-

7/24/2019 Woodsmith - 041

1/24

N O N O T S F R O M T S H O P 2 50

-

7/24/2019 Woodsmith - 041

2/24

WOOOSMITH

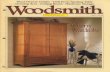

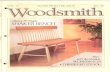

TH\I)IT I )S. If d()iJI~ 'Om lhin~two t e a r : o To o many businesses make deelsionsin a row e.Eablbhes tradition, then I'm based on how much money is going to behappy to .ay that this i. our trn dhional made. The bottom line a11l'3)'sseems toh(lliday i f tiUl. dictate deeisic ns and new ventures,

we've (ned to rome up with projects I think I beue r approach is to makethat \\ uulll makr- Ire ..,nIts, 1\ 1n nt the same decis ions based 011 the service you cantim ' he int, r., tinJ( to huild \\,,, &1,. provide, I try to put myself in the CU$-\, antt.'tl tu ln clu de o ne bl~ ) J 4 . C l espe- iorner's s ho es a nd make m v de c is io ns f ro mcially fur kids, The tin. we came ul' with that perspective. .this year 1h an easel desk. , This is the approa ch we used from the

\Vh IV,' l1 t ,u.rtcd th .. roJ t, I b\\, qu(' '>tinn ' .\\ h) d ic l) OU J U)'~ at l tJ ( H i store m nugcr.$,).il decide to open a store' An> th.n, I ,itf lhe St. l.ouii'loeat ion. \\;11 therego}n$ : tobe muTe ~to,.et-~ A re ) OUgoing to be I lu u- e ::- tO f'f:: ;' In th e future?offer mail'(lrrli'rI)urchru1question (why did We docid. to ~ 1' II) ,h:lk~ out.' th eil we'll see whatopen S $10.... 1) g..1s ot the heart ofh w \\e h.,'pens.apl)ruaclt thin). ,. htrt>at rood~l,/ill '\~h(.>n ()nco la..'1 lque:;tion eonc~rning the s to re :W (H Ki . l t i t l ,s t .ar ted - 't ', 'e l)~eJtn;. aj (I, Ctnt'Clf J)fj ~ )U pl,'n lo Lak e phone Ul'tlO rs or ha e 3 :the ded.i(ons that had to bt.'marl. ' :L ' \ \hat mil- urder ca utlog?the purpo:;eof the comf ll'Y \\l.. K o. Thl'l'C are a lready several excellent

Il', popular 1I0waday. (or th( ' r f

-

7/24/2019 Woodsmith - 041

3/24

\'OOOS MITH

To make the pil'Qt arm, cut a piece orstock to 2 1 1 by IS and trim a l~'c1eanmce,'tit ITone end, Then add a wheel -axlemade Ii'om a machine bolt. CUl oITthethread,andepoxJ itin. holcneat the end.

Nexl, dnl) t wo --din.hO) $in the pivotarm, The rlt$t hole (IFI) is drilled lhrllUgit

Ify ou d h ke 10_. a wood work 'ng up WIthothorea d e rs of W oo ds milh s e nd your Id e a to: ooosmlth Tips Tec hn iq ue s. 2 20 0 G ra nAve.. D es Mcjnos,Iowa5031 2

We pay a ,mum o f $10 fot I 1>$.end :;150more for speclallechniQUos (Illat a re aCC f ix tu re to c le anand dress them up with 8 disc sander,

The base of the fixture ' a p iece of ,pl>'wood that's clamped down to disc' ngle ii; half (abito farm theperp;;ndicular line.

lIST &LOaIN THt SCOmt.

I

4S' ANGLE

'2

1 -t-I - -'- --I, -Jl---.,

eASE UHf

CHECKIN G A 22'/,' MITER

In o rder to makean octagonal (eight s ided Iframe. ,)'OU have to cut 22: ' / : :miters on lh(,frame piece , (This type of mitered frame\\'3< used on the clock. see pg. 10.1

T h e o nly p ro ble mis h ow L a cu taJl tlr(./I-rat. Y omitez Note: T...,hnicall~' you' ,culling a 67~/ al { I~ But to do this, >'OUhave to tip the blade to the mark onthe gauge (91) -22Y, ~6 , ).

However, most58 ' 1 3\Igt'S arc 110lOli( Jus l) ' i naccu ra te , One\\ 8: to :set th e sa waccurately is to use an ;'rti~l'::- ftlljustableprorraeter;Or. OU ca n m ake a {ria lCUt (Inti

__ T_~ Technigu_e_s__

-

7/24/2019 Woodsmith - 041

4/24

\VOODS MI fH

2ORIU If. HOlES 3

. Oft ,

DRIllINGPR O C EDURE

DQU QCnIrf l

, I+OlI,

C Ok N IClOI

~ I. ..HOU

...IOUGH

,lOSS S ECTtON

aoss 00wtt -.01,/

Silk e thl- ('f.nu( (:tol'is u~('lllll)',In ni l t bemajor pieces of tht PI'(' eet, 1 ~lartt tt b~'experimeniinz with mounung tht'I-c.'connt.'C\.(J~to the i'n,i 1)[ a tt~t 'it..., f.lln'la,'toone of the ,heh '~ ,,,Ion thi. n'J ct

The [if' -it fol('Pj to U:o -t ' s quareIf' markthe centerlines of thv htllt>8. I \, IlI'lt(1 toin -llstl l\\ 0 i OI\rll lllr 1)('1 ' )' ll lr, . .c, 1m arked l \\f) lines Ulr(.t:'i lhi' l '11CI;11\(1Ul'{' ofthe w orkpi e cv, ',' X t

-

7/24/2019 Woodsmith - 041

5/24

OOOSMIT H

these eounterbores (In the thickness of the R G lOP VIEW ., ItOUNOOYEa ENDV IEWfoot and located 2V and 7 from the back ON Al l l-OGfS . . 1 ,end. see ~'ig. 1. ~ow drill a v . -hole for the fl ~- lAMINATE1wo PlEa S 1 1. OF4 4 Sl oat TOGtlHtlit eonneeicr bolt the rest o f the way through.

