rising of the crucible

3. Superheat T and temperature variations

bkdas10

OnlyforuseofBPUTM.TechStudents

Czochralski Silicon Crystal Growth

Doping : By adding Si-P, Si-B master alloys

Orientation : By orienting the seed crystal properly

Resistivity : 10-5 1 ohm-m though dopant control

Dislocation Density : zero or 2.5 m

Weight : >100 kg

-

8/10/2019 02.Crystal Growth

4/13

bkdas11

OnlyforuseofBPUTM.TechStudents

Crucible Material

Properties of Crucible Material Required: Refractoriness Tm

Si = 1415C No reaction with liquid Si

No contamination into liquid Si high purity grade needed

Possible Crucible Materials : SiO2, SiC, Si3N4, Al2O3

SiC : Segregation coefficient for C is low.SiC forms at the liquid-solid interface.

Si3N4 : Same problem as SiC

Al2O3: Contamination with Al a p-type dopant

bkdas12

OnlyforuseofBPUTM.TechStudents

Crucible Material

SiO2 : High purity fused quartz is mostly used to contain the liquid Si.

It gives O contamination through Si + SiO22SiO or [O]. It is structurally weak at 1450C and hence is supported by

a graphite crucible.

It devitrifies (i.e., crystallises into crystalline silica) andcracks.

Remnant Si after crystal growth solidifies inside the

crucible. Since silicon expands on solidification, thecrucible cracks. So silica crucible can be used only once.

It is difficult to remove B from silica and hence gives Bcontamination to CZ Si crystal (ko for B ~0.8)

SiO and CO gets released at the SiO2-liquid Si interface andgraphite-SiO2 interfaces. They can be removed by proper flow ofargon gas.

bkdas13

OnlyforuseofBPUTM.TechStudents

Necking During CZ Growth

There are dislocation in the seed.

When crystal grows on these seeds, the

dislocations will grow and multiply.

To reduce the dislocation content,

Growth rate is increased to reduce thediameter of the seed so that a neck forms.

As the neck forms, some of thedislocations will move out of the crystal at

the neck.

Process can be repeated and dislocationfree crystal obtained.

The technique of growing dislocation free crystal is alsoknown as Dash technique after its discoverer W.C.Dash.

seed

Dislocationfree crystal

neck

dislocation

-

8/10/2019 02.Crystal Growth

5/13

bkdas14

OnlyforuseofBPUTM.TechStudents

Heat Flow and Convection

The convection currents inside silicon melt changes direction assilicon crystal grows since heat flow direction through the supporting

stem changes.This changes the curvature of the solid-liquid interface affecting

growth, impurity segregation.

Crystal

TETm

TETm

Tm

Heat flow

End of Growth

bkdas15

OnlyforuseofBPUTM.TechStudents

Crystal Growth Rate

dv

,negligibleisliquidthroughconductionheatgminAssu

rvor

rl2Krdx

dTKrLvor

AKAdx

dTKA

dx

dTKALvor

Adx

dTKA

dx

dTK

dt

dmL

crystaltheofmassm

tyconductivithermalK

velocitygrowthv

fusionofheatlatentL

rl2heatradiatingcrystaltheofareaA

rcrystalofareaALet

2

21

12

L

L2

S1

S

S

L

L

S

S

L

L

S

2

====

====++++

====

++++

====

====

++++

====

++++

====

====

====

====

========

========

The latent heat released on solidification has to dissipate throughthe surface of the crystalcrystal.

Heat flow

d = 2r

L

Diameter of crystal is inverselyproportional to pull rate.

bkdas16

OnlyforuseofBPUTM.TechStudents

Crystal Growth Rate

r3

T2

L8

1v,Therefore

rK3

T2

dx

dT,So

T2

13where)x(

4

3T:Solution

TT,0xat&0T,xAt:conditionsBoundary

rTK

2where,0T

dx

Td,So

T

TK)T(K,knowWe

Tr2dx

TdrK,So

dxTr2dx

dTrK

givescrystaltheinsidelossHeat

5

max

21

m

5

S

2m

21

214

`

m

mm

5

2

2

mmS

4

s

2

22

S

4

s

2S

====

====

====++++

====

============

========

====

====

====

Maximum Growth Rate:

