FX: (256) 891-3459 PH: (256) 891-3458 P.O. BOX 2079 (35950) ALBERTVILLE, AL 35951 417 MARTLING ROAD NOT TO SCALE PROJECT LOCATION APPROXIMATE BUTLER LOWNDES AUTAUGA MOBILE BALDWIN WASHINGTON CHOCTAW SUMTER MONROE CLARKE ESCAMBIA CONECUH WILCOX MARENGO DALLAS PERRY GENEVA COVINGTON COFFEE CRENSHAW PIKE HENRY HOUSTON BARBOUR DALE MONTGOMERY ELMORE BULLOCK MACON RUSSELL LEE CHILTON SHELBY BLOUNT MADISON TUSCALOOSA GREENE HALE PICKENS BIBB WINSTON FAYETTE LAMAR MARION JEFFERSON WALKER CULLMAN LAWRENCE FRANKLIN COLBERT LAUDERDALE MORGAN LIMESTONE TALLAPOOSA COOSA TALLADEGA CLAY CHAMBERS RANDOLPH CALHOUN CHEROKEE ST. CLAIR ETOWAH CLEBURNE DEKALB MARSHALL JACKSON LOCATION MAP - NOT TO SCALE SHEET INDEX PROJECT AREA ALBERTVILLE, AL DOTHAN, AL AUBURN, AL ANDALUSIA, AL HUNTSVILLE, AL HOOVER, AL GADSDEN, AL T OCR AN E H I LL COVER SHEET SITE PLAN PROPOSED PIPING LAYOUT CULLMAN T O GOODHO P E CULLMAN COUNTY COMMISSION WATER SUPERINTENDENT: COMMISSIONER, PLACE 2: COMMISSIONER, PLACE 1: CHAIRMAN: RANDALL WALDREP GARRY MARCHMAN KERRY WATSON KENNETH WALKER PIPING SECTION A PIPING SECTION B CDG PROJECT NUMBER: 121396031 LEGEND PROJECT NOTES PIPING SECTION C STANDARD DETAILS PROPOSED SINGLE LINE DIAGRAM PROPOSED PUMP STATION ELEC. - DEMO PROPOSED PUMP STATION ELEC. - NEW STRUCTURAL GENERAL NOTES STRUCTURAL PLANS STRUCTURAL SECTIONS OCTOBER 2017 CULLMAN COUNTY, ALABAMA CULLMAN COUNTY WATER DEPARTMENT TRIMBLE PUMP STATION UPGRADE 1 2 3 6 7 8 9 10 11-13 5 4 GRADING PLAN EROSION CONTROL PLAN EXISTING PIPING LAYOUT AND DEMO PLAN DATE JAMES G. CHITWOOD, P.E. S1.0 S2.0 S3.0 E1.0 E2.0 E3.0

Welcome message from author

This document is posted to help you gain knowledge. Please leave a comment to let me know what you think about it! Share it to your friends and learn new things together.

Transcript

FX: (256) 891-3459

PH: (256) 891-3458

P.O. BOX 2079 (35950)

ALBERTVILLE, AL 35951

417 MARTLING ROAD

NOT TO SCALE

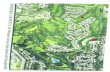

PROJECT LOCATION

APPROXIMATE

BUTLER

LOWNDES

AUTAUGA

MOBILE

BALDWIN

WASHINGTON

CHOCTAW

SUMTER

MONROE

CLARKE

ESCAMBIA

CONECUH

WILCOX

MARENGO

DALLAS

PERRY

GENEVA

COVINGTON

COFFEE

CRENSHAW

PIKE

HENRY

HOUSTON

BARBOUR

DALE

MONTGOMERY

ELMORE

BULLOCK

MACON

RUSSELL

LEE

CHILTON

SHELBY

BLOUNT

MADISON

TUSCALOOSA

GREENE

HALE

PICKENS

BIBB

WINSTON

FAYETTE

LAMAR

MARION

JEFFERSON

WALKER

CULLMAN

LAWRENCE

FRANKLIN

COLBERT

LAUDERDALE

MORGAN

LIMESTONE

TALLAPOOSA

COOSA

TALLADEGA

CLAY

CHAMBERS

RANDOLPH

CALHOUN

CHEROKEE

ST. CLAIR

ETOWAH

CLEBURNE

DEKALBMARSHALL

JACKSON

LOCATION MAP

-

NOT TO SCALE

SHEET INDEX

PROJECT AREA

ALBERTVILLE, AL

DOTHAN, AL

AUBURN, AL

ANDALUSIA, AL

HUNTSVILLE, AL

HOOVER, AL

GADSDEN, AL

TO CRANE HILL

COVER SHEET

SITE PLAN

PROPOSED PIPING LAYOUT

CULLMAN

TO GOOD HOPE

CULLMAN COUNTY COMMISSION

WATER SUPERINTENDENT:

COMMISSIONER, PLACE 2:

COMMISSIONER, PLACE 1:

CHAIRMAN:

RANDALL WALDREP

GARRY MARCHMAN

KERRY WATSON

KENNETH WALKER

PIPING SECTION A

PIPING SECTION B

CDG PROJECT NUMBER: 121396031

LEGEND

PROJECT NOTES

PIPING SECTION C

STANDARD DETAILS

PROPOSED SINGLE LINE DIAGRAM

PROPOSED PUMP STATION ELEC. - DEMO

PROPOSED PUMP STATION ELEC. - NEW

STRUCTURAL GENERAL NOTES

STRUCTURAL PLANS

STRUCTURAL SECTIONS

OCTOBER 2017

CULLMAN COUNTY, ALABAMA

CULLMAN COUNTY WATER DEPARTMENT

TRIMBLE PUMP STATION UPGRADE

1

2

3

6

7

8

9

10

11-13

5

4 GRADING PLAN

EROSION CONTROL PLAN

EXISTING PIPING LAYOUT AND DEMO PLAN

DATE

JAMES G. CHITWOOD, P.E.

S1.0

S2.0

S3.0

E1.0

E2.0

E3.0

FO

100

ENV

115.00

ROADWAY

REQD 18"

REQD 18" RCP

100

F =410.25

F =420.55L

L

TP 4MTD

EL 4MTD

TP 4MTD

E

EL 4MTD

W

G

UTILITIES

PROPOSED

ROADWAY PIPE EXAMPLE

SIDE DRAIN PIPE EXAMPLE

DIRECTION OF FLOW .........................................

REQUIRED PIPE

EXISTING

4

SD

88

8

88

9

DRAINAGE STRUCTURE INDEX NUMBERS

REFERENCE NUMBER.

INDEX NUMBER. THE NUMBER IN THE LOWER HALF OF THE CIRCLE (EXAMPLE 88) IS THE SHEET

THE NUMBER IN THE UPPER HALF OF THE CIRCLE (EXAMPLE 8 OR 9) IS THE DRAINAGE STRUCTURE

WITH WRITE-UPS ARE INDEXED AT EACH END WITH NUMBERS ASSIGNED BY DIRECTION OF FLOW.

DRAINAGE STRUCTURE WRITE-UPS ARE LOCATED ON THE DRAINAGE SECTIONS. STRUCTURES

STRUCTURE INDEX NUMBER.

THE TOP LETTERS (SD) ARE FOR SIDE DRAIN AND THE BOTTOM NUMBER IS THE DRAINAGE

EXISTING PAVEMENT (RETAIN)..................................................................

EXISTING PAVEMENT (REMOVE)................................................................

EXISTING PAVEMENT (RETAIN AND OVERLAY)........................................

CONCRETE (EXISTING OR REQUIRED)......................................................

EXISTING CONCRETE (REMOVE)................................................................

RIP RAP (EXISTING OR REQUIRED)...........................................................

GRAVEL (EXISTING OR REQUIRED)...........................................................

GRASS (EXISTING OR REQUIRED).............................................................

BRICK (EXISTING OR REQUIRED)................................................................

C C

SS

W

M

M

A

G

R

E

S

PS

AV

EM

W

M

A

G

R

E

S

PS

AV

FO

CHEMICAL FEED ..............................................................................

TREATED WATER.............................................................................

AIR/VACUUM RELEASE VALVE ......................................................

PUMP STATION ................................................................................

SPOT ELEVATION ............................................................................

POINT OF EXPOSURE .....................................................................

POINT OF COMPLIANCE .................................................................

SPARGE WELL .................................................................................

EXTRACTION WELL .........................................................................

RECOVERY WELL ............................................................................

ABANDONED MONITORING WELL .................................................

MONITORING WELL .........................................................................

WELL .................................................................................................

BORING LOCATION OR TEST PIT ..................................................

GAS METER ......................................................................................

ELECTRIC TRANSFORMER ............................................................

A/C UNIT ...........................................................................................

STREET LAMP ..................................................................................

ELECTRIC METER............................................................................

MAILBOX ...........................................................................................

SIGN ..................................................................................................

STORM MANHOLE ...........................................................................

SEWER CLEANOUT .........................................................................

SEWER MANHOLE ...........................................................................

FIBEROPTIC POST ..........................................................................

CONCRETE MARKER ......................................................................

SET IRON PIN ...................................................................................

FOUND IRON PIN..............................................................................

RAW WATER ....................................................................................

FILTERED WATER............................................................................

SETTLED WATER ............................................................................

WASH WATER ..................................................................................

BURIED FIBER OPTIC......................................................................

OVERHEAD CABLE TELEVISION....................................................

BURIED CABLE TELEVISION...........................................................

FORCE MAIN.....................................................................................

GAS VALVE ......................................................................................

GAS MAIN .........................................................................................

GAS LINE ..........................................................................................

WATER METER ................................................................................

FIRE HYDRANT ................................................................................

WATER VALVE .................................................................................

WATER MAIN ....................................................................................

WATER LINE .....................................................................................

SANITARY SEWER ..........................................................................

TELEPHONE MANHOLE ..................................................................

OVERHEAD TELEPHONE CABLE ...................................................

BURIED TELEPHONE CABLE ..........................................................

TELEPHONE DUCT ..........................................................................

TELEPHONE PEDESTAL ................................................................. TT

POWER POLE ..................................................................................

LIGHT POLE .....................................................................................

TELEPHONE POLE ..........................................................................

ANCHOR ...........................................................................................

STUB (POWER) ................................................................................

STUB (TELEPHONE) ........................................................................

ELECTRIC DUCT ..............................................................................

BURIED ELECTRIC CABLE .............................................................

OVERHEAD ELECTRIC CABLE .......................................................

ELECTRIC MANHOLE ......................................................................

OVERHEAD UTILITY.........................................................................

TOWER .............................................................................................

BOX CULVERT (ELEVATION VIEW) ..........................................

PIPE CULVERT (ELEVATION VIEW) .........................................

BRIDGE .......................................................................................

(SEE PLANS DESCRIPTION ).....................................................

DROP INLET OR JUNCTION BOX

EXTENDED CULVERT ................................................................

REQUIRED BOX CULVERT ........................................................

EXISTING BOX CULVERT ..........................................................

REQUIRED PIPE END TREATMENT...........................................

(WITH PIPE END TREATMENT)..................................................

EXISTING PIPE ...........................................................................

PROPOSED MINOR CONTOUR .................................................