UPRIGHTS 4 II ~

.L.. JNext, cut fo ur uprights (Bl fro m 4'4 stock , -f F ; co ~ N.cro ~~ i I4. I AD l VJ O N ,to finished dimensions o f aI',wide by 41~~' HOlE fOOT ~ All COR e: IS. . (ASstMStl tWOllong. see Fil(. O . J . ~

. ./. I' ,

BOLESTO \TT-' CU.. ~ t.T. To attach the , i,_ . t - .. . .- (OUJ' lI UO.( ' i T Iuprigh t. to the feet. start by d rilling 8 v..hole , 1 1 deep in the bottom end o f each . . . 4 ~. ~ FRONTVIEW , 140,. ~uprig ht for the connecter boll. Cente r tbe - 4 . .. ~hole all the width an d thickness o f the

. ' >upright, s.. Detail in Fig. D. OAC' RON TUPR IGHt Upt iGHt TOPCORNERDETA ILThen drill a I~ dia .. IV,.-r1ee h()l~fO I' r - l~ ....the cross dowe l on the ins ide facecente red

y up from the bo ttom edge. r_-

c : r- SUELf ,\;';DST Rf;'1'('Ut:RII)Ls' A1\er the . : \holes are drilled on the bottom end. of aU < t \UPRlllHTS i I.~'. IOUND-OVt

four uprights, another series of holes is i Ctll TWO 0 All EDGES 4

drilled to co nnect the she lve e, CenterOF lEAC H (xc ' aO llOM

these V -di a. holes on the width of each , IADtUSONupright. lotating them 17 and : 3 8 1 up

. ' , ' CONNECtOR Al l fOf>C-ORNfRSHOllS FORTO ' SHElf

from t he bottom edge, see 'ig. 5 .Toco nnect the stretche r (F), I wo mOI 'C PIVOTHOLEDETAIL1 holes are dri lled on the back uprights, 21 1 . '(V Ol HO\ O NCenter them o n the wielth. 5 '1, antl7~: p F RO m U llttGHTSfrom t he bottom. see Fig. 5. ON LY'

pn'OT HOI.~:S.There's still one more hole ' . . .to drill in eac h/roll' uprighl (the uprights 4 .. 'IVOI HOll -.cith ,.t the stretcher holes). This hole fS EE D ETAIL} . . ~serves as t he drop-front pivot hole.

MAr k the 1II8id~ faces o f lhe uprights so \ ',. HOlf. ~~. ott ,you have a mi rrored set . Then drill a

. . . . -r \1- I FOR mOT~,..-dia ., ~ -deep hole on the inside face of fOOl C ONNECTORPffAILeach upright, refer to the Pivot Hole Detai l f C O N N ECtOR HOL ESin Fig. 5. FORBono,-\ SHIt' orlU.HOlt

0NS JDff~ C f Of

RDt::< msf, TilE COR:-tR OC H ft10a~, radius. see Detail in Fig. 6. 2 '. ~ t hop l\ ote: J used a quarter (2S~piece; I Sf E DETAilas n template. Then I eased ove r aU the sv. I (-. I~ CO NNECTORedge, on t he reet and up rights (except the r ,-bQlt ,,, end. o f the uprights) with 8 V, + -

~ HOLE. 1'.. DEE-fl'

round-over b it. . .I J ~ -. . .3 .,SHEL VESAND STRETC HER I Gu . NOT e, AU STO Ck. < 4f~ . Hl c~ 1 &ACtl: EDGE

Now lh~ shelves (C, D.El and stretcher (F I ~... t. __

can be cut to s ize from ~'4 stock. Rip the - ~ I- i three shelve. to 3 widt h of r. and the o &AQC.lDG (9@; , ,TO UJl_ OnOMHElf ~

,stretcher 10 \\;dlh o f 3W . Then trim aU 7four pieces 32 long. see ~'ig. 6.

(cur W O .,as ; 0 ;10

\ 1 ~L6IlRILL UOI,':~ FOR BOL TS.Afte r the , II.,. OE fP _

shelve, and stretcher are cut to size, drill ~.3 _ to . i-two holes in th, ,'ncb fc,l' the connector

bolts, (Note: Set id~ the middle shelf T NOTE :. H Olf tsince it won't have any holes in it.) Center NO HOUS OI JW:O MIDDLE _SHelF ,..0. .=the holes on the thiekn~ o f both ends of 1

IN MIOOlt SH ELf lotllH'Cr,m

the top $helf. bottom shelf . and the . . ~,.-

L _t_

stretcher, refer to Fig . (;. ~~

-.DRILL>JOI.1iS-O RfRO,iSI)()II'ELS Final- _. - J1 I

Iy. drill the holes for the cross dowels onthe ,II: , j j , 01 ;; ; . \ : . , . H t ; >L f.bot tom ,.jde o f the tep and bo t lam shelf and . .: : :WH E . ' ft OE[ I

-

7/24/2019 Woodsmith - 041

6/24

\VOO J)SMI'lIi

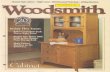

DRAWIR UN IT

Nowthe drs .. r umt conne built l'hL' unuI..;,made h)' j()lJlin~ t tl t' .n il l1l1l'11l'or the tOj)'botlom Aheh' ' '' . .. ,e t Ii: 7

.JUN)&' . CtR ['1 \ Iltt.N' ~l \t. ot thefour .. lde by .-d.'Cp d.d,~ for Ih,d id~ , (.Il tlw , ~od (ar< of thl bottomanti middle . Iv~ ~' f I I : s.

To cut th(':-.\ dsdoe -, It t th~ (11 t I'~bft . . ...:1,.'O the .. \\lcl( ,laclflblad, arwt thlrip fence to 1 ,311rt mal a II , ,1 .AAon 1 ~ l l hshelves, Then flip the board .-nd(on,,,1 tumake dA(I:-.lh\NU11\ ' l)uolan( I' (t .) Iromlh(;t other enci. :\(,\1. r,~t Lhi (\ h\ l (or12V; an ll c ut \\'(1 nl(Ifa) rlallu( s oll ac h

board.1\ I I) Its Ant>r lhll (littltltS ,I I 't' I , . . . .'mI ,J c lc , cu t fou rdrawt-r Cll\'lf lt rl'l (4 ;J (I'Clll1 1stock lQ U f in il'> l, c( ) w id th le ,Ina l( '11 lhtwidth of th e middlo'shel f. andtil h'n~ h uf31r ; ' see }-'iK ti.

ll 1 S t; T il t: i t .sl;( 1:. '. A n , - 10 fa-It'n Ihe h elf U lilt Mtn teller tnth( UI,rij 'hl'. of' ~ j '. IU

DROP fRONT

;\ 0\ \ that the ba...ic :cfc...k u nit j~ s jmt.l(oc\\ Ol k can bt'gin c)n thl' oro}, [runt 'l h,fram' fi t ' hc-l '('P t ht tfl)' 'l

-

7/24/2019 Woodsmith - 041

7/24

00 0 . ( l GU lfI t

CUT HEAD OfF Af TRSCR(W1NG INTO mlf

' OIUSON TOflOU T SID (C O IN( IS

01 Sli lts

N08. 1 ,WOODscllfW

,aOU N OO VUEHOSWITM

flL[

SIIU

I .