Heat flow

d = 2r

L

-

8/10/2019 02.Crystal Growth

6/13

bkdas17

OnlyforuseofBPUTM.TechStudents

%.5bydecreasewilldia,C5byincreasestempifSo

%5100

5

r

dr,C5dT&C50)TT(If

)TT(2

)TT(d

r

dr

)TT(2

)TT(d

dx

dT2

dx

dTd

2

d

r

dr

drr

2dr

rd

r2&v

.liquidthroughdtransferreisheatlatentall.,e.i,dxdTKLIf

drr

d,ttanconsisvIf

rv

o

oom

m

m

m

m

L

L

1

1

1

2

21

211

L

L

2

21

21

========++++====

====

====

====

====

====

====

====

====

====++++

Crystal Growth RateTemperature Control & Diameter of Crystal

Unless temp is controlledaccurately, diameter willvary with time.

bkdas18

OnlyforuseofBPUTM.TechStudents

Impurity Segregation

Along Length of CZ Si Crystal :

Crystal

x

V

(((( )))) 1kooSo

1k

o

oo

1k

oo

ooS

k

o

oo

V

0 o

I

I

o

oLo

o

o

L

So

L

S

o

oo

o

o

x1Nk)x(N,VVxSince

V

V1Nk

V

V1

V

Ik

dV

dI)x(N

V

VVII

VV

dVk

I

dI,Vand0betweengIntegratin

VV

dVIkdVNkdI,dVbyincreasesvolumecrystalIf

melttheofcontentimpuritystartingI

melttheofcontentimpurityI

melttheofvolumestartingV

crystaltheoflength'x'growingaftercrystaltheofvolumeV

tcoefficiennsegregatioumequillibriN

Nk,So

liquidinionconcentratimpurityN

erfaceintgrowthatsolidinionconcentratimpurityN

====

====

====

========

====

====

========

====

====

====

====

========

====

====

0

0.5

1

0 0.2 0.4 0.6 0.8x/L

x

/o

BAs

P

GaAl

bkdas19

OnlyforuseofBPUTM.TechStudents

Impurity Segregation

Effective Segregation Coefficient : In practice there is an impurity build up at

the solid-liquid interface.

This build up diffuses gradually into the

liquid with diffusivity D.

Thickness of diffusion layer is .

This build up will reduce with stirringbetween solid and liquid.

Crystal

High impuritycontent

meltofvelocityangular

melttheofitycosvis

D6.1

velocityfreezingvwhere

D

vexp)k1(k

kk

21

61

31

oo

oeff

====

====

====

====

++++====

As growth velocity increases, keff 1

0.001

0.01

0.1

1

0 8 16

v (mm/min)

keff

BP

SbAl

-

8/10/2019 02.Crystal Growth

7/13

bkdas20

OnlyforuseofBPUTM.TechStudents

Impurity ko Max. solid solubility Diffusion coeff. in melt(at/m3) (m2/sec)

B 0.8 6x1026 2.4x10-8

P 0.35 1.3x1027

5x10-8

As 0.3 1.8x1027 5x10-8

Sb 0.023 7x1025 1.5x10-8

Al 2x10-3 5x1026 7x10-8

Cu 4x10-4 1.5x1024 8x10-8

Ag 10-6 2x1023 8x10-8

Fe 8x10-6 3x1022 -

Ni 3x10-5 8x1023 -Co 8x10-6 2.3x1022 -

Ti 9x10-6 - -Mn 10-5 3x1022 -

O 1.4 2x1024 3.3x10-8

C 0.07 3.5x1023 2x10-8

Impurity Segregation

bkdas21

OnlyforuseofBPUTM.TechStudents

Impurity Segregation

Impurity content can beestimated from measurement ofresistivity of the crystal.

The relationship is given in thegraph on the right.

Higher the resistivity, lower is thedopant concentration.

bkdas22

OnlyforuseofBPUTM.TechStudents

Impurity Segregation

Variation along Diameter :In absence of dislocations, solid nucleates at the edge of thecrystal and grows inwards.

grows in

Center part will be richer in impurity.The difference will depend upon:

Segregation coefficent Stirring of the melt

(i.e. crucible and crystal

rotation speeds)

B

P

center

x

x/

o

edge edge

25 rpm

5 rpm

centre

x

x

/o

edge edge

edge

-

8/10/2019 02.Crystal Growth

8/13

bkdas23

OnlyforuseofBPUTM.TechStudents

Impurity Segregation

Variation along Diameter :If the solid-liquid interface is not flat, there will beadditional variations since the wafer cut is flat.