PROPOSED MAJOR CONTOUR ................................................

EXISTING MINOR CONTOUR ....................................................

EXISTING MAJOR CONTOUR ....................................................

ENVIRONMENTAL CLEARED LIMITS ........................................

SURVEY POINT ..........................................................................

BENCH MARK .............................................................................

TRAFFIC LIGHT ..........................................................................

SATELLITE DISH ........................................................................

REQUIRED GUARDRAIL ............................................................

EXISTING GUARDRAIL ..............................................................

GRAVEL ROAD ...........................................................................

REQUIRED DITCH.......................................................................

EXISTING DITCH ........................................................................

EXISTING FLOWLINE..................................................................

WOODS LINE ..............................................................................

TREES .........................................................................................

HOG WIRE FENCE .....................................................................

ELECTRIC FENCE ......................................................................

CHAIN LINK FENCE ....................................................................

BARBED WIRE FENCE ...............................................................

WOOD FENCE ............................................................................

RAILROAD ...................................................................................

CLEARING LIMITS ......................................................................

CONSTRUCTION LIMITS ...........................................................

REQUIRED FENCE .....................................................................

DENIED ACCESS ........................................................................

ACQUIRED ROW ........................................................................

PRESENT ROW ..........................................................................

PROPERTY LINES ......................................................................

RANGE-TOWNSHIP LINES ........................................................

QUARTER-SECTION LINES .......................................................

SECTION LINES...........................................................................

CITY OR TOWN LIMITS ..............................................................

COUNTY BOUNDARY LINE .......................................................

STATE BOUNDARY LINE............................................................

CENTER LINE .............................................................................

CLEANOUT ........................................................................................ C C

FLAG POLE ........................................................................................

TMHTMH

EM

POC

POE

STM STM

MB

CONST LIM

R-17-E

R-18-E

SEC 23SEC 22

55+00

MARSH (EXISTING)........................................................................................

E

LE

GE

ND

NTS

HY D

WM

WV

GV

MB

GGAS METER .....................................................................................

K:\Projects\1

2\1

3\9

6031 C

ullm

an C

o.

Water

Dept. 2

010 B

ond Issue\Dra

win

gs\Tri

mble P

um

p Station\0

1_LE

GE

ND.d

gn

File P

ath:

01_LEGEND.dgn

1

SCALE:

DATE:

DESIGNED BY:

DRAWN BY:

REVIEWED BY:

QC REVIEWER:

REVISED

DGN:

PROJECT NO:

SHEET NO.

This document and its contents are property of CDG Engineers & Associates, Inc. and may not be distributed, reused, or modified without permission.

FX: (2

56) 891-3

459

PH: (2

56) 891-3

458

P.O.

BO

X 2

079 (35950)

AL

BE

RT

VIL

LE,

AL 3

5951

417 M

AR

TLIN

G R

OA

D

AL

BE

RT

VIL

LE,

AL

DO

TH

AN,

AL

AU

BU

RN,

AL

AN

DA

LU

SIA,

AL

HU

NTS

VIL

LE,

AL

HO

OV

ER,

AL

GA

DS

DE

N,

AL

JGC

CPB

JGC

121396031

CU

LL

MA

N,

CO

UN

TY,

AL

AB

AM

A

CU

LL

MA

N C

OU

NT

Y W

AT

ER D

EP

AR

TM

EN

T

TRIM

BLE P

UM

P S

TA

TIO

N U

PG

RA

DE

A

MABAL

A DESNECIL

REENIGN

E

PROFESSIONAL

No. 17318

D

OO

WTIHC .G SE

M

AJ

OCTOBER 2017

cchitwood

Stamp

1. JOB SITE SAFETY IS SOLELY THE RESPONSIBILITY OF THE CONTRACTOR, INCLUDINGCOMPLIANCE WITH ALL OSHA REQUIREMENTS. NEITHER THE OWNER, NOR THE ENGINEER WILLSUPERVISE OR INSPECT THE JOB WITH REGARD TO SAFETY ISSUES.

2. THE CONTRACTOR IS RESPONSIBLE FOR THE PURCHASE OF A CONTRACTOR’S LICENSE ANDBUSINESS LICENSE FROM THE CITY AND / OR COUNTY AS APPLICABLE, AS WELL AS, ALL OTHERLICENSES AND PERMITS REQUIRED FOR COMPLETION OF THE WORK.

3. EXCEPT FOR EMERGENCY WORK, WORK SHALL NOT BE PERFORMED ON SATURDAY, SUNDAY,OR ANY LEGAL HOLIDAY WITHOUT APPROVAL OF THE OWNER AND ENGINEER. WORK SHALLOCCUR DURING REASONABLE DAY-TIME HOURS. REQUESTS FOR DEVIATIONS FROM THISSCHEDULE SHALL BE MADE TO THE ENGINEER ON A CASE-BY-CASE BASIS A MINIMUM OF 72HOURS PRIOR, EXCEPT FOR EMERGENCIES, IN WHICH CASE NO SUCH APPROVAL IS REQUIRED.

4. THE CONTRACTOR IS RESPONSIBLE FOR DOCUMENTATION OF PRE-EXISTING CONDITIONSPRESENT WITHIN AND ADJACENT TO THE CONSTRUCTION AREA. DOCUMENTATION OF EXISTINGCONDITIONS SHALL CONSIST OF DATE-STAMPED VIDEO, PHOTOGRAPHS, AND WRITTENRECORDS. COPIES OF ALL DOCUMENTATION SHALL BE DELIVERED TO THE ENGINEER PRIOR TOBEGINNING CONSTRUCTION ACTIVITIES. DOCUMENTATION OF PRE-EXISTING CONDITIONS ISREQUIRED TO AVOID CLAIMS FOR DAMAGE TO PROPERTY.

5. THE CONTRACTOR SHALL BE RESPONSIBLE FOR ANY DAMAGE CAUSED BY HIS ACTIVITIES IN THEPROJECT AREA, WHETHER ON PUBLIC OR PRIVATE PROPERTY. DAMAGE SHALL BE REPAIREDTO PRE-CONSTRUCTION CONDITIONS OR BETTER, AND TO THE SATISFACTION OF THEENGINEER AND LAND OWNER(S). REPAIRS SHALL BE MADE AT THE CONTRACTOR’S EXPENSE.

6. THE CONTRACTOR SHALL COORDINATE ALL CONSTRUCTION ACTIVITY IN THE PROJECT AREAWITH THE COUNTY, CITY, AND STATE, AS APPLICABLE.

7. THE CONTRACTOR IS RESPONSIBLE FOR PROVIDING AND MAINTAINING TRAFFIC CONTROL INACCORDANCE WITH THE REQUIREMENTS OF PART 6 OF THE MUTCD, LATEST EDITION, AND THEATTACHED TRAFFIC CONTROL PLAN.

8. UNLESS APPROVED IN ADVANCE BY THE ENGINEER, THE CONTRACTOR SHALL MAINTAIN ACCESSFOR THE TRAVELING PUBLIC, EMERGENCY, AND SCHOOL VEHICLES AT ALL TIMES ALONG ALLCITY, COUNTY, AND STATE RIGHTS OF WAY. IF A ROAD CLOSURE IS ALLOWED, THECONTRACTOR SHALL BE RESPONSIBLE FOR COORDINATING SUCH CLOSURES WITH CITY,COUNTY, AND OR STATE AGENCIES, AND EMERGENCY AGENCIES, IN ACCORDANCE WITH THOSEPARTIES REQUIREMENTS.

9. ALL EQUIPMENT SHALL BE PARKED AND ALL MATERIALS SHALL BE STORED AT A LOCATIONOUTSIDE THE PUBLIC RIGHT OF WAY AT A LOCATION OF THE CONTRACTOR’S CHOOSING. PRIORTO FINAL PAYMENT, THE CONTRACTOR SHALL PROVIDE WRITTEN NOTICE FROM THE OWNER OFSUCH PARKING AND STORAGE AREA(S), THAT THE AREA(S) HAVE BEEN RESTORED TO LANDOWNER’S SATISFACTION.

10. EXISTING DRAINAGE SYSTEMS SHALL REMAIN FULLY OPEN THROUGHOUT THE PROJECTDURATION. ANY DISTURBANCE OR DAMAGE TO EXISTING DRAINAGE SYSTEMS AND STRUCTURESSHALL BE REPAIRED OR REPLACED TO THE SATISFACTION OF THE ENGINEER AND THE CITY,COUNTY, AND/OR STATE AT NO ADDITIONAL COST TO THE OWNER.

11. EXCEPT FOR WHERE THE PLANS REQUIRE TEMPORARY CONSTRUCTION FENCING TO BEINSTALLED, EXISTING FENCES SHALL NOT BE REMOVED, RELOCATED, OR OTHERWISEDAMAGED DURING THE CONSTRUCTION ACTIVITIES. REMOVED, RELOCATED, OR DAMAGEDFENCES SHALL BE REPLACED TO THE SATISFACTION OF THE ENGINEER AND LAND OWNER ATNO ADDITIONAL COST TO THE OWNER.

12. RESIDENTS AND BUSINESS SHALL NOT BE LEFT WITHOUT MAIL SERVICE. IF A MAILBOX MUST BEMOVED TO FACILITATE CONSTRUCTION, IT SHALL BE TEMPORARILY AND SATISFACTORILYRELOCATED AS CLOSE AS PRACTICABLE TO ITS ORIGINAL LOCATION, AND IN SUCH A PLACETHAT IT MAY BE SATISFACTORILY ACCESSED BY MAIL CARRIERS.

13. JOB SITE SHALL BE CLEANED ON A DAILY BASIS. THE CONTRACTOR SHALL RESTORE ALL AREAS,WHETHER PUBLIC OR PRIVATE, AS SOON AS PRACTICABLE FOLLOWING COMPLETION OFPARTICULAR CONSTRUCTION ACTIVITIES.

14. THE CONTRACTOR SHALL REPAIR ALL EXCAVATED AREAS, BACKFILLS, EMBANKMENTS,TRENCHES, AND DITCHES WHICH MAY HAVE SETTLED AT NO ADDITIONAL COST TO THE OWNERUNTIL FINAL ACCEPTANCE OF THE PROJECT AND THROUGHOUT THE WARRANTY PERIOD. ALLSUCH AREAS SHALL BE RESTORED TO PRE-CONSTRUCTION CONTOURS.

15. NO ADDITIONAL PAYMENT SHALL BE MADE FOR ROCK EXCAVATION AND REMOVAL. BIDDERS MAYMAKE THEIR OWN INVESTIGATION AS TO THE AMOUNT AND CHARACTER OF ROCK WHICH MAYNEED TO BE REMOVED. ALL COSTS FOR ROCK EXCAVATION SHALL BE CONSIDERED TO HAVEBEEN INCLUDED IN THE VARIOUS PAY ITEMS IN THE PROPOSAL.

16. THE CONTRACTOR IS RESPONSIBLE FOR MAINTAINING ALL GRASSED AREAS AT ITS EXPENSEUNTIL FINAL ACCEPTANCE AND THROUGHOUT THE WARRANTY PERIOD. MAINTENANCE OFGRASSED AREAS SHALL INCLUDE RE-GRADING, RE-FERTILIZATION, RE-SEEDING, WATERING,MOWING, AND ANY OTHER WORK AS REQUIRED, TO PRODUCE AND KEEP THE GRASS IN ACONDITION ACCEPTABLE TO THE ENGINEER AND LAND OWNER.