.. C

PlY OTPINDET Ail

TOPCO INER DUA lt .. .. POSmON

SlU , I CUT SJ'AGU m TO At GtoOVf101lOM

.... 11 - IK I3

MIDOltSHIll-

STillI

oa T A IIUUMAI l( I ' SIOtC Othtl

.All

1RAlt

1

AU G'fOOYIS (I~Tl a (OON SToc. lC DI('

.ROSS SECTIO N

DR O~ F ltONT PA NEl t.AMJNATI 10rM 'S'DiS Of

co o MASONIlt WI ' ' r~... ~1 H lIIh. (It ill be trimmed to filial(Iimf'n~iclI\~ ater )

(- t T (;nIK)\ t : ' .soy. cut ,b.'TOO\'e- ' n th toin j.)t l ft~~ of th l frame I )i ( ( t l. .. , .nt>t'flancl JU~l ,\j,lt.' l ll0U~h to accept lhtl- ( )nnK a ( O \e red l13n .. -1 , see Cross& C'litnIn f II II

sn .i TJ. \:()'~ Aft. r the gnwJ\.\.-.... an: cutrut stub II nons on thce ,I , ,(the rails to titth. grooves, oc< t 1 : : . I~.

S I '\I t .N ,TRII ' \\'h('n the frame I - -1 'mb , ,1. Ih e bottom rail ha. to ,. ,,-1-uoned FI th e rlr3v.ll~ can be fl:. m(,vt1iwhen th,- (ramt.Ii' til tht ~:lf.:-t'rlposirien,Tile ln th is t()(1 n flat't'Y :-.lnp in the gtVu\(.. ontlu- leunm ,,( paoh stile, ~'(. FiJZ.la.

This ,I nl' b cut to Icnlrlll to equal tll('dislllllc(' u . tw ,IIII1. botto m ofthe bottom,1101(1th. bo ttom 111'111,iddle shelf . 1 '111,

f(lr eh -arnnce, sec ig. 12.(l T THE P\'. :I .. :\c.,\\: dry' as.....emble the

(ntml. to ):'l'{ the ln~ldt. dimensions If tllt_'bottoms of the ~'I OOq..) an atu.karol)('< (QrP 'oUDg. fln-t file the oollom,n

-

7/24/2019 Woodsmith - 041

8/24

\VOOOS MITIl

TH E CH AL K 'R AY

~ ea-el I.' .le'lj(I1\,1 ' Ihp -'ig.1~, i'l('t'1nC)~t~ ..eerv .I bil. rout only to d l'th f about . makelhe cut in two tm -'~c~to I(l'l It (Il'lllh f ,, .

flOl \ 1>1)1(;T il>; ('() It\ I; It ~. Aftol' IIug ro ov e isrouted. round n il f ou r . n l l to1': radiu s. T hen c:,~ t'UVl1r a ll th f' tO fI )\,-ilh a 1 fr'lln(}U\'\'I'tlit

S '- f~ . i) Jt r H R .\ ( .. :n;. 1 0 m41U11\' ht, truvto the bottom ~hl )(. make t \\'1~Ur}pc,,;brackets (~rl jnll (If ,,_,'raJl.t1.. tIH,'k. J'l(tt' tufig, H Th. ,,'re und IIlu,' th,' hrlllk.\ lh, dra\l r nln an d .ublnt,1 ... lin my ...... lhlScarne out to 91 1. - , f.1~ 1'; 2(,.) A&('JI lhc de pie'>. th . . l..n~'1h .huul,1 ', l~ (~r~/~ liIJt. Nt), S Z , , )

Cut II ; Y.- IJil\~ Mil l :,lfll~ rnr tht1 tXtXjo in t> o nthe end of ell~h I li ec . Thofrontback piece. (Nl hov e fiv epin. und sl:.,.1

b

C O RN E R D E TA IL 8 0 nO M

I. MAS ONI

~.l::.-CROSS SECTION

f lU VOID S lEfTIY eonOM GlOOVlWI' rum

,((Nt l' fl'Vu.ONfl O N T S'O

lot

o

J

NOTE AUOIAWf. sroa:US .... N T O .. THlC.a HHS

GIOOYf I. Of fPISU ,-.oss SKt tOH

, .R ON T 8A CKN

(C Ut fOO l ' C IS )

S JAmWl1H

AStOtSIDE 0

,CUTfOU l P1.f US

, JS tAllS W ll A PtHI

. .IDrH Of OlAWl1 OII'( N,,..O llSS , ~.f

1 1 ,5'.

. .S U PP ORT 8 RAC~Er

CHALK TIAY

NOTE.SCREW CHAUt flAY10 IOtTOM SHIl,

(DO NOT ClUJ ,

NOlx t.fh.WOOOSCREW1t. .

I OSITlON TaAY ' 'flo.... IOlTOM Stfftf

AGU .I 19

S C l E W A f 'o IOG W t 'C U ' 1 0 O O n O M : ::: : : iO::f 'ID E O F f I AY

C ~ lOX lIT

. .. .. t rwoN. S~ IS o_ .A ' . -_ ;_ . . . . . . .. . . ..,..... -- -1.j-- -------- ...... : :. ::=r : : , U ; ._ I := . : :. : . . : . : .=-- . . . : '= ' ' =;; ;

lOUT OUt GR O O V E,_Dl1P IY 1 .. W'OI

, C A~l.AY 'CU lllOM .) STOCJcI

,. .U il l .-

-

7/24/2019 Woodsmith - 041

9/24

MASO NITE ., . \1 9 and bottom shelves.

I' ~II II()AIIlJ.Then 1 mad e the pin-upboard fl~.m l>it'Ceof V - thic k c ork g lU M10the -mooth (back) .ide of an acoustical('t~iliJlj{ (ilp I . ( ( ) , ()th(,I' options, Sources ,pg. 21, Onc,' it', r l .cui it 10 fillh. openinK. -< e fig. 21.

To h ld Ih~ 1'' '' 'UJl ho.. .nl in place, cut I w e.tolh(RI from I I ,'.)('k and serewthem toIh. ul,ri~h . Detall in Filt. zt.

inal : lIl.'l'rt Ih I,in'up board I fro m th eback I(I~) und Krt. \\ tht )1~.rule ~'l' k tot~ here Ihe lOp mounting brackets to thefronl ul'n~ht . refer lu Detail in Fig. 21.

No If)\\l'r thl' : -. Ji( Jj n~ h ea d t n th e lo \ \ t: . .. .l~),illf'n anft attach th( I O ' { _ Tmounting

hrack~I'10 Ihe uprights. \\llh th .IidingIw.d MiIIsJ.:llul I th . (0 ~r hracket. in.-talllhe ' I>port ann b.,.., eILo the drop front.

1I. III.r. ...,, (;Ln.:i. To romplcte lhe__',I...k. mount I~ handle on Ihe OUI:-i(lt of the frame. 1'f'C~.. ing the sete\\ 'S , 1 th, .urface on the jde. Also.alUlth nl'lon 1 > . . IIhd.s 10 each foot I~,frum Iht ~n,I, . see F,g. : . O .

t'I'ISIl I ound II ea.,jc.t 10 take thewhol( lhin~ allart for finishing. Then Iappli~d 1 '11 ooat. of .atin polyurelhane. lel.t t1r)\ nnd RAAembl . .dit.