Each layer deposited has a different resistivity withinner layer having higher resistivity.

center

x

x

/o

edge edge

bkdas24

OnlyforuseofBPUTM.TechStudents

O & C in CZ Silicon

Oxygen & carbon content depends on theprocesses at various interfaces:

1. Liquid Si solid interface

segregation

2. Liquid Si gas interface evaporation of SiO from liquid Si

reaction with CO

CO + Si C + SiO or [O]Si3. Quartz Crucible liquid Si interface

Si + SiO2 2SiO or [O]Si4. Graphite Crucible Quartz Crucible

interface

SiO2 + C SiO + CO

Origins of Oxygen & carbon content in CZ Si crystal are silica and

graphite crucibles used to hold the silicon melt.

CZ

SiCrystal

Si melt~1450C

Ar

SiO

Ar+CO+SiO

CO

Ar

CO

bkdas25

OnlyforuseofBPUTM.TechStudents

O & C in CZ Silicon

Oxygen in liquid stays dissolved in the

solid Si since ko>1. Carbon in liquid gets rejected into the

liquid since ko

-

8/10/2019 02.Crystal Growth

9/13

bkdas26

OnlyforuseofBPUTM.TechStudents

Oxygen in CZ Silicon

Normally we get 20ppma 1024/m3 of oxygen interstitiallydissolved in CZ Si crystal.

Interstitial oxygen acts as a n-type donor in silicon. On heating it starts to form SiO4 complexes at 300-500C

0

5

10

15

300 600 900 1200

Temp, degC

[O]x1023

/m3

0

5

10

Time at 450 degC

[O]x1020/m3

bkdas27

OnlyforuseofBPUTM.TechStudents

Oxygen in CZ Silicon

along length of crystal

,ohm-m

asgrown

annealedat650C/2hr

P-doped Si

along length of crystal

,ohm-m

asgrown

annealedat650C/2hr

B-doped Si

Oxygen content affects the resistivity of silicon on heating.On heating dissolved interstitial oxygen (n-type dopant) precipitates out.

This can even change the type of silicon.

bkdas28

OnlyforuseofBPUTM.TechStudents

Oxygen in CZ Silicon

400C [O], dissolved interstitial oxygen, forms donor states.

700C Homogeneous nucleation of SiO4 clusters

800C

900C

1000C

1100C

Oxide precipitate grows.

Oxide precipitates nucleate stacking faults anddislocations

Stacking fault generation

C & O goes into solid solution

Effect of Annealing:

-

8/10/2019 02.Crystal Growth

10/13

bkdas29

OnlyforuseofBPUTM.TechStudents

Point Defects in CZ Silicon

Vacancies and interstitials are present inside silicon.

CV = 1000 exp(-3.66eV/kBT) 1.3x10-8 at Tm

Si

CI = exp(6.11) exp(-3.04eV/kBT) 4x10-7 at Tm

Si

Temp(K) 1688 1500 1300 1100CV 1.3x10

-8 5x10-10 6.5x10-12 1.7x10-14

CI 4x10-7 2.7x10-8 8.6x10-10 7.8x10-12

So self interstitials are predominant point defects present in the CZ

Si crystal.Others are C, O, Fe, Cu, etc.

As silicon cools down, point defects like O and I cluster.

Since VSiO2 2.2 Vsi, such clustering results in strain in the crystal.This can result in 1) Prismatic dislocations

2) Emission of Si interstitials3) Absorption of vacancies

bkdas30

OnlyforuseofBPUTM.TechStudents

Stacking Faults in CZ Silicon

Extrinsic

Due to condensation of

interstitials

IntrinsicDue to condensation ofvacancies

Due to creation of interstitials and vacancies, they can

condense and nucleate a stacking fault bounded by a

dislocation loop. These can be extrinsic or intrinsic types.

bkdas31

OnlyforuseofBPUTM.TechStudents

Swirl Defects in CZ Silicon

The growth interface is convex at the start and

becomes concave at the end of crystal growth dueto heat flow conditions.

Since silicon grows layer by layer in absence of

dislocations, when a wafer is cut, one sees circulardefects in the wafer corresponding to each layergrown.

These defects are cluster of point defects.