1. THE GENERAL LOCATION OF UTILITIES SHOWN REFLECTS THE OWNER’S BEST RECORDS ANDON-SITE INVESTIGATION. NEITHER THE OWNER NOR THE ENGINEER MAKES ANY EXPRESSED ORIMPLIED GUARANTEE OF THE ACCURACY OF UTILITIES SHOWN OR ANY GUARANTEE THAT ALLUTILITIES LOCATED WITHIN THE CONSTRUCTION AREA ARE SHOWN HEREIN.

2. THE CONTRACTOR SHALL CALL ALABAMA ONE CALL AT 811 FOR UTILITY MARKING PRIOR TOCOMMENCING CONSTRUCTION. IT SHALL BE THE CONTRACTOR’S RESPONSIBILITY TODETERMINE THE EXACT LOCATION OF ALL UNDERGROUND UTILITIES BEFORE COMMENCINGWORK. ANY DAMAGE TO EXISTING UTILITIES SHALL BE REPAIRED AT THE CONTRACTOR’SEXPENSE.

3. THE CONTRACTOR SHALL COORDINATE ALL WORK ADJACENT TO EXISTING UTILITY POLES ANDGUY WIRES WITH THE LOCAL POWER COMPANY. THE CONTRACTOR SHALL CONTACT THELOCAL POWER COMPANY TO HOLD SAID UTILITY POLES/GUY WIRES DURING BORING OR OPENCUT OPERATIONS. THE COST OF THIS WORK SHALL BE CONSIDERED INCIDENTAL TO THEPROJECT AND NO ADDITIONAL PAYMENT WILL BE MADE.

4. THE CONTRACTOR SHALL COORDINATE ALL TIE-INS, CONNECTIONS, OUTAGES, AND VALVINGOPERATIONS WITH THE UTILITY OWNER. THE CONTRACTOR SHALL GIVE 72 HOURS NOTICE TOTHE UTILITY OWNER OF WHEN SUCH OPERATIONS ARE TO TAKE PLACE.

5. THE CONTRACTOR SHALL COORDINATE WITH AND PROVIDE REASONABLE NOTICE TORESIDENTS AND BUSINESSES OF SERVICE OUTAGES PRIOR TO BEGINNING SUCH OPERATIONS.NO RESIDENT OR BUSINESS SHALL BE LEFT WITH OUT SERVICE OVERNIGHT.

1. ALL WORK SHALL BE CONFINED TO THE LIMITS OF THE PROPERTY AS SHOWN ON THE PLANS.THE CONTRACTOR SHALL NOT DISTURB ANY AREA OUTSIDE THESE LIMITS.

2. CONTRACTOR SHALL REMOVE ALL EXISTING VALVE BOXES WHICH WILL NO LONGER BE IN USEUPON COMPLETION OF THE PROJECT.

3. PUMPS NO.1 AND NO.2 SHALL BE MAIN DUTY PUMPS AND SHALL OPERATE ALTERNATIVELY. PUMPNO.3 SHALL ENGAGE ONLY WHEN THE GENERATOR IS RUNNING.

4. CONTRACTOR SHALL COORDINATE CONSTRUCTION ACTIVITIES WITH THE OWNER TO ENSURETHAT THE PUMP STATION REMAINS IN OPERATION AT ALL TIMES.

1. DEMOLITION OF CHLORINE ROOM2. COMPLETE ALL STRUCTURAL MODIFICATIONS3. COMPLETE ALL SITE WORK, EXCLUDING FENCE4. INSTALL NEW SUCTION PIPES INTO AND THROUGH STATION WELL5. REMOVE EXISTING PUMP "B" AND ASSOICATED PIPING6. INSTALL NEW SKID AND PIPES FOR PUMP NO.27. INSTALL ELECTRICAL FOR PUMP NO.28. START UP PUMP NO.29. REMOVE EXISTING PUMP "A" AND ASSOCIATED PIPING10. INSTALL NEW SKID AND PIPES FOR PUMP NO.111. COMPLETE ELECTRICAL INSTALLATION12. INSTALL EMERGENCY PUMP13. START UP REMAINING PUMPS14. COMPLETE ELECTRICAL WORK15. GRASSING, CLEANUP AND FENCE

1. THE CONTRACTOR SHALL TAKE ALL NECESSARY MEASURES TO ENSURE NO SEDIMENT LEAVESTHE SITE.

2. THE CONTRACTOR SHALL PROPERLY INSTALL ALL EROSION CONTROL MEASURES, INCLUDINGSILT FENCING AND RIP-RAP, PRIOR TO, OR AS SOON AS PRACTICABLE FOLLOWING, GROUNDDISTURBANCE IN A PARTICULAR AREA.

3. THE CONTRACTOR SHALL PROPERLY MAINTAIN ALL EROSION CONTROL MEASURES UNTIL FINALACCEPTANCE IN ACCORDANCE WITH THE ATTACHED CBMPP DEVELOPED FOR THIS PROJECT.

cchitwood

Stamp

SCALE:

DATE:

DESIGNED BY:

DRAWN BY:

REVIEWED BY:

QC REVIEWER:

REVISED

DGN:

PROJECT NO:

SHEET NO.

This document and its contents are property of CDG Engineers & Associates, Inc. and may not be distributed, reused, or modified without permission.

FX: (2

56) 891-3

459

PH: (2

56) 891-3

458

P.O.

BO

X 2

079 (35950)

AL

BE

RT

VIL

LE,

AL 3

5951

417 M

AR

TLIN

G R

OA

D

AL

BE

RT

VIL

LE,

AL

DO

TH

AN,

AL

AU

BU

RN,

AL

AN

DA

LU

SIA,

AL

HU

NTS

VIL

LE,

AL

HO

OV

ER,

AL

GA

DS

DE

N,

AL

JGC

CPB

JGC

121396031

CU

LL

MA

N,

CO

UN

TY,

AL

AB

AM

A

CU

LL

MA

N C

OU

NT

Y W

AT

ER D

EP

AR

TM

EN

T

TRIM

BLE P

UM

P S

TA

TIO

N U

PG

RA

DE

A

MABAL

A DESNECIL

REENIGN

E

PROFESSIONAL

No. 17318

D

OO

WTIHC .G SE

M

AJ

OCTOBER 2017

665.57'

F.F. ELEV.

BUILDING

ANTENNA

ELEV. 670.70'T.B.M. MAG NAIL

CO

UN

TY R

OA

D 222

EX. 8" D.I.

EX. 12" D.I.

GRAVEL

DRIVE

EXISTI

NG

W

W

1"=5'

505

SCALE : 1"= 5'

10

LEAF GATE

12' WIDE DOUBLE

REQUIRED:

GEN

ERATO

R

EXISTI

NG

8' CL 350 D.I.

REQUIRED:

2'

OF PROPERTY CORNER

APPROXIMATE LOCATION

OF PROPERTY LINES

APPROXIMATE LOCATION

OF PROPERTY CORNER

APPROXIMATE LOCATION

80' R.O.W.

80' R.O.W.

EXISTI

NG W

ATER M

AIN

LINES AS SHOWN

ALONG THE PROPERTY

8' HIGH CHAIN LINK FENCE

REQUIRED:

GG

10.00'

13.00'

9.00'

5.00'

7.00'

CRANE RAIL BEAM

REQUIRED:

NEW D

OO

RS

CENTER

OF

14'

1 - WET CONNECTION

1 - 12" GATE VALVE

2 - 8" GATE VALVES

2 - 12" x 8" TEES

REQUIRED:

26'

7'

7'

6'

8'

6'

CC

EC

BY

PA

D

TR

ANSF

OR

ME

R

W

W

W

SIT

E P

LA

N

10'

5.00'

5.00'

SUCTION AND DISCHARGE LINES AT C.R. 222

CONNECTION POINT OF EXISTING PUMP STATION

CONTRACTOR SHALL EXCAVATE TO VERIFY

REQUIRED:

CONTRACT)

DEPARTMENT (NOT IN

CULLMAN COUNTY ROAD

ASPHALT DRIVEWAY, BY

AND VALVE BOXES

REMOVE EXIST. VALVES

REQUIRED:1 ~ CAP EXIST. WATER MAIN

REQUIRED:

AND METER BOX

1 ~ 3/4" BALL VALVE

REQUIRED:

EXISTI

NG W

ATER M

AIN (T

O R

EMAI

N)

3

03_SITE PLAN.dgn

K:\Projects\1

2\1

3\9

6031 C

ullm

an C

o.

Water

Dept. 2

010 B

ond Issue\Dra

win

gs\Tri

mble P

um

p Station\0

3_SIT

E P

LA

N.d

gn

File P

ath:

TO CHLORINE RESIDUAL METER

55 L.F. - 3/4" PEX TUBING

SADDLE AND RUN APPROX.

TAP EXIST. MAIN WITH 3/4"

REQUIRED:

2'

cchitwood

Stamp

665.57'

F.F. ELEV.

BUILDING

661

660

662

663

666

667

668

669

670

671

672

667

666

665

664

663

661

660

659

658

ANTENNA

ELEV. 670.70'T.B.M. MAG NAIL

CO

UN

TY R

OA

D 222

EX. 8" D.I.

EX. 12" D.I.

GRAVEL

DRIVE

EXISTI

NG

W

W

SCALE:

DATE:

DESIGNED BY:

DRAWN BY:

REVIEWED BY:

QC REVIEWER:

REVISED

DGN:

PROJECT NO:

SHEET NO.

This document and its contents are property of CDG Engineers & Associates, Inc. and may not be distributed, reused, or modified without permission.

FX: (2

56) 891-3

459

PH: (2

56) 891-3

458

P.O.

BO

X 2

079 (35950)

AL

BE

RT

VIL

LE,

AL 3

5951

417 M

AR

TLIN

G R

OA

D

AL

BE

RT

VIL

LE,

AL

DO

TH

AN,

AL

AU

BU

RN,

AL

AN

DA

LU

SIA,

AL

HU

NTS

VIL

LE,

AL

HO

OV

ER,

AL

GA

DS

DE

N,

AL

JGC

CPB

JGC

121396031

CU

LL

MA

N,

CO

UN

TY,

AL

AB

AM

A

CU

LL

MA

N C

OU

NT

Y W

AT

ER D

EP

AR

TM

EN

T

TRIM

BLE P

UM

P S

TA

TIO

N U

PG

RA

DE

A

MABAL

A DESNECIL

REENIGN

E

PROFESSIONAL

No. 17318

D

OO

WTIHC .G SE

M

AJ

OCTOBER 2017

505

SCALE : 1"= 5'

10

GEN

ERATO

R

EXISTI

NG

OF PROPERTY CORNER

APPROXIMATE LOCATION

OF PROPERTY LINES

APPROXIMATE LOCATION

OF PROPERTY CORNER

APPROXIMATE LOCATION

80' R.O.W.

80' R.O.W.