-

7/24/2019 Woodsmith - 041

10/24

\),'OOOS MITIi0

- , ItO PA SS

- FI R St ASS

NotE : R UN OPI'OSlTt E O O EAG AIHS T ffN C E ro a

2n d AN D - Cth PA S S

eurnNG I NLAY G.OOV

Of aLADE I~ . HIGH

passes to widen the inla)' ,l l'OO\'.

to its final width of '1 ' C UT TIN G TH EINLAY

M er this een ie r g rooveis CUL,aninlay strip is ripped (from eontrasting wood) to fit thv groove.

RIP 1- 1 ..\): Start b) ' ripping npiece of ~'4 stock the same lengthas the case workpiece 8JKl just ahair ever Y, thick (so when it's inthe groove it will stick above thesurface of the workpiece).

Shop Note: \Vhen rippingpieces thi. thin. I use push jilthat ri des on the fenee ofthe tablesaw, see Fig . 1 For more onbuild ing thisjig, se e Thlking Shopin I I' oo to thewidth ofthe ''OOve,see Fig . o Tomaintain a unifonn width, I us~da small push stick to press thestrip again'L the fence just aheadof the blade.

IN LAYTHE STR IP. After the inlay 511;1>iscut to lit the groove, glue it in place. \Vhcnthe glue is dl1: plane the inla)' flush withthe surface of the workpieee. Next, roundover al l four edges with a ,. round-overbit. see Fig . 6. Then cut the ends square ,

CUTTING THE MITE RS

Now th e five s m a ll s e ct io n .. .. f o r t heclockease run be cut orr lhi. workpiece. Each ofthc:--t ,)if>C( 1 t qUlrt ' 22l tj miters ,

SF.TT II~ ;\~(:LE. Adjust the blade to :l2', angle and make a teSl rut on a scrap o r2.1. (S n,'c all of t he case pieces will be cuton thl' \\'IISle side, check the angle on rhepi , Iltul i I off)

r ~ 1 :~

AWAY

~

cu r GIOOVTO M ATCH :W:.oJlj~f C ROSS SECTIO N

.. -.- --

~r [J : -; ur ~ l:{ , ...

,N ,OTE:.UN 0 ' EDGAOAlNSr flHCt fO:2 nd A N O 4 ,1 -1 PA S S

SECON,'AS' /

_ r-I

CUmNG ANEl GJOO Y(Sso alADf H1Gtt flNCt

Sometimes It s hard to imagine

how little wood it lakes to build nclock, Th,> ca for this desk cluckran be m ade from a few small.CTlIpS of hardwood, and themovement ~ an inexpensivebattery-powered quart,l( model.(~ Sourees,pg. 2 < l 1

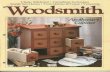

THE CASE

T he case for this clock is based onmaking part of an octagonal(eig lt-sicled) Il-ame.It starts outas one piece oi 44 stock ripped toa width uf2 VtaJld about 22 long,se e Fig, I (This is loneer thanneeded to provide a handle forcutting the mite,. on th~ smallcase pieces.)

The inside su rface of the clockcase has two grooves lhal holdlhe fronl and back panels. However, before these grooves can becut, I id the preliminary work oflaminating the stock for tho panels so I ould determine th~ f inal - -- -- -'width needed for thc panel grooves. neee.. :uy to widen the groove to fit the

TlI r~\- LS.The easiest way t o make Formica, Masonite lamination. tlf using the panel, is 1 use Yo hardwood plywood. plywood, tho groo\'. would be widen )But I wanted to add a lillie color to the THf: t~l.A C:ROO\ E.After the grllO\'CSclock. so I made the panels by laminating a for the panels are cut, a '-\\ 'idc by V, _5 by 10' piece of ~ 'o.-micato a piece (If ' d I' groove is cut centered on the outside

~la.'Qnite using ntact cement. surfaee of the case for an inlay strip . To cutPA...ELGROO \ES.Now the YI -dceppanel this centered groove. adjUSt lhe fcnw ;0~OO\ e can be cut so they're .et in Y? from the blade is almost centered on the work -the front and back edges of th~ C1iS(' . piece , see fig. 3.

Th do this, a(liust the fence se it's ' Then plow a groove the length oi thefrom Ihe blade, see Fig. 2. Then pia a workpiece, Swap ends and make a secondgroove down one side of the workpiece. pass. This will produce a gt'OO\'C exoeLlySwap ends an dplow a second groove on the centered on the width of the workpiece,opposite edge, Since must blades CUl a kerr Then it's just a matter of mo\ing the fell''

-

7/24/2019 Woodsmith - 041

11/24

1

\ N LAY S lO I00_

Itl-TllM NO TO

C O R RtelT H E ANGlE

__ 2 . - ~

r

flG U If 1 3

,NLAYS E

ooWN

lE ..rllM tN O WORKPIECEro COItRCTTHEANGlf

R OUt E l

SAW S lADE

Uf -E JIS( ni t JI G Y

~. WOOO SCIAP

PR ES SUR E sn CK

FlGUU S ..

R [.S ET S TO P B L OCKTOWAID BlA DE TOC U TS M A l U i t eelS

.fGMENTINL A Y

S I D E

AGUJt 1

WO RKm-CESAWDUSt

.ruiFSA. WII .AD

F I G U R E :JO

IOU ERTAalf

O U H D oVER

AGUR

GLUt INLAY N TO G R OO VE - -

} 1STO CK

t m .RiP A

-WIDE

STilt.

RQUIf 4 -

~

WOO DSMlTH

To help eheck the blade anb~e. I drew n22~' angle on a piece of p ap er am icheekedthe mi ter on the 2x ~ cul-off, see Fig. 7.(F or infonnation on how to draw lh._ angie . ee T ip> Tec hniq ues o n P I .:1.)

~ET U ' TifF. ~ \\\. Once the blade angle issei .] used the following set -up tc mnerthepieces to length. First. I clamped a s10pblock 10 the Ienee to gaul(\' the lenj (h ufthesegment . see fig. 8.

Shop Kote: To prevent any chance ofkickback, IK -sure lhe step block b in frontof lh, ' blade far enough that the workpiececan't eontact the block and the bladeal thesame time.

Abo. 10 help hold the wo rkpiece , ead;'when cutting the small pieces, addedan auxiliary fence to the miter gauge. CUIthis fence 1(1length 0 it extend s about Ibeyond th saw b lade tso it .u1'I'0rt, boththe workpiece and th ej menlbeing CUIoff on the far ,ide of the blade),

One other tip: To prevent the workpiecefrom Uding tluringthe CIlIJl. glue a ;LJ;IIof,andpaper to the fa t .. . o fthe renee,

SJ::T ('\'T-(W>' t.t:S GTH Now the two up-rights for the cluck ease can be cut to alength of 3 . (mea.

