What’s inside your coating station? Welcome to the Next Generation Anilox- & Metering Rolls for the Offset industry! Start your own coating quality revolution • Boost your Profitability • Achieve Smooth and Consistent Coating Results • Plug & Play Convenience • Lightweight Roll Changes • ReadyRoll Prompt In-Stock Delivery UltraCell PRECISION · DURABILITY · RELIABILITY THE OFFSET COATING REVOLUTION Invented by Apex International Genetic Transfer Technology EUROPE: EP 2121339 USA: 8.397.633 B2 CHINA: ZL 200880125338.2 JAPAN: 5301562 TAIWAN: I 471227 Other foreign patents pending GTT - Patents Profits or Problems? The Measure of Quality. COATING TRANSFER INNOVATIONS FOR OFFSET

Welcome message from author

This document is posted to help you gain knowledge. Please leave a comment to let me know what you think about it! Share it to your friends and learn new things together.

Transcript

What’s insideyour coating station?

Welcome to the Next Generation Anilox-& Metering Rolls for the Offset industry!Start your own coating quality revolution

• Boost your Profitability

• Achieve Smooth and Consistent Coating Results

• Plug & Play Convenience

• Lightweight Roll Changes

• ReadyRoll Prompt In-Stock Delivery

UltraCellPRECISION · DURABILITY · RELIABILITY THE OFFSET COATING REVOLUTION

Invented byApex International

Genetic TransferTechnology

EUROPE: EP 2121339USA: 8.397.633 B2CHINA: ZL 200880125338.2JAPAN: 5301562TAIWAN: I 471227Other foreign patents pending

GTT - Patents

Profits or Problems?

The Measure of Quality.

COATING TRANSFER INNOVATIONS FOR OFFSET

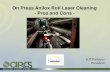

GTTOFFSET

Metering Rolls

OPEN SLALOM CHANNEL Sets your coating free and avoids turbulence and foaming.

CONSTANT BEAM LASER ENGRAVING Our continuous laser process creates a consistent and

precise channel. This proven, patented technology guarantees a controlled coating transfer.

SUPER-HARD HYBRID CERAMIC Apex GTT hybrid ceramic layer uses 80% CrO2 and adds

20% Titanium Dioxide particles, which minimizes porosity.

Apex GTTOFFSET rolls are nothing short ofa revolution in quality coating transfer.

A D VA N C E D

UltraCellAnilox Rolls

Offset professionals know that coatings and varnishes can bring a printed piece to life- or ruin it. Orange-peel and pinholing can diminish even the finest, tightest-register multi-color job. But most printers don’t realize

they have options to boost quality, predictability and profitability in their lacquer-transfer anilox rolls.With Apex, now the choice is yours. Tested, approved and recommended by leading press manufacturers, our UltraCell and revolutionary GTT coating rolls deliver quality, reliability and profitability for all of your coating requirements.

Customer Quotes“My print quality has gone up, because of the smooth and equal coating layer“

“I used the same amount of coating and the number of gloss points increased enormously while using GTT L”

“I save a lot on coating and achieve the same result“

CERAMIC SURFACE Homogenous and compact ceramic with a porosity less

than 1% without using any sealer and post treatment.

ULTRAMELT LASER ENGRAVING All conventional anilox rolls are engraved with a pulse

laser, using the UltraMelt technology, a method that melts the ceramic after engraving, resulting in a smooth ceramic layer.

Apex UltraCell anilox rolls are deliverablein all requested engraving specifications.

UltraCell for Offset Lacquer/Coating Transfer

Solutions for Offset Coating Start your own coating quality revolution with GTT

CO N V E N T I O N A L

BE

TT

ER

FE

AT

UR

ES

Gloss CheckerGloss Checker ConventionalAnilox Sm

oothness

GTT Sm

oothness

PRECISION · DURABILITY · RELIABILITY THE OFFSET COATING REVOLUTION

GTTOFFSET for Lacquer/Coating TransferB

ES

TF

EA

TU

RE

S

Maximize your visual coating results• Enjoy a smoother coating surface and a homogenous laydown• Experience more gloss• Solve pinholing, orange-peel effect and micro-foaming

Boost your profitability• Coating savings!• Higher efficiency, because of rare roll changes.• Better margins due to a higher value print work.

Universal GTT profile selectionL Profile : applicable for 80% of all water based coatingsM Profile : more economical print of water based coatingsS Profile : special applications (ex. Silver, Gold, etc)XL Profile : best results in UV coatingsXXL Profile : even more optical UV gloss.

All Apex UltraCell and GTT Coating rollsshare these common benefits:

LIGHTWEIGHT Our strong, lightweight aluminium-core base (produced according

to OEM standards) enables safer, faster roll changes and handling.PLUG & PLAY PERFORMANCE Right out of the box, your roll is press-ready, including bearings, tooling and mounting.FAST DELIVERY Our stock program ensures t he most frequently-used roll sizes to be in-stock, awaiting your order.