LINES AS SHOWN

ALONG THE PROPERTY

8' HIGH CHAIN LINK FENCE

REQUIRED:

GG

W

W

W

1"=5'

505

SCALE : 1"= 5'

10

663

664

665

665

666

667

668

667

665

664

663

x 665.35

ELE

V. 6

66.00

CC

EC

BY

PA

D

TR

ANSF

OR

ME

R

GR

ADIN

G P

LA

N

665.35 x

x 665.20

666

665.21

INV. EL.

665.01

INV. EL.

TOP EL. 665.48

6" WIDE TRENCH DRAIN,

REQUIRED:

INV. EL. 663.25

7' ~ 6" SCH. 40 PVC,

REQUIRED:

COVER DRIVEWAY W/ 6" OF NO.78 STONE.

STANDARD PROCTOR DENSITY.

COMPACT SUBGRADE TO 100%

FILL AND GRADE SITE AS SHOWN.

REQUIRED:

4

04_GRADING PLAN.dgn

K:\Projects\1

2\1

3\9

6031 C

ullm

an C

o.

Water

Dept. 2

010 B

ond Issue\Dra

win

gs\Tri

mble P

um

p Station\0

4_

GR

ADIN

G P

LA

N.d

gn

File P

ath:

cchitwood

Stamp

665.57'

F.F. ELEV.

BUILDING

661

660

662

663

666

667

668

669

670

671

672

667

666

665

664

663

661

660

659

658

ANTENNA

ELEV. 670.70'T.B.M. MAG NAIL

CO

UN

TY R

OA

D 222

EX. 8" D.I.

EX. 12" D.I.

GRAVEL

DRIVE

EXISTI

NG

W

W

SCALE:

DATE:

DESIGNED BY:

DRAWN BY:

REVIEWED BY:

QC REVIEWER:

REVISED

DGN:

PROJECT NO:

SHEET NO.

This document and its contents are property of CDG Engineers & Associates, Inc. and may not be distributed, reused, or modified without permission.

FX: (2

56) 891-3

459

PH: (2

56) 891-3

458

P.O.

BO

X 2

079 (35950)

AL

BE

RT

VIL

LE,

AL 3

5951

417 M

AR

TLIN

G R

OA

D

AL

BE

RT

VIL

LE,

AL

DO

TH

AN,

AL

AU

BU

RN,

AL

AN

DA

LU

SIA,

AL

HU

NTS

VIL

LE,

AL

HO

OV

ER,

AL

GA

DS

DE

N,

AL

JGC

CPB

JGC

121396031

CU

LL

MA

N,

CO

UN

TY,

AL

AB

AM

A

CU

LL

MA

N C

OU

NT

Y W

AT

ER D

EP

AR

TM

EN

T

TRIM

BLE P

UM

P S

TA

TIO

N U

PG

RA

DE

A

MABAL

A DESNECIL

REENIGN

E

PROFESSIONAL

No. 17318

D

OO

WTIHC .G SE

M

AJ

OCTOBER 2017

665.57'

F.F. ELEV.

BUILDING

661

660

662

663

666

667

668

669

670

671

672

667

666

665

664

663

661

660

659

658

ANTENNA

ELEV. 670.70'T.B.M. MAG NAIL

CO

UN

TY R

OA

D 222

EX. 8" D.I.

EX. 12" D.I.

GRAVEL

DRIVE

EXISTI

NG

W

W

505

SCALE : 1"= 5'

10

GEN

ERATO

R

EXISTI

NG

OF PROPERTY CORNER

APPROXIMATE LOCATION

OF PROPERTY LINES

APPROXIMATE LOCATION

OF PROPERTY CORNER

APPROXIMATE LOCATION

80' R.O.W.

80' R.O.W.

LINES AS SHOWN

ALONG THE PROPERTY

8' HIGH CHAIN LINK FENCE

REQUIRED:

GG

W

W

W

505

SCALE : 1"= 5'

10

663

664

665

665

666

667

668

667

665

664

663

666

1"=5'

SILT FENCE

REQUIRED:

ER

OSIO

N C

ON

TR

OL P

LA

N

K:\Projects\1

2\1

3\9

6031 C

ullm

an C

o.

Water

Dept. 2

010 B

ond Issue\Dra

win

gs\Tri

mble P

um

p Station\0

5_E

RO

SIO

N C

ON

TR

OL P

LA

N.d

gn

File P

ath:

5

05_EROSION CONTROL PLAN.dgn

cchitwood

Stamp

1"=1'

101

SCALE : 1"= 1'

2

ELECTRICAL

VENT24" X 24"

CEILING HEIGHT - 10'

CHLORINE ROOM

HEATER AND GAS PIPEREMOVE EXISTING GAS

REQUIRED:

CONDUIT. SEE ELECTRIC PLANSREMOVE ELECTRICAL BOX AND SEAL

REQUIRED:

3ft 0in

6in

6ft 0in

20"

EXISTING VENT FAN TO BE REMOVEDREQUIRED:

30" 28"

6" 90° ELL

BUTTERFLY4"

VALVE4" PUMP CONTROL

3" X 3" TEE

3'-0" DOOR

REDUCER6" X 4"

TEE6" X 6"

6" 90° ELL

REDUCER6" X 4"

VALVE4" CHECK

BUTTERFLY4"

VALVE4" PUMP CONTROL

3" X 3" TEE

4"

4" 90° ELL4"

6" 90° ELL

4" BUTTERFLY

4" CHECK VALVE

6" GATE VALVE

6" GATE VALVE

3ft 9in

5ft 0in

4ft 0in

5ft 0in5ft 6in

OPENING WITH BLOCK AND BRICKREMOVE EXISTING VENT AND SEAL

REQUIRED:

INSTALL BLIND FLANGEREMOVE METER AND

REQUIRED:

(SEE SHEET S2.0)

REMOVE EXISTING DOORS.

REQUIRED:

(SEE SHEET S2.0)

REMOVE EXISTING BLOCK WALL

REQUIRED:

DISCONNECT AND REMOVE EXISTING CHLORINE PIPEREQUIRED:

(TO REMAIN)OF WINDOW 46" OFF FLOOREXISTING 36"x36" WINDOW. BOTTOM

FLOOR LEVEL

AND CAP OFF WATER SUPLLY LINES AT

REMOVE EXISTING CHART RECORDERS

REQUIRED:

( SEE SHEET S2.0)

A

PUMP

B

PUMP

RELOCATED BY OWNERTELEMETRY BOX TO BE

EXISTING WALL MOUNTED

SEE NOTES ON SHT. 2REMOVE ALL EXISTING PIPE FITTINGS AND PUMPS.REQUIRED:

6

METERRIGHT ANGLE

EXIS

TIN

G PIPIN

G L

AY

OU

T A

ND D

EM

OLITIO

N P

LA

N

K:\Projects\1

2\1

3\9

6031 C

ullm

an C

o.

Water

Dept. 2

010 B

ond Issue\Dra

win

gs\Tri

mble P

um

p Station\0

6_E

X PIPIN

G L

AY

OU

T.d

gn

File P

ath:

06_EX PIPING LAYOUT.dgn

SCALE:

DATE:

DESIGNED BY:

DRAWN BY:

REVIEWED BY:

QC REVIEWER:

REVISED

DGN:

PROJECT NO:

SHEET NO.

This document and its contents are property of CDG Engineers & Associates, Inc. and may not be distributed, reused, or modified without permission.

FX: (2

56) 891-3

459

PH: (2

56) 891-3

458

P.O.

BO

X 2

079 (35950)

AL

BE

RT

VIL

LE,

AL 3

5951

417 M

AR

TLIN

G R

OA

D

AL

BE

RT

VIL

LE,

AL

DO

TH

AN,

AL

AU

BU

RN,

AL

AN

DA

LU

SIA,

AL

HU

NTS

VIL

LE,

AL

HO

OV

ER,

AL

GA

DS

DE

N,

AL

JGC

CPB

JGC

121396031

CU

LL

MA

N,

CO

UN

TY,

AL

AB

AM

A

CU

LL

MA

N C

OU

NT

Y W

AT

ER D

EP

AR

TM

EN

T

TRIM

BLE P

UM

P S

TA

TIO

N U

PG

RA

DE

A

MABAL

A DESNECIL

REENIGN

E

PROFESSIONAL

No. 17318

D

OO

WTIHC .G SE

M

AJ

OCTOBER 2017

cchitwood

Stamp

101 2

36" WINDOW

CEILING HEIGHT - 10'-3"

A A

8" D.I.8" D.I.

200 H.P. MOTOR

200 H.P. MOTOR

C

*

*

*

*

*

*

* NE

W E

LE

CT

RIC

AL P

AN

ELS - S

EE E

LE

CT

RIC

AL D

RA

WIN

GS

*

PUMP SKID

2'-2"(TYP)

B

B

C

6" 45° BEND

6" FLAP VALVE

12"

90° BEND6"x3" FL.

45° BEND6"x6" FL.

SPOOL PIECE6" FL.xP.E.

COUPLING6" DRESSER

SPOOL PIECE6" FL.xP.E.

VALVE6" FL. CHECK

FLY VALVE6" FL. BUTTER-

90° BEND8"x6" FL.

COUPLING8" DRESSER

FL. TEE8"x6"

*90° BEND6"x3" FL.

45° BEND6"x6" FL.

DETAILSUPPORT, SEE

CONCRETE PIPE

FLY VALVE6" FL. BUTTER-

COUPLING6" DRESSER

2" 90° BEND

2" 90° BEND

REDUCER6"x3" FL.

SPOOL PIECE8" FL.xP.E.

SPOOL PIECE8" FL.xP.E.

90° BEND6"x3" FL.

45° BEND6"x6" FL.

FLY VALVE6" FL. BUTTER-

VALVE6" FL. CHECK

COUPLING6" DRESSER

SPOOL PIECE6" FL.xP.E.

SPOOL PIECE6" FL.xP.E.

VALVECHECK6" FL.

90° BEND8"x8" M.J.

90° BEND8"x8" M.J.

90° BEND6"x6" FL.

SLEEVE6" D.I. WALL

M.J. TEE8"x8"

12'-8"

FLY VALVE8" FL. BUTTER-

METER8" FL. FLOW

PIPING (7'-0" OFF FIN. FL.)6" D.I. PRESSURE RELIEF

6'-8" (TYP.)

PUMP SKID

NO.1PUMP

800 GPM

NO.2PUMP

800 GPM

75 H.PO. PUMP(500 GPM)

NO.3

ON 4" BRANCH.BLIND FLANGE REQUIREDCONNECT TO EXIST. 8" TEE.

8'-0"

3" 3"

6'-0"

FOR DETAILS)STRUCTURAL PLANSDOUBLE DOORS, SEEREQUIRED:

8" 90° BEND

HOIST BEAMREQUIRED:

2'-1"

2'-11"

NEW VFD

PA

NE

L M

PA

NE

W

XRL ATSPANEL MP

DRAIN THROUGH WALL

HVAC UNIT

FOR CONTINUATION(SHT. 3)

SEE SITE PLAN

PR

OP

OS

ED PIPIN

G L

AY

OU

T

7

07_PROP PIPING LAYOUT.dgn

1"=1'-0"

SCALE : 1"= 1'-0"

K:\Projects\1

2\1

3\9

6031 C

ullm

an C

o.