-

7/24/2019 Woodsmith - 041

12/24

\VOODS MITH1 2

TAACf INSfOiOf CAS'

ON lACKOJClOCK'A N lt

4' ~I ngth e , . . I gr OU \'(>; onth e

JJ ..f( urtaees , IW\ ' ,, jg . 15.\\'hen t h .. I , ,, 1' 1 ('('( are ali),'llt.'d, p

them lil[h ll)' 10g.lh. ,. (ur about a minut e

while K, dlllj[ h 'mb y flalaj 3in. 'an>I, n, .... ~ 11( 1 0. Ii(, elIl'\Julnot 1 0 Sire ,IlK ~ ' .,IOIIIIS

MAK l THE PANE LS

.st, ttu F urm iea-covered panels canbecut til E lZ,,, l~( ) in b~' cutting 1\\ '0 5 'I un' Then measure the distance be

I t','n Ih b olt o m .o (Ih~ I(I't>Ilve,;n the I 'n~ht., and CUIIh, ' I';III('lsto fit.

It T nu, (O R '~;I l.~:-;CXI .the corners ofth, panel, art cut 10 match the angles intIK' < -' . Slid~ thv panel inln the ca:.li~'l1,~1with th.. an(rlur~m~nl d n Crom each upperrorner on Ih~ .. de to ( th~ pan~l.

XU,\ cu t o crlh l ':tn)orners at a 15 3111(1,lartinl{ at th, mark,_ After the cornerg ha\'~ bt,,'n rut . lid( the ~lIels backinto th,' c,. ..... Th~n lIIark whe re the upnghts end, and Irion the exee~s off the

= = = = = = = = == = = =:: : : :~===:: ; ; ; ; : : ; ; ; ;= == = = = = = ~ ~ x > = I :lo : m ::. .o rt he panel, .e Fig. 17.

-

7/24/2019 Woodsmith - 041

13/24

1 3

DIMENSION O F H A NO S

HO ORHA NO

MlNlItEH N

oPOUitONING . 1

I O K

1 ~

oo

b.>l

t t...

J e

l : :

I;

~~ 13 -

NOTE:CU t HA N D S TO leNGT H

WITH SCtS.SOI:S

CROSS SECTION

AUGN INLJ. Y mlWITH ACtE-Nf S TRI /qNr RfO ONa AS E -

C NTEaSCltW

INLA YSTRIP

L.__~

R O U lt 5OUIf .

lRA Ci lOCAn ON OfPOSIOONIN G BLOC:

ON TO lASE

ACC-EN.lstlt lf ...

SAND SClfWSflUS H w nHS PA C E. J1 G

r

S AW O FfSCltCW

ftGURE

CLO CK PANEL

ctl

JIG

- ,ll.F hWO O O S C R W

S J'ACflt JIG

R GUIitE20

WOO DSMITH

MAKE TH E FACE

When the panels fit the frame. I mad theclock face by drillinJ holes for the move-ment and hour markers,

I'OSITI():< T il.: ( F.. I wanted to makec erta in th e fa cewas centered even thou~hthe panel m ig ht b e c oc ke din the case. So Islid the face panel in to th eease an d t ra cedthe inside of the case on the back ,ide of'thepanel, see Fi l:. 18.

The cluck hands are attached to at hr ea d e d s tu d that p ro ject s f romthe clockmovement through the face panel. Imarked the location for this stud 2\~ upfromthe bottom and centered between th~tmced lin es see Fig. 19.

After ma rking th. location for the stud,the posiuons of the hour ma rker ' are 1 0cated b) using a compass to draw H l . -radius around the cen ter hole. Then use asquare to mark the location. of the hourmarkers on Ih e circle.

DR11.1.rue 1I01.f S.Aner the IlOllitionKofthe ho le. are marked, drill a hole for themovement'sthread ed stu d.(I drilled fromthe back to avoid marring the face.)

HOLR ~1ARKR$. I w an ted tohave brasshour markers. SOI made them out of N o. 1 4bra s roundheadscrews inserted from theback, see S um es ,pr ;. 24. Drill '%, holes(for a tight friction fit) and epoxy thescreW inpla c e .

After these screws are inserted, cutthem to uniform length b y U S U 11 ta .pacerjig m ade o ut ofV . ~1a:.onue. see f~ig. 0.Drill four hoI es in the jig to match Ih~positions of the sc rew s, Place the jij'( overthe screws an d cut them off flush with a

hacksaw, see F i .'S . 2 1 and 22. T hen lindthe end. smooth. (Brass ill sand e .,ily.l

MAKE THE BASE

f'inally, the bas is m ade. It's asandwichof the same wood used to make the easean d the inlay s trip. sec Fig. 23 . FOJth. IWOoutside pieces, rip tw o p ie ce sor.J,'4 stock toa width of lV,., and about 7 long.

Lam inate thes e two pieces to a ' ripthat's the w idth ofthe inlay sU ip on thec a eframe.When th e glue is dry, plane thes ur fa ce andtrim the base to a le ng th o f6 .Then round over the top edges,

POSITIO:< O LO CK. The case is mounted tothe base with a sm allblock. Thi. blockis as ide as the space between the f ro nt an dback panels and as long as the d istancebetween the uprights, sec fig. 24.

'Iraee th e outline of the bloc k on thebase. Then glue it in place When the glueIs dry. hold t he dock frame to the base anddnll tw o holes (for No.8 X IY ,' screws)through the base into the bottom o f the

. h F -png ts, see 19. G I\ E IT Til E W O RK S. : -low mount the

movement to the face panel and C UL thehand 00 l 'i ze , s ee F ig . 26 . F inal ly.I appliedtwo coats of tung 011to the CMe.

-

7/24/2019 Woodsmith - 041

14/24

WOODSM 1TH4

~ 9' . ... NC 'JliII used for grooves 6 and #7 consistof two strips 1% wide lhal go ag ainst the~0 l' s. an d n st rip 3 w idet h at ~s agains tthe fence,see F ig, 10. I labeled this set wit h.. [' .ymbol,

stnp of 'Y' wood,

When the spacers art mounted. the~l~nit(' st rips a re placed again:':t Utestopblock.,~ the grooves stop ~. shorter thanthe eemer p''Oo e. see Fig. S.

The ] \ \ d. 'pacer is placed against thefence to ,hilt the groove~ I to each $ideofthe center zroeve. (Cut this spacer longenough 10 iiI .nlljtly bet ween tbe V space,'>' it holds them up a~'l ins t the stops andkeeps them from tipp ing, see Fig . 8.)

Shop Note: J found t hal labeling the~pace~ \ithP 8phic~~rmbolsma( lejtea:-it I10keel)the sets togelberduringthe routmg

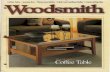

)lakmg n round trivet like the one beneath

the teapot ~ an interes ting challenge. Thislli cl ha. 'grooves routed til lighl angle> on 1 1 > p o .srite side....ofthe workpiece to create aunique lattice pattern,

\\'ben J IiIOI :;8,. une of tbese trivets, Icouldn't helpwonrlerlnj how ttl hold a roundworkpiece in place to rout parallel jlTOO e.,Then il da wned on me - rout the ~'TOO eswhile the wo rkpiece issqunrc.theu cUIIItothe round shape.

