-- '+

Welcome message from author

This document is posted to help you gain knowledge. Please leave a comment to let me know what you think about it! Share it to your friends and learn new things together.

Transcript

-- '+

A SERVICE PUBLICATION OFLOCKHEED AERONAUTICALSYSTEMS COMPANY-GEORGIA

EditorCharles I. Gale

ArtDirectorAnne G. Anderson

Vol. 17, No. 1, January-March 1990

CONTENTS

Focal PointBard Allison, Executive Vice President-LASCGeneral Manager-Georgia

Preventing Aircraft CorrosionThe second of two comprehensive articles oncontrolling aircraft corrosion, this installmentoffers valuable guidance on mounting aneffective counterattack against the corrosiveprocesses that shorten airframe life.

Photographic Support: John Rossino

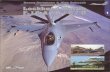

Front Cover: In a Florida test of airborne mos-quito-control equipment. a chase plane moni-torsthedispersal pattern of simulated insecticideas it streams from wing-mounted nozzles on anAir Force C-l 30. The dye-containing water sprayis shadowed behind the right wing by the verti-cal stabilizer. Aerial spraying is but one of themany specialized tasks of the worldwide Her-cules fleet that expose the airframe to thedestructive effects of corrosion.

Back Cover: Corrosion takes many forms, noneof them attractive, and the bottom line is alwaysthe same: higher costs and reduced service life.

It is always a pleasure for me to speak for andcomment about the Hercules team at LASC-Georgia.

Last month, the Hercules Country Employee of theYear was selected from the twelve monthly winners for1989. The Hercules team was gathered for the cere-mony, and I had a chance to thank them for theirdedication and contribution to the success of the Her-cules. With every aircraft delivered goes the pride ofour Georgia people for a quality product ready to meetthe customer’s mission needs, but delivery does notend our commitment to the customer.

Bard Allison When a Hercules leaves the factory, we turn itslifetime care over to our Product Support team. Thisgroup is supported by our entire organization, as is the

Manufacturing team on the production floor. Knowing that we have provided a quality product toyou, the operators in the USA and around the world, lets us all sleep a little better at night.

Last year we delivered the 1900th C-130 to the U.S. Air Force. At that gathering we weredelighted to have the very first production C-130 nose to nose on the ramp with number1900. Thatsays a good bit for the capabilities, flexibility, and life expectancy of the C-130 program.

We are dedicated to Hercules production well into the next century, a continuous productionline with continuous improvements in our process and product. If you have an opportunity to visitus here in Marietta, you will find a modernized production line. We haveendeavored to provideour people with a better work environment. New stands, improved lighting, adequate storage,more highly accessible power and air are just a few of the changes you will notice. Theseimprovements and a renewed spirit of pride in producing quality products for you, our customers,are evident throughout the plant.

Our challenge is continuous improvement in both productivity and quality to keep theHercules affordable in the world marketplace and serve your mission needs effectively. Althoughsome of our people move on into retirement and others take their place, the Hercules heritageremains. “Hercules Country” is more than just our facilities. It is a dedication to a cause-to buildand support the Hercules to the best of our abilities.

The feature article in this issue is entitled “Preventing Aircraft Corrosion.” It is my job toprevent organizational corrosion, and I accept that challenge for the Hercules team. I extend toeach of you an open invitation to visit us and see us in action.

Sincerely,

Bard Allison,Executive Vice President-LASCGeneral Manager-Georgia

J. D. ADAMS (ACTING) DIRECTOR

C-130/HERCULES SUPPLY TECHNICAL SUPPORTABILITY TRAINING

SERVICE SUPPORT PUBLICATIONS TECHNOLOGY SYSTEMS

J. F. Parnigoni D. R. Steele C. E. Adams H. D. Hall E. L. Parker

by Everett J. Smith, Specialist EngineerMaterials and Producibility Technology Department

This is the second of two articles concerning preven-tion and control of corrosion in the Hercules aircraft. Asin the case of the first installment, thisdiscussion is notintended to be all-encompassing; rather, it presents an

overview of the basic requirements for maintaining the --Hercules airlifter regardless of airplane age.

The first article (“sion,” Lockheed Service News, Vol. 15, No. 4, Oct.-Dec.

1988) pointed out that except for outward appearances, the Hercules has evolved into essentially a new airplane

over the past 30-plus years. Along with numerous other-‘improvements, advanced alloys, finishes, and sealing processes are now incorporated in every new Hercules forthe purpose of enhancing structural integrity andincreasing the aircraft’s resistance to corrosive attack.

Unfortunately, new materials and improved processescannot in themselves guarantee a permanently corrosion-free airplane. A certain amount of corrosion is inevitableeven with the best of care. Furthermore, as an airplaneages, corrosion problems tend to increase. This leads toan increase in labor, parts, and materials costs. Just howrapidly these increased costs will accumulate depends to agreat extent upon the quality of the operator’s corrosion-prevention and control program and his commitment tofollowing through on it.

Corrosion prevention must begin when the airplane ismanufactured and continue until the airplane is retired.In theory, an airplane could be operated indefinitely if itreceives thorough inspections and prompt repairs. Inpractice, at some point the operator will probably decideto retire the airplane because of escalating maintenancecosts.

Lockheed SERVICE NEWS V17Nl 3

Cleaning the Airplane

The two primary reasons for cleaning airplanes are toremove corrosion-causing contaminants and provide cleansurfaces for good corrosion inspections. An added benefit,though perhaps the least important part of a corrosion-prevention program, is appearance of the airplane.

The importance of cleaning airplanes regularly cannotbe overemphasized. How often an airplane requires clean-ing is dependent upon its operational environment. Forexample, airplanes operating in arid, pollution-free envi-ronments require less frequent cleaning than airplanesoperating in hot and humid climates, within about ten miles

of seacoasts, or in most desert regions. Even though theclimate may otherwise be acceptable, most deserts are thesites of ancient sea beds and the sand often contains asignificant amount of salt. This has important con-sequences in terms of exposure to corrosive attack.