Water

Dept. 2

010 B

ond Issue\Dra

win

gs\Tri

mble P

um

p Station\0

7_P

RO

P PIPIN

G L

AY

OU

T.d

gn

File P

ath:

SEE SITE PLAN3/4" PEX TUBING,REQUIRED:

LOCATION OF PIPE STAND (TYP.)

NEW ELECTRICAL PANELS. REFER TO ELECTRICAL DRAWINGS FOR LOCATION OF2.

AND DOOR DETAILS.REFER TO STRUCTURAL DRAWINGS FOR NEW WALL1.

NOTES:

8'-0"

CHLORINE ANALYZERHACH C117

*

2" STEEL

*

2" STEEL

6" D.I.

*

9"3'-0"8"

REDUCER6"x3" FL.

SPOOL PIECE6" FL.xFL.

SLEEVE6" D.I. WALL

FLY VALVE6" FL. BUTTER-

3'-0"

6" D.I.

*SLEEVE6" D.I. WALL

SPOOL PIECE6" FL.xFL.

REDUCER6"x3" FL.

FLY VALVE6" FL. BUTTER-

9"3'-0"8"

2'-10 1/2"

90° BEND8"x6" FL.

6" D.I.

90° BEND8"x6" FL.

6" D.I.

6" D.I.

A 250 PSI WORKING PRESSURE.VALVES SHALL BE CAPABLE OF OPERATING WITHALL DISCHARGE PIPING, FLANGES, FITTINGS AND

NOTE:

SCALE:

DATE:

DESIGNED BY:

DRAWN BY:

REVIEWED BY:

QC REVIEWER:

REVISED

DGN:

PROJECT NO:

SHEET NO.

This document and its contents are property of CDG Engineers & Associates, Inc. and may not be distributed, reused, or modified without permission.

FX: (2

56) 891-3

459

PH: (2

56) 891-3

458

P.O.

BO

X 2

079 (35950)

AL

BE

RT

VIL

LE,

AL 3

5951

417 M

AR

TLIN

G R

OA

D

AL

BE

RT

VIL

LE,

AL

DO

TH

AN,

AL

AU

BU

RN,

AL

AN

DA

LU

SIA,

AL

HU

NTS

VIL

LE,

AL

HO

OV

ER,

AL

GA

DS

DE

N,

AL

JGC

CPB

JGC

121396031

CU

LL

MA

N,

CO

UN

TY,

AL

AB

AM

A

CU

LL

MA

N C

OU

NT

Y W

AT

ER D

EP

AR

TM

EN

T

TRIM

BLE P

UM

P S

TA

TIO

N U

PG

RA

DE

A

MABAL

A DESNECIL

REENIGN

E

PROFESSIONAL

No. 17318

D

OO

WTIHC .G SE

M

AJ

OCTOBER 2017

cchitwood

Stamp

101 2

PIPIN

G S

EC

TIO

N A

46"

WINDOW 36"

SECTION A - A

8" D.I.

200 H.P. MOTORPUMP800 GPM

1'-4"

PUMP SKID

CONCRETE PIER

90° BEND6"x3" FL.

45° BEND6"x6" FL.

SPOOL PIECE6" FL.xP.E.

VALVE6" FL. CHECK

FLY VALVE6" FL. BUTTER-

SPOOL PIECE6" FL. x P.E.

COUPLING6" DRESSER

6" 45° BEND

8.00ft

PRESSURE RELIEF VALVE6" RIGHT ANGLE

& GROUT AROUND PIPE TO SEAL HOLECUT HOLE IN WALL FOR NEW PIPE

REQUIRED:

3'-8 1/2"

7'-6"

HOIST BEAM

ELECTRICALNEW

ELECTRICALNEW

K:\Projects\1

2\1

3\9

6031 C

ullm

an C

o.

Water

Dept. 2

010 B

ond Issue\Dra

win

gs\Tri

mble P

um

p Station\0

8_S

EC

TIO

N.d

gn

File P

ath:

8

08_SECTION.dgn

1"=1'-0"

SCALE : 1"= 1'-0"

(TYP.)PIPE STAND

10'-3"

7'-0"

6" D.I.REDUCER8"x6" FL.

6" D.I.

REDUCER6"x3" FL.

SPOOL PIECE6" FL.xFL.

90° BEND8"x6" FL.

FLY VALVE6" FL. BUTTER-

6" D.I.

SCALE:

DATE:

DESIGNED BY:

DRAWN BY:

REVIEWED BY:

QC REVIEWER:

REVISED

DGN:

PROJECT NO:

SHEET NO.

This document and its contents are property of CDG Engineers & Associates, Inc. and may not be distributed, reused, or modified without permission.

FX: (2

56) 891-3

459

PH: (2

56) 891-3

458

P.O.

BO

X 2

079 (35950)

AL

BE

RT

VIL

LE,

AL 3

5951

417 M

AR

TLIN

G R

OA

D

AL

BE

RT

VIL

LE,

AL

DO

TH

AN,

AL

AU

BU

RN,

AL

AN

DA

LU

SIA,

AL

HU

NTS

VIL

LE,

AL

HO

OV

ER,

AL

GA

DS

DE

N,

AL

JGC

CPB

JGC

121396031

CU

LL

MA

N,

CO

UN

TY,

AL

AB

AM

A

CU

LL

MA

N C

OU

NT

Y W

AT

ER D

EP

AR

TM

EN

T

TRIM

BLE P

UM

P S

TA

TIO

N U

PG

RA

DE

A

MABAL

A DESNECIL

REENIGN

E

PROFESSIONAL

No. 17318

D

OO

WTIHC .G SE

M

AJ

OCTOBER 2017

cchitwood

Stamp

101 2

PIPIN

G S

EC

TIO

N B

12"

WINDOW

4" BLIND FLANGE

SECTION B - B

PRESSURE RELIEF VALVE

8" D.I.

8" D.I.

MOTOR200 H.P.

MOTOR200 H.P.

NO. 3(500 GPM)

75 H.P. PUMP

METER8" FL. FLOW8"x6" FL. TEE8"x6" FL. TEE

90° BEND8"x6" FL.

COUPLING8" DRESSER

FLY VALVE8" FL. BUTTER-

8"x6" FL. TEE

45° BEND6"x6" FL.

6" FLAP VALVE

12"

6" D.I.

ANCHORED TO CEILING JOISTS6" D.I. PRESSURE RELIEF PIPE

6'-0"

HOIST BEAM

7'-6"7'-0"

3'-8 1/2"

ELECTRIC NEW

K:\Projects\1

2\1

3\9

6031 C

ullm

an C

o.

Water

Dept. 2

010 B

ond Issue\Dra

win

gs\Tri

mble P

um

p Station\0

9_S

EC

TIO

N.d

gn

File P

ath:

SCALE : 1"= 1'-0"

1"=1'-0"

9

09_SECTION.dgn

6" D.I.

10'-3"

SCALE:

DATE:

DESIGNED BY:

DRAWN BY:

REVIEWED BY:

QC REVIEWER:

REVISED

DGN:

PROJECT NO:

SHEET NO.

This document and its contents are property of CDG Engineers & Associates, Inc. and may not be distributed, reused, or modified without permission.

FX: (2

56) 891-3

459

PH: (2

56) 891-3

458

P.O.

BO

X 2

079 (35950)

AL

BE

RT

VIL

LE,

AL 3

5951

417 M

AR

TLIN

G R

OA

D

AL

BE

RT

VIL

LE,

AL

DO

TH

AN,

AL

AU

BU

RN,

AL

AN

DA

LU

SIA,

AL

HU

NTS

VIL

LE,

AL

HO

OV

ER,

AL

GA

DS

DE

N,

AL

JGC

CPB

JGC

121396031

CU

LL

MA

N,

CO

UN

TY,

AL

AB

AM

A

CU

LL

MA

N C

OU

NT

Y W

AT

ER D

EP

AR

TM

EN

T

TRIM

BLE P

UM

P S

TA

TIO

N U

PG

RA

DE

A

MABAL

A DESNECIL

REENIGN

E

PROFESSIONAL

No. 17318

D

OO

WTIHC .G SE

M

AJ

OCTOBER 2017

cchitwood

Stamp

101 2

PIPIN

G S

EC

TIO

N C

WINDOW 36"

SECTION C - C

PUMP SKID

2'-3"

8" D.I.

90° BEND6"x6" FL.

SPOOL PIECE6" FL.

WALL SLEEVE6" FL.

REDUCER6"x3" FL.

FITTING3" FL. SUCTION

2 1/2" FL. x 2 1/2" FNTP

CHARGE FITTING2 1/2" FL. DIS-

90° BENDREDUCING

6"x3" FL.

3 1/2" FL. x 2 1/2" FNTP

2 1/2" NTP PIPE

NO. 3(500 GPM)75 H.P. PUMP

6" 45° BEND

VALVE6" FL. CHECK

FLY VALVE6" FL. BUTTER-

45° BEND6"x6" FL.

7'-6"

2'-3"

6" FL. COUPLING

SPOOL PIECE6" FL. x P.E.

PRESSURE RELIEF VALVE6" D.I. RIGHT ANGLE

ANCHORED TO CEILING JOIST6" D.I. PRESSURE RELIEF PIPE

VALVEBUTTERFLY6" FL.

STANDPIPE

HOIST BEAM

3'-8 1/2"

ELECTRICALNEW

ELECTRICALNEW

K:\Projects\1

2\1

3\9

6031 C

ullm

an C

o.

Water

Dept. 2

010 B

ond Issue\Dra

win

gs\Tri

mble P

um

p Station\1

0_S

EC

TIO

N.d

gn

File P

ath:

10

10_SECTION.dgn

1"=1'-0"

SCALE : 1"= 1'-0"

6" D.I.

10'-3"

(TYP.)PIPE STAND

8'-0"

7'-0"

SCALE:

DATE:

DESIGNED BY:

DRAWN BY:

REVIEWED BY:

QC REVIEWER:

REVISED

DGN:

PROJECT NO:

SHEET NO.

This document and its contents are property of CDG Engineers & Associates, Inc. and may not be distributed, reused, or modified without permission.

FX: (2

56) 891-3

459

PH: (2

56) 891-3

458

P.O.

BO

X 2

079 (35950)

AL

BE

RT

VIL

LE,

AL 3

5951

417 M

AR

TLIN

G R

OA

D

AL

BE

RT

VIL

LE,

AL

DO

TH

AN,

AL

AU

BU

RN,

AL

AN

DA

LU

SIA,

AL

HU

NTS

VIL

LE,

AL

HO

OV

ER,

AL

GA

DS

DE

N,

AL

JGC

CPB

JGC

121396031

CU

LL

MA

N,

CO

UN

TY,

AL

AB

AM

A

CU

LL

MA

N C

OU

NT

Y W

AT

ER D

EP

AR

TM

EN

T

TRIM

BLE P

UM

P S

TA

TIO

N U

PG

RA

DE

A

MABAL

A DESNECIL

REENIGN

E

PROFESSIONAL

No. 17318

D

OO

WTIHC .G SE

M

AJ

OCTOBER 2017

cchitwood

Stamp

10'-0" MAXIMUM

POST SHALL A MINIMUM OF

CONCRETE FOOTING AT LINE

CHAIN LINK FENCE

9 GAUGE ~ 2 X 2 GALV.

WIRE TIES @ 24" C.C.