A J began experirnenung with makingtnvets . r found lhnl t he thickness of Ih.stock pl nyt'd. bigpart inthe overall appearance o f the lattice paue rn. Ueing stockthat's ,to ',. thick seems to look best.

: S O .to start. I esawed ( ripped on edg~) me stock 10 a thickness of ' ,., Then tumake an l:f 'dia. round trivet, I glued upenough ~. stock to form a g' squa re. se eDetail in Vig, 1.

ROUTER TABLESETUP

The Iattiee pattern i~ ormed by l'Oulinjtdouble-stopped grocves all both {ace. ofthis square, Tot up the router table tocutlhe gro,)\'es, mount a ~. carbide-tippedc ore b ox bit,

Shop :':ole: r experimented with bulhstraight bit' and core box bits, A

-

7/24/2019 Woodsmith - 041

15/24

IS

.. WIDESPACf lS

\VOOO$MITH

fQ UR TH PASSGlOOVES: 6 AND .7

II 3 'WII>' ACU

~ f1

..... WID - Sl'AC f.S

,1

o

S jCO NO PA SSGtOOVES_2 AND If3,. WlO( SPACI.

Gun . ~,

f IR ~T PA S SNO S'AGtRS

\ : : :F ;W OHIIJlfCEOVU TOtOUl

GROOVE 1O N ID E ..

U n

~.J.. - _ 00.' s ,.,.

1 1

~ U E

$TOP

I U 2TH E ROUTING SEQUENCEIVhen th e sp acer; h av e b een cut10 sizthe grocvescan be routed. The depth ofCU Imust bealittlemore than haJfthethiclrnesso f th e sto ck to p ro du ce th e la ttic e p atte rn .On I', .lhickstockI found the bestdepth forthe grooves was o/Ili

For a smooth cut. it's.bestto

make twopasses. On the first pass groove, arerouted to halfdepth (about to'). Then th eentire sequence is repeated to deepen thegraO\'''S to the fulldepth of '

Tll~,'IRS 'I' \55. Now th e routing ea n begin. Thel'outinll'sequence:rtartswilhapa...t't o( cuts

createsth e two groovescnboth.idl.,. ith.center groove (grocves 2 and 3 ). Thissequence is shown in Figures :l thru Ii.

The pcsition of these gl'OO\'C'iS i~ on-trelledby th e Ospacer set. see Fig.8. \\1ththe threespacers in position.place thestoekin the upper li),(hlhalld corner an d rout1, 1'00\'(' #2, see Fig. 3. Then keep the sameI aee u p b ut1'O18ll' the sq uare 1 80and cu tgroove - 3 on the oth er id e of the centergroove. see Fig . ~.

Anel' these tw o g rooves are routed. nipth e squareOVCI 'and repeat the processOilth e opposite side, see Fi~. 5 and 6.

THE TOIRJ) PASS. The thil't set of cutsrequires the x s-pacersto rout groove;, ~

and fiG, see tig. 9. It's repemlve, but justm ake sure the visible g rooves (on thetops ide o f the werkp leee )art pointing towardthe fence w hen the cuts are m ade.

TH.: FOliRTIl P. \SS.Finaltv,th e fou rtb setofCUl u_the LsPHcersct, and follows theA A lIIe p r oc e du re a s b e fo re ,

REPEAT\T .VLL 1>':P1'8. After all sevenjm)O.e~ have been routed on each side toapproxim~lely h alf d ep th , a dju st th eheighto f th e b it soit c uts to f ull d e pth Y,. ). Thenrepeat the en tir e sequence ofpassesonboths id e s o fthe workpiece.

-

7/24/2019 Woodsmith - 041

16/24

\VOO DSMITH16

~ oowa flGU lf 14 RGU lt 1 7

M AKE 'ARtIA l C UT WITH .....ROU No.ovt ... r

ro PIOOOCl -au u NOS'

/ '. .OOND-.OVER ar tFIGURE 14

VISE

- W O R XPl E a

l ooft . --

WORKe (,..CH PLYWOOD. . . .

cR O SS s eC TION RAMMElPOINT

lOP IEW

. ,.LOf HOU: fOltI LOWEIING ant OWIEIt R

S CRA P 2 _4TO P VIEW

(S PA C E '., DO WfL S

TOCa. .ESf )NDW I T H H O l E 'S r N

.. WOa1C KE

D lU,l HOtEfOtflAMME l POtNt

CNTUlO GOWU _.-

I ~

rT

~ : t :LL1 5 11 rr; ;~at IIII I I I maua-

D 'lI c-tl'

WORJ PIECt M A K IN G 'T RO UND

After the groeves are routed, the trivet canbe CUt to the round shnpeusing areueerwltha ~,' slnlighl bit anda tramme lauachment,

Tilt: ROt,. ,,, : J 1edge of the trivet circumfe rence.

'O\\' rout the ci rcumference in three1 ' '' ,,

-

7/24/2019 Woodsmith - 041

17/24

17

=\VOODSM1T H

not'

lout liGHT TO un

~ PAClR BtOO

RGU E .

S EC ON D PAS S

StOO

MtASU IlE FROh\OUT SID E fOG Of 8ff

HNCf

Arter this groove i< cut. carefully tip theworkpiece up and Il.waytrcm thl' bit, Thenrotate the square 18(t antirepeat the cut tmake the second gJ'Wve.

To rout the groove.; on the OPIJO.itl'~id ,nl11lhe ~U1lJ e ever A nd position i t aga instth e ,top and the fence, Make certain thef.. JC)\ ( ~ on th e to psurface are rp 1I~ i IIiarto(ptlinting toward) the fence, The cutth... jIrOtI\'CS o n th is side,

P\s.'''~~T\lOAl'II) THR ,Tos('\ up [a thesecond set ofcuts. place the I'-wide spacertlbtaill. . tthe fenceand repeal the~(Ioquen(.'i o(four ,, -s . see Fig. :1, Finally. lace the2 -Willt'spacer against the fence and ,'OutIh, four outer grooves. see F ijl ~

II'h,, .Il.ixgl'uovei- have bee routed Oilt -< : '( 'h . .ide, r\ f . ; , tthe router bi t to a Yi( ; depthand , ejJ< .,tthe routing sequence to take the

grl'l \,~' \ full depth,ROU N D THE CORNE~S ND EDGES

ROUTING SEQUENC E After all the groove< were cut to fulldepth.Iuscda 'luartcr(251' piece)10 m ar k a n a rc on

Aflerthe spacers have been cut to size. the tht .. >nler . nnrl sanded them to the line.rout ing sequencecan start, This is a series Then I rounded tbe edges with a I roundof cuts 00 each side of the trivet to produce over b,t 011 Ih, ' router table,Ilro ,~.',,deep, However. I found the cut R~;ll(l \ I illftS 'IAR Kl>.Te remove thew as smoother if the bit starts al half depth bun, mllrJ OS ITtO \ $1' (, ~ :RS , This set-up on thE(router table is us ed to ro ut the inner pail ofgroove.Qneith. ,.~ideofthecent.rline, Th.p os uio n o fIht ne~t p air o fgro:, i>enntrolled by a spseer th8~ placed betweenthe fence and the workpiece.