The Washrack Crew

Safety must always be the first consideration in anyactivity involving aircraft, and the washrack is no excep-tion. In particular, an appropriately designed safety deviceis necessary to protect workers from falls while they arecleaning upper wing surfaces. One such device is a cablerunning spanwise and 6-7 feet above the wing. Each end ofthe cable is fixed to the indoor facility wall, or to posts in thecase of an outdoor facility. To this cable the worker attachesa lanyard which is fastened to his safety harness.

In spite of the recognized complexities involved incleaning airplanes properly, many operators use washrackworkers who have been given very little training in safe andeffective airplane cleaning techniques. The most seriousproblem that results from this lack of training is the misuseof washrack chemicals. If not mixed and used correctly,these substances can do substantial damage to the airplane.

For example, Stoddard solvent and solvent-type clean-ing compounds will cause deterioration of most rubberproducts if not mixed in the correct proportions or notrinsed off completely during use. Strong, alkaline cleaningcompounds will corrode aluminum alloys, and can etch anddamage some types of protective finishes. For the sake ofthe airplane, it is always best to use a dedicated cleaningcrew. A well-trained, dedicated crew will soon master allthe intricacies of airplane cleaning techniques, and performmore efficiently than a “made-up” crew.

Whether the operator has enough work to justify adedicated crew or not, everyone engaged in cleaning air-planes must be thoroughly trained. In addition to the per-sonal safety aspects, the crew must be knowledgeable aboutthe handling, mixing, and storage of all chemicals used onthe washrack. Each crew member must also know how touse the chemicals, tools, and equipment without causingdamage to the airplane.

Washrack workers need the protection of safety harnesseswhen working on the upper surfaces of the aircraft.

Washing Facilities

An airplane cleaning facility need not be elaborate to beeffective, but it must be adequate to do the job year-round.It could be just a concrete pad, or it might be an elegantindoor facility with all the modern amenities. In eithercase, there are certain requirements for even the most basicwash facility.

Unless built-in stands are used, the facility must belarge enough to allow movement of portable stands com-pletely around the airplane. Stands, movable or fixed,should be of sufficient height to allow easy access to allexterior surfaces of the airplane. If airplane cleaning isdone at night, the lighting should be bright enough toprovide good visibility, with a minimum of shadows, for allsurfaces being cleaned.

An automated outdoor rinsing facility helps protect CoastGuard aircraft from the corrosive effects of salt spray.

4 Lockheed SERVICE NEWS V17Nl

Rinse water pressure is not as important as the volumeof water. As a rule of thumb, adequate pressure is availablewhen the top of the tail can be rinsed by a worker standingon the ground. The volume of water used should be suffi-cient to provide a free-flowing action over the surface beingrinsed; this requires a minimum flow of about eight gallonsper minute.

Note that in some parts of the world, the local water isnot acceptable for cleaning airplanes because of its “hard-ness.” Hardness is a general term used to describe theamount of dissolved minerals, primarily calcium carbonate(CaCO,), that a given water sample contains. Hard watercontaining no more than the following levels of dissolvedsolids in parts per million (ppm) is considered satisfactoryfor washing aircraft:

Total dissolved solids 472 ppmTotal hardness as CaCO, 420 ppmBicarbonate (HCO,) 384 ppmSulfate (SO,) 107 ppmChloride (Cl) 20 ppmHydrogen conc. (pH) 6-8 at 50°F

When water analysis indicates values significantly inexcess of those listed, the water should be chemicallytreated to reduce the level of impurities before it is used towash an airplane.

Cleaning Hints-Aircraft Exterior

All operators use the standard cleaning brushes, abra-sive pad kits, buckets, and so forth, and most operators alsoprovide safety equipment such as face masks, rubbergloves, and wet weather gear to their airplane washers.There are, however, additional items that some operatorsalready use which make the job easier, provide a cleanerairplane, and help prevent corrosion.

There is no substitute for a wet-or-dry vacuum cleaner toremove dirt and water from joints and crevices afterwashing.

During the airplane exterior wash, in particular usingoutdoor facilities, it is a good idea to use a foam genera-tor. This equipment applies a layer of cleaning solutionfoam which clings equally well to vertical and lowerhorizontal surfaces, thereby keeping the cleaning solu-tion against the surface for better cleaning action. Thefoam also resists drying on the airplane surface longerthan the liquid solution. Low-pressure compressed air isrequired to operate the foam generator.

n Although cleaning solutions can be mixed by hand,mistakes in cleaner-to-water ratios can happen. The useof a chemical proportioner will eliminate mixing errors.Built-in mixing equipment, although more sophisti-cated, functions much the same way as the portableproportioner. In use, the equipment is connected to a

water source and to a container of concentrated cleaningcompound. The operator turns a valve to the desired mixratio, activates the machine, and applies the mixed clean-ing solution to the aircraft surface.

n Unless a built-in bulk storage and pumping system existsat the wash facility, an air-operated barrel pump isneeded to transfer cleaning chemicals from the storagedrums to mixing tanks, etc.

n The use of hot water (about 130’F) increases cleanabilityand rinsability, and reduces man-hours by as much as 20percent, according to U.S. Air Force studies. If only alimited amount of hot water is available, use it for apply-ing the cleaning solution and then rinse with cold water.

During airplane exterior cleaning, the brushes, mops,etc. should not be placed on the ground where they may pickup dirt that will damage the paint. Also, high-pressurewater should not be directed toward wheel bearings or otherlubrication points, or at thin-sheet honeycomb panels. Afterthe wash, and before the airplane dries, apply a thin coat ofsoil barrier (Cee Bee A-6 or Eldorado PC 1020 or equiv-alent) to hard-to-clean areas and to areas subject to urinespray. Typical of such locations are engine exhaust tracksand aft fuselage belly and ramp skin panels. Relubricate alllubrication points within the cleaned area.

Cleaning Hints-Aircraft Interior

The use of water hoses for cleaning inside the airplane isnot recommended because of possible damage to the elec-trical equipment, and also because of the corrosion thatcould be caused by water and cleaning solutions enteringinaccessible areas of the airplane and remaining there. It is

Foam generators can produce a cleaning solution foam that willadhere to both vertical and horizontal surfaces.