STEEL

3'-0"

9" DIA.

1 5/8" O.D. TOP RAIL

FINISHED GRADE

A MINIMUM OF 9" DIA.

3 STRANDS ~ 12 GAUGE-

2500 psi CONCRETE

CONTINUOUS 9 GAUGE

AT ALL CORNERS, EACH WAY AND

1 5/8" O.D. HORIZONTAL BRACE

STAY WIRE

10'-0" MAXIMUM

4 BARB WIRE

2 7/8 O.D.

3'-6"

CORNER POST

8'-0"

3'-0"

AND TERMINAL POSTS SHALL BE

CONCRETE FOOTING AT CORNER

AT ALL TERMINAL AND GATE POSTS.

TENSION BAR

WIRE TIES @ 14" C.C.

2.375" O.D. LINE POST

TO SHED WATER

CROWN FOOTING

8"'

8"'

RETAINER GLANDS

WITH ADJUSTABLE VALVE BOX

RESILIENT SEAT GATE VALVE

DE

TE

RMIN

ED B

Y G

RA

DE

36"

MIN.

MAINTAIN TRENCH

2'-0" + PIPE O.D. (MIN.)

PIPE.

WIDTH TO 1'-0"

ABOVE TOP OF

INITIAL BACKFILL

(LIGHTLY COMPACTED)

REMOVE ALL STONES

AND OTHER MATERIAL

OVER 4" IN ANY

DIMENSION.

CLASS I EMBEDMENT

MATERIAL (#57 STONE)

1'-0" MIN.

3'-0" MIN.'

#10 COPPER

LOCATING WIRE

1'-0"'

12"'12"'

3' - 0"'

12' - 0"'

1' - 0"'

8' - 0"'

4' - 0"'

4 BARBED WIRE

12 GAUGE

3 STRANDS

GATE POST

3" O.D.

BRACING

1 -5/8" O.D.

CONCRETE

2500 PSI

STEEL FENCE FABRIC

9 GAUGE 2 X 2 GALV.

TAPE (CONTINUOUS)

PLASTIC RIBBON

SEED AND MULCH

6" TOPSOIL WITH

12' - 0"'

ST

AN

DA

RD D

ET

AIL

S

NTS

NUMBERCHANNEL

601

602

603

604

605

38

43

43

44

45

4-1/16"

4-3/8"

4-11/16"

5"

5-5/16"

4-3/8"

4-11/16"

5"

5-5/16"

5-5/8"

LBS.WEIGHT

DIM. AINLET

DIM. BOUTLET

TRENCH DRAIN CHANNELNOT TO SCALE

0 11/64 "

R

#4 REBAR

6" MIN.

NOT TO SCALE

TRENCH DRAIN CHAIR INSTALLATION

DIMPLES OF CHANNELCHAIR IN BOTTOM

CHAIR (SECUREINSTALLATION

VA

RIE

S

ANY DIMENSION)

(NO ROCKS OVER 6" IN

EXCAVATED MATERIAL

FINAL BACKFILL WITH

NOT TO SCALE

TYPICAL TRENCH DETAIL

NOT TO SCALE

GATE VALVE & BOX

NOT TO SCALE

8' CHAIN-LINK FENCE DETAILNOT TO SCALE

8' TALL DOUBLE SWING GATE DETAIL

K:\Projects\1

2\1

3\9

6031 C

ullm

an C

o.

Water

Dept. 2

010 B

ond Issue\Dra

win

gs\Tri

mble P

um

p Station\1

1-1

3_

DE

TAIL

S.d

gn

File P

ath:

11

11-13_DETAILS.dgn

18"

INITIA

L C

ON

CR

ET

E P

OU

R

EXCAVATION WIDTH (TYP.)

BUIL

DIN

G

CONCRETE3,000 PSI

DUTY FRAMEGRATE W/ HEAVY

SLOTTED CAST IRON

6" MIN.

5 /14"

6 1/4"

3/4"

SECTIONPRESLOPED CHANNELPOLYMER CONCRETE

OUTLET ON SOUTH END.

ON NORTH END AND 6" PVC

PROVIDE SOLID END CAP

NOTE:

SCALE:

DATE:

DESIGNED BY:

DRAWN BY:

REVIEWED BY:

QC REVIEWER:

REVISED

DGN:

PROJECT NO:

SHEET NO.

This document and its contents are property of CDG Engineers & Associates, Inc. and may not be distributed, reused, or modified without permission.

FX: (2

56) 891-3

459

PH: (2

56) 891-3

458

P.O.

BO

X 2

079 (35950)

AL

BE

RT

VIL

LE,

AL 3

5951

417 M

AR

TLIN

G R

OA

D

AL

BE

RT

VIL

LE,

AL

DO

TH

AN,

AL

AU

BU

RN,

AL

AN

DA

LU

SIA,

AL

HU

NTS

VIL

LE,

AL

HO

OV

ER,

AL

GA

DS

DE

N,

AL

JGC

CPB

JGC

121396031

CU

LL

MA

N,

CO

UN

TY,

AL

AB

AM

A

CU

LL

MA

N C

OU

NT

Y W

AT

ER D

EP

AR

TM

EN

T

TRIM

BLE P

UM

P S

TA

TIO

N U

PG

RA

DE

A

MABAL

A DESNECIL

REENIGN

E

PROFESSIONAL

No. 17318

D

OO

WTIHC .G SE

M

AJ

OCTOBER 2017

cchitwood

Stamp

A

° BENDS2122 ° BENDS4

111

PIPE DIA. A K L A K L MIN. COVER

4" 2" 1'-1" 4" 2" 1'-0" 3" 2'-6"

6" 4" 1'-0" 6" 2" 1'-0" 4" 2'-6"

8" 6" 1'-0" 8" 4" 1'-0" 5" 3'-0"

10" 8" 1'-1" 10" 5" 1'-0" 6" 3'-0"

12" "2110 1'-7" 1'-0" 6" 1'-0" 7" 4'-0"

14" "2111 2'-1" 1'-2" 8" 1'-0" 8" 4'-0"

16" 1'-1" 2'-5" 1'-8" 10" 1'-0" 9" 4'-0"

18" 1'-0" 2'-1" 1'-10" 1'-0" 1'-0" 10" 4'-0"

20" 1'-2" 2'-1" 2'-1" 1'-1" 1'-0" 1'-0" 5'-0"

24" 1'-5" 2'-10" 2'-6" 1'-3" 1'-0" 1'-3" 5'-0"

PIPE DIA. A B C D K MIN. COVER

4" "213 1'-0" 6" "2

14 1'-1" 3'-0"

6" "216 9" 9" "2

14 1'-2" 3'-0"

8" 10" 3" 1'-0" "214 1'-2" 3'-0"

10" "211'-1 -- 1'-3" "2

14 1'-4" 3'-0"

12" "211'-4 -- 1'-6" 6" 1'-8" 4'-0"

14" "211'-4 -- 1'-9" 6" 1'-8" 4'-0"

16" 1'-7" -- 2'-0" 6" 1'-10" 4'-0"

18" "211'-9 -- 2'-3" 6" 2'-4" 4'-0"

20" 1'-11" -- 2'-6" 6" 2'-4" 5'-0"

24" 2'-3" -- 3'-0" 7" 2'-10" 5'-0"

PIPE DIA. A B C D K MIN. COVER

4" 6" 1'-8" 6" "214 1'-10" 3'-0"

6" 1'-0" 1'-7" 9" "214 1'-9" 3'-0"

8" 1'-3" 1'-6" 1'-0" "214 1'-9" 3'-0"

10" 2'-1" 1'-1" 1'-3" "214 1'-11" 3'-0"

12" 2'-6" 1'-0" 1'-6" 6" 1'-11" 4'-0"

14" 2'-6" 1'-2" 1'-9" 6" 2'-0" 4'-0"

16" 2'-11" 1'-0" 2'-0" 6" 2'-1" 4'-0"

18" 3'-4" 10" 2'-3" 6" 2'-2" 4'-0"

20" 3'-6" 11" 2'-6" 6" 2'-3" 5'-0"

24" 4'-3" 8" 3'-0" 7" 2'-5" 5'-0"

COVER

ID41

K

L

L D

A A

B

COVER

ID41

K

C

C

D

B

A A

COVER

ID41

K

C

C

UNDISTURBED SOIL

NOTE: CONCRETE MUST BE POURED AGAINST

UNDISTURBED SOIL

NOTE: CONCRETE MUST BE POURED AGAINST

UNDISTURBED SOIL

NOTE: CONCRETE MUST BE POURED AGAINST

PLAN

PLAN

PLAN

SECTION "A"

SECTION "B"

SECTION "C"

A

A

B

C

B

C

21

41TYPICAL 11

PIPE DIA. A B C D K MIN. COVER

4" 6" 1'-8" 6" "214 1'-10" 3'-0"

6" 1'-0" 1'-7" 9" "214 1'-9" 3'-0"

8" 1'-3" 1'-6" 1'-0" "214 1'-9" 3'-0"

10" 2'-1" 1'-1" 1'-3" "214 1'-11" 3'-0"

12" 2'-6" 1'-0" 1'-6" 6" 1'-11" 4'-0"

14" 2'-6" 1'-2" 1'-9" 6" 2'-0" 4'-0"

16" 2'-11" 1'-0" 2'-0" 6" 2'-1" 4'-0"

18" 3'-4" 10" 2'-3" 6" 2'-2" 4'-0"

20" 3'-6" 11" 2'-6" 6" 2'-3" 5'-0"

24" 4'-3" 8" 3'-0" 7" 2'-5" 5'-0"

TYPICAL TEE THRUST BLOCK

COVER

PLAN

SECTION "D"

D

D

K

C

C

B

A A

ID41

ANY CONCRETE UNDER PIPE.

POURED AGAINST UNDISTURBED SOIL. DO NOT PLACE

BETWEEN PIPE AND CONCRETE. CONCRETE MUST BE

NOTE: WRAP PIPE W/ POLYETHYLENE TO PREVENT CONTACT

UNDER PIPE

ANY CONCRETE

DO NOT PLACE

UNDER PIPE

ANY CONCRETE

DO NOT PLACE

UNDER PIPE

ANY CONCRETE

DO NOT PLACE

A

NTS

12

11-13_DETAILS.dgn

K:\Projects\1

2\1

3\9

6031 C

ullm

an C

o.

Water

Dept. 2

010 B

ond Issue\Dra

win

gs\Tri

mble P

um

p Station\1

1-1

3_

DE

TAIL

S.d

gn

File P

ath:

ST

AN

DA

RD D

ET

AIL

S

SCALE:

DATE:

DESIGNED BY:

DRAWN BY:

REVIEWED BY:

QC REVIEWER:

REVISED

DGN:

PROJECT NO:

SHEET NO.

This document and its contents are property of CDG Engineers & Associates, Inc. and may not be distributed, reused, or modified without permission.

FX: (2

56) 891-3

459

PH: (2

56) 891-3

458

P.O.