Cut thisspaeer ' widealidlon ~II(>ul1h Ifit betw n the stops, see Fig, :I Theil fo,the third pair o f grooves. cu t D spacer 2wide. sec Fig, 4,

guare rivet

-

7/24/2019 Woodsmith - 041

18/24

WOO DSMlTH

~ l fAlOf

~ CHASSISADOfO R CAB

H AM fE R D ETAil

OADO JOt AXlf

O AOOfO R AXLE

, .

- AXlIOA~ S DElr

AGU U 1 - ~ L i - - ._ _ ~ .L =rr ..Lr- I '. long an d til n rough w idth o (2;, .

A \I . t : II\1 K)~. Then I cut two dadoes onthe bottom to hold the axles. Both of the'.dadoes are V wide by V deep. The frontdado is positioned V z from the front of thechassis, and the back dado L 2' (,.om theback end of the chassis, .e< Side View in ig. I.

( All IIA IJ O. There's another dado 10 cuto n the lop s ide o f the cbas sis w here th e cnh\\ilI be mounted. Thi. dado i> Y odeep. an dthe width is equal 10 the thickness of twopieces of YI stock. (The cab that fits inthisdadu is made by laminating IWI) pk'C(>;o f~'4 stock togethcJ:)

Shop Note: Although these three dadoes(and the groove lhal follows) can be cut

with a dado I (I wo bl.ri~. and chippers),it leave; a ~tightly Irregular bonum. Instead, I cut these dadoes on the outertable using'a Vi s ln lig ht b ittoget a smoothbottnm.

To cut the dadoes on the MITt workpiece needed for the chassis. first clamp anauxiliary fence over the router table sreneeto cover th e s aw d us thole, see rig. :1 .Then use a push board (a piece of 0 /,plyw o o d works well) to guide the workpiecethrough the bit, see Fig. 2.

TRIM TO WID T H .After the three dad(for the two axles and the cab) are routed.the chassis can be trimmed 1( 1a final widthuf 2 . m;m off both edges to clean up an yehipout caused when cutti ng the dadoes.)

C ; S T t:R G R ()O E . Finally.. a groove isrouted down the center of the ehassis 10hold the engine compartment and als o thesecret sliding m e ch an is m, T his D 'O IJ \'eis deep by 1',,. wide. see Fig. I.

To rout thls groove .0 if centered, Iused a two-pass procedure, refer 10 Fig. a .Start b)l setting the fence on the routertable so the bit is near the cent ..r of theworkpiece, Now make one pass with oneedge of the workpiece against the fence,and then flil the piece around to make

_ _ E_oy Bank TruckMON E Y ON THE MOV E

-

7/24/2019 Woodsmith - 041

19/24

19

r

MO U NT F lU $.H- W tn4tOl< . l mGf O, Vl ( 'J

r . - . '.,'

L ~

( E D. 1r - :0. ......

~

. S .D E V IEWGUREqfRONT VIEW

OIlUKOLESWlIHPO.TAlION

G U .~

G lU E A ,N D C l AM PENGINE IN

C(NftR GlOOVE

CUT SCIA':: ; ro F IT

CA.0

RGUlt f 6

; l.... G H T. .,

CHAMftI l.1 1

,.eamI. Oft . W r Do E

RABBETIN G DETAILIG URE 5

.J .~t__ _L_~ _

I I

, ==--====l l -}-.-__ ~~~ J..

COIN REMOVAl HOlT 9P VIEW

. .t .. . . T'., r tr--~r----;-l

I .O IA. kOlE .. 0 -

ftOU U that theblock tend ' to slide on thl: glue 3. it ,clamped in place,

Th make thi. alignment easier; I cut a>Cntp pieceto w id t h to li t in the cab dado(,pr Fig. 6'. 0 lhE'engine b lo ck c ou l dhe

hutted ltainS this blocklL Ih.

clamp istightened. (Note: n e lh~engine bloek i.clampedin p la ce , r em o ve th e.c rd p h l ,,~ inease any excess glue has seeped out whichmight glue it in the dado.)

When the glue is dl,),. slice o rrthe frontend of the engine eomparunemso it's Hushwith the front of the chassis. see Fig, 7,

ORII.I.HO L E S .The last step o n th eenginecompartment is to mark the position of thebole. needed for the headlights, therad iator cap, and the front bumper,

The headlights are y screw hole buttens and need Yz-,dia. hole. bout v,,deep, see F ig. S . T heradiator ca p is a Vdowel thaI fits in a 4-,dia.hole on the topof the e ng in e b lo ck .

And finally. the from bumpe r e) is eutto size it ~ .thick. V,,,,ide by a long.It', mounted with two bumper suppo rtpin>(which are Yaxle pegs). Mark thesehole. on the front en,l of tl chassis andwhile they'...,drilled, make sure you don'ldrill into the axle dad . see Cross Sectionin Fig. II.

Shop ~ow: A A er m ark in gth

-

7/24/2019 Woodsmith - 041

20/24

WOOOSM ITH

~. oow nFOI GASCM

fr

oID EVIEWi

W ID'> OflANK BOXE Q U AL to

HaGHTOf CA8

r

.

m A.W A T 22 '~-4., 7'-, ,',

, .. ~

f

FIGUU 15

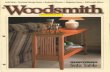

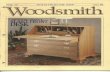

THE CA8

The challenge in building the cab is how tomake th~ windows. The solution turnedout to be kind of like the theory behindcarving - )'OU lout away everything thatdoesn't look like a window .

The basic procedure is to CUt dadees intwo pieces (D) of 1 '4 stock and laminatethese two pieces together, see fig. II.Howevez I found It WII> easierte start bv, .wO kingwith one longer pleee rather thant 0 short pieces. I >tatted it hone pieceof J 1stock cut to a rough size of3Y' wideb~' 10' long. see Fig. 10.

Cl'TI)AOOES.Then t eu t : 1 1 : -wide dar locv . from hath ends o f this workpiece . Thiscan be don on the router table (refer toI ig.21,or on a table saw with the use ofanauxiliary f.,K't' on the miter gauge. ClampR $t0l' block at one end of ibe auxiliaryfence nod use the rip fence at the other end10 cernrul the width of CUt for each dado.>'00 Detail in Fill. 10.

CIT TU S IZE . Aftt'r lh d:ld_ are cut,trim the workpiece 10 a final width of3 .....(Trim offbolh edges, removing any chipoutcaused when the dadoes were cul.)

Then cut off the two blocks (D) fot thecab, cUlting 2' below the d ado to produceblocks I long, see rig. II .