Lockheed SERVICE NEWS V17N1 5

best to use a rag or sponge to apply cleaning solution from abucket. After scrubbing interior surfaces with a soft, bristlebrush, wipe off all dirt and cleaning solution thoroughlywith a rag or sponge, rinsing frequently in clean water. Usea wet-or-dry vacuum cleaner or dry rags or sponges toremove excess water. Apply corrosion-preventive com-pound to all joints and crevices.

Another criterion which must be taken into account isthe type of cargo being hauled. Anytime a corrosive cargosuch as cement, fertilizer, animals or animal carcasses,etc., is transported, the airplane interior should be thor-oughly cleaned after each mission, including under thefloor if a cargo spill is suspected. Each operator shouldevaluate his own operation and establish a cleaning fre-quency that will satisfy the requirements of his individualcorrosion-prevention program.

Fire Extinguishing Agents

Most fire extinguishing agents are corrosive and canvery quickly produce severe corrosion on airplane struc-ture. Foam and bromochloromethane-type agents are themost notable offenders in this regard. Some of the morecommonly used dry powder-type agents such as potassiumbicarbonate (PKP) are in themselves only mildly corrosive,but after exposure to heat the residue may convert topotassium hydroxide, which is very corrosive indeed.

As if that were not already bad enough, both of thesepotassium salts are hygroscopic and will absorb moisture,creating a corrosive poultice on airplane surfaces. The sootgenerated by an airplane fire is carbon contaminated by avariety of combustion byproducts, depending on what isbeing burned. Like the agents in dry powder extinguishers,soot is both corrosive and hygroscopic. Airplanes con-taminated with fire extinguishing chemicals and soot mustbe cleaned and neutralized as soon as possible afterexposure.

Inspecting for Corrosion

Have you ever wondered why some mechanics arebetter at finding corrosion than others? In addition to beingwell-trained, mechanics who show a special knack forfinding corrosion have developed the ability to recognizecorrosion “indicators.” Indicators are those little thingsthat point toward a potential corrosion problem. These canbe anything out of the ordinary, such as missing sealant in ajoint, a wet area or tide marks where water has been incontact with aircraft surfaces, or chipped or discoloredpaint.

Finding corrosion is perhaps as important as removingit because once the corrosion is found and documented, theairplane’s condition has become a “known.” As long assafety of flight is not affected, the corrosion may beremoved at another time.

Aircraft interiors must be cleaned thoroughly after each mis-sion involving the transportation of animals.

Remember, however, that the severity of corrosionincreases with time, so repairs should not be delayed toolong. After a few inspections, a pattern often emerges inwhich corrosion will be found in the same areas on allHercules aircraft operating out of a similar environment.Some problems will differ from model to model because ofchanges in materials and processing, and the finishingimprovements that have been incorporated over the yearssince the first Hercules airplane was built.

Training for anyone performing corrosion inspectionsshould, as a minimum, consist of thorough familiarizationwith the types of corrosion which may be encountered, andthe corrosion history of the airplanes that will be inspected.The only tools required are a bright light, a 10x magnifyingglass, a mirror, a pit depth gage, and a machinist’s scribefor probing suspected corrosion. A borescope is ideal forlooking into small openings without requiring disassemblyof the adjacent structure.

There are two recognized methods of removing corro-sion, chemical and mechanical. For a number of reasons,the chemical method of corrosion removal is not widelyused by operational organizations. Chemicals work moreslowly than the mechanical methods, and there is a dangerthat chemicals will enter joints, be difficult to remove, andcause further corrosion. There are also questions of per-sonal safety and waste disposal to be considered.

Most corrosion problems have to be attacked mechan-ically, and there are a number of methods by which this canbe done. These include everything from the use of sand-paper to complex methods involving abrasive blasting. Themethod of selection will depend upon the type of metal, the

6 Lockheed SERVICE NEWS V17Nl

Most corrosion must be removed mechanically; in many casesan abrasive blaster can speed up the cleaning chore.

location and accessibility of the corroded area, the degreeof damage, and the type of corrosion involved. A typicalcorrosion removal sequence proceeds as follows:

Protect the area surrounding the corroded area fromdamage during the corrosion repair.

Clean the affected area of dirt, grease, etc.

Remove the corrosion. To avoid stress risers (crack start-ing points), be sure the corrosion removal surface is leftin the shape of a saucer, with no sharp angles. Alsoensure that all corrosion is removed and the affected areais polished smooth.

Check the depth of the area where corrosion wasremoved with a depth gage and do the necessary docu-mentation. Some operators require this step before andafter removing corrosion.

Shot-peen the treated area when required.

Apply conversion coating (Alodine) to the removal areaon aluminum. Follow the operator’s finish requirementsfor other pretreatments.

Fill depressions on upper horizontal surfaces with acorrosion-inhibiting sealant to prevent water puddlesfrom forming in them.

Reapply appropriate finish after sealant has cured.

to exclude moisture and water, and to separate joined met-als. Exterior joints and gaps are filled with sealants toprevent water and chemicals from entering. Sealant is alsoused for wet-installation of fasteners and for pressuresealing.

The use of sealant specifically to combat corrosion inthe Hercules aircraft started with the manufacture of Lock-heed serial number LAC 4127 in May of 1965. At first, anon-inhibiting sealant of the MIL-S-8802 type wasemployed. Beginning with LAC 4331, which was built inSeptember of 1968, a corrosion-inhibiting sealant conform-ing to MIL-S-81733 was introduced.

Some sealants are formulated for specific uses such asapplications in high-heat areas, containment of fuel, andelectrical conduction with corrosion protection. In general,a sealant should be used only for its intended purpose, butsome sealants may be used as substitutes for others whennecessary. Listed below are sealant types commonly usedin the Hercules aircraft and a chart describing sealantcharactistics and where these products may be.obtained:

MIL-S-38249-A polyacrylate firewall sealant, thismaterial is formulated for use in sustained temperaturesranging from -65°F to +400'F Type I can withstand aflash temperature of +2000'F for 15 minutes and Type IIfor 15 minutes at +35OO'F Lockheed also uses a siliconehigh-temperature sealant, AMS specification 3374(RTV 133, manufactured by General Electric Co.), inter-changeably with MIL-S-38249.

n MIL-C-83982-This material is a chemical-resistantpolyurethane sealant with a temperature range of -65°Fto +180'F. It is used in areas where chemicals, paintremover, urine, etc., would damage other types of seal-ants and cause premature failure. For this reason, MIL-C-83982 is used to fill exterior skin panel and wing panel

The use of sealants during aircraft manufacture has proved aneffective and versatile weapon against corrosion.