Swirl defects

-

8/10/2019 02.Crystal Growth

11/13

bkdas32

OnlyforuseofBPUTM.TechStudents

Float Zone (FZ) Silicon Crystals

Method:A part of the silicon held vertically is melted using an

induction coil. The molten part (molten zone) holds

through surface tension if conditions are right. Aseed crystal is put at the bottom and the liquid zone

is moved up to grow the crystal.

Advantages: Completely crucibleless no contamination Silicon can be free of oxygen and carbon Purification during crystal growth possible

Disadvantages: High dislocation density due to sharp

temperature gradient present Limitation on largest diameter that can be

grown

L

seed

Si

InductionCoil forheating

bkdas33

OnlyforuseofBPUTM.TechStudents

FZ Silicon Crystals

Si

l

L

========

====

========

============

====

========

====

====

====

====

====

====

====

l

xkexp)k1(1CC,lA

NkCSince

l

xkexp)k1(1

k

lACN,Solving

lAC)0xat(N,conditionBoundary

dxl

NkdxACdxACkdxACdxACdxACdN

,'x'from'dx'bymoveszonetheAs

impurityfortcoefficiennsegregatiok

lACzoneliquidinatomsimpurityofamountN

crystaltheofdensity

crystaltheofareationalseccrossA

startfrom'x'atsiliconFZtheinimpurityofionconcentrat)x(C

siliconstartingtheinimpurityofionconcentratC

zoneliquidtheinimpurityofionconcentratC

crystaltheoflengthL

zonetheoflengthlLet

oomS

LoS

oo

o

mL

mL

LomLomSmL

o

LL

s

m

L

Purification :

.ncalculatioCforkreplacewillkand

D

vexp)k1(k

kk

,liquidinsideimpurityofdiffusionlittleisthereIf

Soeff

oo

oeff

++++====

bkdas34

OnlyforuseofBPUTM.TechStudents

FZ Silicon Crystals

19

20

21

22

23

0 5 10

x/L

at/m

3

10

10

10

10

10

Normal freezing

1 zone pass

23

4

-

8/10/2019 02.Crystal Growth

12/13

bkdas35

OnlyforuseofBPUTM.TechStudents

FZ Silicon Crystals

Impurity Segregation :

If ko < 1,impurity goes to the finishing end.

If ko > 1,impurity goes to the starting end.

FZ Silicon Crystals:upto 100 mm diameter

> 10 ohm-m (1000 ohm-cm)

bkdas36

OnlyforuseofBPUTM.TechStudents

NTD Silicon

Neutron Transmuted Doped Silicon (NTD Si):

30Si + 1n 31P + -rays

Extremely high purity FZ silicon (1000 ohm-cm) is irradiated withneutrons in a reactor. This produces P atoms inside sil icon.

Penetration depth for neutrons is ~100cm. So crystal getsuniformly doped with P.

Half life of 31P is ~14 days. So crystal needs to be kept isolated for

about 30 days before use.

x

Rs

Rs/ Rs = 10%

bkdas37

OnlyforuseofBPUTM.TechStudents

Ingot to wafer :Ingot Boule forming wafer slicing (ID saw)

Wafers Lapping & polishing

Boule forming, orientation measurement

old standard: flatperpendicular to direction;Wafer slicing using ID saw typically within 0.5

, 2 - 5 off axis

Silicon Wafer Fabrication

ID saw

Boule formationSi

Diamond

-

8/10/2019 02.Crystal Growth

13/13

bkdas38

OnlyforuseofBPUTM.TechStudents

[110]

{111}p-type

[110]

{111}n-type

45

[011]

{100}

p-type

[011]

{100}

n-type

Orientation Flats in Silicon Wafer

bkdas39

OnlyforuseofBPUTM.TechStudents

lapping grind both sides, flatness ~2-3 m

~20 m per side removed

edge profiling

etching chemical etch to remove surface damaged layer

~20 m per side removed polishing

chemi-mechanical polish, SiO2/ NaOH slurry

~25 m per polished side removed gives wafers a mirror finish

cleaning and inspection

Silicon Wafer Fabrication

bkdas40

OnlyforuseofBPUTM.TechStudents

Available Silicon Material

CZ/FZ Silicon Crystal :

O - 2 ppma, 100 kg

Silicon Wafer :

Diameter 200 0.2 mmThickness 625 10 mTaper - < 10 mGlobal flatness - < 3 mLocal flatness - < 1 m over

20x20mm

Bow - < 10 mWarpage - < 10 mOrientation - or Surface finish 10 nm for

polishedwafer