..II I xT w l~rl \ \ .These dadoes producethe ,id windows when lhe blocks arelaminated. Rut 10 produce the frontwindow, hoi .., have In be drilled in one oiIh piece s, see rig. I . Mark the centerpoints for fou rY' -dia, holes at the cornersof the fronl window. Then drill out theholes and CUI OUllhe window wiLha ('Oiling

L >aw, sec I Ig _.1.. \.I1I S.\1 E It ;( ES. When the f ollt

window is complete. laminate the twohili. log,lh.r . To prevent the blocksfrom ,Iiding on the glued surfaces, I dry.clamped the two piece. together anddrilk-d hole~ fo r two alignment pins l Y' owo)$l. Ole Fig. 13. After the hole, aredrilled, apply gl ue, lap the pins in place. nd damp the pieces LOgethe r;

H.; ' .:1 . tD G E S . \Vilen the glue is clry.bevel rip tile edges at a 22' angle. Notp: Ifall has gone aecording to plan. these beveleuts will leave a v.. -wide pillar on hath,itl of the front window. see F ig. 1

-

7/24/2019 Woodsmith - 041

21/24

21

,

. .,3'.' , NOTE: I 0

'I EMIlUD IlAN' t rw ll lOX IS ... I'IfDll JHAN lACK

~ Of '.

~~ B.

t CHAMfER DElAl lr ( ,~o

I ,

f

- -... .

A G U R l20TOP VI~W

O'ejoint.1b make this joint. cut a y ; -widc gruove d, , .,0 the imide fac e ofthe sid es and

fronLb,k JliPCtlS. sec Deta il in Fig. 17.ll()1 TtI'1 N t) \\ to ge l the final size of the

bottom. drya.,- (: mble the box lind UJ~a~Ufi'lh,' lll,icJl' dimensions, adding ,~. forthe ton 'lIe~. 1 11 < 11cut ra bbet s on ail (ollr(.-d~>iO tu Il'.I\ t. l~)I.gu . $to fit $ I\ug l ~ tn thegroove-, xt't_ lJ.cl:\llll' ~ iR.17.

II H. I' II 11(l1..~.The la$t step bC4fo , ,,mhl v ,. tu drill t wo I't-dia. helosfo r t he eOlI11;n1Ilrltl hole. RJKl use a copingsaw to cut \,ul this hfj . . ,see Fig. 17 .

'S W 'IIH.I :-;.. w Ih., FI.I ,,and fl'ontJbnck

am he1(1u< ~1alMI

camp ..,1

tu the bouom .rue rru-To um l,1l'1l tht 00> , the p ie cefor the toV (11 ' cut to .. 7 A ; so i t's V w iderIhnn th,' I , ~ ,I to .1 . ugh limgtb of 10 .TM n th. ecru 1,,1can be CU t.

Set I' t h. toblo sa w to cut. slotcentered on Ih, 1 ~lh and length of thep iece f' c. t'til It'l' S,)t, oroI.rct the bladeapproxlmnu-ly n l.... on the length.place the .-Illt 0[(1... or kvi~tlgllinst theh la de a nt i I ) I I h, h 11 : 111of the bladeUlll il li ll .' 1 '101 \\ h, , .the billde enters andIe . . . , .the W I r. r t h, ood are about1 .. apart.'1t hj: II' Then mark th is1.,:-ilic)11em 'tl 1..1.1M~\

l.ov.' .'r llll' hla.) . ~tOft U~ a btock to clampthe \\t1r.,lIl ('l 011 I h.. tnarkA, ~ fo~ig.18.:\0Y. lUl'n un tlu' sa~ l l lMlral '4. th (* blade.st IJJ}IIJ: \\ 111Il ll 1. . ... 1 1$ ~tPltn lximateJ.\ 1 t(1 2 long

n l 1 It 11 :-; , 'XI.tU the to p to1~II~h .., Ih.. com .101 I_ ....111

-

7/24/2019 Woodsmith - 041

22/24

\VOO DS~UTH

TIle S( i .' r, , tto g.. tlin)t .,Ollr m oney out fthi> bank (n, ck iI the ,Iidi ~ tongue IKIth at c ov ers 'he coin ot (In the bottom ofthe chassis ThJ O flngue is housed in thecenter groove ill th chassis a nd is pulledout by u,ing the . . . , ITbumper Il> a handle

ITT 1'(' a t; m SI7.E. CUI the tongue towidth :illlllh iekness so it slides easily in thewoo, e in the chassis , The lenJ ;th should be

IUllllcr than the bank box.Sl P ER. After the tongue is eut to .i e,

th o bum r eL )can be added . Start with apit< of 4 I SCTliI' S long and wide enoughto work with comfortably. Then CUt a dadoal 'rh: -; ': -o .lht enter of lhi~ piece to accepttheend IIrthe tongue . see ~ i~. a.

Arter Ih~ dado cut lice o T a t -thickI ' ''''' tor th. hump r and gl ue it to the enel~)rht : lf~I ~e\ ith the aid of two ,/ ' dowe~Ill :;. ; l Fig . 2:i,

HU.t: .\.,t I S The tongue held in lh~chl,.....~ )rnJO\ l with a sp ring -release pinthaI II lhflllg h the rear axle . (Befn redrilling' the bo le... for thi.- pin. if . w t < t til11lI' IhI' pin and 'prinl ' in hRnd 10~ ot lh, 'n~hl dimensions for lite holes.)

Thepin is an Sd finish Mil, and the small~flnnl (com pression coil ) i~ rom an oldball point pen. see Sources, PI . 24.

11. mount the pin, fir

-

7/24/2019 Woodsmith - 041

23/24

HO , . 1 . W~w

= ROSS SE q10N

u se :POSI E.IO....OAS-S'Aa l WHEN

GLUI HGt N

sa s

G U I 31tGUlf 31

c.lAMPsa P to CK ASS1S'0 TlS' SUOI NG lONG U,A N OSf & JN G R E L E A S E , IN

NOTE ,4 n A CH fEND .

SO CLU.I'$WHEn

SUDING TONGUE

AGUltf 3- 0I CROSS SECT ION~

fhe - -1

Dl U MS A NDE l

Go Utl q

.--------~ .UU SIZ E PATTERN

MAkt- F'''SlC UT A lOfliG

8OnOME OG(Of ItUNNING

BO ARDS

.,

\ . 1

1. 1 t

M f~NDER

...,

WOO DSMITH

the ( Jo~I position on the. chassis, andI)u.h an t nail thfQugh the ho le in th~ axl.block. e' I~II 8 1 ( cut toshape (0 lookjust like real fenders. (J knowthis shape 10 0 -, fragile . but they're Ii lotstronger than they leck.)

The fenders a re made b)' marking a1\'. -radius arc and a I'Y, rndiu. a rc on Apiece o f tq scrap, see Fig. 27. Then use aquarter < ic piece to CU \,e the,. ares tilthe ;(, ' Iight lines that extend back to formthe running board. (Thp pattern shown inc o o )

-

7/24/2019 Woodsmith - 041

24/24