Sealants

Sealant may be the most versatile and effective weaponin preventing aircraft corrosion ever introduced. It is used

Lockheed SERVICE NEWS V17Nl

ITEM SPECIFICATION

Sealant, MIL-S-38249.Firewall Type I-l/2

USE

Faying surfacesealing, wetins l la t ion offasteners andfillet sealingin hot areas.

APPL. TACK CURE MANUFACTURER’S ADDRESSTIME FREE TIME DESIGNATION DISTRIBUTOR (See PQ. 15)

1-1/2 hrs 24 hrs 72 hrs Pro-seal 700 Products Research 34

Sealant, ML-C-83962,Polyurethane Class B2Fluid-Resistant

Fillet sealing 2 hrs 24 hrs 46 hrsand brush over-coating to protectagainst chemical.exposure.

Class B6 6 hrs 46 hrs 166 hrs

Sealant, STM 40.114,Synthetic Class B1/2Rubber,ElectricallyConductive,CorrosionInhibiting

Class B2

Faying surface 1/2 hr 10 hrs 30 hrsand wet install-ation of fastenerswhere electricalconductivity isrewired.

PartingAgent

For separable sealswhere conductivityis required.

PartingAgent

For separable sealswhere conductivityis not required.

2 hrs 40 hrs 72 hrs

PL-106 Primer,PL-410 Sealant

B. F. Goodrich 19

Pro-Seal 872. B1/2 Products Research

Pro-Seal 872, B2 Products Research

RAM 225 Ram Chemicals

Plastilease 643 Ram Chemicals

34

34

36

36

Sealant. MIL-S-6764 Faying surface seal- 1/2 hr IO hrs 166 hrs PR-1321, B1/2 Products Research 34Synthetic Class B1/2 ing, wet installation GC-200, B1/2 Goal Chemical 16Rubber, of removable parts CS-3300, B1/2 Chem Seal Corp. 9Low Adhesion and fasteners.

Class B2 2 hrs 24 hrs 166 hrs PR-1321, B2 Products Research 34GC-200, B2 Goal Chemical 16cs-3300, B2 Chem Seal Corp. 9

Sealant, AMS 3267 Faying surface seal- hr IO hrs 46 hrs PR-1403G. B1/2 Products Research 34Synthetic Class B1/2 ing. wet installationRubber, of removable partsLow Adhesion and fasteners. (NOTCorrosion for use in fuel-wettedInhibiting areas.)

Class B2 2 hrs IO hrs 46 hrs PR-1403G. B2 Products Research 34

Sealant, MIL-S-8802 Fillet sealing in 1/2 hr 10 hrs 4 6 h r s CG-408, B1/2 Ram Chemicals 36Synthetic Type II-U fuel areas. PR-1422. B1/2 Products Research 34Rubber, Pro-Seal 690, B1/2 Products Research 34Fuel Tank CS-3204. B1/2 Chem Seal Corp. 9

Type II-2 2 hrs 40 hrs 72 hrs CG-408, 82 Ram Chemicals 36PR-1422, B2 Products Research 34Pro-Seal 690. B2 Products Research 34

Type II-4 4 hrs 46 hrs 90 hrs CG-406, B4 Ram Chemicals 36cs-3204, B4 Chem Seal Corp. 9PR-1422, B4 Products Research 34

8 Lockheed SERVICE NEWS V17Nl

SEALANTS (contd)

SPECIFICATION USEAPPL. TACK CURE MANUFACTURER’S ADDRESSTIME FREE TIME DESIGNATION DISTRIBUTOR (See Pg. 15)

Sealant.SyntheticRubber,Fuel Tank(contd)

Type I-H

Type l-2

Brush coating infuel areas.

1/2 hi 40 hrs 72 hrs CG-408, AH Ram Chemicals 36PR-1422. AH Products Research 34CS-3204, A1/2 Chem Seal Corp. 9Pro-Seal 890, AH Products Research 34

2 hrs 48 hrs 9O hrs PR-1422, A2 Products Research 34GC-408, A2 Ram Chemicals 36

Sealant,SyntheticRubber,CorrosionInhibiting

MIL-S-81733Type II-1/2

Type II-2

Type I-W

Type l-2

Type IV-12

Type IV-24

Faying surfacesealant, wetinstallationof fasteners.

Wet installationof fasteners.

Faying surfacesealing, wetinstallation offasteners.

1/2 hr 10 hrs 30 hrs PR-1422G, B1/2Pro-Seal 870. B1/2

2 hrs 40 hrs 72 hrs PR-1422G, B2 Products ResearchPro-Seal 670, B2 Products Research

1/2 hr 10 hrs 48 hrs PR-1422G. A1/2

2 hrs 40 hrs 72 hrs PR-1422G. A2Pro-Seal 870, A2

Products Research

Products ResearchProducts Research

12 hrs 120 hrs 180 hrs PR-1431G, B12Pro-seal 870, B12

24 hrs 192 hrs 240 hrs PR-1431G, B24Pro-Seal 870, B24

Products ResearchProducts Research

Products ResearchProducts Research

Products ResearchProducts Research

3434

3434

34

3434

3434

3434

NOTE: All application, tack-free, and cure times given in the above assume 77(+/-2) F temperature and 50(+/-5)% relative humidity.

joints, and for fillet sealing under the latrine area. Thistwo-part sealant is sold by B. F. Goodrich as PL-106(primer) and PL-410 (sealant). It is available in both classB2 and B6 formulations.

STM 40.114-This is a polysulfide corrosion-inhibitingsealant with aluminum particles added to provide elec-trical conductivity. Its temperature range is -65°F to+250'F It is used for faying surface sealing when corro-sion protection and electrical conductivity are required;i.e., to protect structure under antennas. This material iscommercially available as Pro-Seal 872, manufacturedby Products Research Corporation.

n MIL-S-8784-A low-adhesion polysulfide sealant in the-65°F to +225'F temperature range, this material is used

for sealing removable panels. It is available in formula-tions for brushing (Class A) or for use with a spatula orsealant gun (Class B). This material should not be usedfor permanent installations. Although MIL-S-8784 has apeel strength of only 2 pounds per square inch, be sure toapply a coat of bond release agent such as RAM 225 orRAM 843 to the panel during reinstallation to makeremoval even easier.