Micro-photographs compare lacquer surface smoothness in conventional UltraCell hexagonal cell anilox and GTTOFFSET. While uniform lacquerapplication is assured with all Apex rolls, GTT maximizes consistent quality and minimizes pinholing, orange peel and other common coating complaints.

TRIHELICALPOSITIVEENGRAVING

ELONGATEDHEXAGON

30°-60°HEXAGONAL

APEX CONVENTIONAL ANILOX ROLLS ARE AVAILABLEIN ALL LASER-ENGRAVING GEOMETRIES

AN

D M

ORE

!

SALES OFFICES APEX ASIA T + 65 (0) 6284 7606 E [email protected]

APEX DEUTSCHLAND T + 49 (0) 2823 929360 E [email protected]

APEX FRANCE T + 33 (0) 475 46 39 42 E [email protected]

APEX IBÉRICA T + 34 93 583 10 12 E [email protected]

PRODUCTION FACILITIES APEX EUROPE T + 31 (0) 497 36 11 11 E [email protected]

APEX ITALY T + 39 0331 379 063 E [email protected]

APEX LATIN AMERICA T + 55 (41) 3677 2678 E [email protected]

APEX NORTH AMERICA T + 1 (0) 724 379 8880 E [email protected]

HEADQUARTERS APEX EUROPEMetaalweg 85527 AK Hapert NL T 31 (0) 497 36 11 11 E [email protected] www.apex-groupofcompanies.com

Apex Group of Companies is the world’s largest manufacturer of precision coating- and ink-transfer technology products. Apex supplies anilox/metering rolls and bridge/plate sleeves for offset, label, flexible packaging, corrugated and industrial coating applications. Apex products are tested, approved and deployed by all leading press manufacturers in the offset and flexographic industries. Reliability, durability, innovation and precision are hallmarks of all Apex products. With manufacturing and sales operations on six continents in more than 80 countries, Apex provides added value by supplying customers with end-to-end anilox or GTT solutions including measurement devices, cleaning and maintenance products, and educational/use-and-care seminars. Ask your local sales person for more information or contact the Apex Offset department at [email protected]

Des

ign

and

real

izat

ion:

Com

cord

e G

rafim

edia

, The

Net

herl

ands

About Apex Group of Companies

Banded Roll Program for GTT Profile SelectionThere are 5 standard profiles available in the GTTOFFSET range: S, M, L, XL, XXL.It is very easy to make a selection, dependent on your application.If you are not certain which profile suits your application best, youcan make use of the live banded roll test. Apex holds several bandedrolls in stock for most of the common machine types.Ask your local contact for more information on this unique service.

Coating Calculator"What is my actual coating transfer?” This is an often raised question by many offset printers. Apex created a calculator which gives an advice on how to achieve the optimal wet transfer result through different cell patterns. This convenient tool makes the selection for your application as easy as possible. It can be found on our website: www.apex-groupofcompanies.com/coatingcalculator.

Scan this QR-code and download the Coating Calculator!www.apex-groupofcompanies.com

GTTOFFSET Structure Wet transfer

S 2,15 g/m2

M 2,50 g/m2

L 3,25 g/m2

XL 4,30 g/m2

XXL 5,00 g/m2

Hexagonal Wet transfer

7 cm3/m2 4,5 BCM 160 L/cm 1,80 g/m2

10 cm3/m2 6,4 BCM 120 L/cm 2,50 g/m2

13 cm3/m2 8,4 BCM 100 L/cm 3,25 g/m2

16 cm3/m2 10,3 BCM 80 L/cm 4,00 g/m2

20 cm3/m2 12,9 BCM 60 L/cm 5,00 g/m2

Haschure / Tri-helical Wet transfer

7 cm3/m2 4,5 BCM 160 L/cm 2,30 g/m2

10 cm3/m2 6,4 BCM 120 L/cm 3,30 g/m2

13 cm3/m2 8,4 BCM 100 L/cm 4,30 g/m2

16 cm3/m2 10,3 BCM 80 L/cm 5,00 g/m2

20 cm3/m2 12,9 BCM 60 L/cm 6,50 g/m2

Positive Screen Wet transfer

7 cm3/m2 4,5 BCM 160 L/cm 2,70 g/m2

10 cm3/m2 6,4 BCM 120 L/cm 3,70 g/m2

13 cm3/m2 8,4 BCM 100 L/cm 5,00 g/m2

16 cm3/m2 10,3 BCM 80 L/cm 6,00 g/m2

20 cm3/m2 12,9 BCM 60 L/cm 7,50 g/m2

The Measure of Quality.

Wet Transfer Coating Calculator Apex Anilox / GTT

This calculator provides general recommendations. Many variables affect the performance, including coating characteristics, viscosity and atmospheric conditions. Your results may vary depending upon these conditions. If your screen-volume requirement is not mentioned on this calculator, please contact us, we will review together with you the possibilities to come to a solution.

The Measure of Quality.www.apex-groupofcompanies.com

Related Documents