BO

X 2

079 (35950)

AL

BE

RT

VIL

LE,

AL 3

5951

417 M

AR

TLIN

G R

OA

D

AL

BE

RT

VIL

LE,

AL

DO

TH

AN,

AL

AU

BU

RN,

AL

AN

DA

LU

SIA,

AL

HU

NTS

VIL

LE,

AL

HO

OV

ER,

AL

GA

DS

DE

N,

AL

JGC

CPB

JGC

121396031

CU

LL

MA

N,

CO

UN

TY,

AL

AB

AM

A

CU

LL

MA

N C

OU

NT

Y W

AT

ER D

EP

AR

TM

EN

T

TRIM

BLE P

UM

P S

TA

TIO

N U

PG

RA

DE

A

MABAL

A DESNECIL

REENIGN

E

PROFESSIONAL

No. 17318

D

OO

WTIHC .G SE

M

AJ

OCTOBER 2017

cchitwood

Stamp

PIPE DIA. A B C

4" - 8" 6'-0" MIN. 3'-0" MIN. 1'-6"

10" & 12" 8'-0" MIN. 4'-0" MIN. 1'-8"

16" - 24" 10'-0" MIN. 5'-0" MIN. 2'-0"

ID + 8

ID/2 + 18"

ID/2 + 6"

ID/2 + 10"

1D/2 + 10"

6"6"

1'-6"

8"

1'-0"

1'-0"

1'-3"ID/2 + 6"

B

A

C

3" CLEAR

1' - 0" MIN.

BELL O.D. PLUS 2' - 0" MIN.

E

E

F

F

SECTION "E"ELEVATION

ELEVATION

ELEVATION

SECTION "F"

SECTION

DETAIL - PIPE TERMINATION THRUST BLOCK

AGAINST UNDISTURBED SOIL.

NOTE: CONCRETE TO BE POURED

IS TO BE TERMINATED

* APPLIES ONLY WHERE PIPE

DETAILS - TYPICAL THRUST BLOCK FOR UPWARD VERTICAL BENDS

DETAILS - TYPICAL THRUST BLOCK FOR DOWNWARD VERTICAL BENDS

1'-0"

1'-0"

ANY CONCRETE UNDER PIPE.

POURED AGAINST UNDISTURBED SOIL. DO NOT PLACE

BETWEEN PIPE AND CONCRETE. CONCRETE MUST BE

NOTE: WRAP PIPE W/ POLYETHYLENE TO PREVENT CONTACT

CORTEN STRAP

" X 2"83

UNDISTURBED SOIL

EW ( 12" PIPE & LARGER )

#5 BARS @ 8" OC,

BOLT W/ HEX NUT

" ANCHOR43

OF CONCRETE THRUST BLOCK

HAND EXCAVATE IN AREA

UNDISTURBED SOIL

" X 2" CORTEN STRAP83

" ANCHOR BOLT W/ HEX NUT43

ALL REINF. #5 BARS @ 8" OC

#5 BARS @ 8"OC, EW, EF

#5 BARS @ 8"OC, EW, EF

DOUBLE RETAINER GLANDS

M.J. PLUG*

REMOVAL OF THRUST BLOCK.

W/ END HOOK FOR FUTURE

" EYE BOLT43INSTALL

#4 BARS @ 6"OC, EW

M.J. PLUG

6'-0"

NTS

DETAIL - TYPICAL LONGITUDINAL ANCHOR

K:\Projects\1

2\1

3\9

6031 C

ullm

an C

o.

Water

Dept. 2

010 B

ond Issue\Dra

win

gs\Tri

mble P

um

p Station\1

1-1

3_

DE

TAIL

S.d

gn

File P

ath:

13

11-13_DETAILS.dgn

ST

AN

DA

RD D

ET

AIL

S

SCALE:

DATE:

DESIGNED BY:

DRAWN BY:

REVIEWED BY:

QC REVIEWER:

REVISED

DGN:

PROJECT NO:

SHEET NO.

This document and its contents are property of CDG Engineers & Associates, Inc. and may not be distributed, reused, or modified without permission.

FX: (2

56) 891-3

459

PH: (2

56) 891-3

458

P.O.

BO

X 2

079 (35950)

AL

BE

RT

VIL

LE,

AL 3

5951

417 M

AR

TLIN

G R

OA

D

AL

BE

RT

VIL

LE,

AL

DO

TH

AN,

AL

AU

BU

RN,

AL

AN

DA

LU

SIA,

AL

HU

NTS

VIL

LE,

AL

HO

OV

ER,

AL

GA

DS

DE

N,

AL

JGC

CPB

JGC

121396031

CU

LL

MA

N,

CO

UN

TY,

AL

AB

AM

A

CU

LL

MA

N C

OU

NT

Y W

AT

ER D

EP

AR

TM

EN

T

TRIM

BLE P

UM

P S

TA

TIO

N U

PG

RA

DE

A

MABAL

A DESNECIL

REENIGN

E

PROFESSIONAL

No. 17318

D

OO

WTIHC .G SE

M

AJ

OCTOBER 2017

cchitwood

Stamp

cchitwood

Typewritten Text

cchitwood

Typewritten Text

FILE

:16195 S

tructural.dw

g T

AB

:S

1.0

P

D:4/4/2017 10:19 A

M P

B:C

laude M

oore

810 Regal Drive SW

Suite C

Huntsville, AL 35801

Phone: 256.864.2542

Structural Engineers, Inc.

Project No. 16195

EXISTING CONSTRUCTION:

1. THE CONTRACTOR IS RESPONSIBLE FOR PROTECTING AND MAINTAINING THE STRUCTURAL

INTEGRITY OF THE EXISTING BUILDING AT THE INTERFACE CONNECTIONS DURING ALL

STAGES OF CONSTRUCTION.

2. THE CONTRACTOR IS RESPONSIBLE FOR THE DESIGN OF ALL TEMPORARY SHORING

REQUIRED TO SUPPORT THE EXISTING BUILDING UNTIL PERMANENT STRUCTURAL SUPPORT

AS SHOWN HAS BEEN INSTALLED.

3. CONNECTIONS, ADDITIONS AND ALTERATIONS AS SHOWN TO EXISTING BUILDING ARE

BASED ON A VISUAL OBSERVATION OF THE PROJECT SITE AND ON INFORMATION PROVIDED

BY THE CLIENT.

4. THE CONTRACTOR SHALL FIELD-VERIFY ALL DIMENSIONS, ELEVATIONS, AND CONDITIONS

SHOWN PRIOR TO FABRICATION/CONSTRUCTION. THIS INFORMATION SHALL BE

INCORPORATED INTO THE SHOP DRAWINGS PRIOR SUBMITTING TO ARCHITECT/ENGINEER

FOR REVIEW.

5. IF EXISTING CONDITIONS DIFFER FROM THE CONDITIONS SHOWN IN THE DRAWINGS OR

ASSUMED FOR DESIGN, THE ARCHITECT/ENGINEER SHALL BE NOTIFIED OF ALL

DISCREPANCIES, ALLOWED TO EXAMINE THE AS-BUILT CONDITION, AND MODIFY THE

DESIGN AS REQUIRED.

6. IF CONDITIONS ARE ENCOUNTERED DURING CONSTRUCTION WHICH REQUIRE THE

REMOVAL OF EXISTING LOAD-BEARING CONSTRUCTION NOT SHOWN ON THE STRUCTURAL

DRAWINGS, THE ARCHITECT AND THE STRUCTURAL ENGINEER SHALL BE NOTIFIED PRIOR

TO REMOVAL.

7. EXCEPT WHERE NEW PERMANENT LOADS OR COMPONENTS HAVE BEEN ADDED AS SHOWN

IN THE STRUCTURAL DRAWINGS, THE EXISTING STRUCTURE HAS NOT BEEN ANALYZED BY

ECHOLS, LINDSEY & MOORE STRUCTURAL ENGINEERS, INC.

CONCRETE MASONRY:

1. MASONRY CONSTRUCTION SHALL CONFORM TO ACI 530.1 SPECIFICATION.

2. MASONRY COMPRESSIVE STRENGTH (f'm) SHALL BE 1500 PSI BASED ON THE UNIT

STRENGTH METHOD OR VERIFIED BY PRISM TESTS IN ACCORDANCE WITH ASTM C 1314.

3. MORTAR SHALL BE TYPE S OR M.

4. REINFORCING BARS SHALL CONFORM TO ASTM A615, GRADE 60.

5. BLOCK FILL SHALL BE GROUT WITH AN 8" TO 11" SLUMP, PROPORTIONED PER ASTM C 476

OR ATTAINING 3000 PSI AT 28 DAYS PER ASTM C 1019. DO NOT USE MORTAR AS BLOCK FILL.

6. ALL GROUT SHALL BE CONSOLIDATED AT TIME OF PLACEMENT USING A LOW-VELOCITY

MECHANICAL VIBRATOR WITH A 3/4-INCH HEAD. RE-CONSOLIDATE GROUT AFTER INITIAL

WATER LOSS AND SETTLEMENT HAS OCCURRED. DO NOT PLACE NEXT LIFT OF GROUT

UNTIL LOWER LIFT HAS BEEN RE-CONSOLIDATED.

LIGHTGAUGE METAL FRAMING:

1. STRUCTURAL PROPERTIES OF METAL STUDS SHALL BE COMPUTED IN ACCORDANCE

WITH AISI "SPECIFICATION FOR DESIGN OF COLD-FORMED STEEL STRUCTURAL

MEMBERS".

2. INSTALL FRAMING USING WALL BRACING, CONNECTION DETAILS, AND DOOR/WINDOW

HEADERS AS RECOMMENDED BY THE STUD MANUFACTURER FOR LOAD-BEARING

AND/OR CURTAINWALL STUDS, UNLESS NOTED OTHERWISE.

3. MEMBERS DESIGNATED AS 20 GA. AND 18 GA. SHALL BE 33 KSI, UNLESS NOTED.

MEMBERS DESIGNATED AS 16GA., 14 GA. AND 12 GA. SHALL BE 50 KSI, UNLESS

NOTED.

4. BOTTOM TRACKS & STANDARD TOP TRACKS SHALL MATCH STUD GAUGE. TOP

DEFLECTION TRACKS, WHERE REQUIRED, SHALL BE ONE GAUGE THICKNESS

HEAVIER THAN THE STUDS.

5. ALL WALL STUDS, TRACK, BRIDGING AND ACCESSORIES SHALL BE FORMED FROM

STEEL HAVING A G60 GALVANIZED COATING MEETING THE REQUIREMENTS OF ASTM

A653.

6. UNLESS NOTED OTHERWISE, MINIMUM TRACK FASTENING SHALL BE .177" DIAMETER

POWDER ACTUATED FASTENERS SPACED @ 8" O.C. WITH 1" MINIMUM PENETRATION

INTO CONCRETE.

7. SPLICES ARE NOT PERMITTED IN STUDS, JOISTS, RAFTERS, HEADERS OR BEAMS.

TRACK SPLICES SHALL BE SECURELY ANCHORED TO A COMMON ELEMENT (i.e., STUD

OR HEADER) OR BUTT-WELDED TOGETHER.