Lockheed SERVICE NEWS V17Nl

n AMS 3267-This is also a low-adhesion sealant withabout the same properties as MIL-S-8784; however, thismaterial contains corrosion inhibitors. It is used for thesame purpose and in the same manner as MIL-S-8784. Ifgiven a choice between MIL-S-8784 and AMS 3267sealants, choose the AMS 3267 to take advantage of itscorrosion-inhibiting qualities.

n

n

9

MIL-S-8802-This is a polysulfide sealant that is used forfillet sealing joints and brush-overcoating of fasteners infuel tanks. Its effective temperature range is from -65°Fto +250 'F. As a last resort, MIL-S-8802 may be used asa substitute for MIL-S-81733 for faying surface sealingand wet installation of fasteners.

MIL-S-81733-This material is a polysulfide sealant thatcontains corrosion inhibitors. It is widely used for fayingsurface sealing of permanently joined repairs and struc-ture, and also for wet-installation of permanent fas-teners. Its temperature range is -65°F to +250'F. Type Iis brushable; Type II is a paste for use with a spatula orsealant gun; Type III is sprayable; and Type IV is usedwhen extended assembly time is required.

Structure under antennas is a common site for corrosion, par-ticularly where the antenna is not sealed, or gaskets have beendamaged.

Sealant Sawy

All sealants have a specified shelf life listed on thecontainer. Shelf life is the length of time the material may bestored before use without affecting its integrity. However, toreach its full shelf life, a sealant should be stored in a cool,dry area. Under no circumstances should sealant be storedwhere a temperature of 80°F is exceeded. Since the temper-ature in most parts of the world rises above 8O'F, at leastduring the summer, it is advisable to use an explosion-proofrefrigerator for sealant storage.

Some sealants may still be usable for a while afterexpiration of their shelf life date, but extreme caution shouldbe exercised before using them. It is very disappointing todiscover that the sealant will not cure after structure hasbeen assembled. To avoid encountering this situation, mixa small amount of sealant as a test and note the cure time. Ifthe base material is smooth and free of lumps, if the catalysthas not dried out, and if the cure time is within the manufac-turer’s specification shown on the container, the sealant isusable.

There are three main problems encountered while mix-ing and using sealants, and all are avoidable with propercare and attention to detail. (1) When sealant does not cureor takes too long to cure, the problem usually is that thesealant was over- or under-catalyzed. Occasionally, out-dated sealant will be the cause. The use of a gram scale toweigh the sealant base and catalyst accurately will ensurea correct mix ratio every time. (2) Marbleized (streaky)sealant is caused by incomplete mixing, and as a resultthe streaked areas of catalyst or base material will not cure.(3) Surfaces must be really clean for good sealant adhe-sion; otherwise, moisture will penetrate between the seal-ant and the structure by capillary action and cause hiddencorrosion.

Temperature and humidity greatly affect curing of seal-ant. For example, curing times for sealants are based on a

standard condition of 77°F and 50 percent relative humid-ity. A 15°F decrease in temperature will double the curetime, and a 15°F increase in temperature over the standardcondition will halve the cure time. Cure times may beshortened by applying heat, but do not exceed 140°F duringthe cure cycle. Before applying sealant, ensure that thestructure is 40°F or warmer and will remain so until com-plete cure of the sealant.

Corrosion Preventive Compounds

There are several types of corrosion preventive com-pounds (CPCs) available, formulated for various uses. Allprovide excellent temporary protection against corrosion.The two categories of CPCs are water-displacing and non-water-displacing. Non-water-displacing CPCs provide cor-rosion protection for longer periods because they containgrease of a more viscous oil than the water-displacing kind.

Since the water-displacing types contain lighter oil,they penetrate tight joints better than the non-water-displac-ing formulations. Neither type provides permanent corro-sion protection. Reapplication is required every four to sixmonths and more often in damp or wet regions. AlthoughCPCs contain oil, they provide poor lubricity and shouldnot be used in sliding joints. Also, CPCs should not be usedon or near liquid oxygen systems and equipment, on or offthe airplane. Oxygen in contact with CPCs could result infire or explosion. Most CPCs may be obtained in either bulkform or packaged in aerosol containers. The bulk materialmay be applied by spraying, dipping, or brushing, depend-ing upon the viscosity of the material being used.

n

n

n

10

Three commonly used CPCs are identified below:

MIL-C-16173-This CPC may be obtained in five grades,ranging from a very viscous, cosmoline-type material toa very thin, transparent film CPC. Grades 3 and 4 are thetwo types most often used on airplanes. Grade 3 is awater-displacing type and Grade 4 is non-water-displacing.

MIL-C-81309-There are two types and classes of thisCPC, all of which are water-displacing. Type II, Class 1,is supplied in bulk form; Type II, Class 2, is distributedin aerosol containers. Both Class 1 and Class 2 are forcorrosion protection of metallic structure. Type III, inboth Class I (bulk form) and Class 2 (aerosol container)is avionics grade. The dielectric of both types is 25,000volts.

MIL-C-85054-This material is also known asAmylguard. It forms a clear, dry flexible film which isremovable with solvent. Amylguard should not be usedin tight-fitting joints, or moving or sliding parts. It offersexcellent temporary protection for chipped paint spots,etc.

Lockheed SERVICE NEWS V17Nl

CPCs-Materials and Vendors Listing

As noted above, several types and two categories ofCPC are available for aircraft use. Careful selection and useof the proper CPC will help in preventing the onset ofcorrosion in many areas of the Hercules aircraft. Remember

that while CPCs are very practical weapons in the corrosioncontrol arsenal, they are not intended to provide permanentcorrosion protection and must be periodically reapplied toremain effective. The following table lists a selection ofCPCs by military specification and where they may beobtained commercially.

CORROSION PREVENTIVE COMPOUNDS

ITEM SPECIFICATIONMANUFACTURER’SDESIGNATION DISTRIBUTOR

ADDRESS(See Pg. 15)

Heavy Grease, MIL-C-16173,Soft Film Grade 2

Water Displacing, MIL-C-16173,Soft Film Grade 3

Heavy Grease, MIL-C-16173,Hard Film Grade 1

Valvoline Tectyl 690Braycote 103, 103-T890-BC, Rusterizer 12Rusterizer 12-R-2convoy 731Nox-Rust 201 8Veedol Anorustol 297Interfilm Type II blackF&L 5890Rust-Foil 161-lCosmoline 1056Jesco 707Petrotect 1X,Petrotect 1XARoyco 103No-Rust 21 BNokorode 731,Nokorode 731-RVisconorust 1601 Black

Valvoline Tectyl 502CBraycote 137, 137E502C-BCConvoy BH 16D 2,Convoy 732Nox-Rust 207Veedol Anorustal 260Lubra Kote BlackF&L 5502-CRust Preventive 1612ACosmoline 1102Rustek PP 11Steelgard MS IOLPS-3Petrotect 2Royco 137RST 1502, No-Rust 27, P2AVisconrust N O. 1602

Valvoline Tectyl 694Braycote 153E694-BCConvoy BH 18D 3,Convoy 733NOX-Rust 206Veedol Anorustol 270F&L 5694Rust-Foil 161-3Rustek RP 12Steelgard MS-12Omega 512-5.Western Omega 512-5Oakite Special ProtectiveOil QPetrotect 3Ferrocote 364-BL.Ferrocote 376-BLRoyco 153RSTl894, No-Rust 26, P3AVisconorust No. 1603

Lockheed SERVICE NEWS V17Nl 11

Ashland Petroleum Co. 4Burmah-Castrol Inc. 7Bulk Chemicals Dist. 6

Convoy Oil Corporation IODaubert Chemical Co. 12Deutsche Veedol GmbH 13Esgard Incorporated 14F&L Company Inc. 16Franklin Oil Corp. 17E. F. Houghton & Co. 22Jesco Resources Inc. 23Penreco 32

Royal Lubricants Co.Steven IndustriesLion Oil Company

373624

Viscosity Oil Co. 40

Ashland Petroleum Co. 4Burma-Castro1 Inc. 7Bulk Chemicals Dist. 6Convoy Oil Corporation 10

Daubert Chemical Co. 12Deutsche Veedol GmbH 13Esgard Incorporated 14F&L Company Inc. 16Franklin Oil Corp. 17E. F. Houghton &Co. 22A. Margolis & Sons Corp. 25Harry Miller Corp. 20Holt Lloyd Corporation 21Penerco 32Royal Lubricants Co. 37Steven Industries 38Viscosity Oil Co. 40

Ashland Petroleum Co. 4Burmah-Castrol Inc. 7Bulk Chemicals Dist. 6Convoy Oil Corporation IO

Daubert Chemical Co. 12Deutsche Veedol GmbH 13F&L Company Inc. 16Franklin Oil Corp. 17A. Margolis & Sons Corp. 25Harry Miller Corp. 20MSCI Limited 26

Oakite Products Inc. 26

Penreco 32Quaker Chemical Corp. 35

Royal Lubricants Co.Steven IndustriesViscosity Oil Co.

373640

CORROSION PREVENTIVE COMPOUNDS (contd)

ITEM SPECIFICATIONMANUFACTURER’SDESIGNATION DISTRIBUTOR

ADDRESS(See Pg. 15)

LOW PressureSteam-RemovableFilm

MIL-C-16173,Grade 5

Water-Displacing, MIL-C-61309,Ultra-Thin Film Type IIBulk Class 1

Water-Displacing. MIL-C-81309,Ultra-Thin Film, Type llAerosol Class 2

Water-Displacing,Utra-Thin Film,Bulk

Water Displacing,Ultra-Thin Film,Avionics Grade,Aerosol

MIL-C-61309,Type IIIClass 1

MIL-C-81309.Type IllClass 2

Transparent, MIL-C-16173,Non-Tacky Film Grade 4

Valvoline Tectyl 646Braycote 194,Braycote 194E6 4 6 - Kconvoy 734,Nox-Rust X-110Veedol AnorustolRust-Ban 397F&L 5646Cosmoline 1112Rustek R P 13Petrotect AmberPoly Oleum 5000Royco 194RST1846,No-Rust X-IO, P4AVisconorust 1600 Amber

Ashland Petroleum Co.Burmah-Castrol Inc.

47

Bulk Chemical Dist. 6Convoy Oil Corporation 10Daubert Chemical Company 12Deutsche Veedol GmbH 13Esso A.G. 15F&L Company Inc. 16E. F. Houghton & Co. 22A. Margolis & Sons Corp. 25Penreco 32Poly Oleum Corporation 33Royal Lubricants Co. 37Steven Industries 38

Viscosity Oil Company 40

Valvoline Tectyl 511 MBraycote 198E51 1 M-BCConvoy 735,Convoy BH 18D 5

Ashland Petroleum Co. 4Burmah-Castrol, Inc. 7Bulk Chemicals Dist. 6Convoy Oil Corporation 10

F&L 5511 M F&L Company Inc. 16Petrotect 5 Penreco 32Royco 195 Royal Lubricants Co. 37ST 1511, P5A Steven Industries 36

Alox 2026CM Bulk2775Octoil 5068Aldchim Alox 2026Ardox 3204Batco Rust Preventative,Type llD-5026 Bulk

Alox Corp.Omega Chemical Corp.Octagon Process Inc.Aldchim LimitedArdox IncorporatedBattenfield Grease & Oil

23029

135

Zip Aerosol Products 41

2028-8000 Bulk Chemicals Dist. 6Care 2023-B Murd CO. 27LPS813A Holt Lloyd Corporation 2122028C2 Steven Industries 36

Alox 2028D2780Octoil 5069Omni 4150ATechnolub.? FE-006D-5026CRC 3-36Ardox 3205Batco Rust Preventative.