8. A UNIFORM BEARING SURFACE SHALL BE PROVIDED BENEATH THE BOTTOM TRACK IN

LOAD-BEARING WALLS. INSTALL LOAD-BEARING SHIMS OR GROUT BETWEEN THE

UNDERSIDE OF THE BOTTOM TRACK AND THE TOP OF SLAB OR FOUNDATION WALL AT

LOCATIONS WITH A GAP LARGER THAN 1/8" TO ENSURE A UNIFORM BEARING

SURFACE ON SUPPORTING CONCRETE OR MASONRY CONSTRUCTION.

9. STUDS SHALL HAVE FULL BEARING AGAINST THE INSIDE TRACK WEB TOP AND

BOTTOM (1/16" MAX. GAP). STUDS MUST BE CUT SQUARE.

10. A MINIMUM OF 10" OF UN-PUNCHED STEEL IS REQUIRED AT BOTH ENDS OF STUDS (NO

PUNCHING HOLES OF ANY SIZE IS PERMITTED IN THESE 10 INCHES).

11. BOTH STUD FLANGES MUST BE ATTACHED TO TRACK AT TOP & BOTTOM WITH #12

SCREWS OR WELD.

12. INSTALL COLD-FORMED STEEL FRAMING LEVEL, PLUMB, AND TRUE TO LINE TO A

MAXIMUM ALLOWABLE TOLERANCE VARIATION OF 1/8 INCH IN 10 FEET.

13. PROVIDE PERMANENT LATERAL BRIDGING AT ALL LOAD-BEARING/CURTAINWALL

STUDS. BRIDGING SHALL BE 1 1/2" CRC CHANNEL IN 3 5/8" OR 4" STUDS AND 2 1/2" CRC

IN 6" STUDS. BRIDGING SHALL BE SPACED AT NO MORE THAN 4'-0" O.C. VERTICALLY

AT APPROXIMATELY THE THIRD POINT VERTICALLY. LATERAL BRIDGING MUST BE

SECURED WITH SCREWS OR WELDS BEFORE AXIAL LOAD IS APPLIED.

14. FULL-HEIGHT STUDS ON EACH SIDE OF WALL OPENINGS SHALL BE EQUAL TO 1/2 OF

THE INTERRUPTED STUDS PLUS ONE STUD AT EACH SIDE. USE MINIMUM OF TWO (2)

STUDS EACH SIDE. CONNECT JAMB STUDS TOGETHER WITH 6" LONG PIECES OF

TRACK OF GAUGE EQUAL TO THE STUDS AT THE JAMB STUD QUARTER POINTS.

CONNECT EACH PIECE OF TRACK TO EACH STUD WITH 2 #10 SCREWS. OTHERWISE,

WELD STUD FLANGES TOGETHER WITH FILLET WELDS, 2" TOP & BOTTOM & 1" @ 24"

O.C. BOTH SIDES IN BETWEEN.

15. HEADERS SHALL TRANSFER ALL SHEAR BY FULL BEARING ON JACK STUDS OR BY

SHEAR PLATES. SHEAR PLATES SHALL BE 16 GA. MINIMUM. ATTACH CLIP L'S TOP &

BOTTOM OF HEADERS AT EACH END.

16. FIELD WELDING OF MATERIAL LESS THAN 18 GA. SHALL NOT BE PERMITTED. WELDS

SHALL BE PERFORMED BY OPERATORS QUALIFIED IN ACCORDANCE WITH SECTION 6.0

OF THE AWS "STRUCTURAL WELDING CODE-SHEET METAL" (AWS D1.3). ALL WELDS

SHALL BE TOUCHED UP WITH ZINC RICH PAINT.

17. WALL SHEATHING, UNLESS NOTED: 15/32" MIN. THICKNESS APA RATED (32/16)

PLYWOOD OR OSB, EXPOSURE 1, ON BOTH FACES WITH LONG EDGES OF PANEL

PERPENDICULAR TO STUDS. PANEL EDGES SHALL BE FULLY BLOCKED WITH A

MINIMUM OF 1 1/2" WIDE HORIZONTAL BLOCKING OF THE SAME MATERIAL AND

THICKNESS AS THE TRACK AND STUDS.

18. SHEATHING FASTENING, UNLESS NOTED: NO. 8 x 1 INCH BUGLE HEAD SCREW PLACED

AT 6 INCHES AT ALL FOUR PANEL EDGES AND AT 12 INCHES AT INTERMEDIATE

MEMBERS. SCREWS SHALL BE PLACED A MINIMUM OF 3/8" FROM PANEL EDGES.

CONCRETE:

1. CONCRETE SCHEDULES

ITEM 28 DAY COMPRESSIVE STRENGTH

A. CONCRETE FILL FOR MASONRY 3000 PSI GROUT W/ 8" TO 11" SLUMP

(ASTM C 1019 OR ASTM C 476)

B. ALL OTHER CONCRETE 3000 PSI NORMAL WEIGHT

2. CONCRETE COVER OVER REINFORCING (U.N.O.)

A. CAST AGAINST AND PERMANENTLY EXPOSED TO EARTH: 3 IN.

B. EXPOSED TO EARTH OR WEATHER:

#6 AND LARGER 2 IN.

#5 AND SMALLER 1 1/2 IN.

C. NOT EXPOSED TO EARTH OR WEATHER:

SLABS, WALLS, JOISTS:

#14 AND LARGER: 1 1/2 IN.

#11 AND SMALLER: 3/4 IN.

BEAMS, COLUMNS:

STIRRUPS, SPIRALS, AND TIES: 1 1/2 IN.

PRIMARY REINFORCEMENT: 2 IN.

3. CONCRETING OPERATIONS SHALL COMPLY WITH ACI 117 AND ACI 301.

4. ALL REINFORCING SHALL CONFORM TO THE LATEST REVISION OF ASTM SPECIFICATION A615.

GRADE 60.

5. ALL REINFORCING SHALL BE DETAILED IN ACCORDANCE WITH A.C.I. STANDARD 315.

6. NO REINFORCING BAR SHALL BE WELDED IN ANY MANNER.

7. SPLICES FOR REINFORCING ARE SHOWN SPECIFICALLY ON STRUCTURAL DRAWINGS. A DDITIONAL

SPLICES TO FACILITATE CONSTRUCTION SHALL BE CLASS "B" TENSION LAP SPLICES.

SHOP DRAWINGS & SUBMITTALS:

1. STRUCTURAL DRAWINGS INDICATE TYPICAL AND CERTAIN SPECIFIC CONDITIONS ONLY.

ALL CONDITIONS SHALL BE DETAILED ON THE SHOP DRAWINGS IN ACCORDANCE WITH

SPECIFIED STANDARDS AND THE SPECIFIC REQUIREMENTS OF THIS PROJECT AS

INDICATED ON THE DRAWINGS.

2. ALL SHOP DRAWINGS SHALL BE NEWLY PREPARED. REPRODUCTIONS OF CONTRACT

STRUCTURAL DRAWINGS FOR USE AS ERECTION DRAWINGS WILL NOT BE PERMITTED.

SHOULD SHOP DRAWING SUBMITTALS CONTAIN ANY REPRODUCTIONS OF CONTRACT

STRUCTURAL DRAWINGS, THEY WILL BE REJECTED AND RETURNED WITHOUT ENGINEER

REVIEW. A LICENSE TO USE ANY PORTION OR ALL OF THE STRUCTURAL CAD FILES FOR

THE LIMITED PURPOSE OF ASSISTING THE CONTRACTOR'S PREPARATION OF SHOP

DRAWINGS FOR SUBMITTAL MAY BE OBTAINED FROM THE STRUCTURAL ENGINEER

UNDER A STANDARD FORM OF AGREEMENT FOR A FEE OF $500.00.

3. CONTRACTOR SHALL REVIEW ALL SUBMITTALS AND STAMP WITH APPROVAL PRIOR TO

SUBMISSION TO ARCHITECT/ ENGINEER. SHOP DRAWINGS RECEIVED BY

ARCHITECT/ENGINEER THAT HAVE NOT BEEN CHECKED AND COORDINATED BY THE

CONTRACTOR WILL BE RETURNED WITHOUT ARCHITECT/ENGINEER'S REVIEW.

4. CONTRACTOR SHALL SUBMIT SHOP DRAWINGS IN ELECTRONIC (PDF) FORMAT ONLY

(INSTEAD OF PAPER COPIES). THESE WILL BE REVIEWED AND RETURNED BY THE

STRUCTURAL ENGINEER IN PDF FORMAT ONLY. ALLOW TWO WEEKS FOR THE REVIEW OF

EACH SUBMITTAL.

STRUCTURAL STEEL:

1. ALL STRUCTURAL STEEL WIDE FLANGE SHAPES SHALL CONFORM TO ASTM A992

2. ALL STRUCTURAL STEEL PLATES, ANGLES AND CHANNELS SHALL CONFORM TO ASTM A36

3. ALL STRUCTURAL STEEL TUBING SHALL CONFORM TO ASTM A500, GRADE B

4. FABRICATION AND ERECTION SHALL CONFORM TO AISC CODE OF STANDARD PRACTICE.

SUBMIT SHOP & ERECTION DRAWINGS FOR REVIEW, INCLUDING THE REQUIRED

CONNECTION DESIGN INFORMATION DESCRIBED BELOW. SUBMITTALS THAT ARE

SUBSTANTIALLY INCOMPLETE WILL BE REJECTED WITHOUT REVIEW.

5. ALL STRUCTURAL STEEL CONNECTIONS NOT SPECIFICALLY DETAILED ON THE DRAWINGS

SHALL BE DESIGNED BY THE FABRICATOR, UNDER THE DIRECT SUPERVISION OF A

PROFESSIONAL ENGINEER REGISTERED IN TH E STATE OF ALABAMA TO RESIST THE

FORCES INDICATED. UNLESS STAMPED BY THE FABRICATOR'S ENGINEER, THE SHOP

DRAWINGS SHALL INCLUDE A SEALED LETTER FROM THE FABRICATOR'S ENGINEER

CERTIFYING THAT THE CONNECTIONS SHOWN IN THE SHOP DRAWINGS ARE ADEQUATE

FOR THE REQUIRED LOADS. DO NOT SUBMIT CALCULATIONS EXCEPT WHERE

SPECIFICALLY REQUESTED.

6. ALL CONNECTIONS SHALL BE DESIGNED USING THE ALLOWABLE STRESS DESIGN (ASD)

METHOD. ALL REACTIONS SHOWN OR CALCULATED SHALL BE SERVICE-LOAD LEVEL

FORCES, UNLESS NOTED.

7. WELDED CONNECTIONS (AWS D1.1): E70XX ELECTRODES, E308XX FOR STAINLESS STEEL

(AWS D1.6). THICKNESS OF WELDS SHALL BE AS SHOWN, SPECIFIED OR REQUIRED, BUT

NOT LESS THAN 3/16" FILLET WELD.

8. BOLTED CONNECTIONS: BEARING TYPE A325-N, SNUG-TIGHT IN ACCORDANCE WITH AISC

"SPECIFICATION FOR STRUCTURAL JOINTS USING ASTM A325 OR A490 BOLTS", U.N.O. BOLTS

THROUGH 4" WIDE BEAM FLANGES SHALL BE 5/8" DIAMETER. OTHER BOLTS SHALL BE 3/4"