Type ll

22028C2-3LPS-814A2028-MLCOCare 2023-ACRC 3-36 Aerosol

Alox CorporationOmega Chemical Corp.Octagon Processes Inc.Omnitech InternationalTechnolube Products CO.Zip Aerosol ProductsCRC Chemicals EuropeArdox IncorporatedBattenfield Grease & Oil

230293139411135

Steven Industries 36Holt Lloyd Corporation 21Bulk Chemical Dist. 6Murd Company 27CRC Chemicals Europe 11

Water Displacing, MIL-C-85054;Hard Film Type I (Aerosol)(Amylguard) Type II (Bulk)

1900 (Aerosol)1900 (Bulk)

Care Laboratories 8

Lockheed SERVICE NEWS V17Nl

Special Problems

Many engineering drawings and specifications havetraditionally required that antenna mating surfaces andfasteners be free of insulating finishes in order to providefor electrical conductivity. Where antennas are not sealed,corrosion is commonplace on structure under the installa-tion. Wherever metal-to-metal contact is required, the rea-son for corrosion susceptibility is obvious.

Some antennas are installed with rubber or cork gas-kets. A common corrosion hazard associated with rubbergaskets is that they may be damaged or deformed by air-plane cleaning chemicals and weathering, which allowsmoisture to penetrate. Cork gaskets are also somewhatproblematical; they tend to wick water into the antenna andstructure interface.

Service News, Vol. 14, No. 4 (Oct.-Dec 1987), providesa helpful procedure for sealing VHF NAV antennas. Thisprocedure may be used to install any antenna where metal-to-metal contact is required. Don’t forget to apply a bondrelease agent to the antenna before installation. The pro-cedure may also be used in lieu of installing the rubber orcork gasket when its use is not prohibited by maintenancemanagers or engineering.

If a gasket must be used, apply about 10 mils of sealantto the structure before installing the gasket and antenna.After installation apply a fillet seal around the antennaperiphery with MIL-S-83982 fluid-resistant sealant. Notethat this is a two-part system which requires that the primerbe applied before sealing.

Prevention and Repair Examples

Regardless of airplane age, doing frequent inspections,cleaning regularly, removing corrosion promptly, and keep-ing finishes and sealant intact will minimize corrosiondamage on the Hercules airplane. The following paragraphsoffer several examples of corrosion-prone or corrosionproblem areas and the recommended prevention and repairtechniques:

Latrine, urinal, and galley areas are more subject tocorrosive attack than anywhere else on the airplane. Specialsealing and acid-resistant finishes have been used on struc-ture under this equipment since Lockheed serial numberLAC 4127. This means that airplanes that were manufac-tured previously will require more attention to these areasthan the newer ones.

On all airplanes, look for corrosive fluids, dirt, chippedor deteriorated paint, and missing or damaged sealant onstructure under and around these installations. After clean-ing and drying, carry out the necessary corrosion, paint,and sealant repairs. Apply a coat of non-water-displacingCPC to the underfloor areas and especially to areas directly

The corrosion resistance of the cargo floor chine caps can beenhanced by cleaning, sealing, and painting the upper surfaces.

under the latrine, urinal, and galley. Pay particular atten-tion to structural joints and crevices. If there is any chanceof the CPC being inadvertently applied to avionics equip-ment under the galley, either protect the equipment or usean avionics-grade CPC in the galley area. Be sure to removeany CPC overspray which may have reached the floor; CPCsare slippery.

Over the years there have been many instances of severecorrosion on the upper surface of cargo floor chine caps.Water entering through open doors and hatches, spilledcargo and latrine fluids all contribute to the corrosiveenvironment of these chine caps. On airplanes with theaerial delivery system rails installed, fluids enter the railand structure interface by capillary action. Fluids and soilscan also be entrapped in the opening between the chine capand the inboard portion of the Z-shaped doubler under theD-ring fittings where sealant is not used to prevent entry.

Corrosion-preventive compounds should be applied regularlyto structure under the latrine, urinal, and galley areas.

Lockheed SERVICE NEWS V17N1 13

Since moisture will remain under the rails and doublerslonger than in an open area, corrosion will progress morerapidly. To prevent corrosion of the chine cap. remove therails (if used) and the doublers and thoroughly clean the capupper surface. Remove any corrosion found, apply conver-sion coating to the affected area and fill any depressions toslightly above the cap surface with corrosion-inhibitingsealant. Once the sealant has cured to at least a tack-freestate, apply one coat each of epoxy primer and polyurethaneenamel to the whole chine cap upper surface. After the painthas dried, reinstall the Z-doubler, D-ring, and bolts with acorrosion-inhibiting sealant between all contacting sur-faces. Use low-adhesion sealant for bolt installation. Do notapply sealant to the underside of the rails.

There have been instances where attempts were made togrind corrosion from steel fasteners on wing and empen-nage panels with the fasteners still in place. This practiceweakens both the fastener and the surrounding aluminumstructure. When rusty fasteners are found, they should bereplaced. Use corrosion-inhibiting sealant to install the newpermanent fasteners. Wet-install temporary fasteners withlow-adhesion sealant.

An alternative to fastener replacement is to remove therust with Vat-U-Blast equipment and No. 13 glass beads.provided there is no corrosion in the fastener-to-structureinterface. Adjust the air pressure to the lowest setting whichwill remove the rust but not cause damage to the fastener orsurrounding structure. Immediately after corrosionremoval or new fastener installation, clean the area andapply the appropriate finish system. Do not use the sameglass beads for abrasive blasting more than one type ofmetal. The glass beads become contaminated with minuteparticles from the part being blasted, which could causecorrosion of a dissimilar metal. Also, blasting of metalswith a thickness of 0.0625 inch or less could damage themetal.

Glued to the fuselage side panels are vertical rows of feltwhich act as stand-offs for the cargo compartment insula-tion blankets. There have been reports of corrosion formingbehind these strips. If corrosion is found on your airplane.remove the felt strips and underlying old glue with wood orphenolic scrapers. Remove the corrosion, clean the affectedarea, apply conversion coating to unpainted spots, andtouch up the paint. After the paint has dried, reinstall thefelt strips (or install new strips) with sealant, extending thesealant slightly beyond the width of the felt to preventmoisture that may entrap in the felt from contacting themetal structure.

Have you ever seen a drain hole that appeared to bedrilled in the wrong place because it did not completelydrain the low spot? Misdrilled holes are not unheard of, butevery effort is made to drill the hole at the lowest point. Thisis not always possible, however, because of structural con-siderations. When low spots are found not completely

drained, take note of the water level and then thoroughlydry the area. Remove the dirt and debris and fill the spot upto the water line with corrosion-inhibiting sealant. Slopethe sealant toward the drain hole, being careful not to clogthe hole. After the sealant is tack-free, apply a thin coat ofpolyurethane enamel over the sealant.

Sometimes engineers design unusual drain systemswhich require special attention to remain effective. Such isthe case with the rubber seal at the base of the pylons thatsupport the external fuel tanks. Although this extrudedrubber strip is designed as an aerodynamic seal, it is alsosupposed to permit fluids inside the pylon to drain out frombeneath the seal and at sites where the seal strips overlap.Unfortunately, the seals may stick to the paint on the tank,trapping the fluid inside the pylon. If sticking of this sealbecomes a problem, a simple remedy to maintain a waterpassage is to cut a narrow notch in the seal on each side ofthe pylon just forward and aft of the forward beam.

Remember that drainage problems are not limited toplaces that are easy to see and inspect. Under the rightconditions, hidden drainage problems can turn up in someunusual parts of the aircraft structure, such as the dorsaland the horizontal stabilizer. Information on draining mois-ture from the dorsal of airplanes built prior to LAC 5058can be found in Service News, Vol. 13, No. 4 (October-December 1986). Preventing moisture entrapment in thehorizontal stabilizer is discussed in Service News, Vol. 14.No. 3 (July-September 1987).

No Magic Formula

We have already noted that the evolution of the Herculeshas resulted in a more corrosion-resistant airplane. It is not,however, immune to corrosion. The longevity of the Her-cules aircraft is largely dependent on how well the airplaneis maintained by the operator. In order for the Hercules torealize its maximum service life, each operator must estab-lish a viable corrosion prevention and control program.There is no magic formula involved. It takes personalinterest, professional attention. and a lot of hard work,beginning at the time of manufacture and continuingthroughout the life of the airplane.

The operator should first review present capabilitiesversus what is required to establish and maintain an effec-tive program. Second, he should build a tailored program,and ensure that everyone within the maintenance complexknows and does his part. The quality of the operator’sprogram depends upon the skill and dedication of allinvolved. But the rewards are worth the effort. A goodcorrosion prevention and control program will help ensuremany years of safe and reliable Hercules operation.

14 Lockheed SERVICE NEWS V17Nl

Address Address

10

11

12

13

14

Code Code

1 Alchim LimitedP.O. Box 103Roanana 43100Israel

15

2 Alox CorporationP.O. Box 517Niagara Falls, NY 14302

16

Ardrox Inc.16961 Knott Ave.L a Mirada, CA 90628

17

Ashland Petroleum Co.21st & Front StreetsAshland, KY 41114

16

Battenfield Grease & Oil1174 Erie Ave.Box 726North Tonowanda, NY 14120

19

Bulk Chemicals DistributorsDivision of Malter Intl.60 First St.Gretna, LA 70053

20

Burmah-Castrol Inc.Bray Products Division16815 Von Karman Ave.Irvine, CA 92714

21

Care LaboratoriesP.0. Box F3474 Germantown PikeCollegeville, PA 19426

22

Chem Seal Corporation11120 Sherman WaySun Valley, CA St352

23

Convoy Oil Corporation1410 North Front St.Philadelphia, PA 19122

24

CRC Chemicals EuropeTouwslagerstrstt 1N9140 ZeleBelgium

25

Daubert Chemical Co.4700 South Central Ave.Chicago, IL 60638

26

Deutsche Veedol GmbHHauptabt. GroBverbraucherEsplanade 39,2000 Hamburg 36. W. Germany

27

Esgard IncorporatedP.0. Box 2696Lafayette, LA 70502

26

Lockheed SERVICE NEWS V17Nl

ESSO A.G.Kapstadtring 22000 Hamburg 60West Germany

F&L Company IncP.O. Box 46451537 E. Del Amo Blvd.Carson. CA 90746

Franklin Oil Corp.40 South Park St.Bedford, OH 44146

Goal Chemical Corp.3137 E. 26th St.Los Angeles, CA 60023

B. F. Goodrich Co.500 South Main St.Bldg. 513Akron, OH 44316

Harry Miller Corp.4th & Bristol StreetsPhiladelphia, PA 19140

Holt Lloyd Corp.4647 Hugh Howell Rd.Tucker. GA 30064

E. F. Houghton & Co.Madison & Van Buren Aves.Valley Forge, PA 19482

Jesco Resources Inc.1437 Gentry St.P.O. Box 12337N. Kansas City, MO 64116

Lion Oil Company1000 McHenry St.El Dorado, AR 71730

A. Margolis & Sons Corp.1504 Atlantic Ave.Brooklyn. NY 11216

MSCI LimitedSurface Conditioners6935 West 62ns St.Chicago, IL 60636

Murd Company2314 N. American St.Philadelphia, PA 19133

Oakite Products Inc.50 Valley Rd.Berkeley Heights, NJ 07922

AddressCode

29

30

31

32

33

34

35

36

37

36

39

40

41

Octagon Processes Inc.596 River RoadEdgewater, NJ 07020

Omega Chemical Corp.6935 West 62nd St.Chicago, IL 60636

Omitech International Inc.600 North Arcadia Rd.Thibodaux, LA 70301

PenrecoP.O. Box 971Butler, PA 16001

Poly Oleum Corporation13531 Greenfield Rd.Detroit, MI 46227

Products Research & Chemical5454 San Fernando Rd.Glendale, CA 91203

Quaker Chemical Corp.Elm and Lime StreetsConshohocken. PA 19426

Ram Chemicals210 E. Alondra Blvd.Gardena, CA 30247

Royal Lubicants Co.River RoadEast Hanover, NJ 07936

Steven Industries Inc.39 Avenue CBayonne, NJ 07002

Technolube Products Co.5614 East 61st St.Los Angeles, CA 90040

Viscosity Oil Company3200 S. Western Ave.Chicago, IL 60608

Zip Aerosol ProductsDivision of Mitann Inc.21320 Deering CourtCanoga Park, CA 91304

Related Documents